Composition used for preparing EVA copolymer, EVA copolymer and preparation method of EVA copolymer

A technology of a composition and a copolymer, applied to the composition for preparing an EVA copolymer, an EVA copolymer and the preparation field thereof, can solve the problems such as the EVA copolymer forming foam or fisheye, and the difficulty of directly cross-linking and regulating MI, Achieving the effect of high melt tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

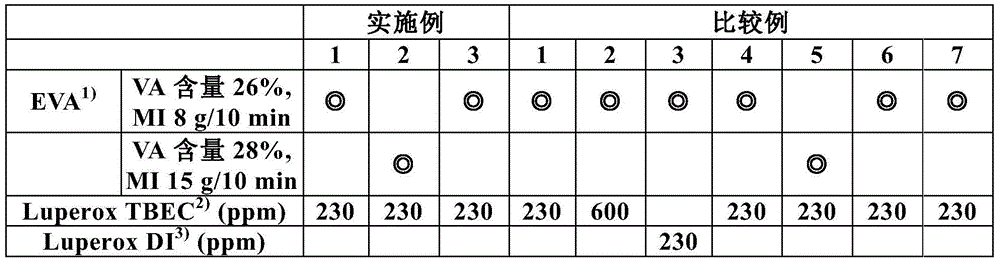

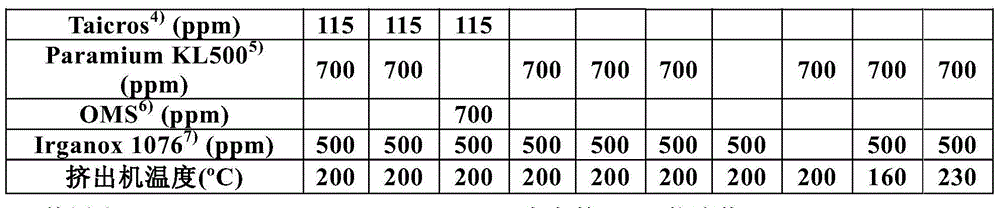

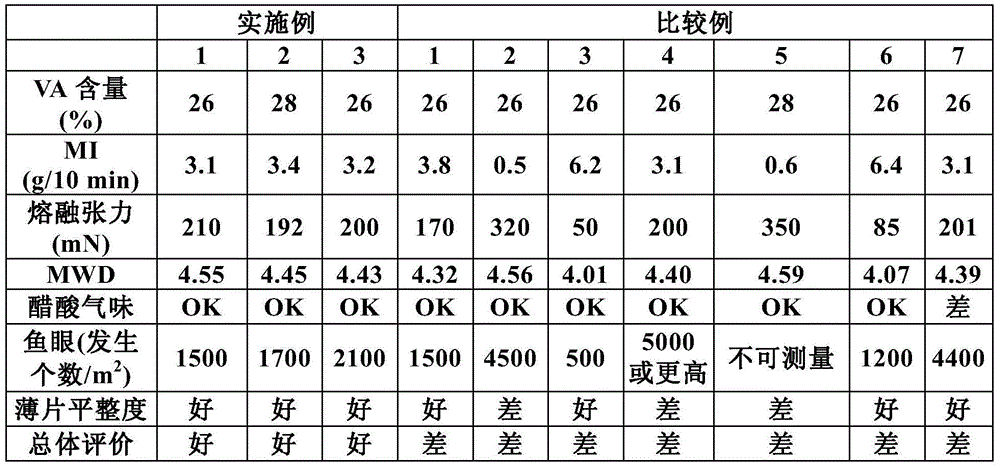

Embodiment 1

[0041] EVA copolymer (MI=8g / 10min, VA=26wt%) (produced by Samsung Total Petrochemicals Co., containing 500ppm of Irganox1076 as an antioxidant) and 230ppm of tert-butyl-(2-ethylhexyl) as a crosslinking agent Monoperoxycarbonate (Luperox TBEC, produced by Arkema), 115 ppm of triallyl isocyanurate (TAICROS, produced by Evonik) as a co-crosslinking agent, and 700 ppm of white mineral oil (Palamium KL-500, Seojin Chemical Co. Production) mixed at room temperature for 10 minutes, after which the trace crosslinkability of the composition used to prepare the EVA copolymer was evaluated by extrusion at 200 ° C using a twin-screw extruder with a screw speed of 50 rpm. obtained, and the evaluation results are shown in Table 2.

Embodiment 2

[0043] EVA copolymer (MI=15g / 10min, VA=28wt%) (produced by Samsung Total Petrochemicals Co., containing 500ppm of Irganox 1076 as an antioxidant) and 230ppm of tert-butyl-(2-ethylhexyl) as a crosslinking agent Monoperoxycarbonate (Luperox TBEC, produced by Arkema), 115 ppm of triallyl isocyanurate (TAICROS, produced by Evonik) as a co-crosslinking agent, and 700 ppm of white mineral oil (Palamium KL-500, produced by Seojin Chemical Co. ) were mixed at room temperature for 10 minutes before evaluating the trace crosslinkability of the composition for the preparation of the EVA copolymer obtained by extrusion at 200° C. using a twin-screw extruder with a screw speed of 50 rpm , Table 2 shows the evaluation results.

Embodiment 3

[0045] A composition for preparing an EVA copolymer was prepared in the same manner as in Example 1 in terms of mixing ratio and extrusion method, except that 700 ppm of isoparaffin (IP1620, produced by Idemitsu) was used as a diluent instead of white mineral oil . The trace crosslinkability of the prepared compositions was evaluated, and the evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com