A kind of halogen-free flame-retardant polyimide foam material and preparation method thereof

A polyimide and foam material technology, applied in the field of halogen-free flame retardant polyimide foam material and its preparation, can solve the secondary hazards of toxic gas and corrosive gas, the thickening effect of liquid raw materials, and the blockage of conveying pipelines. and other problems, to achieve the effect of facilitating production and maintenance, simple mixing and preparation process, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

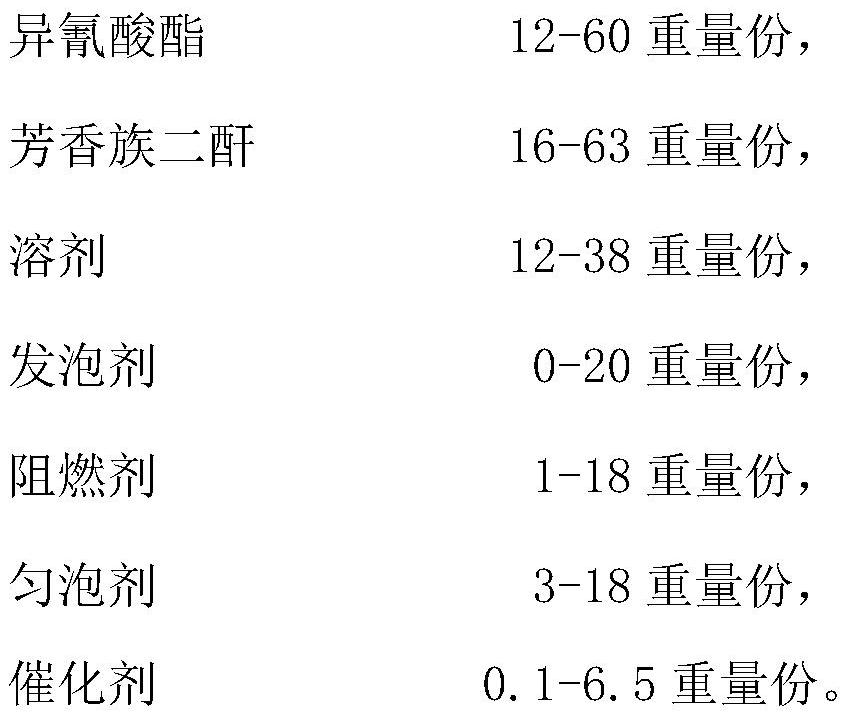

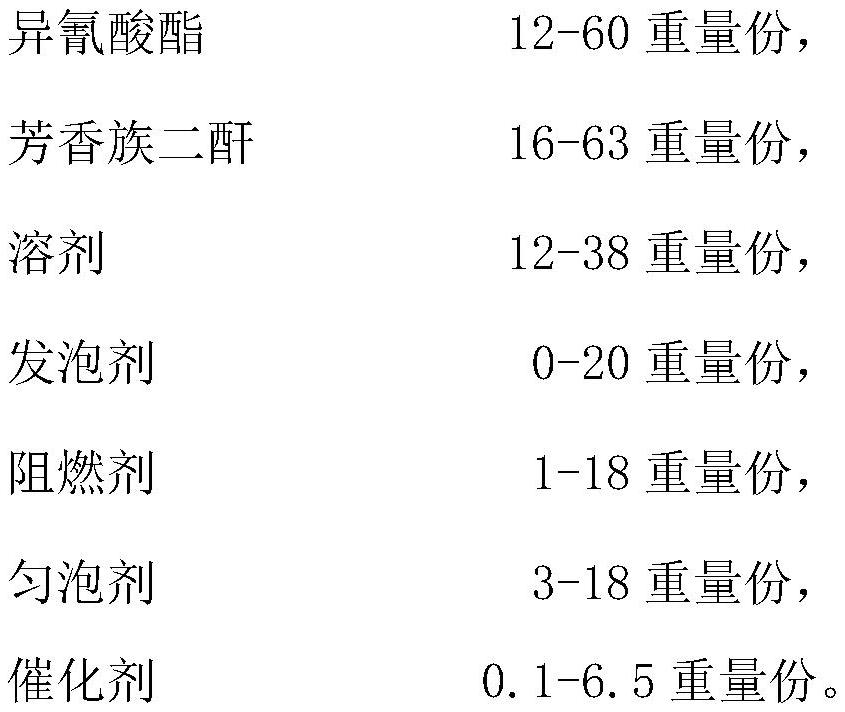

[0042]A preparation method of a halogen-free flame-retardant polyimide foam material, comprising the following steps:

[0043] Step 1: Pour isocyanate into tank A;

[0044] Step 2: Dissolving the aromatic dianhydride in the solvent;

[0045] Step 3: Add foaming agent and flame retardant to the solution prepared in Step 2, stir well and pour into tank B;

[0046] Step 4: Stir the foam stabilizer and catalyst evenly and pour them into tank C;

[0047] Step 5: Stir tanks A, B and C respectively, and then remove the air in the raw materials through vacuuming and nitrogen ventilation;

[0048] Step 6: Control the flow of material tanks A, B, and C by computer, inject them into the mold car for foaming after high-speed mixing in a closed mixing chamber, and then perform microwave treatment or heat treatment to prepare the polyimide foam material.

[0049] As a preferred preferred embodiment of the present invention, step 2 is specifically adding the formulated amount of dianhydr...

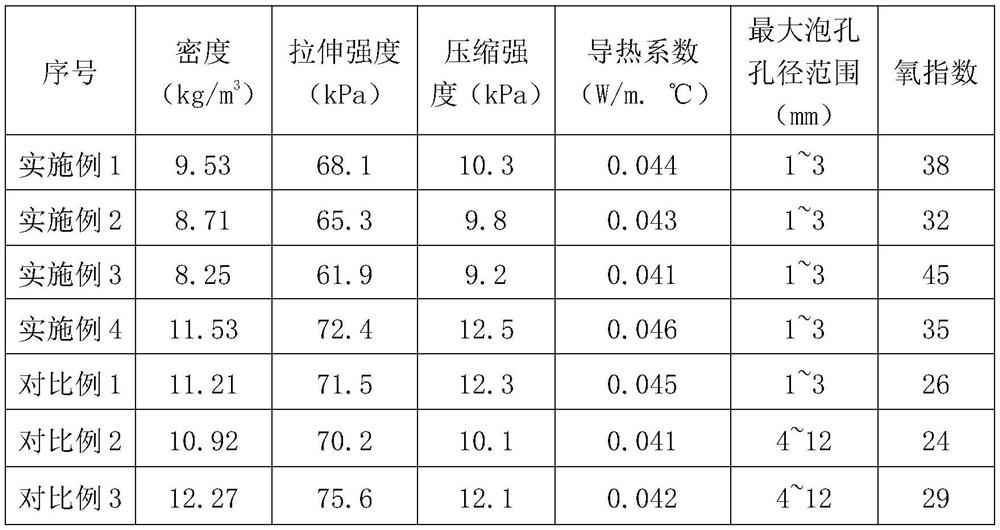

Embodiment 1

[0055] The polyimide foam material was prepared according to the formula of 20wt% isocyanate, 50wt% aromatic dianhydride, 15wt% solvent, 2wt% blowing agent, 5wt% flame retardant, 5wt% foam stabilizer and 3wt% catalyst. Specifically, 20 parts of polyaromatic isocyanate (PMDI) is poured into tank A. Take 20 parts of 3,3',4,4'-biphenyl dianhydride, 10 parts of 3,3',4,4'-benzophenone tetracarboxylic dianhydride and 20 parts of 4,4'-diphenyl ether dianhydride , was added to 15 parts of N-methylpyrrolidone, and stirred at 110°C until the solid was completely dissolved. Then wait for the solution to cool down to 35°C, add 1 part of water, 1 part of ethylene glycol-600, 3 parts of diphenyl phosphate and 2 parts of octyldiphenyl phosphite, stir well and pour it into the B material tank. Take 2 copies of DC198, 3 copies of B8487, 2 copies 8154 and 1 copy A-33, stir evenly and pour into C material tank. Set the stirring speed of material tank A to 500rpm, the stirring speed of mate...

Embodiment 2

[0057] According to the formula 50wt% of isocyanate, 20wt% of aromatic dianhydride, 18wt% of solvent, 4wt% of blowing agent, 1wt% of flame retardant, 6wt% of foam stabilizer, and 1wt% of catalyst to prepare polyimide foam material. Specifically, 30 parts of diphenylmethane diisocyanate (MDI), 10 parts of methyl diisocyanate (TDI) and 10 parts of hexamethylene diisocyanate (HDI) were poured into the material tank A. Add 20 parts of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride into a mixed solvent of 9 parts of dimethyl sulfoxide and 9 parts of ethanol, and stir at 92°C until the solid is completely dissolved. Then wait for the solution to cool to 20°C, add 1 part of methanol, 2 parts of n-pentane, 1 part of tetrahydrofuran, 0.5 part of trioleyl phosphate and 0.5 part of m-phenylene tetraphenyl bisphosphate, stir well and pour into B in the tank. Take 4 copies of DC6154, 2 copies L-620, 0.5 parts 5 and 0.5 parts -15, Stir evenly and pour into C material tank. Set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com