High speed signal transmission cable insulating material with extrusion resistance and foaming technology thereof

A high-speed signal and transmission cable technology, applied in the field of high-speed cables, can solve the problems of poor heat resistance and fire resistance, poor wire attenuation value, unstable characteristic impedance, etc., to improve the strength and impact resistance, and reduce the deformation rate. , the effect of increasing the extrusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

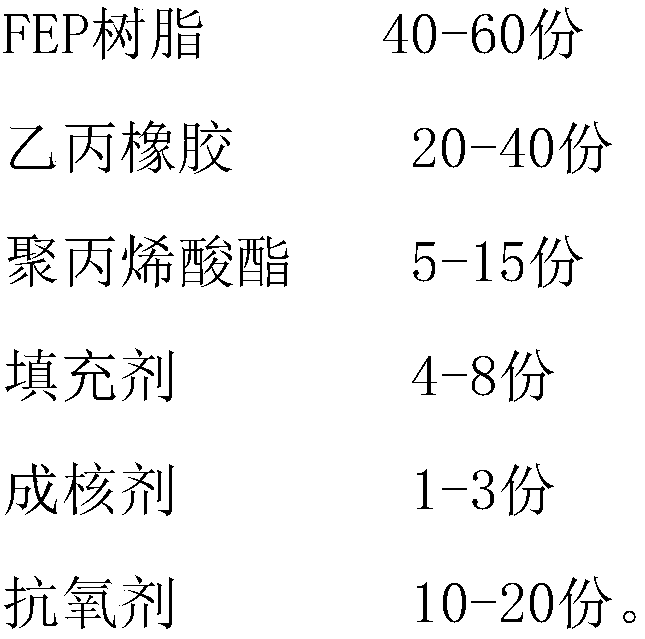

[0028] An extrusion-resistant high-speed signal transmission cable insulation material, comprising the following raw materials in parts by weight:

[0029]

[0030]

[0031] The FEP resin is a mixture of high-melting fat FEP, low-melting fat FEP and ether-modified FEP in a weight ratio of 0.8:1:1.5.

[0032] The ether-modified FEP is a perfluoroalkyl vinyl ether-modified FEP containing 1% by weight of ether, a melting point of 280° C., and an MFR value of 15 g / min.

[0033] The filler is a mixture of silicon dioxide, calcium carbonate and rare earth oxides in a weight ratio of 0.5:1:1.8.

[0034] The calcium carbonate is nano active calcium carbonate with a particle size of 10-50nm and modified by nonylphenol polyoxyethylene ether.

[0035] The rare earth oxide is a mixture of lanthanum oxide, cerium oxide and yttrium oxide in a weight ratio of 1:0.8:1.

[0036] The nucleating agent is a mixture of boron nitride, silicon nitride and silicon fluoride in a weight ratio o...

Embodiment 2

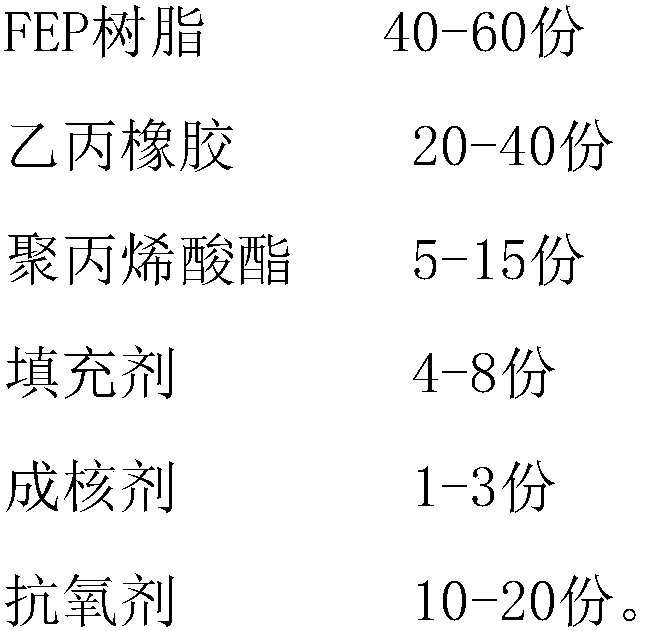

[0040] An extrusion-resistant high-speed signal transmission cable insulation material, comprising the following raw materials in parts by weight:

[0041]

[0042]

[0043] The FEP resin is a mixture of high-melting fat FEP, low-melting fat FEP and ether-modified FEP in a weight ratio of 0.9:1:1.8.

[0044] The ether-modified FEP is a perfluoroalkyl vinyl ether-modified FEP containing 2% by weight of ether, a melting point of 285° C., and an MFR value of 18 g / min.

[0045] The filler is a mixture of silicon dioxide, calcium carbonate and rare earth oxides in a weight ratio of 0.8:1:2.

[0046] The calcium carbonate is nano-active calcium carbonate with a particle diameter of 20 nm and modified by nonylphenol polyoxyethylene ether.

[0047] The rare earth oxide is a mixture of lanthanum oxide, cerium oxide and yttrium oxide in a weight ratio of 1.2:0.9:1.

[0048] The nucleating agent is a mixture of boron nitride, silicon nitride and silicon fluoride in a weight ratio...

Embodiment 3

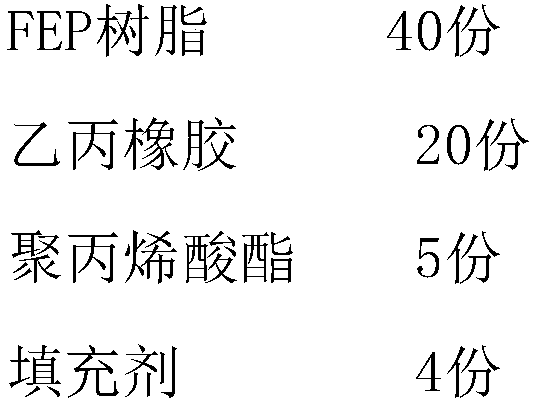

[0052] An extrusion-resistant high-speed signal transmission cable insulation material, comprising the following raw materials in parts by weight:

[0053]

[0054] The FEP resin is a mixture of high-melting fat FEP, low-melting fat FEP and ether-modified FEP in a weight ratio of 1:1:2.

[0055] The ether-modified FEP is a perfluoroalkyl vinyl ether-modified FEP containing 3% by weight of ether, a melting point of 290° C., and an MFR value of 20 g / min.

[0056] The filler is a mixture of silicon dioxide, calcium carbonate and rare earth oxides in a weight ratio of 1:1:2.2.

[0057] The calcium carbonate is nano active calcium carbonate with a particle size of 10-50nm and modified by nonylphenol polyoxyethylene ether.

[0058] The rare earth oxide is a mixture of lanthanum oxide, cerium oxide and yttrium oxide in a weight ratio of 1.5:1:1.

[0059] The nucleating agent is a mixture of boron nitride, silicon nitride and silicon fluoride in a weight ratio of 0.6:1:1.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com