Heat-resistant food container, and manufacturing method for same

A food container, heat-resistant technology, used in containers, thermal insulation containers, flexible containers, etc., can solve the problem of not having heat resistance, and achieve the effects of improving crystallinity, reducing manufacturing costs, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] [Preparation of PET resin material]

[0094] 83 parts by weight of PET resin (manufactured by Unitika "MA-2101M": intrinsic viscosity 0.62dl / g, water content 2,900ppm) and 10 parts by weight of talc MB (Tokyo Ink Co., Ltd. "PEX1470" manufactured by the company: 30% by weight of LPDE + 70% by weight of talc), 1 part by weight of chain extender MB (prototype product of Meisai Chemical Co., Ltd.: 70% by weight of PETG + 30% by weight of ADR4368S manufactured by BASF Japan Co., Ltd.), 4 parts by weight of white pigment MB ("L-9583" manufactured by Dainippon Ink Co., Ltd.: PET50% by weight + 50% by weight of white pigment), 2 parts by weight of compatibilizer ("LOTADER AX8840" manufactured by ARKEMA Co., Ltd., use The mixer mixes well.

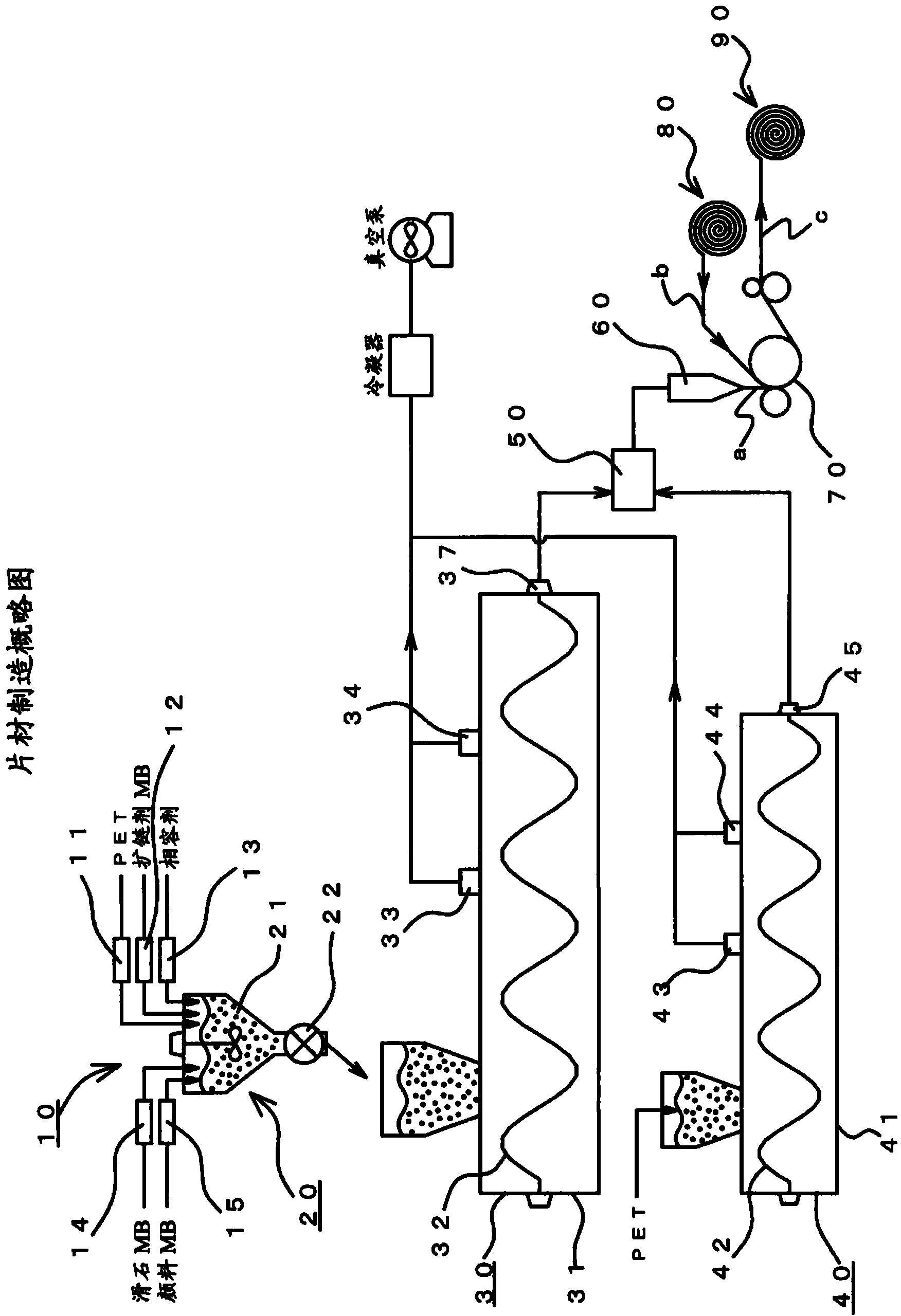

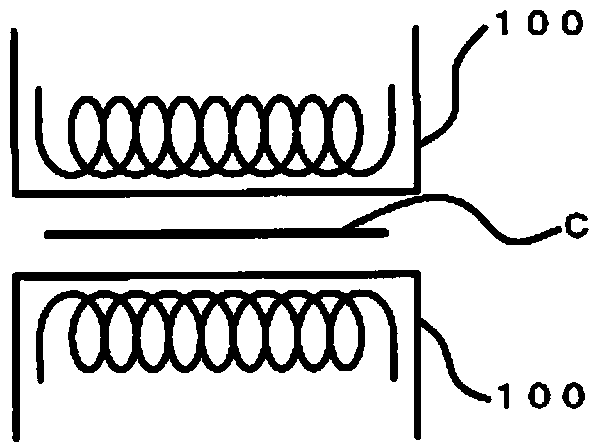

[0095] [Manufacturing of laminated sheets]

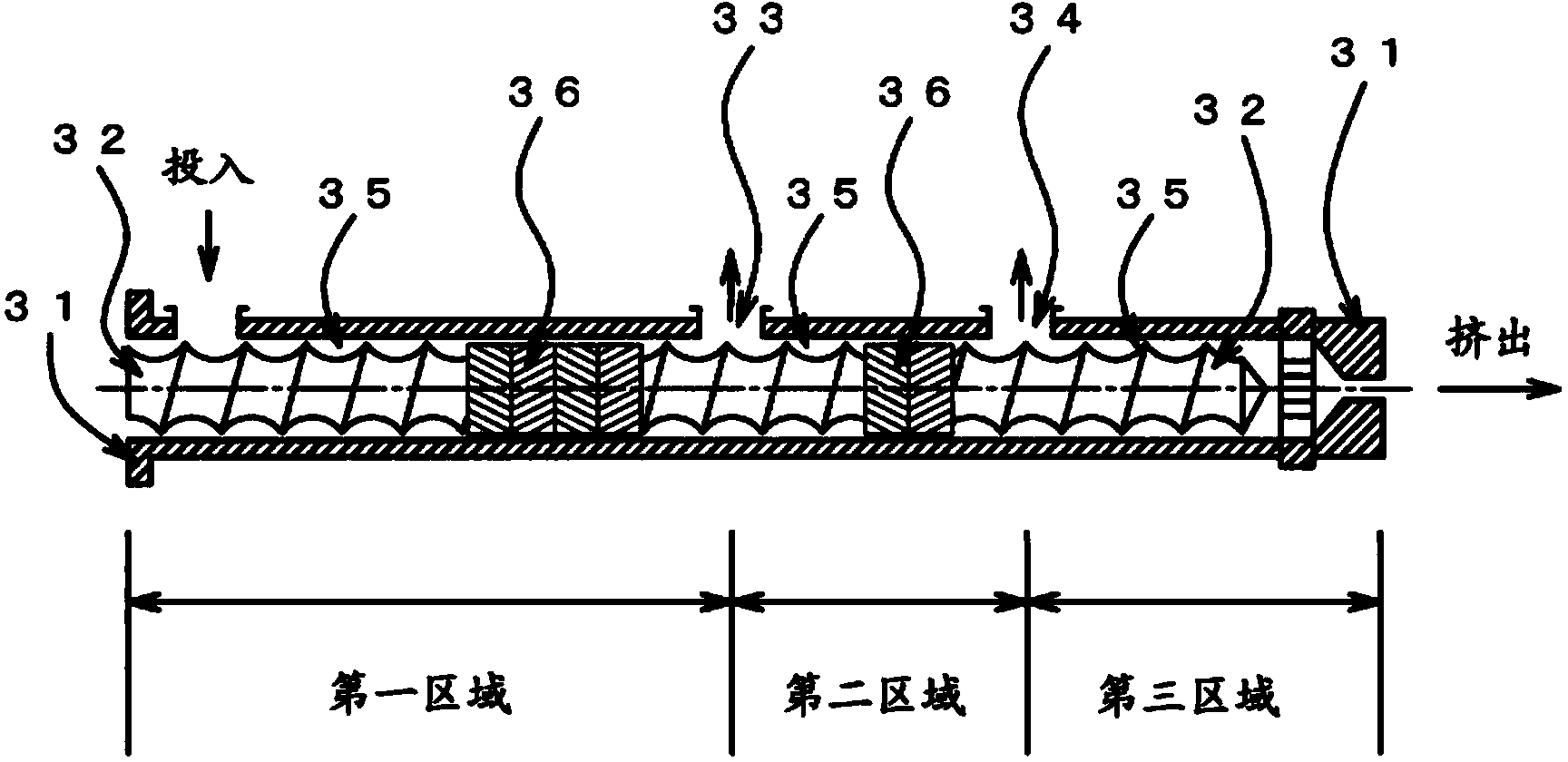

[0096] Put the PET resin material (for the main layer) into the main extruder ("TEX105α" manufactured by Japan Steel Works Co., Ltd.: L / D=31.5, twin-screw, two vent holes), at an extrusion tempe...

Embodiment 2

[0134] [Manufacturing of laminated sheets]

[0135] As the resin material for the main extruder, 84 parts by weight of PET resin (manufactured by Unitika "MA-2101M"), 1 part by weight of chain extender MB (manufactured by Mingcai Chemical Co., Ltd.), talc MB (Tokyo "PEX1470" manufactured by Ink Co., Ltd.) 10 parts by weight, compatibilizer ("LOTADER AX8840" manufactured by ARKEMA Co., Ltd. 2 parts by weight), black pigment MB (Dainippon Ink Co., Ltd. "BK-250DCT": PET70% + black pigment 30 %) 3 parts by weight of the PET resin material, as the resin material for the sub-extruder, what used was PET resin ("MA-2101M" manufactured by Unitika Corporation), except that, in the same device as in Example 1 A laminated sheet with a total thickness of 330 μm of the main layer (300 μm) / inner layer (30 μm) was produced under the same conditions. In addition, the printed film was not bonded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com