Thermoplastic polyester resin composition and molded article

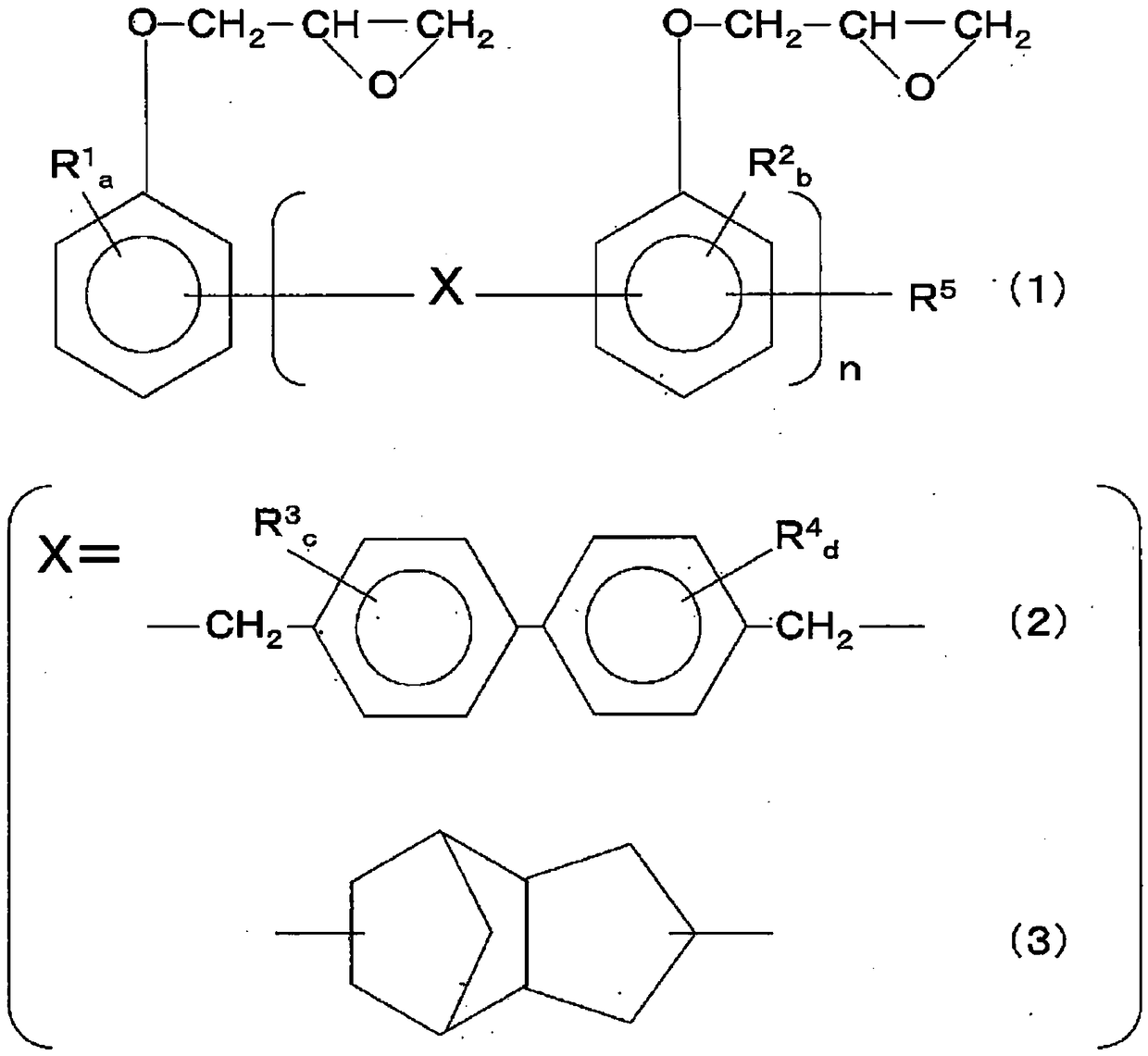

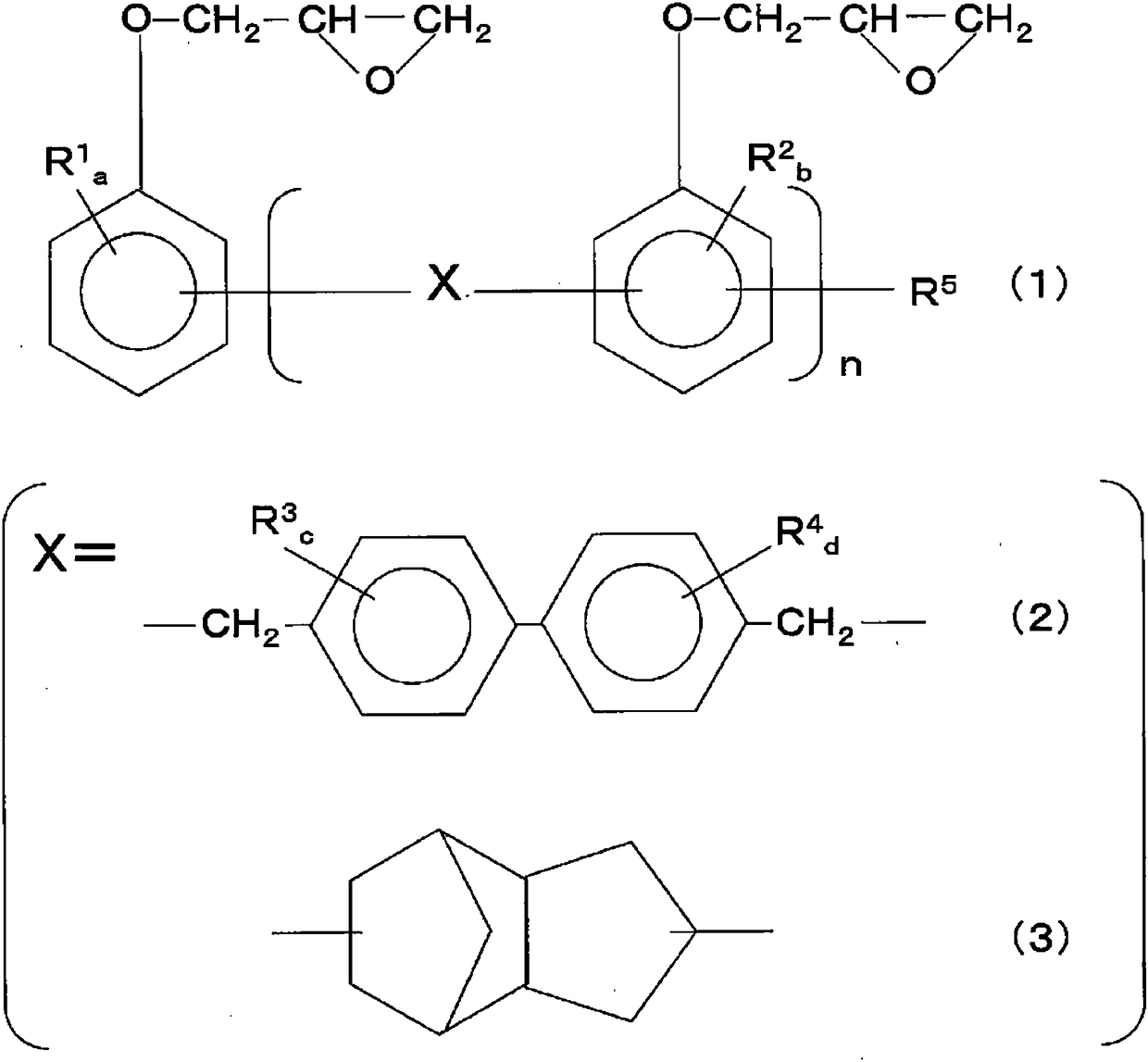

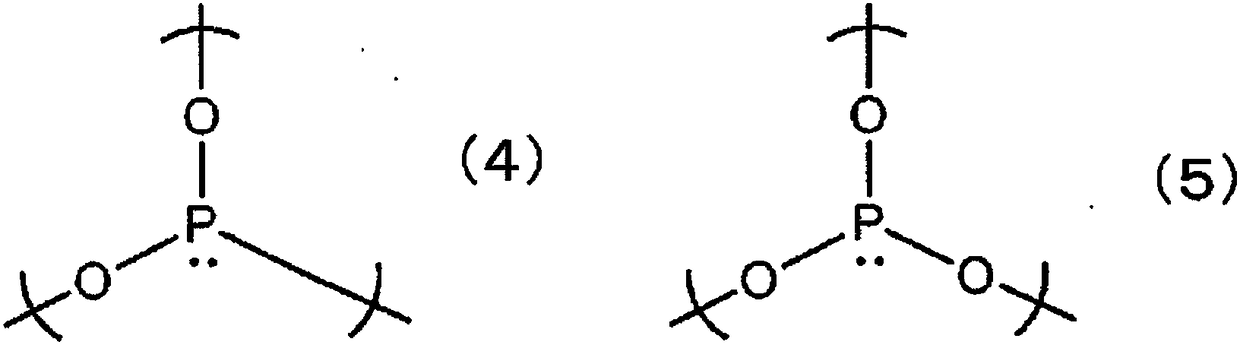

A thermoplastic polyester and resin composition technology, applied in the field of thermoplastic polyester resin composition, can solve the problems of insufficient heat resistance and insufficient hydrolysis resistance of the resin composition, and achieve excellent hydrolysis resistance and retention stability. The effect of excellent, excellent mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~84

[0237] [Examples 1-84], [Comparative Examples 1-10]

[0238] (A) thermoplastic polyester resin, (B) or (B' ) Novolac epoxy resin, (C) phosphorus stabilizer, (D) monofunctional epoxy compound, (E) reaction catalyst and other materials except glass fibers as required are contained in Tables 1 to 16. The components were mixed and added from the main feed section of the twin-screw extruder. (F-5) The glass fiber was added from between the main feed part and the vent part using the side feeder according to the content composition shown in Table 2, 8, and 15. Melt mixing was carried out under the extrusion conditions of a kneading temperature of 260° C. and a screw rotation speed of 150 rpm, and the resulting resin composition was discharged into strands, passed through a cooling bath, and pelletized by a strand pelletizer.

[0239] The obtained pellets were dried with a hot air dryer at a temperature of 110° C. for 6 hours, and then evaluated by the above-mentioned method. Tables...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com