Semiaromatic polyamide, semiaromatic polyamide resin composition, and molded article

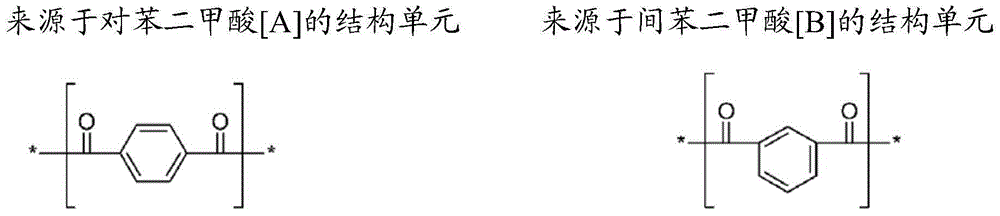

一种聚酰胺树脂、半芳香族的技术,应用在半芳香族聚酰胺树脂组合物及成型品,半芳香族聚酰胺领域,能够解决成型品厚度变化、反应难以控制、成型品力学强度降低等问题,达到优异物性、高熔融张力、控制结晶性和耐热性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

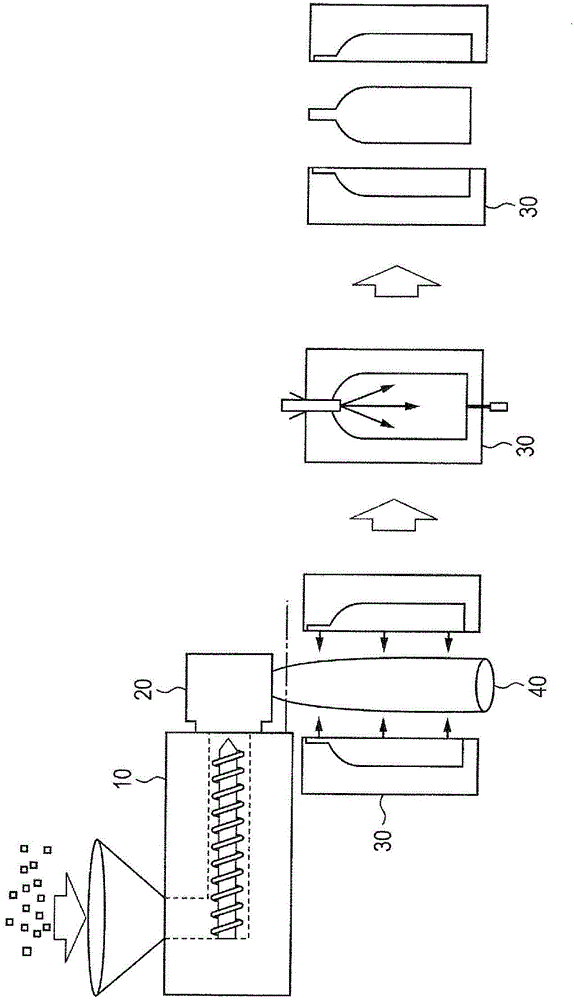

Method used

Image

Examples

Embodiment 1

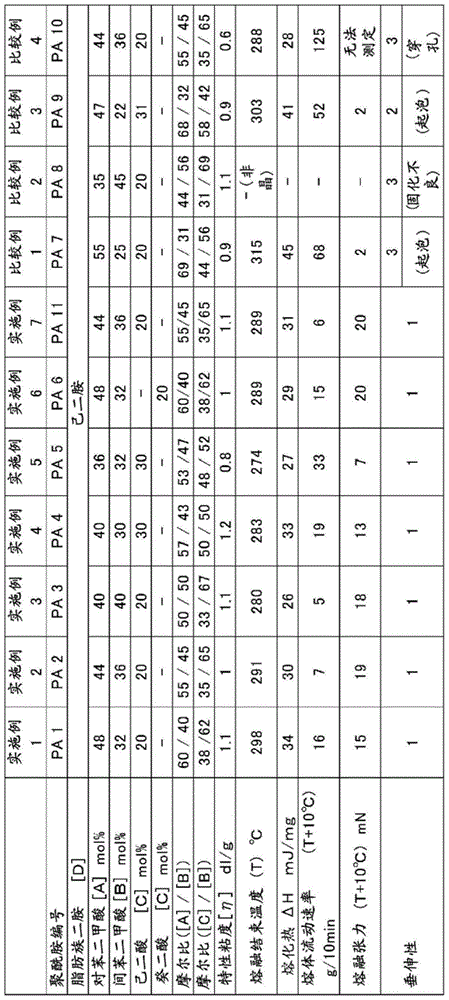

[0214] 1906 g (11.5 moles) of terephthalic acid, 2800 g (24.1 moles) of 1,6-hexamethylene diamine, 1271 g (7.6 moles) of isophthalic acid, 699 g (4.8 moles) of adipic acid, 36.5 g (0.3 moles) of benzoic acid ), 5.7 g of sodium hypophosphite monohydrate (0.08% by weight relative to the raw material), and 545 g of distilled water were put into an autoclave with an inner volume of 13.6 L, and replaced with nitrogen. Stirring was started from 190°C, and the internal temperature was increased to 250°C over 3 hours. At this time, the internal pressure of the autoclave was increased to 3.03 MPa. After continuing the reaction in this state for 1 hour, air was released from a nozzle provided in the lower part of the autoclave, and the low-grade condensate was taken out. Then, after cooling to room temperature, it was pulverized to a particle size of 1.5 mm or less with a pulverizer, and dried at 110°C for 24 hours. The moisture content of the obtained low-grade condensate was 4100 ppm...

Embodiment 2

[0216] Except having changed the amount of terephthalic acid and isophthalic acid, it carried out similarly to Example 1, and prepared polyamide resin (PA2). Table 1 shows the physical properties of the obtained polyamide resin.

Embodiment 3

[0218] Except having changed the amount of terephthalic acid and isophthalic acid, it carried out similarly to Example 1, and prepared polyamide resin (PA3). Table 1 shows the physical properties of the obtained polyamide resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat of fusion | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com