Physical foaming thermoplastic elastomer composition for floating cable and preparation method thereof

A thermoplastic elastomer and physical foaming technology, applied in the field of thermoplastic elastomer compositions, can solve the problems of the water-blocking layer of the foamed sheath, poor resistance to flexing, poor fatigue resistance of the sheath layer, and temperature sensitivity, etc., to achieve development Uniform cells, smooth surface, and improved polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

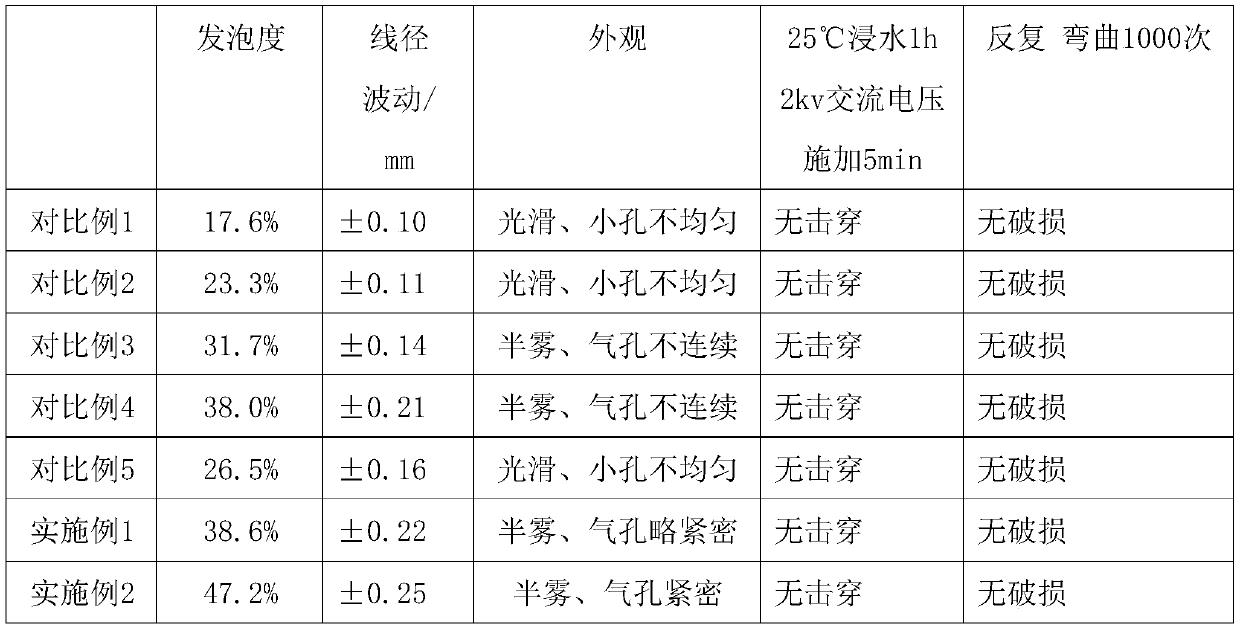

Examples

preparation example Construction

[0034] A method for preparing a physically foamed thermoplastic elastomer composition for floating cables, comprising:

[0035] Mixing steps: Add SEBS and white mineral oil to a mixer with a rotation speed of 300-600r / min and stir for 3-5 minutes according to the formula ratio, then add polypropylene, polyolefin elastomer, maleic anhydride compatibilizer, silicone masterbatch, Foaming agent, antioxidant, stirring for 25-30 minutes to obtain a mixture;

[0036] Extrusion step: Pour the mixture into an extruder to melt and granulate at a temperature of 140-170° C. and an extrusion speed of 200-350 rpm to obtain a physically foamed thermoplastic elastomer composition.

[0037] As a further embodiment, the extruder is a co-rotating twin-screw extruder with an aspect ratio of 40-48.

Embodiment 1

[0041] A physical foaming thermoplastic elastomer composition for floating cables comprises the following components by weight: 20 parts of softening plasticizer, 32 parts of SEBS, 28 parts of polypropylene, 10 parts of polyolefin elastomer, 8 parts of compatibilizer 1 part, 2 parts of silicone masterbatch, 1 part of foaming agent, 0.1 part of antioxidant.

[0042] A method for preparing a physically foamed thermoplastic elastomer composition for floating cables, comprising:

[0043]Mixing steps: Add SEBS and white mineral oil to a mixer with a rotation speed of 300r / min and stir for 3 minutes according to the formula ratio, then add polypropylene, polyolefin elastomer, maleic anhydride compatibilizer, silicone masterbatch, foaming agent, antioxidant, stirred for 25 minutes to obtain a mixture;

[0044] Extrusion step: Pour the mixture into an extruder to melt and granulate it at a temperature of 140° C. and an extrusion speed of 200 rpm to obtain a physically foamed thermopl...

Embodiment 2

[0047] A physical foaming thermoplastic elastomer composition for floating cables comprises the following components by weight: 22 parts of softening plasticizer, 31 parts of SEBS, 27 parts of polypropylene, 10 parts of polyolefin elastomer, 8 parts of compatibilizer 1 part, 2 parts of silicone masterbatch, 1 part of foaming agent, 0.1 part of antioxidant.

[0048] A method for preparing a physically foamed thermoplastic elastomer composition for floating cables, comprising:

[0049] Mixing steps: Add SEBS and white mineral oil to a mixer with a speed of 600r / min and stir for 5 minutes according to the formula ratio, then add polypropylene, polyolefin elastomer, maleic anhydride compatibilizer, silicone masterbatch, foaming agent, antioxidant, stirred for 30 minutes to obtain a mixture;

[0050] Extrusion step: Pour the mixture into an extruder to melt and granulate it at a temperature of 170° C. and an extrusion speed of 350 rpm to obtain a physically foamed thermoplastic el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com