Foamed sheath for foamed FEP (fluorinated ethylene propylene) cables and preparation method thereof

A sheath and cable technology, applied in the field of wire and cable, can solve the problems of easy rupture of foamed melt, unstable electrical performance, unstable wire diameter, etc., to reduce the possibility of melt fracture, improve the performance of the sheath, and reduce attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

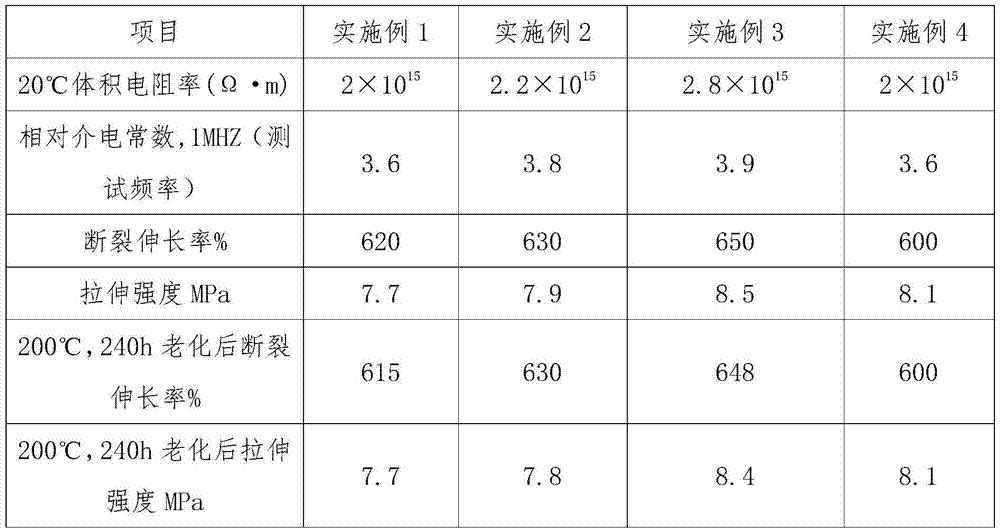

Examples

Embodiment 1-4

[0022] The preparation method of the foamed sheath of foamed FEP cable, the method may further comprise the steps:

[0023] (1) prepare materials according to the components and content listed in the examples in Table 1;

[0024] ⑵Put the raw materials into the high-speed mixer according to the ratio, mix at a high speed of 1800-2500rpm, and mix for 3-5 minutes;

[0025] ⑶ Low speed 400-800rpm discharge;

[0026] ⑷Put the mixed raw materials into the fluoroplastic extruder, the extruding temperature is 360-380°C, and evenly adhere to the outside of the foam layer after being extruded by this machine.

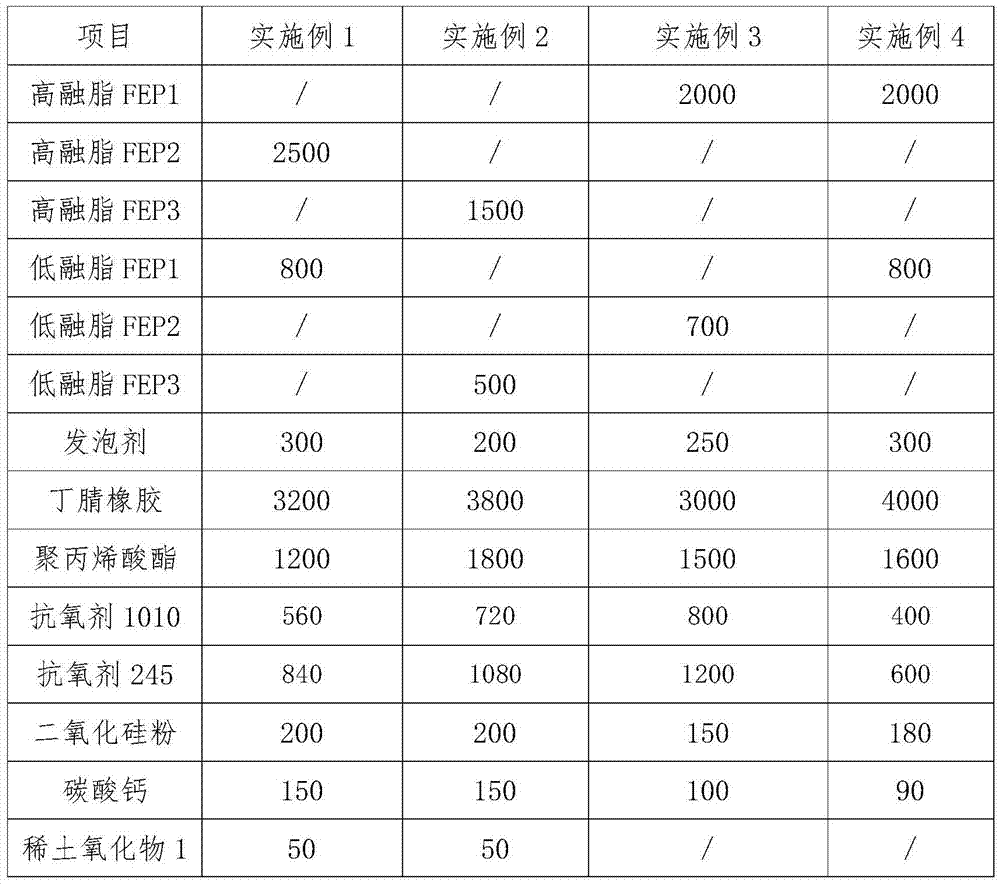

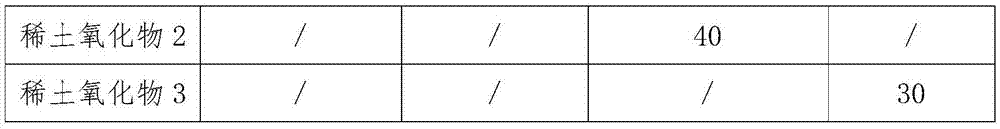

[0027] The formula table (unit: gram) of the formula table of table 1 embodiment 1-4

[0028]

[0029]

[0030] Related substance parameters in Table 1:

[0031] High melting fat FEP1, the melting index is 35g / 10min; high melting fat FEP2, the melting index is 30g / 10min; high melting fat FEP3, the melting index is 38g / 10min;

[0032] Low melting fat FEP1, the melting i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com