Patents

Literature

110 results about "Metal colloids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lateral flow assay and device using magnetic particles

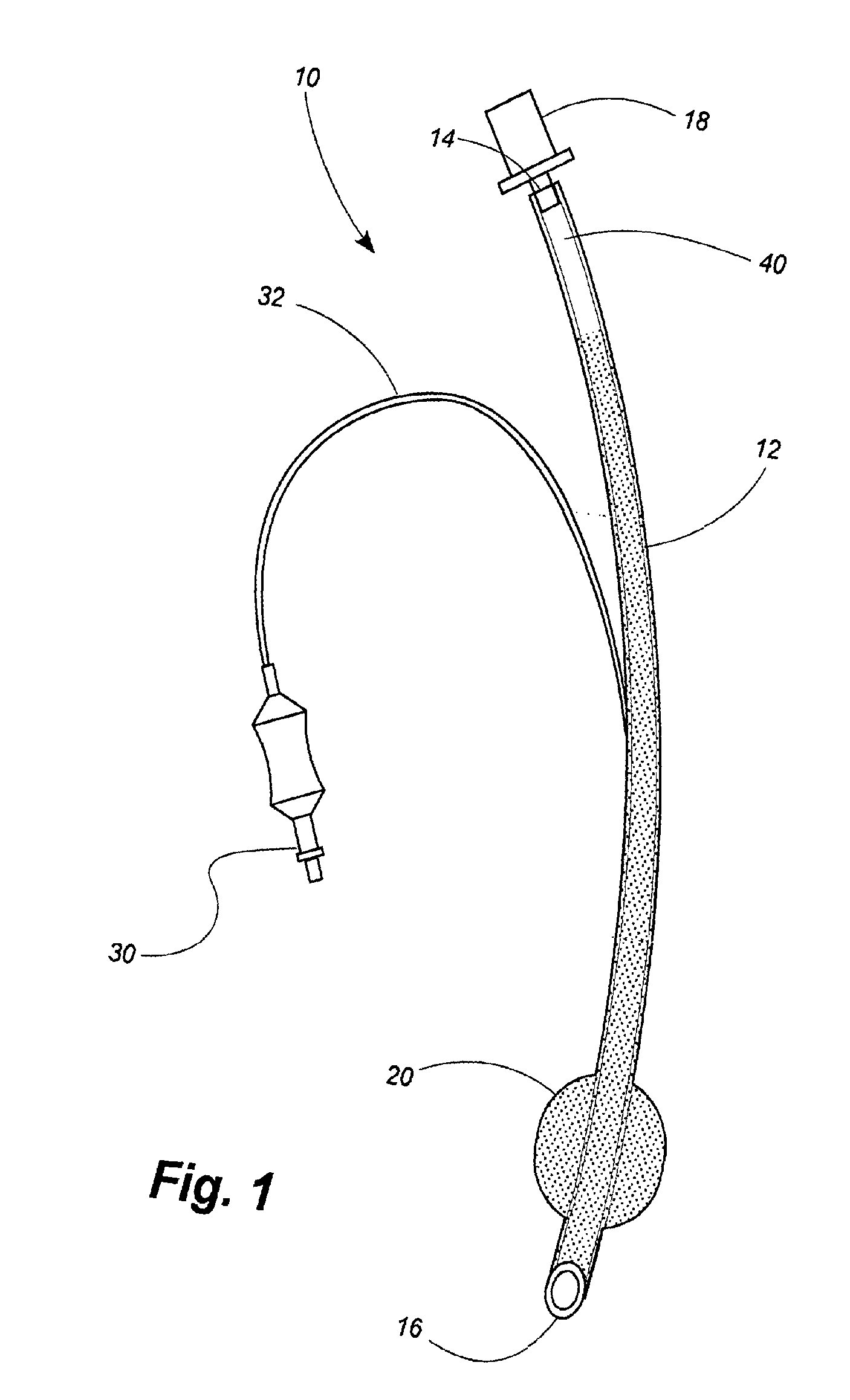

A complex including magnetic particle bound to a metal colloid. The complex may be part of a reagent for use in a method for determining analytes. The reagent may include a binding partner specific for an analyte. The reagent may further include a first label that is distinguishable from a second label that is used to detect the analyte. The reagent is used in kits and methods for detecting analytes in samples. The methods include immunoassay methods, including method where the first label is used to calibrate the assay.

Owner:IDEXX LABORATORIES

Metal colloid and catalyst produced from such metal colloid

InactiveUS20060079396A1Inhibit aggregationHigh water-solubility of the colloidOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsAluminum IonMischmetal

Disclosed is a metal colloid comprising: a solvent composed of water or a mixed solvent of water and an organic solvent; cluster particles comprising one or more metal species; and a protective agent for protecting the cluster particles, characterised in that the protective agent comprises a polymeric material which can be bound to one or more ion species selected from the group consisting of alkali earth metal ions, transition metal ions, rare earth metal ions, an aluminum ion and a gallium ion, and the protective agent has one or more ion species selected from the group consisting of alkali earth metal ions, transition metal ions, rare earth metal ions, an aluminum ion and a gallium ion bounded thereto.

Owner:TANAKA PRECIOUS METAL IND

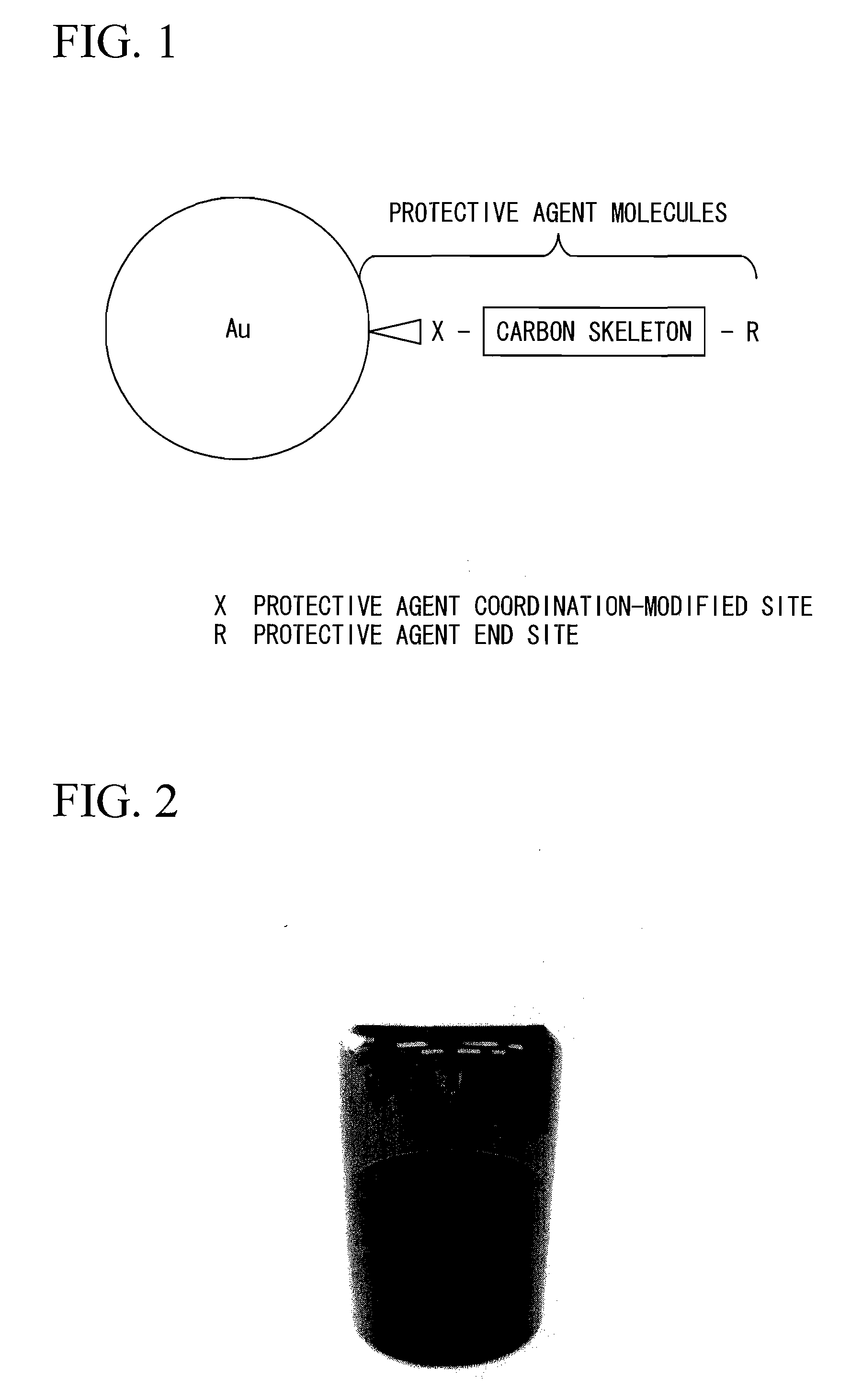

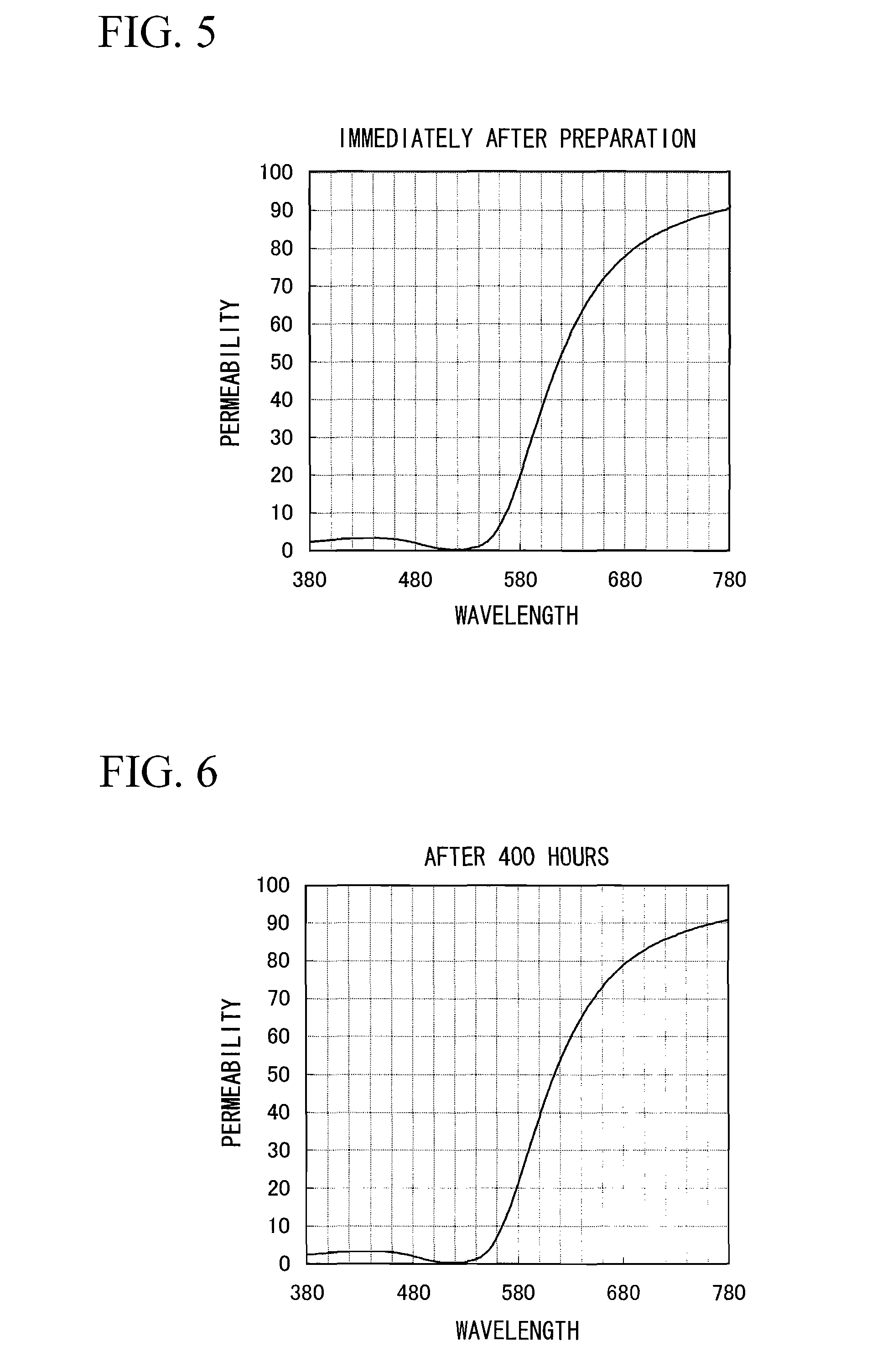

Metal Colloidal Particles, Metal Colloid and Use of Metal Colloid

InactiveUS20080277630A1Improve heat resistanceGood quality effectMaterial nanotechnologyPigmenting treatmentAtomic groupSulfur

With respect to the metal colloid of the present invention, metal colloidal particles capable of forming a metal colloid by dispersing in either or both of an aqueous dispersion medium and a nonaqueous dispersion medium in a predetermined proportion while mixing, comprise metal particles and a protective agent coordination-modified on the surface of the particles, the protective agent having a carbon skeleton containing either or both of sulfur and oxygen in the molecule, and having a structure of being coordination-modified on the surface of the metal particles using an atom or an atomic group of either or both of sulfur and oxygen as an anchor, wherein the protective agent has one, or two or more functional groups selected from the group consisting of alkoxysilyl group, silanol group and hydroxyalkyl group in a molecular structure.

Owner:MITSUBISHI MATERIALS CORP +1

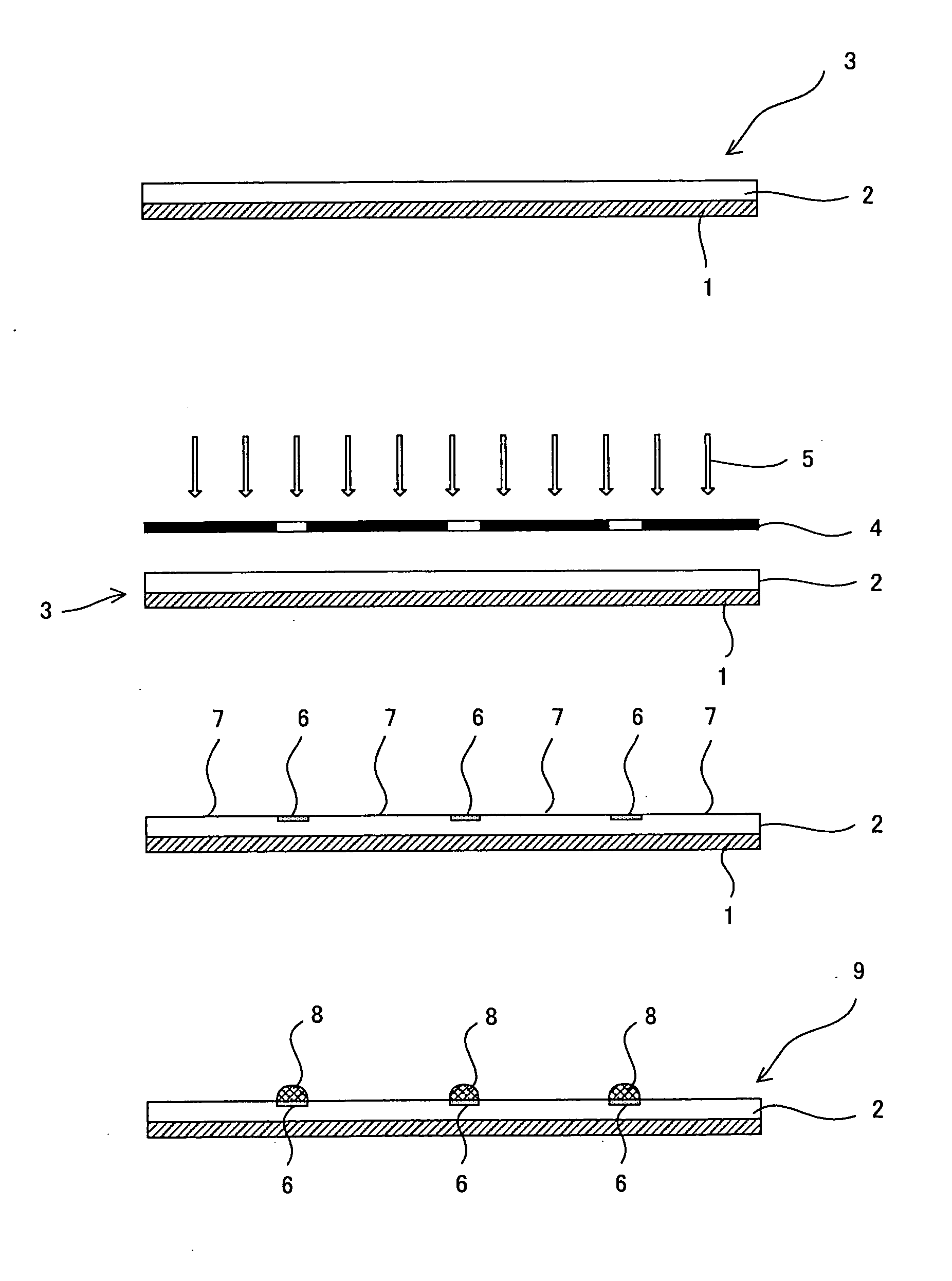

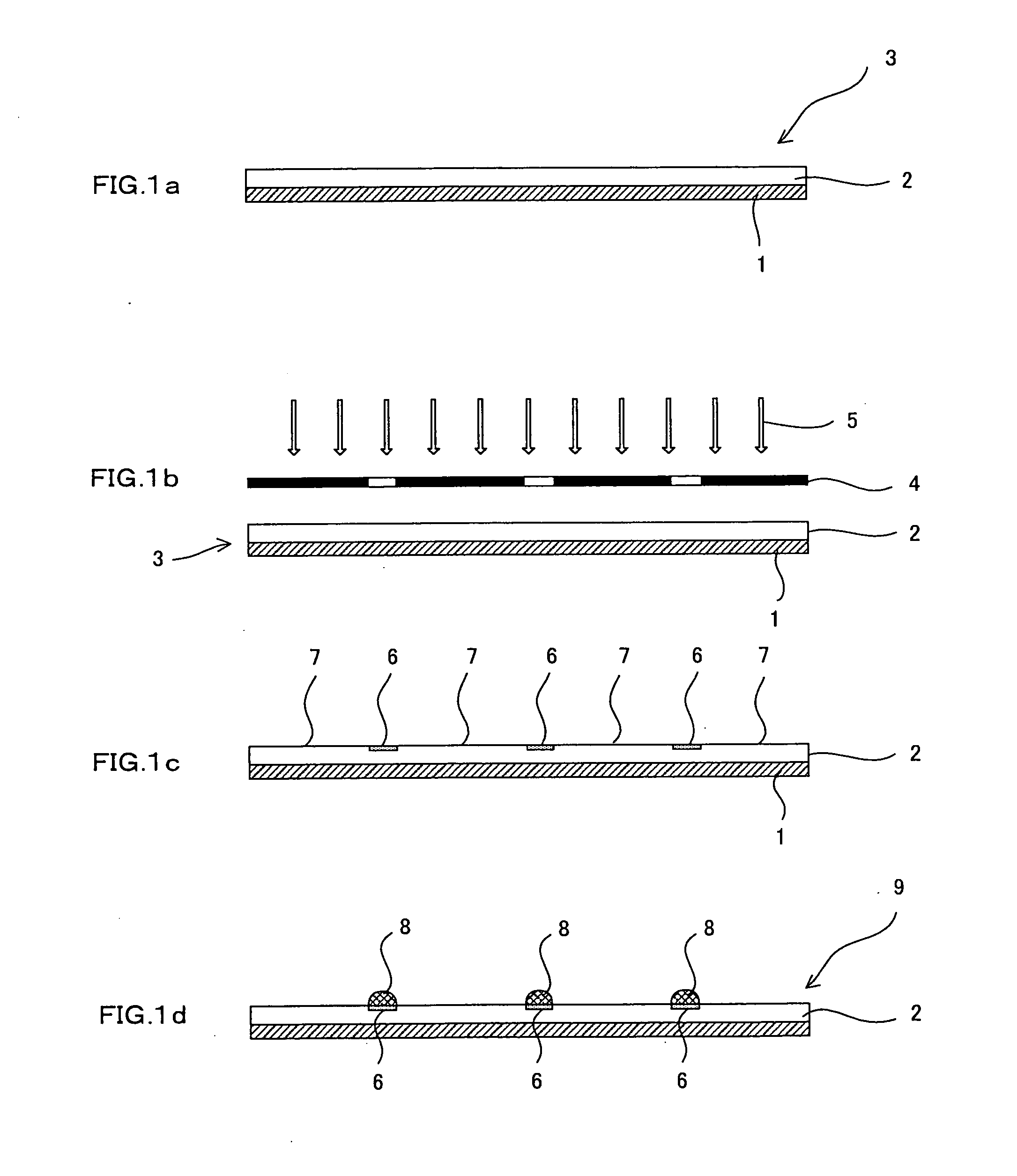

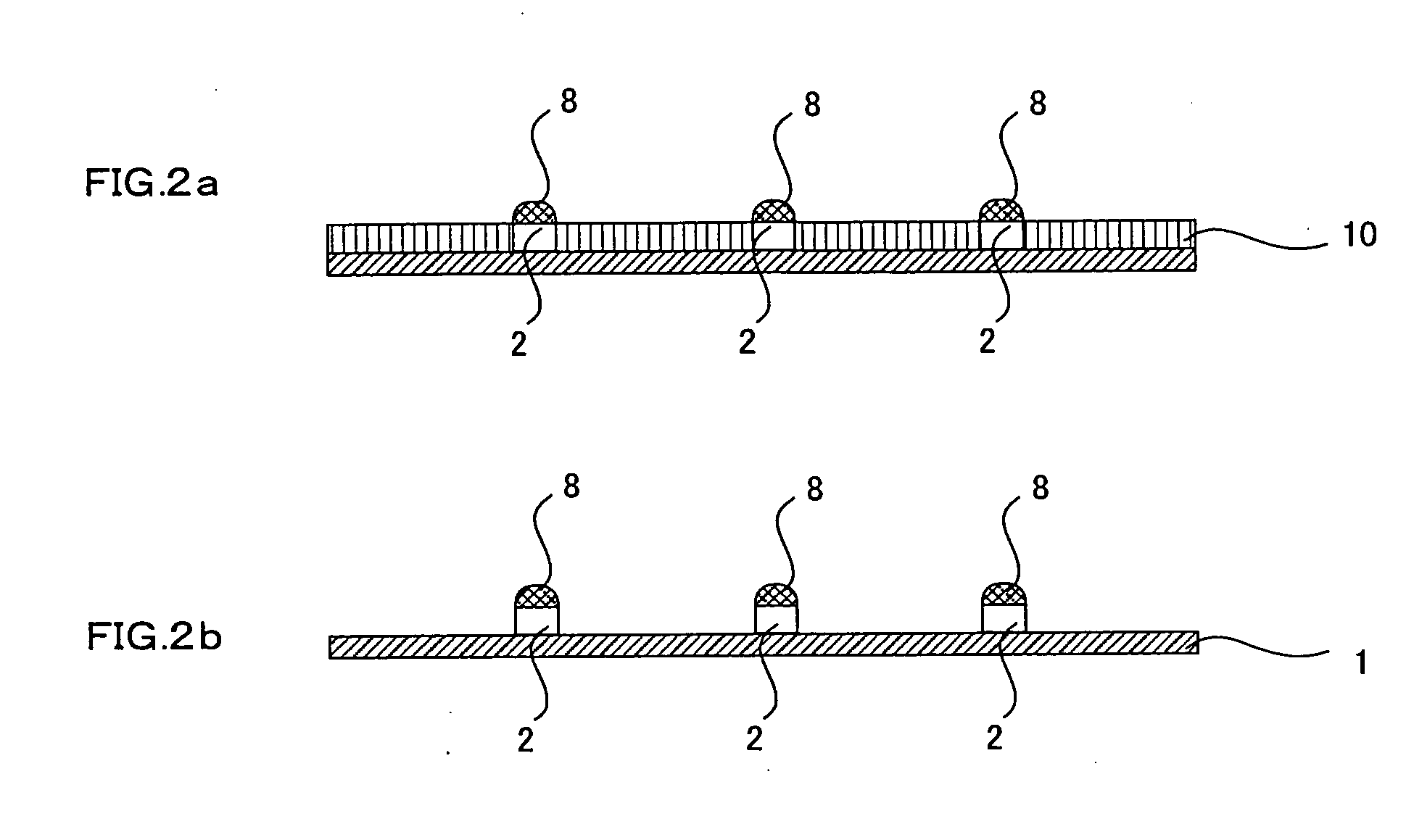

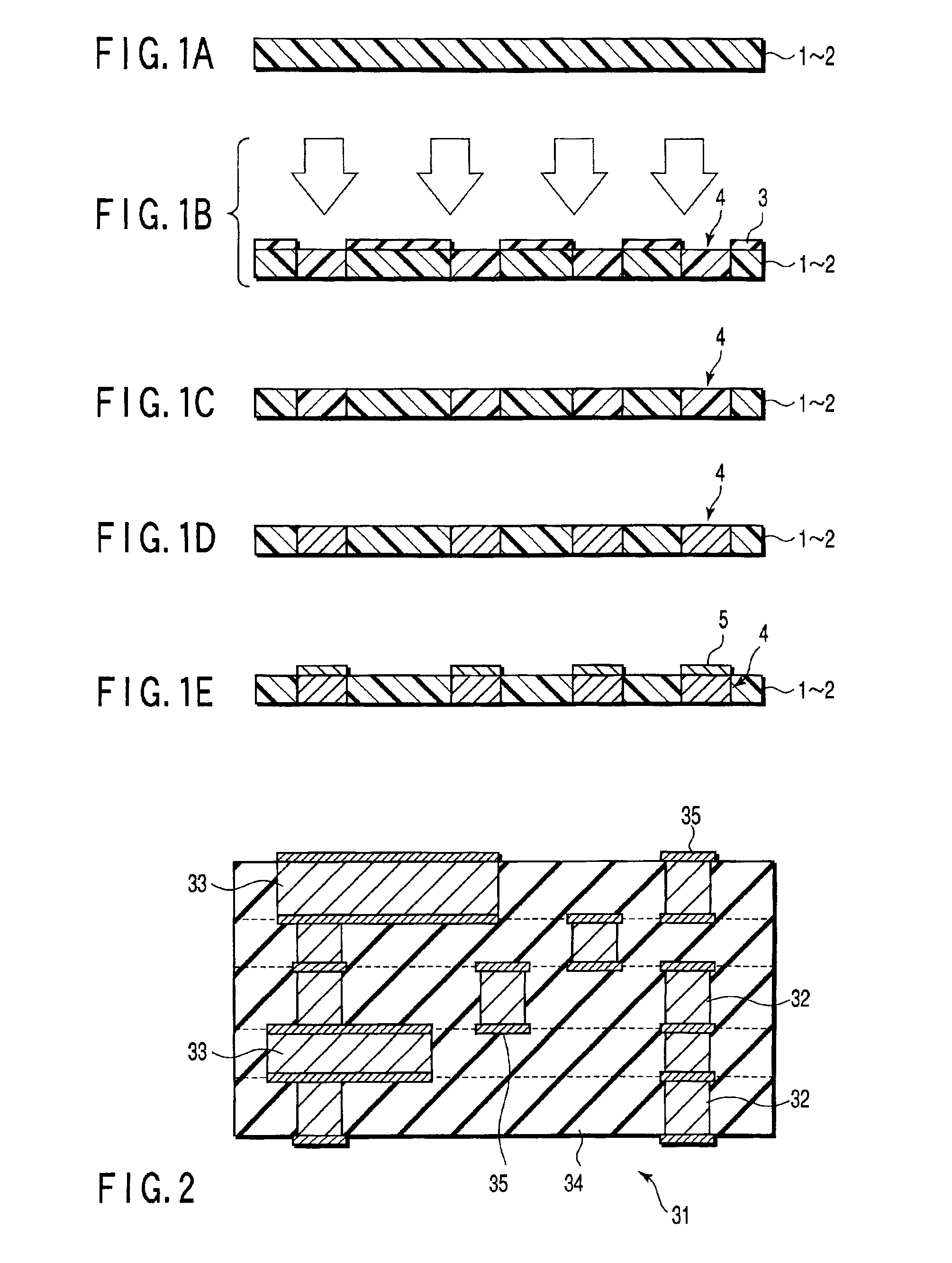

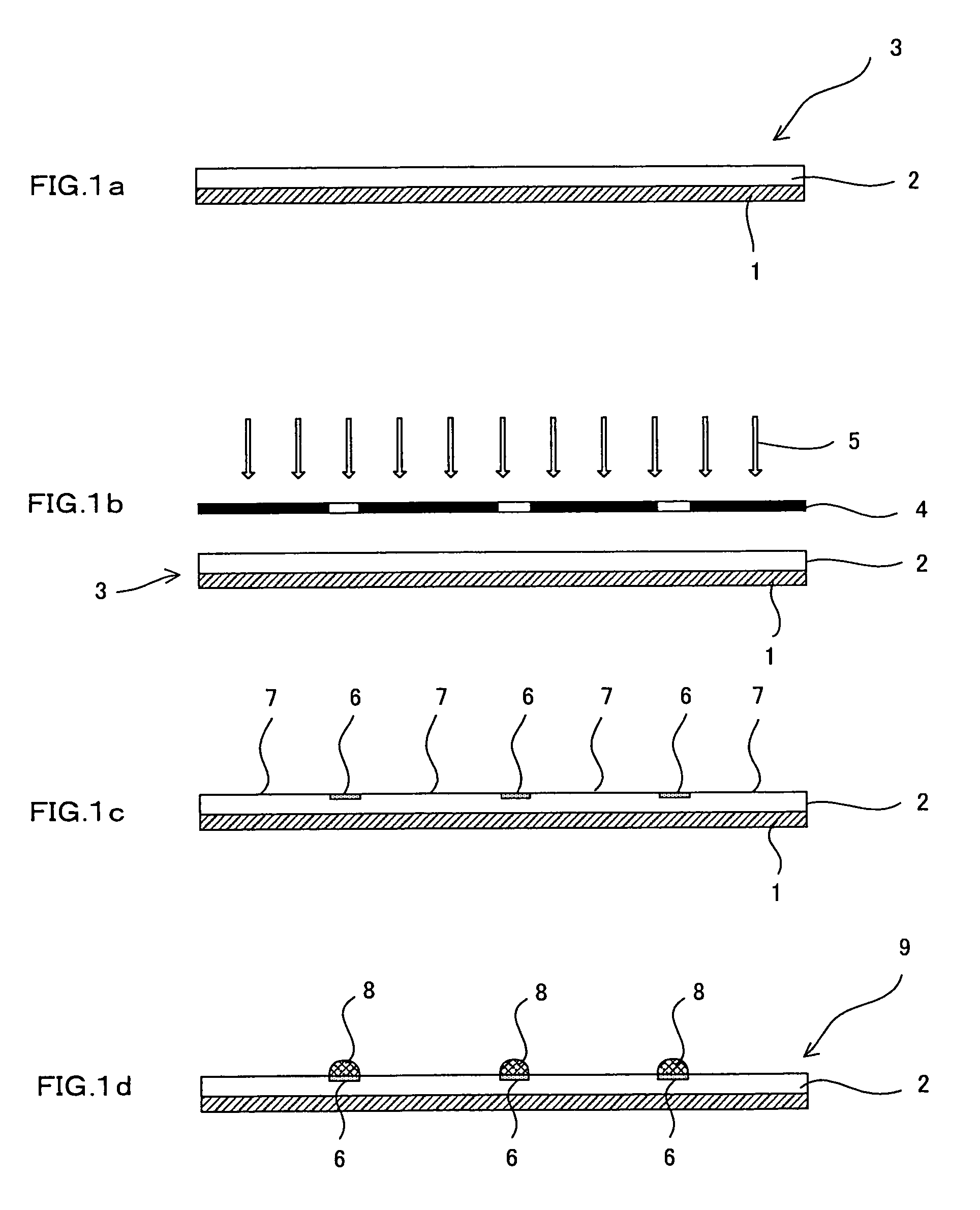

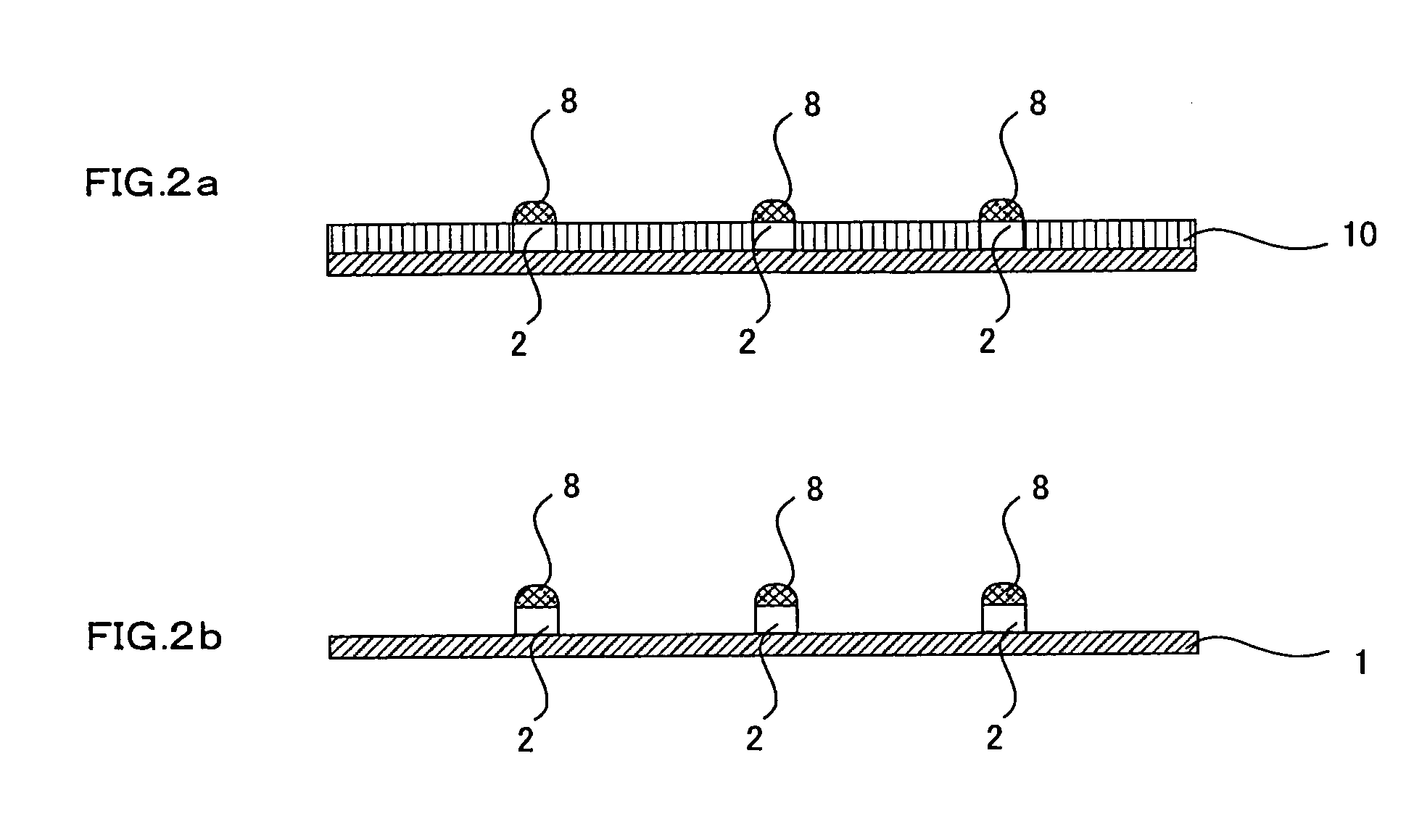

Method for manufacturing conductive pattern forming body

InactiveUS20050112810A1Excellent conductive pattern forming bodyEasy to produceMaterial nanotechnologySemiconductor/solid-state device manufacturingMetal colloidsForming processes

It is a main object of the present invention to provide a method for manufacturing a conductive pattern capable of forming a highly precise pattern, also capable of forming by using a simple process, and being free from problems such as treatment of waste fluids. In order to attain the above object, the present invention provides a method for manufacturing a conductive pattern forming body comprising: a pattern forming body substrate preparing process of preparing pattern forming body substrate comprising a base material, and a photocatalyst containing layer formed on the base material comprising a photocatalyst and a binder whose wettability of an energy irradiated part is changed so as a contact angle to a liquid is reduced; a wettability pattern forming process of forming wettability pattern comprising a liquid repellent area and a lyophilic area on the photocatalyst containing layer by irradiating the photocatalyst containing layer in a pattern with energy; a metal colloid coating process of adhering a metal colloid only to the lyophilic area of the surface of the photocatalyst containing layer on which the wettability pattern is formed, by coating the metal colloid; and a conductive pattern forming process of forming conductive pattern by solidifying the metal colloid adhered to the lyophilic area of the wettability pattern.

Owner:DAI NIPPON PRINTING CO LTD

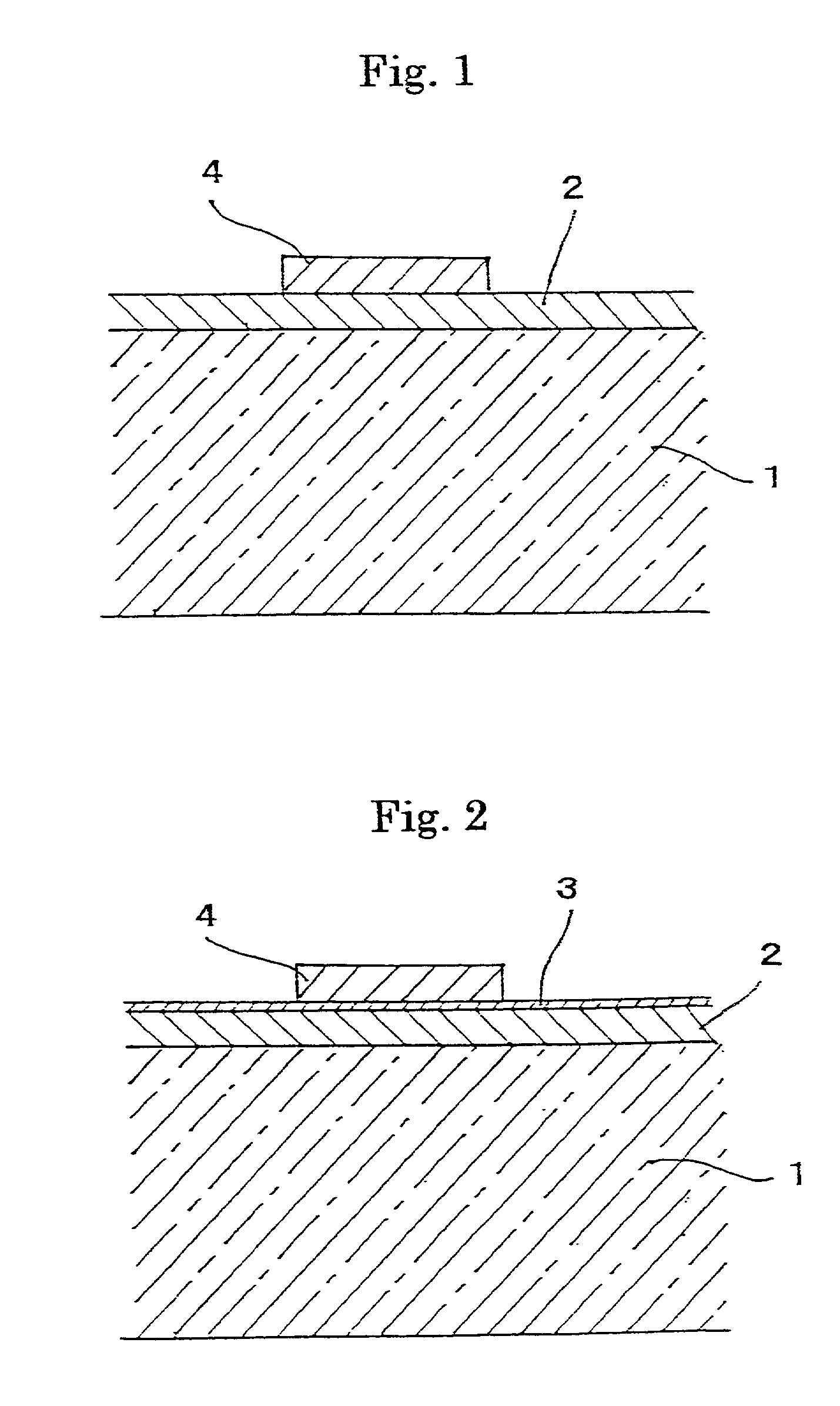

Glass article and glass substrate for display panel

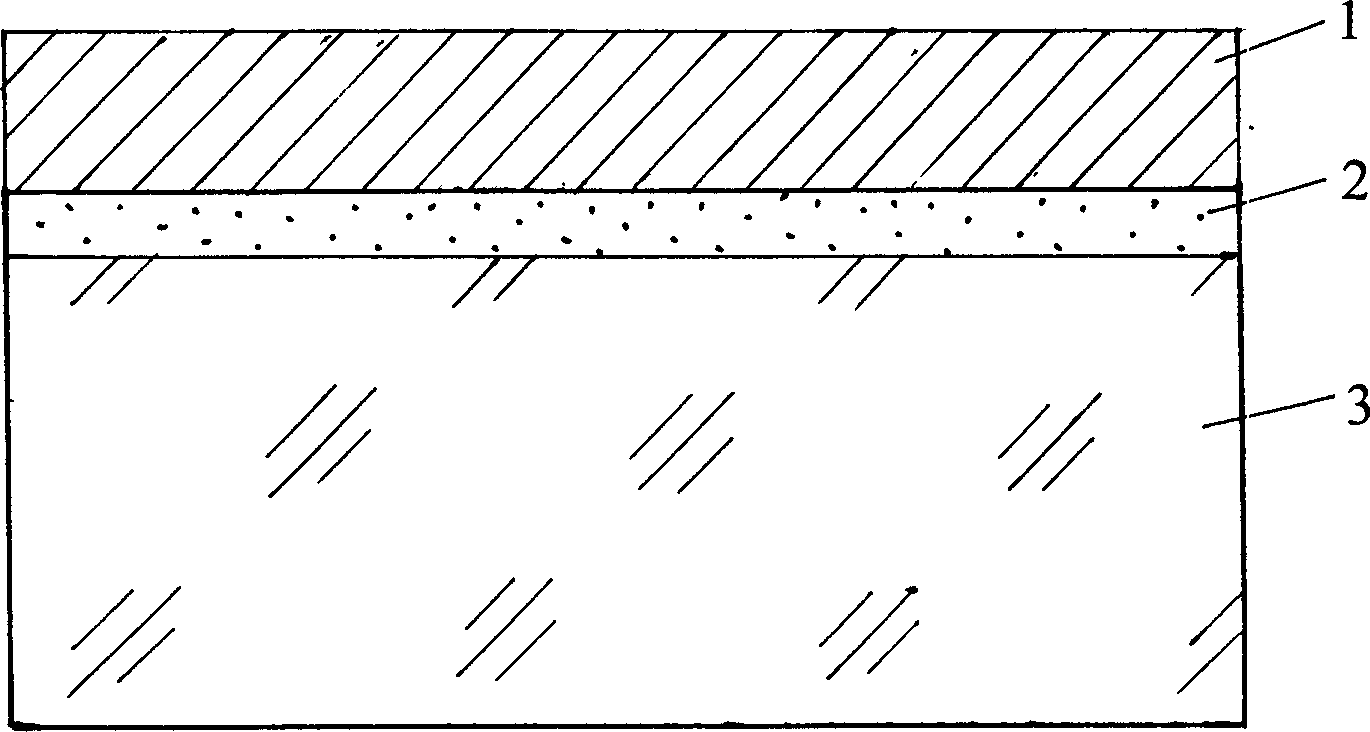

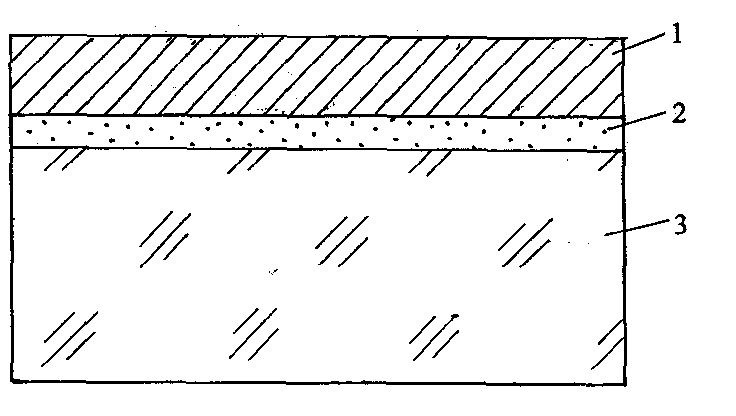

InactiveUS20010016253A1Excellent efficiency of preventing diffusion of metal ionInhibited DiffusionGas discharge vessels/containersLayered productsAlkali ionsElectrical resistance and conductance

A glass article having no problem of stain due to metal colloids because of its excellent efficiency of preventing the diffusion of metal ions, and a glass substrate for a high-quality display comprising the aforementioned glass article are provided. The glass article comprises an alkali-containing glass substrate 1, and a barrier film 2 formed on a surface of the alkali-containing glass substrate 1. The metal ion diffusion barrier film 2 mainly contains indium oxide and / or tin oxide. A glass substrate for a display comprises: an alkali-containing glass substrate 1; an alkali ion diffusion barrier film 5 formed on a surface of said alkali-containing glass substrate 1; a barrier film 2 mainly containing indium oxide and / or tin oxide; an insulating film 3; and an electrode film 4. The surface electrical resistance of the insulating film is kept in a range from 1.0x106 OMEGA / square to 1.0x1016 OMEGA / square even after heating process at 550° C. for 1 hour.

Owner:NIPPON SHEET GLASS CO LTD

Preparation method of C10+ bicyclo-heavy aromatics selective hydrogenation cracking catalyst

ActiveCN103551180AHigh selectivityIncrease liquid collectionMolecular sieve catalystsHydrocarbonsCeriumMetal colloids

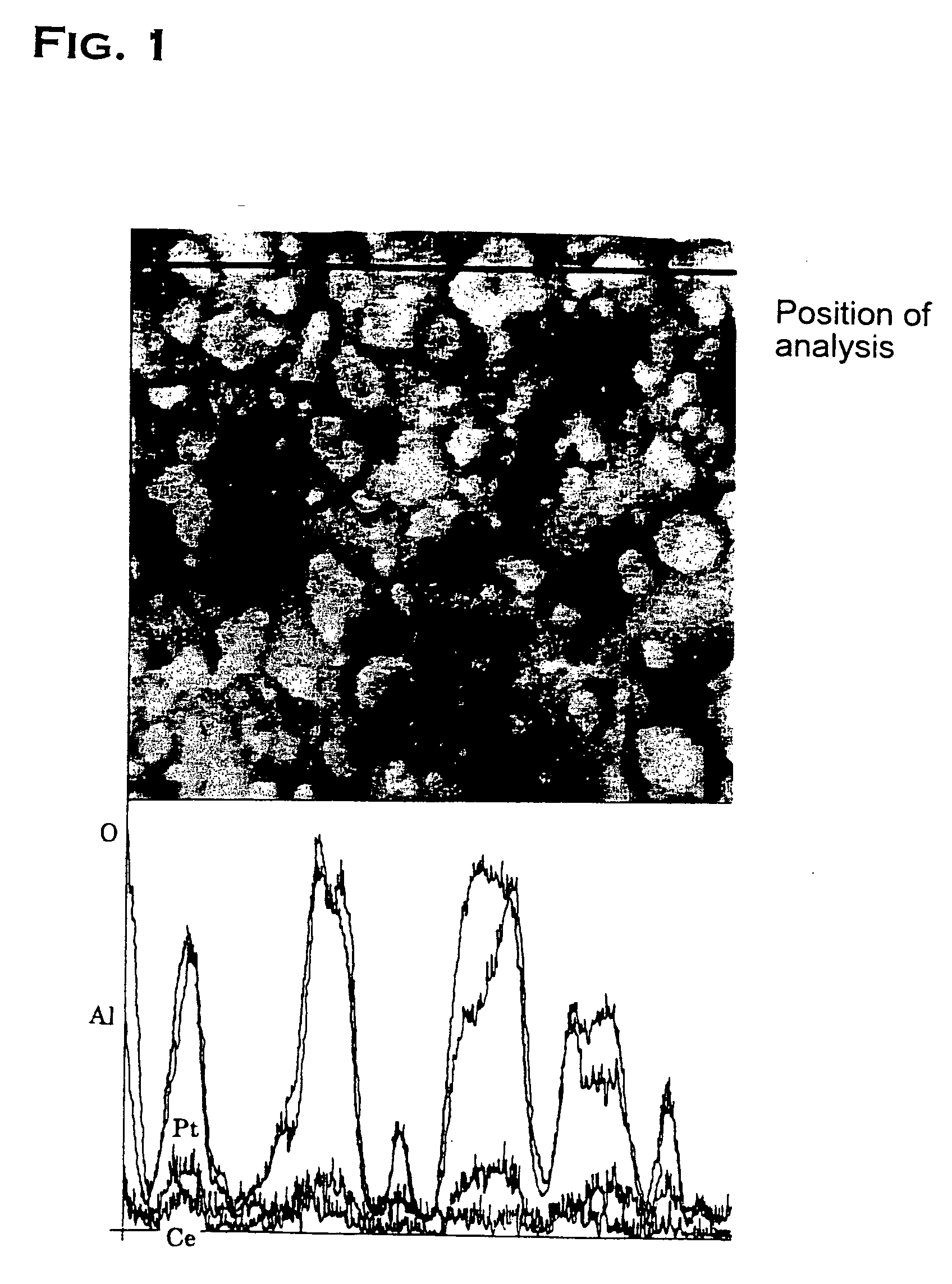

The invention relates to a preparation method of a C10+ bicyclo-heavy aromatics selective hydrogenation cracking catalyst. The preparation method comprises the following steps of adding a surface active agent into an ethanol solution of nanometer lanthanum, cerium and yttrium oxides, uniformly stirring the mixture, slowly dropwise adding H2PtCl4 and / or H2PdCl4 solution under a microwave stirring condition, and forming stable metal colloid; loading the metal colloid on a carrier; drying the obtained catalyst in the shade under a room-temperature condition for 36 to 54 hours, and then drying the catalyst in an oxygen-free atmosphere at the temperature of 80DEG C to 180DEG C. The catalyst adopts one or two of Y molecular sieve and aluminum dioxide as the carrier, one or two of platinum and palladium as a main agent and one or more of lanthanum, cerium and yttrium as assistant, wherein based on the catalyst, the content of the main agent is 0.01 to 0.1 percent by weight, the content of the assistant is 1 to 5 percent by weight, and in the C10+ heavy aromatics selective hydrogenation cracking reaction, the catalyst has the characteristics of high hydrogenation reaction activity, high single-loop saturation selectivity and high liquid yield.

Owner:CHINA NAT OFFSHORE OIL CORP +2

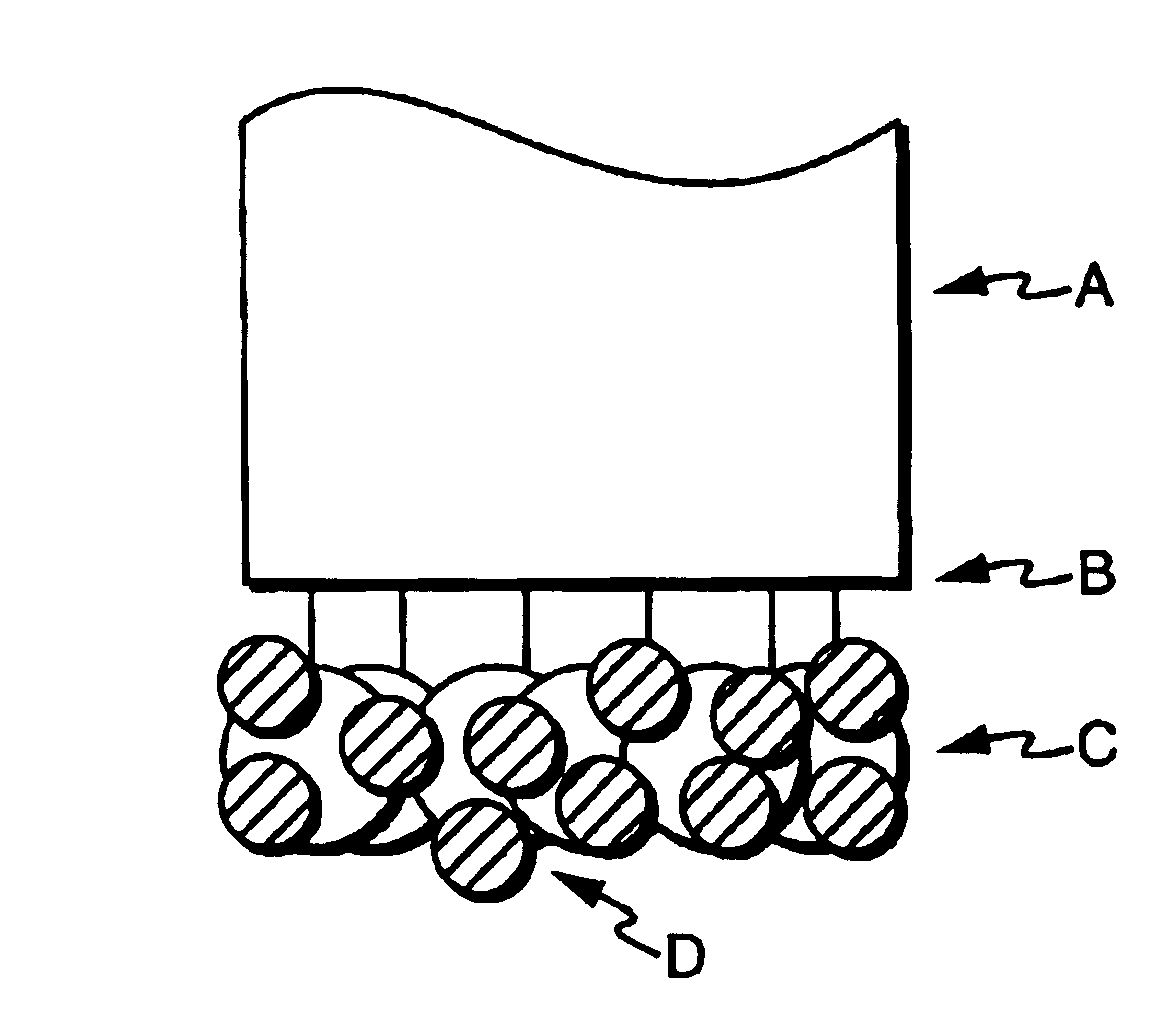

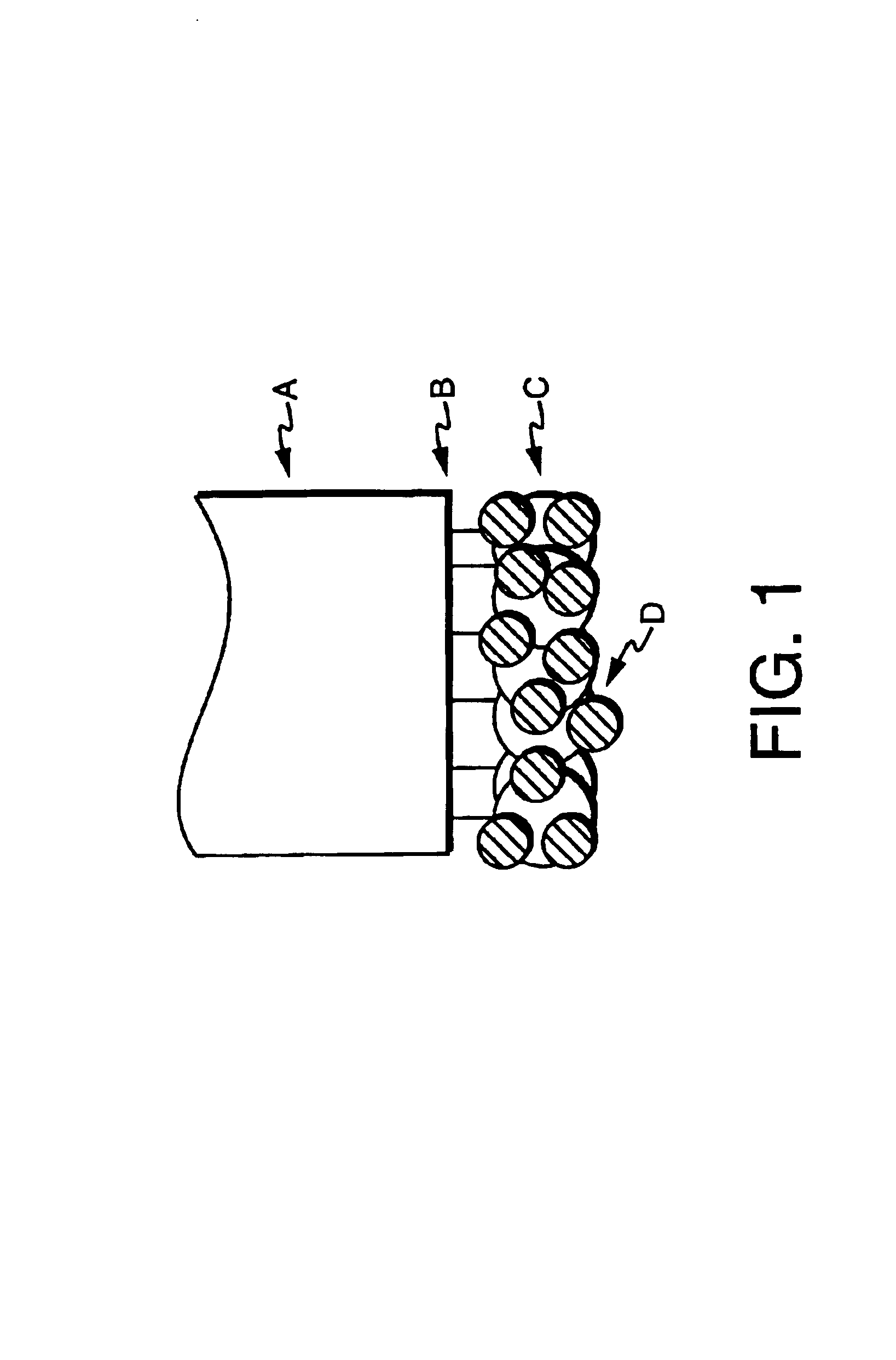

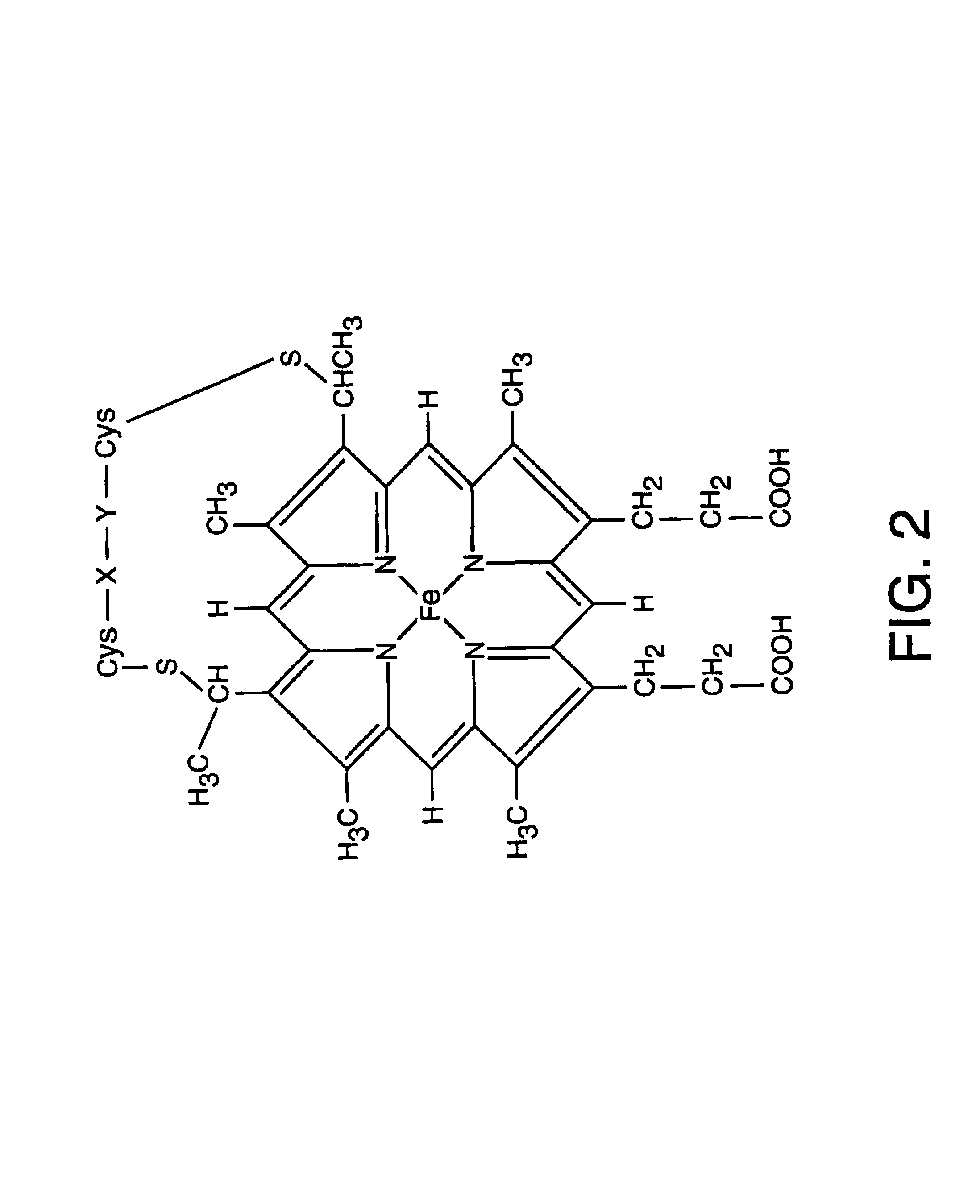

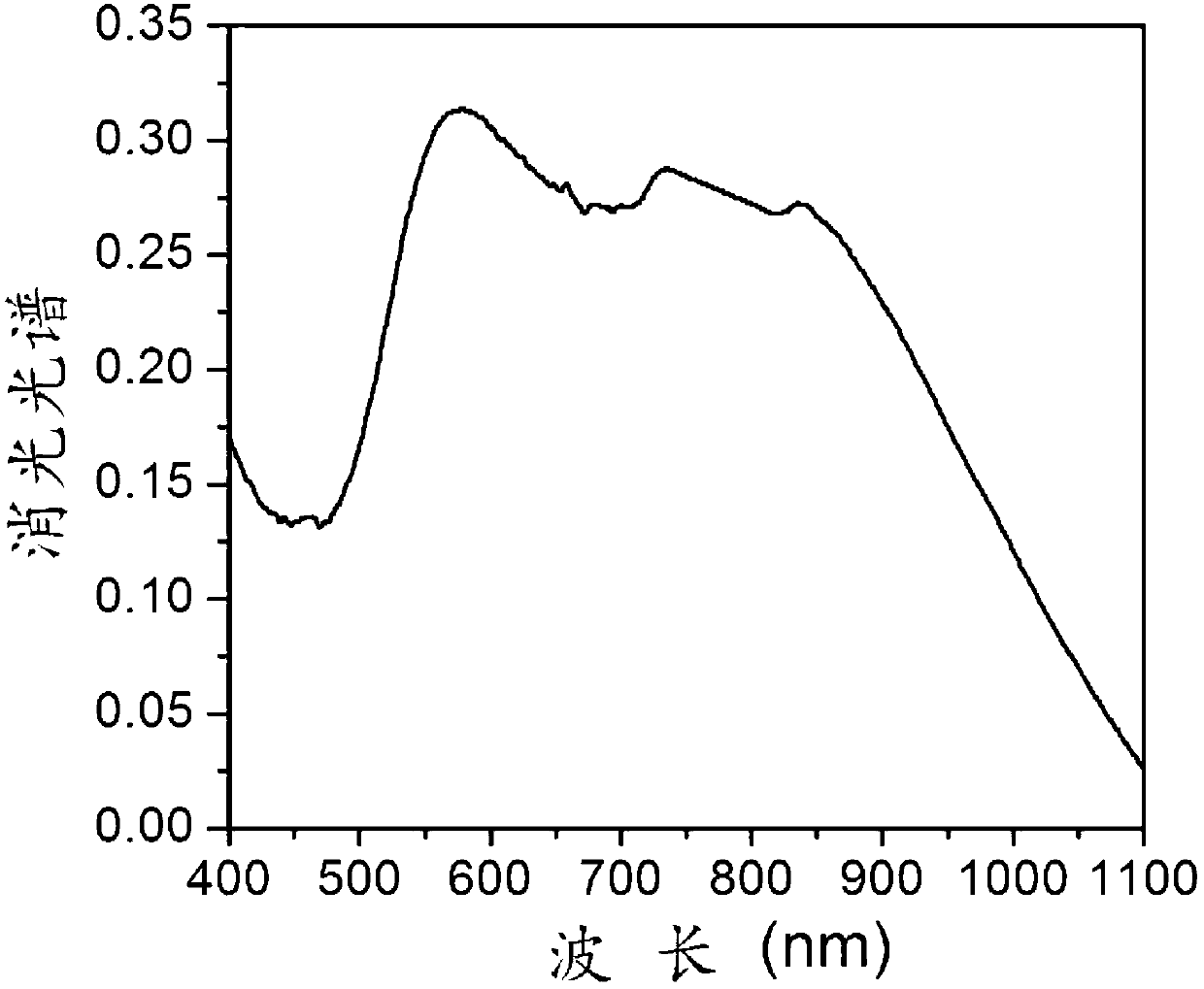

Optical sensors for the detection of nitric oxide

InactiveUS6900891B2Improve signal-to-noise ratioFast and sensitive enough to catchMaterial nanotechnologySpectrum investigationAnalyteMetal particle

Optical fiber sensors and fiberless optical sensors for measuring analytes, and in particular nitric oxide, are described utilizing metals, and more particularly, metal colloids. Proteins (or fragments thereof) with selective binding are immobilized on metal particles. The proteins may be dye-labeled for increased sensitivity.

Owner:RGT UNIV OF MICHIGAN

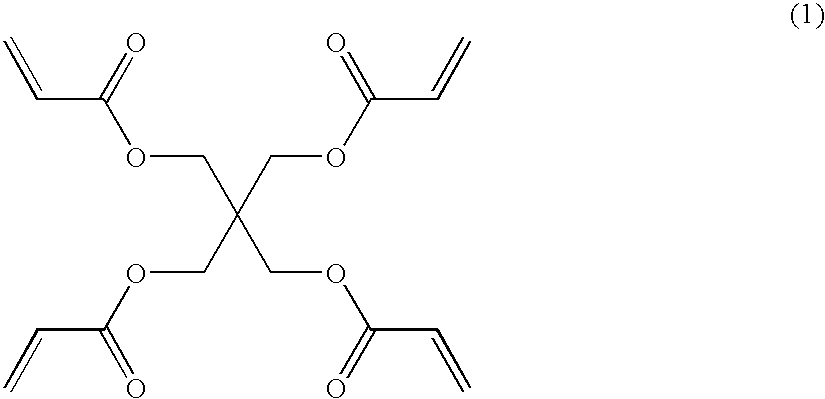

Method of manufacturing composite member, photosensitive composition, porous base material, insulating body and composite member

InactiveUS6899999B2Low costLow cost manufacturingPhotosensitive materialsSemiconductor/solid-state device manufacturingChemical compoundIon exchange

Disclosed is a method of manufacturing a composite member having a conductive pattern, comprising (1) forming on a surface of an insulating body a photosensitive layer containing both a photosensitive compound forming an ion-exchange group upon irradiation with an energy beam and a crosslinkable compound having a crosslinkable group, (2) forming a pattern of ion-exchange groups by selectively exposing the photosensitive layer to an energy beam so as to form an ion-exchange group in the exposed portion, (3) crosslinking the crosslinkable compound contained in at least the exposed portion of the photosensitive layer, (4) allowing metal ions, or a metal colloid to be adsorbed on the pattern of ion-exchange groups formed by the selectively exposing, and (5) forming a composite member having conductive pattern by depositing a conductive material on the pattern of ion-exchange groups having the metal ions, or the metal colloid adsorbed thereon using an electroless plating.

Owner:KK TOSHIBA

Lateral flow assay and device using magnetic particles

A complex including magnetic particle bound to a metal colloid. The complex may be part of a reagent for use in a method for determining analytes. The reagent may include a binding partner specific for an analyte. The reagent may further include a first label that is distinguishable from a second label that is used to detect the analyte. The reagent is used in kits and methods for detecting analytes in samples. The methods include immunoassay methods, including method where the first label is used to calibrate the assay.

Owner:IDEXX LABORATORIES

A preparation method of acetate propylene ester synthesis catalysts

InactiveCN101157030AAdjustable thicknessAdjustable positionOrganic compound preparationCarboxylic acid esters preparationCeriumPotassium

The invention relates to a preparation method for acetic acid propylene ester synthetic catalyst. The carrier of the catalyst is silicon dioxide or the mixture of the silicon dioxide and aluminum oxide, and active components comprise main catalyst palladium, one of auxiliary catalyst of gold, copper, tin, cadmium, cerium, or a mixture of more auxiliary catalyst, kalium, etc. Being prepared by adopting a metal colloid method, the catalyst has the advantages that the grain size distribution is concentrated, the dispersion degree is high, the distribution of the active components on the carrier can be adjusted and controlled, etc. In the reaction of acetic acid propylene ester synthesized with propylene, acetic acid, and oxygen, the catalyst prepared by the method has the advantages that the selectivity is high, the activity is good, etc.

Owner:CHINA NAT OFFSHORE OIL CORP +1

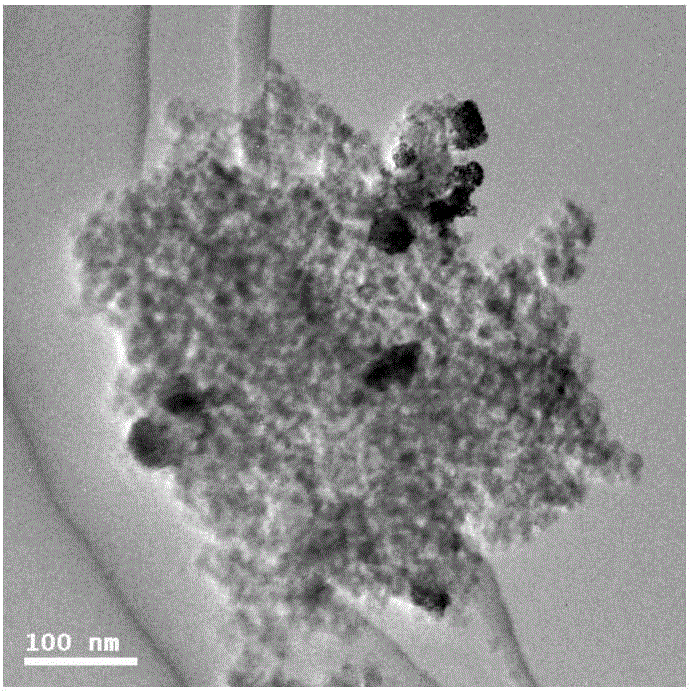

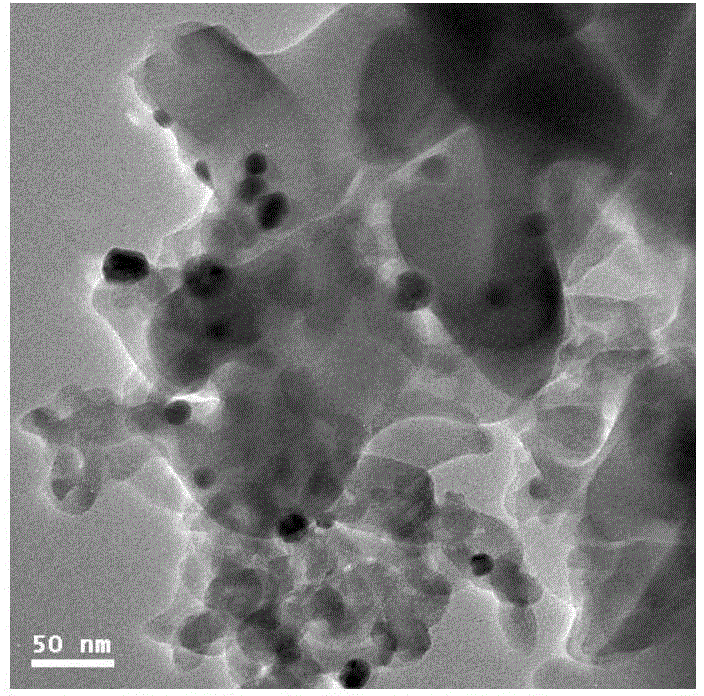

Preparation method for direct methanoic acid fuel cell palladium-on-carbon nano-catalyst

InactiveCN101318131ASmall particle sizeImprove performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPalladium on carbonNano catalyst

The invention belongs to a preparation method for a direct formic acid fuel cell carbon-supported palladium nanometer catalyst, which takes (WO3) n and xH2O or (MoO3) n and xH2O as colloid source to form metal colloid with PdCl2 and uses NaBH4 for reducing, thus obtaining the carbon-supported palladium catalyst. The palladium particles of the catalyst have uniform distribution and small average grain size. The catalyst prepared by the method has higher performance on the catalytic oxidation of formic acid than the carbon-supported palladium catalyst prepared by the traditional impregnation method which has the same loading capacity but no colloid source. The method with simple practice does not need protective agent and the colloid source can be removed through simple washing; therefore, the method is suitable for batch preparation of the carbon-supported palladium catalyst.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

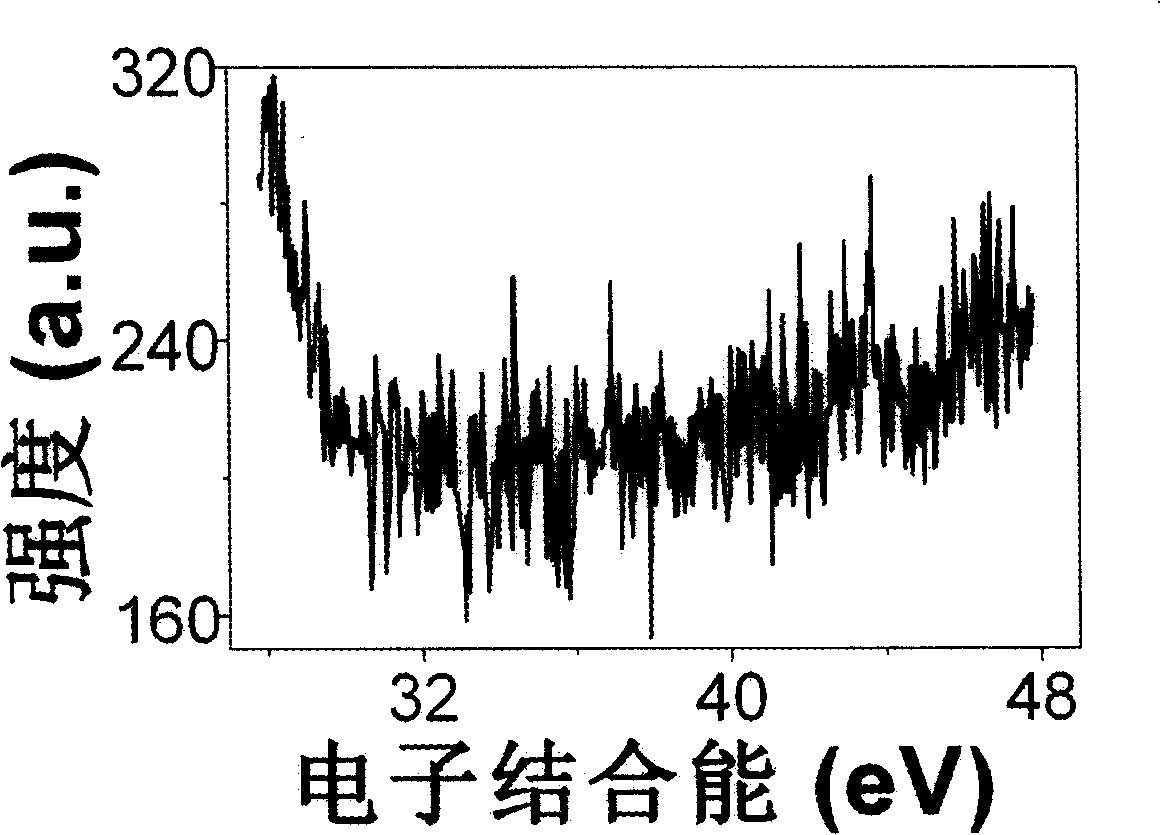

Method for preparing surface-enhanced Raman scattering substrate by solution method and application

ActiveCN103344624AReduce manufacturing costIncrease the areaRaman scatteringOrganic solventRhodamine 6G

The invention relates to a method for preparing surface-enhanced Raman scattering (SERS) substrate by a solution method and application, and belongs to the technical field of SERS substrates. The method comprises the following steps: preparing hydrocarbyl mercaptan modified metal nanoparticles with the diameter of 1 to 5 nm; dissolving the metal nanoparticles with the diameter of 1 to 5 nm into an organic solvent to prepare metal nanoparticle sol of 60 to 100 mg / ml; and coating the metal nanoparticle sol on a substrate, placing a sample coated with a metal colloid film in a precise muffle furnace or a tube furnace, heating to 140 to 250 DEG C within 5 minutes, maintaining for 5 to 30 minutes, and cooling to room temperature. When the SERS substrate obtained by the method is applied to detection of rhodamine 6G and 4-mercaptopyridine, the enhancement factor is 107, and the relative standard difference of Raman signal intensity distribution at different positions is 5%.

Owner:BEIJING UNIV OF TECH

Metal colloid dispersions and their aqueous metal inks

InactiveUS20070105979A1Easy to controlLow resistivityInksPrinted circuit manufactureAdditive ingredientPolyethylene glycol

A silver dispersion is obtained by reducing a silver compound in the presence of a polymeric dispersant of an ionic hydrophilic segments, such as methacrylic acid segments and nonionic hydrophilic segments of alkoxy-terminated polyethylene glycol segments. Aqueous inkjet inks may contain such dispersants and other common ingredients such as a humectant. The printed inks can be sintered under heat to form solid, conductive patterns of silver.

Owner:LEXMARK INT INC

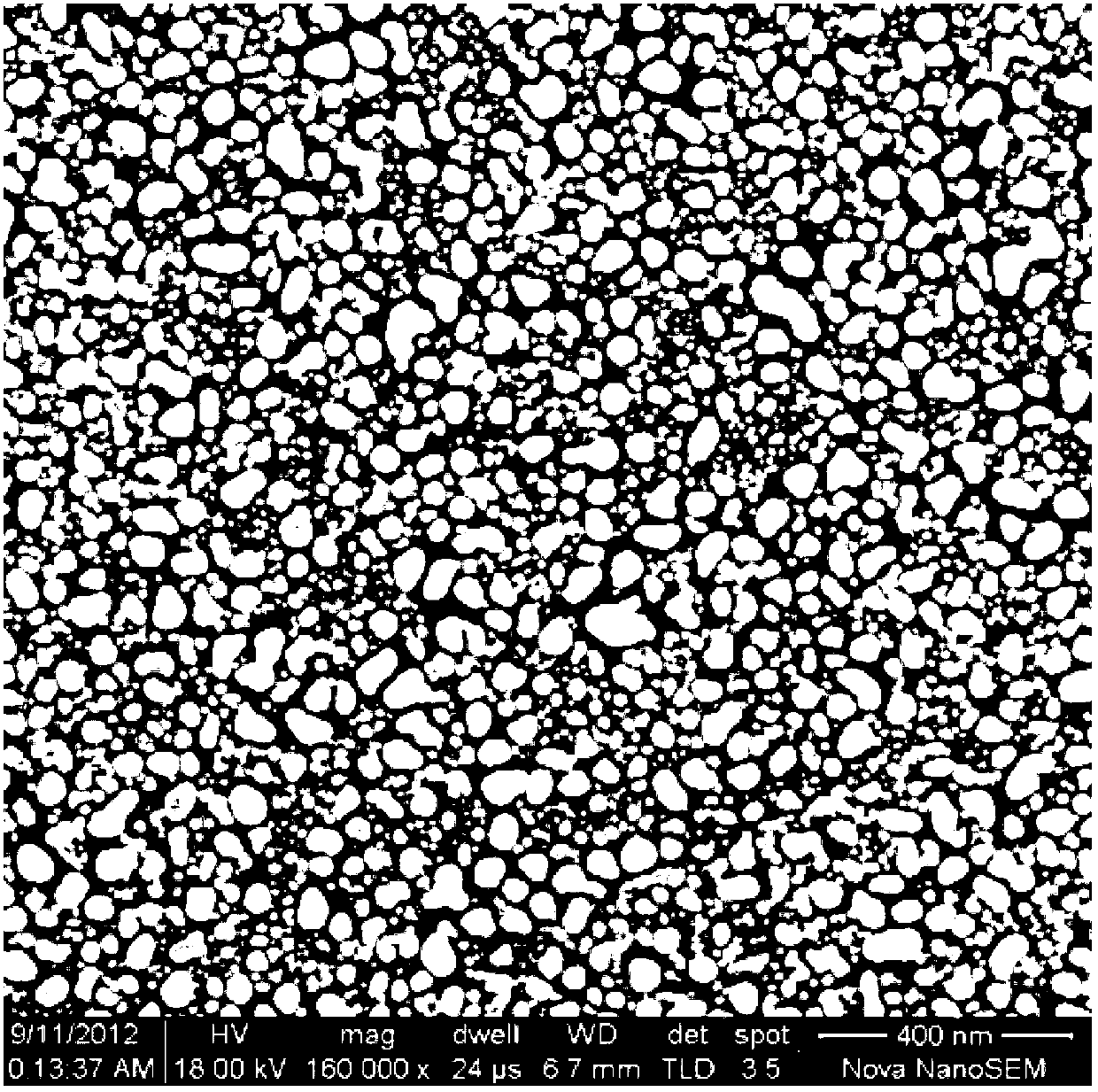

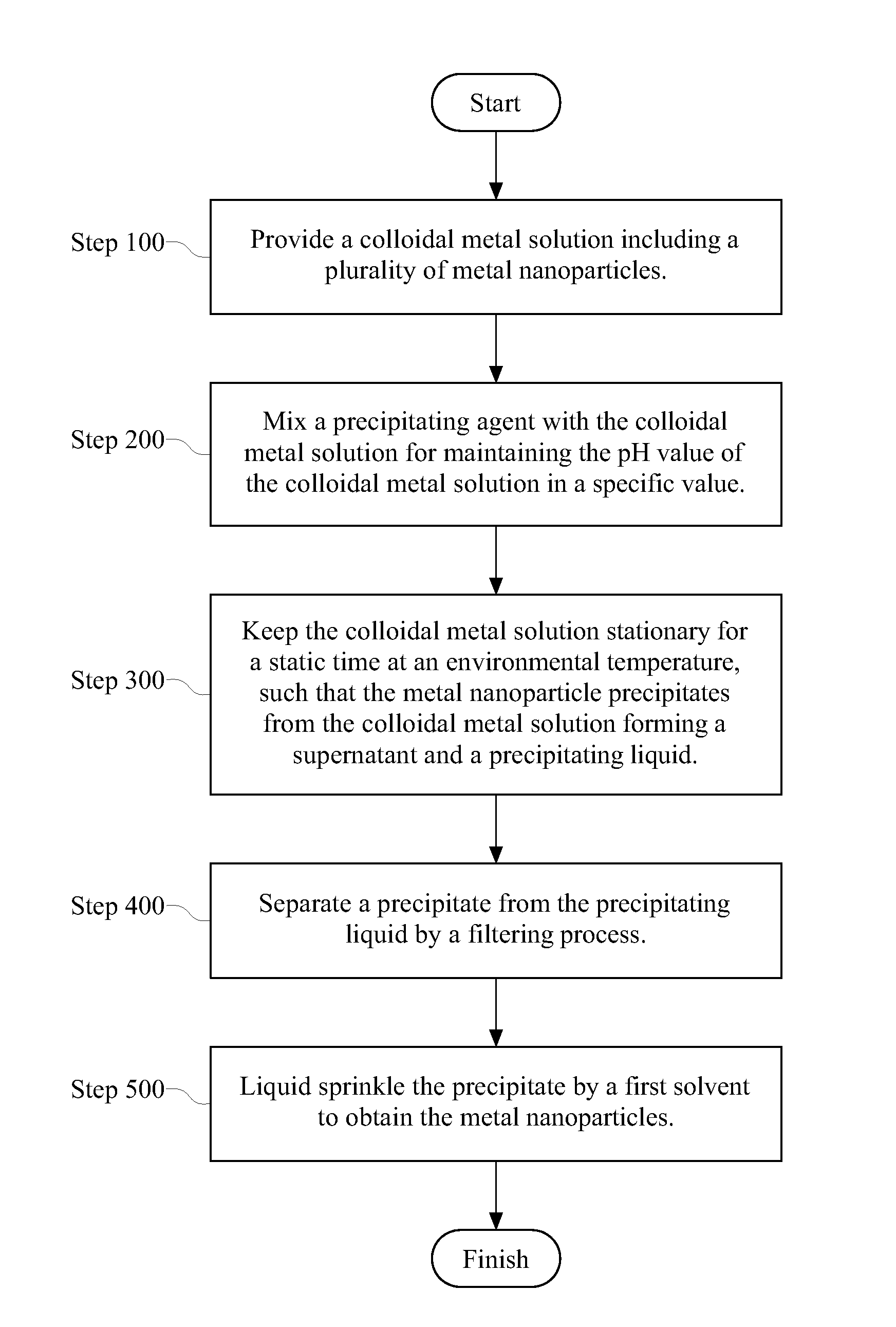

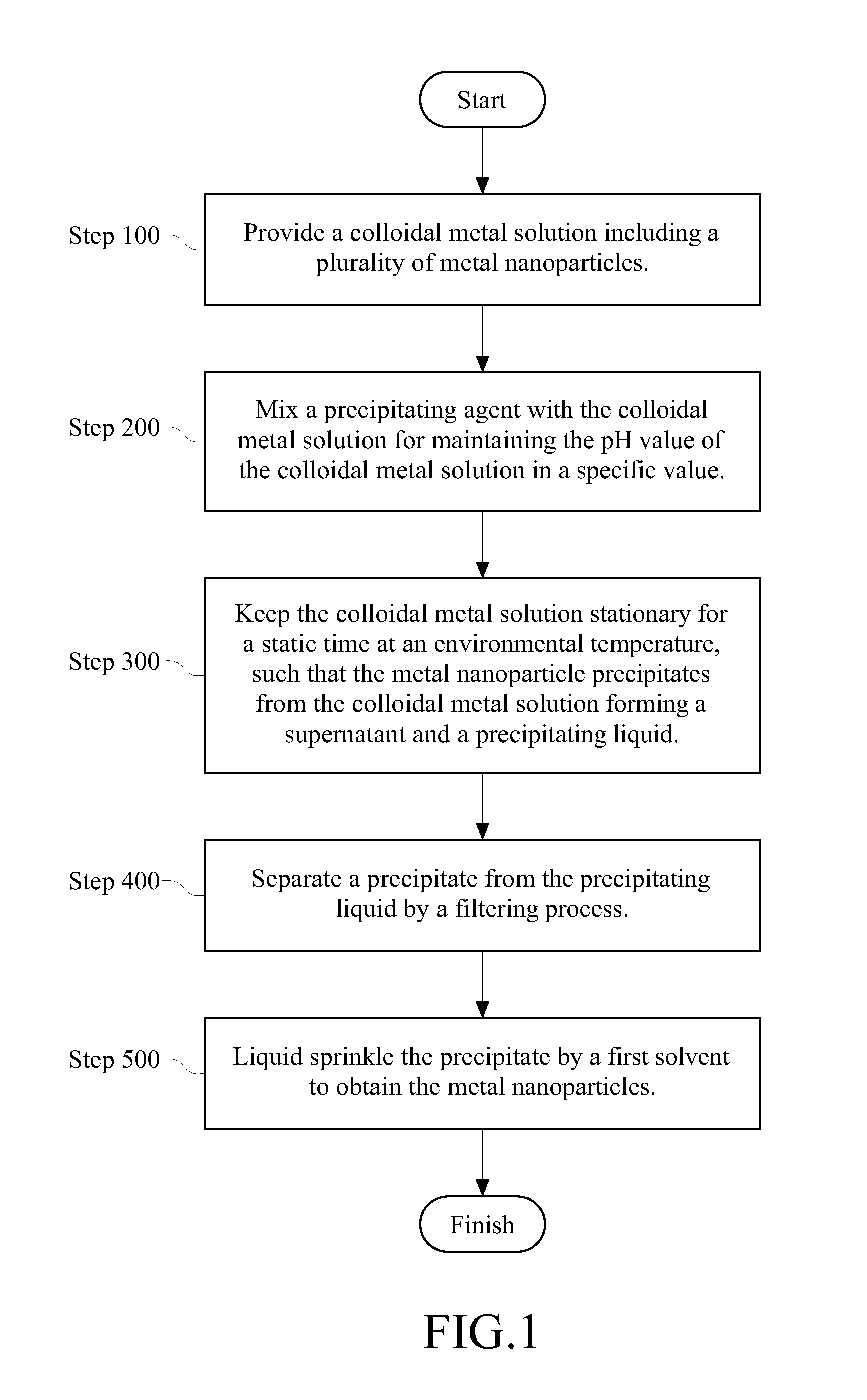

Method for separating metal nanoparticles from colloidal metal solution

ActiveUS20140033870A1Material nanotechnologyTransportation and packagingMetal colloidsColloidal Solution

A method for separating metal nanoparticles from colloidal metal solution includes providing a colloidal metal solution, including a plurality of metal nanoparticles; mixing a precipitating agent with the colloidal metal solution for maintaining the power of hydrogen value (pH) of the colloidal metal solution in a specific value; keeping the colloidal metal solution stationary for a static time at an environmental temperature such that the metal nanoparticle precipitates from the colloidal metal solution, and the colloidal metal solution forms a supernatant and a precipitating liquid; separating a precipitate from the precipitating liquid by a filtering process; and liquid blasting the precipitate by a first solvent to obtain the metal nanoparticles.

Owner:NAT CHUNG SHAN INST SCI & TECH

Metal colloid-colored glass ceramic and colorless glass convertible into same

ActiveUS20080269038A1Promote lowerGlass/slag layered productsMetal layered productsOxidation-Reduction AgentRedox

The colorless transparent colloid-former-containing glass that is convertible into a colorless transparent glass ceramic or a metal colloid-colored glass ceramic via respective heat treatments contains a combination of one or more metal colloid formers and one or more redox partners. The metal colloid formers are compounds containing Au, Ag, As, Bi, Nb, Cu, Fe, Pd, Pt, Sb and / or Sn. The redox partners are compounds containing As, Ce, Fe, Mn, Sb, Sn and / or W, with the proviso that the redox partner must be different from the metal colloid former.

Owner:SCHOTT AG

Graphite alkenyl conductive material and preparation method thereof

InactiveCN102254582AReduce the temperatureOvercome the hassleMaterial nanotechnologyCarbon compoundsHydrogen pressureHydrazine compound

The invention provides a method for preparing a graphite alkenyl conductive material, comprising the following steps of: preparing oxidation graphite alkenyl sol and metal salt solution and / or metal colloid solution into a solid film on a substrate layer; and then, after separating or not separating the solid film from the substrate layer, placing at minus 50 to 200 DEG C for 30 seconds to 10000 hours at hydrogen pressure of 0.2-100 MPa to obtain the graphite alkenyl conductive material. The invention further provides a graphite alkenyl conductive material which is prepared by the method. Thepreparation method provided by the invention can be carried out at a low temperature. The hydrogen as a reducing agent used in the invention is a cheap and easily obtained raw material. Because no toxic hydrazine is used as a reducing agent, the preparation process is simple and environmentally-friendly.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

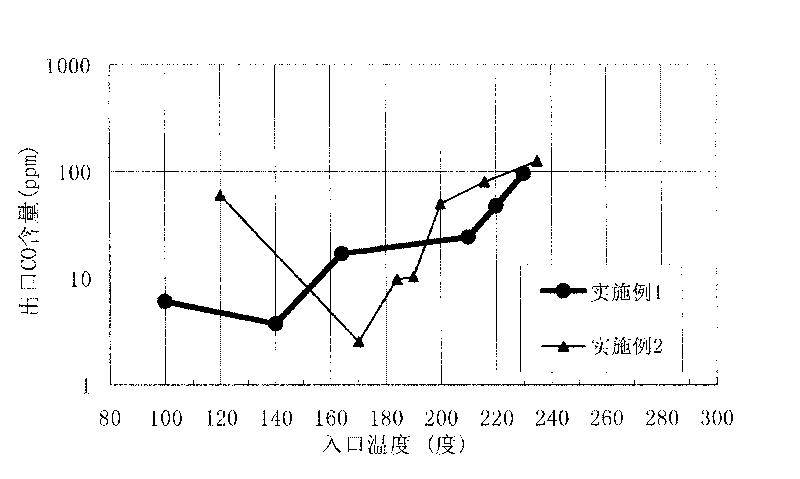

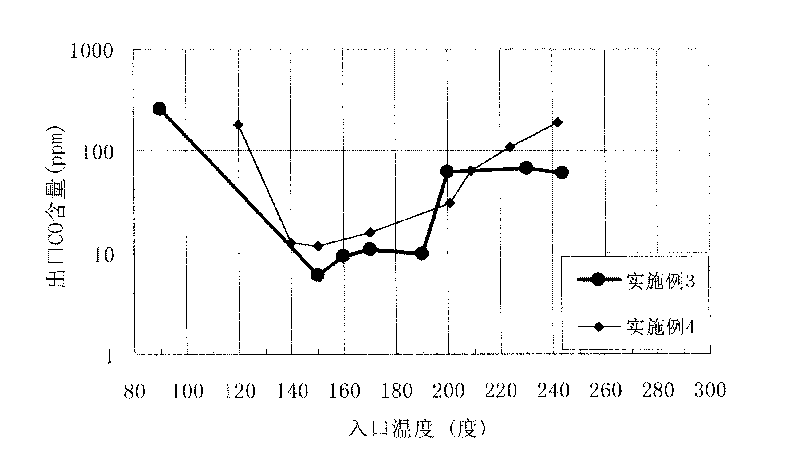

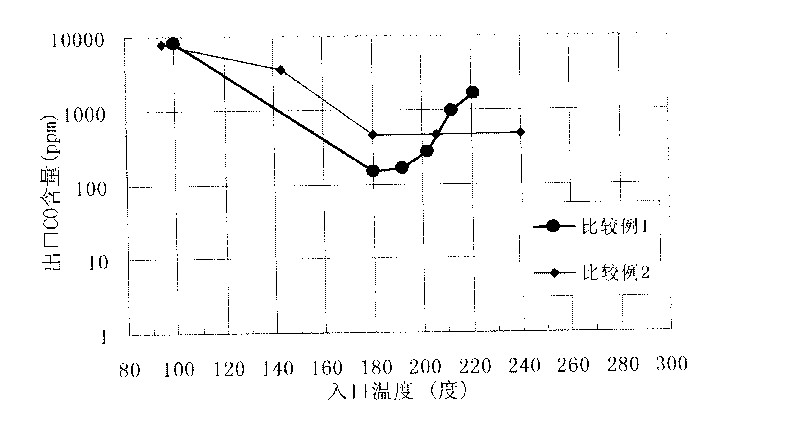

Method for preparing catalyst for removing CO by selective oxidation

InactiveCN101690892AThickness is easy to controlPosition is easy to controlHydrogen separation using solid contactCatalyst activation/preparationMetal colloidsReducing agent

The invention provides a method for preparing a catalyst for removing CO from a hydrogen-rich atmosphere by selective oxidation. The catalyst is characterized in that the carrier thereof adopts Al2O3 or SiO2-Al2O3 with the weight percentage of SiO2 being 3-40%; and the active component thereof is one or more than one selected from the following noble metal elements: Ru, Rh, Pd and Pt. Based on a metallic colloid method, the method of the invention for preparing the catalyst comprises the following steps: adding surfactant to the aqueous solution of metal salt of the active components in the noble metal elements; slowly adding reducing agent drop by drop while stirring intensely, so as to obtain stable noble metal colloid with the particle size thereof being 2-10nm through reduction by a reducing agent; properly regulating loading conditions and loading the noble metal colloid onto the carrier, so as to obtain a loading-type metal colloid catalyst; and subjecting the metal colloid catalyst to room-temperature airing, oven-drying and reducing, to obtain the finished catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

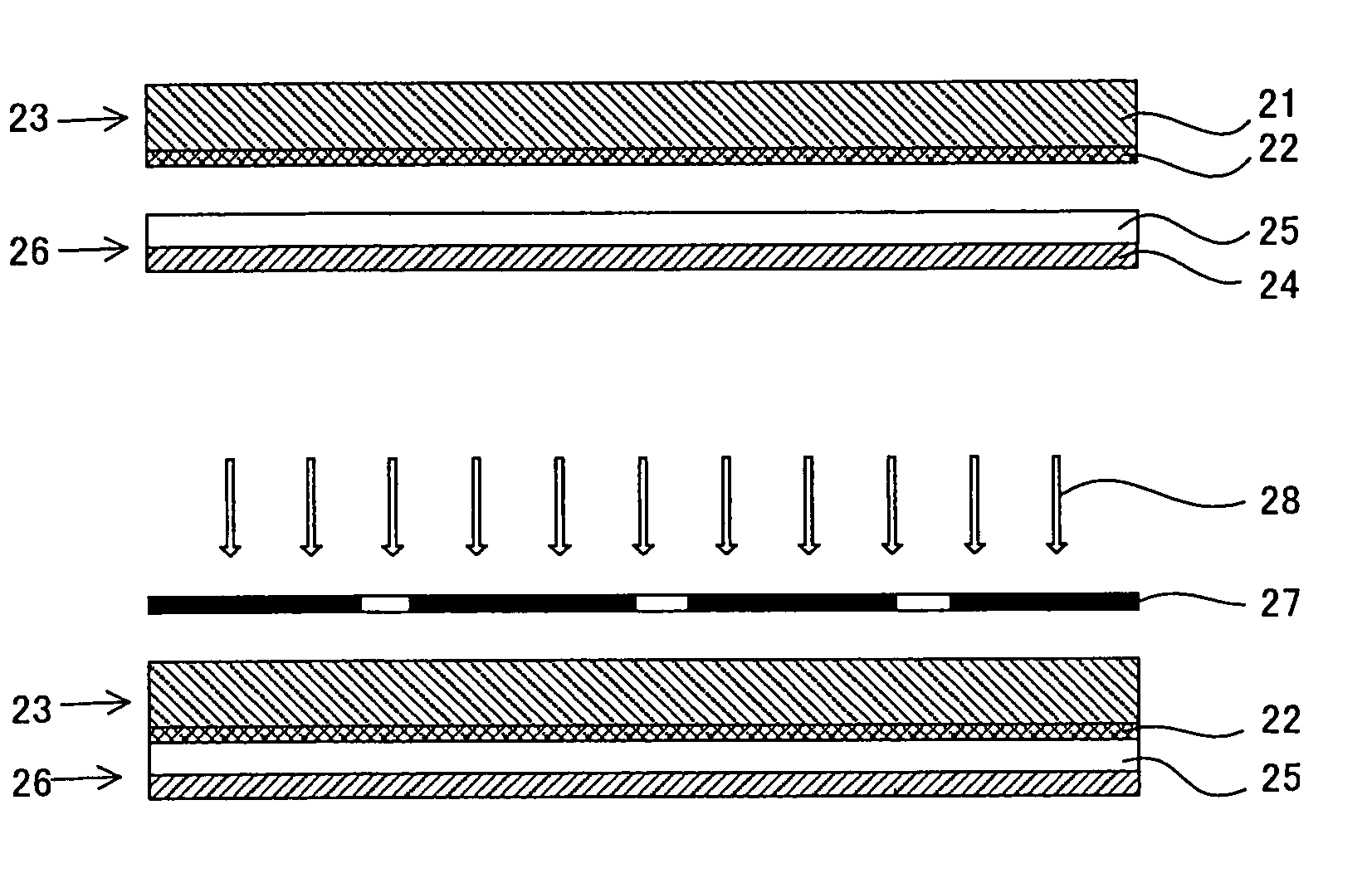

Method for manufacturing conductive pattern forming body

InactiveUS7749684B2High precision formingSimple processMaterial nanotechnologySemiconductor/solid-state device manufacturingMetal colloidsMaterials science

A method for manufacturing a conductive pattern capable of forming a highly precise pattern, also capable of forming by using a simple process, and being free from problems such as treatment of waste fluids. The method for manufacturing a conductive pattern forming body includes a process of preparing a pattern forming body substrate including a base material, and a photocatalyst containing layer formed on the base material including a photocatalyst and a binder whose wettability of an energy irradiated part is changed so as a contact angle to a liquid is reduced; a process of forming wettability pattern including a liquid repellent area and a lyophilic area on the photocatalyst containing layer by irradiating the photocatalyst containing layer in a pattern with energy; a metal colloid coating process of adhering a metal colloid only to the lyophilic area of the surface of the photocatalyst containing layer on which the wettability pattern is formed, by coating the metal colloid; and a process of forming a conductive pattern by solidifying the metal colloid adhered to the lyophilic area of the wettability pattern.

Owner:DAI NIPPON PRINTING CO LTD

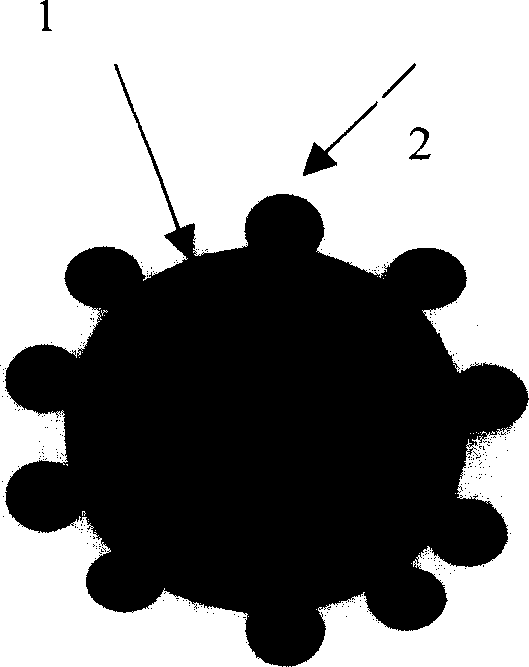

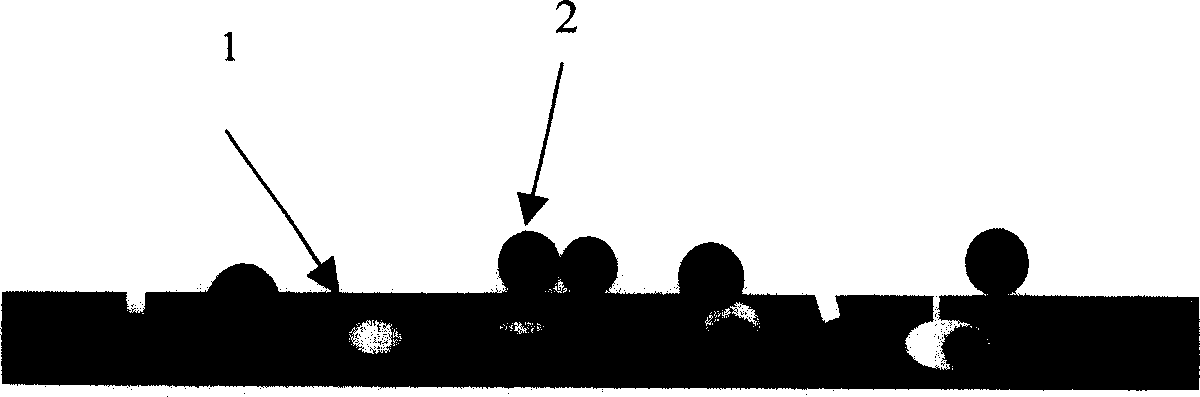

Conductive adhesive for screen printing, joined body of inorganic material, and method for producing same

ActiveUS20150282330A1Improve conductivityImprove productivityPrinted circuit assemblingNon-macromolecular adhesive additivesAdhesiveMetal colloids

The present invention relates to a conductive adhesive for screen printing containing metal colloid particles (A) containing metal nanoparticles (A1) and a protective colloid (A2) containing an organic compound having a carboxyl group and a polymer dispersant having a carboxyl group, a viscosity modifier (B) having an amide bond and / or a urea bond, and a dispersion solvent (C).

Owner:MITSUBOSHI BELTING LTD

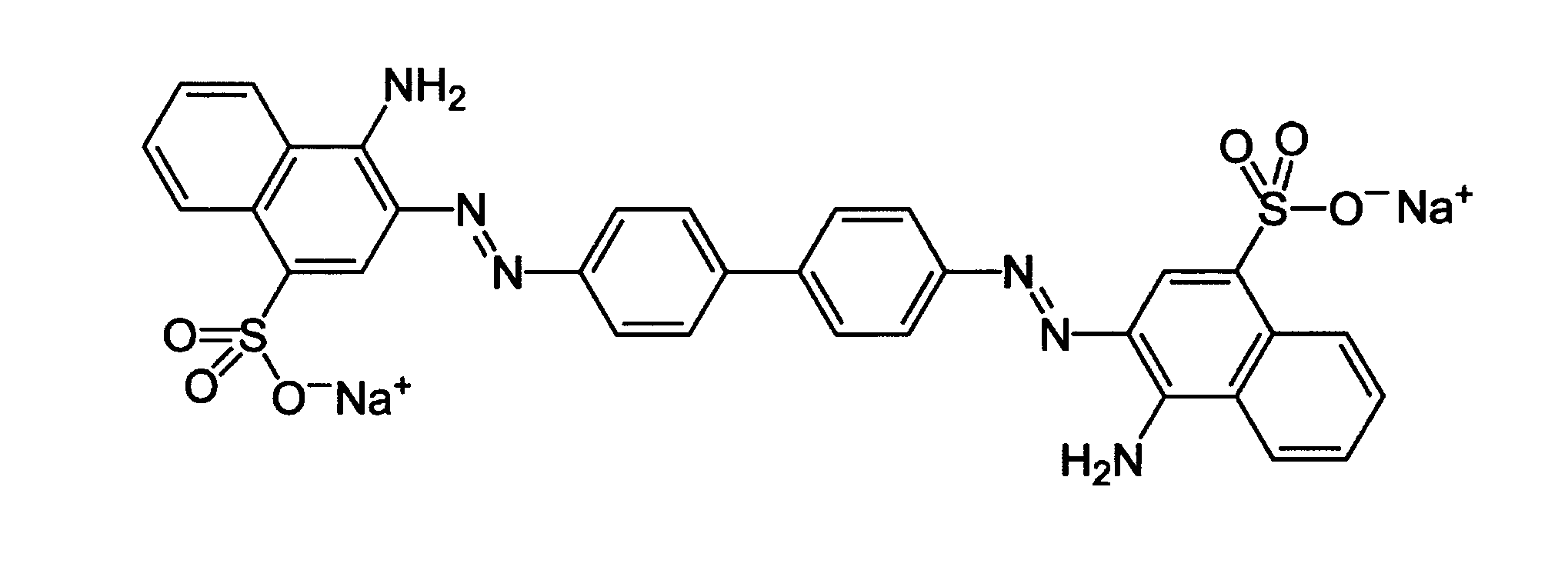

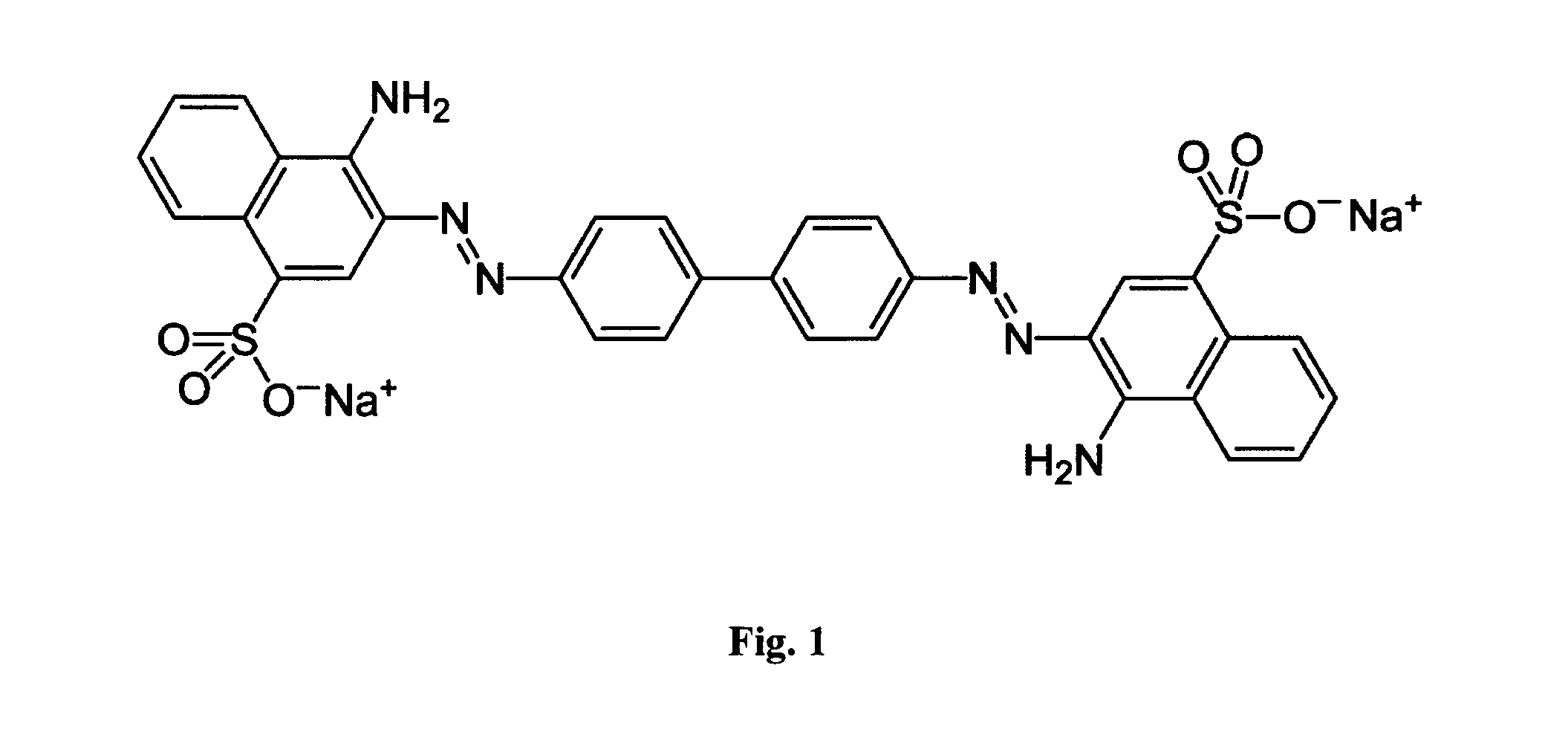

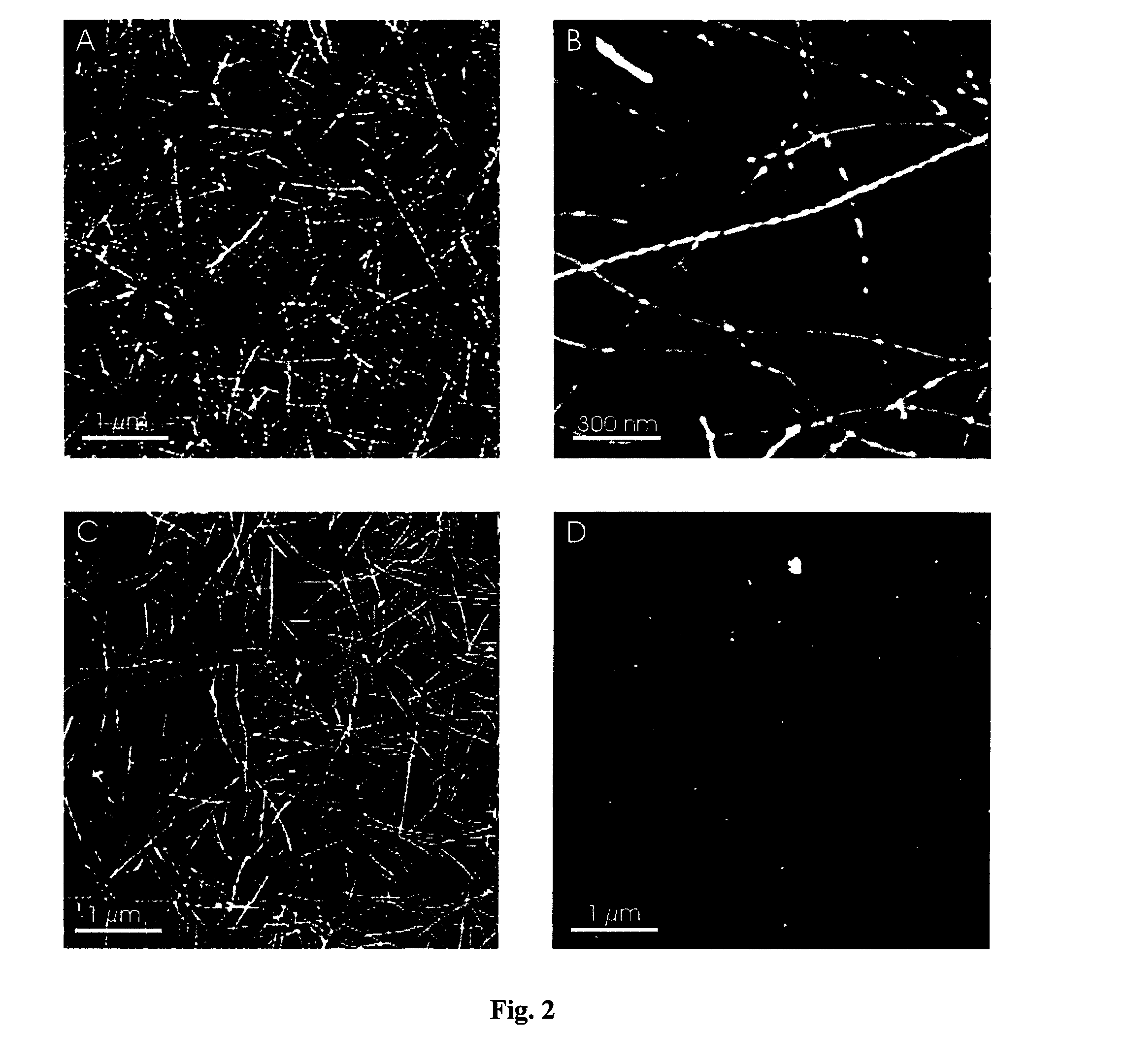

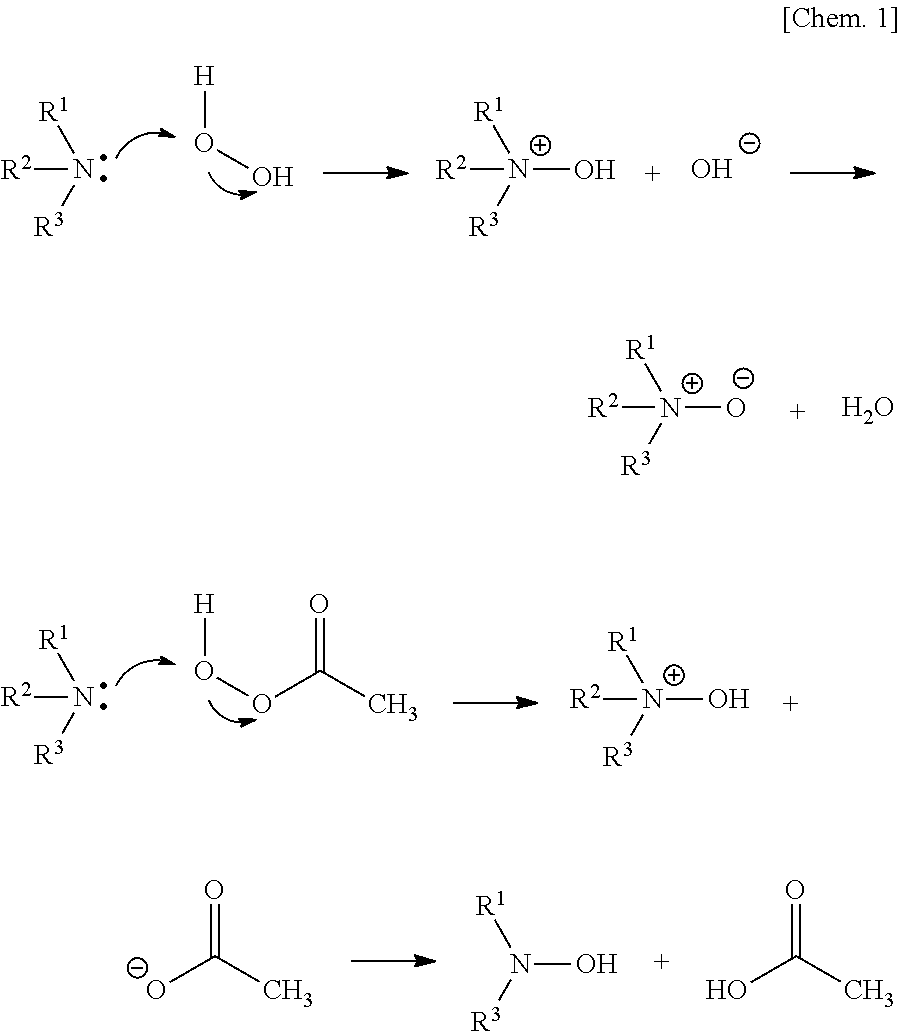

Compositions and methods for removal or destruction of amyloid fibril or amyloid adhesin comprising aggregates

InactiveUS20130115257A1Reduce riskFacilitate communicationAntibacterial agentsOrganic active ingredientsHuntingtons choreaAmyloid beta

Methods and compositions for treating biofilms and diseases associated with amyloidosis such as Alzheimer's, Parkinson's and Huntington's disease, and Type 2 diabetes, by destroying amyloid fibrils in a two-step treatment are disclosed. The first step consists of binding to the amyloid fibril an intercalating molecule with a negatively charged group such as Congo red. The second step consists of adding metal ions, such as silver, gold(I), copper(I), palladium or lead ions or metal colloids of silver or gold, which destabilize the amyloid-dye complex. This process results in a disintegration of the fibril into peptide monomers and small aggregates of monomers.

Owner:KATHOLIEKE UNIV LEUVEN

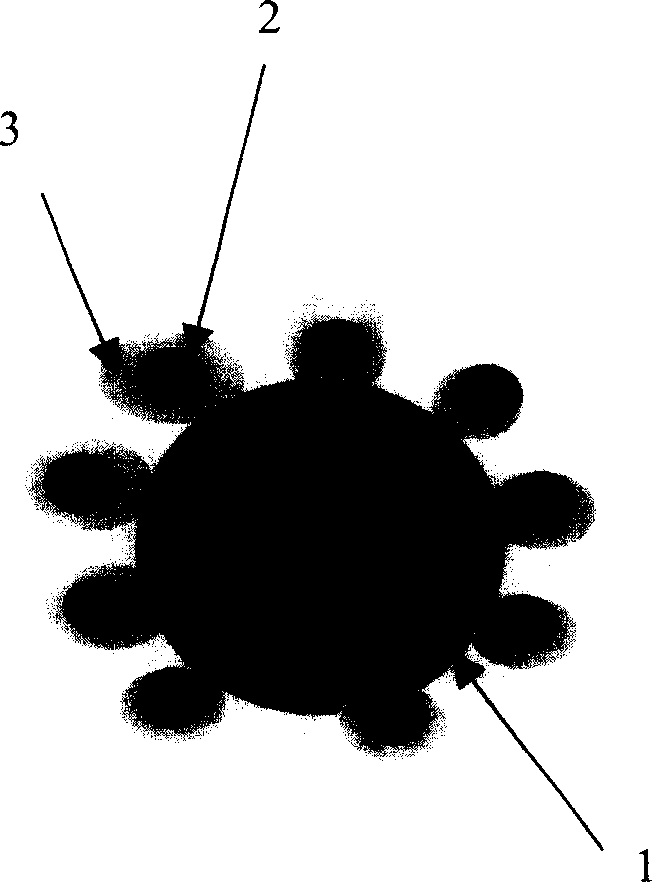

Metal nanoparticle composite body, metal colloidal solution, and methods for producing these

ActiveUS20150203700A1Good low-temperature firing propertyGood low temperatureMaterial nanotechnologyTransportation and packagingDispersion stabilityNanometre

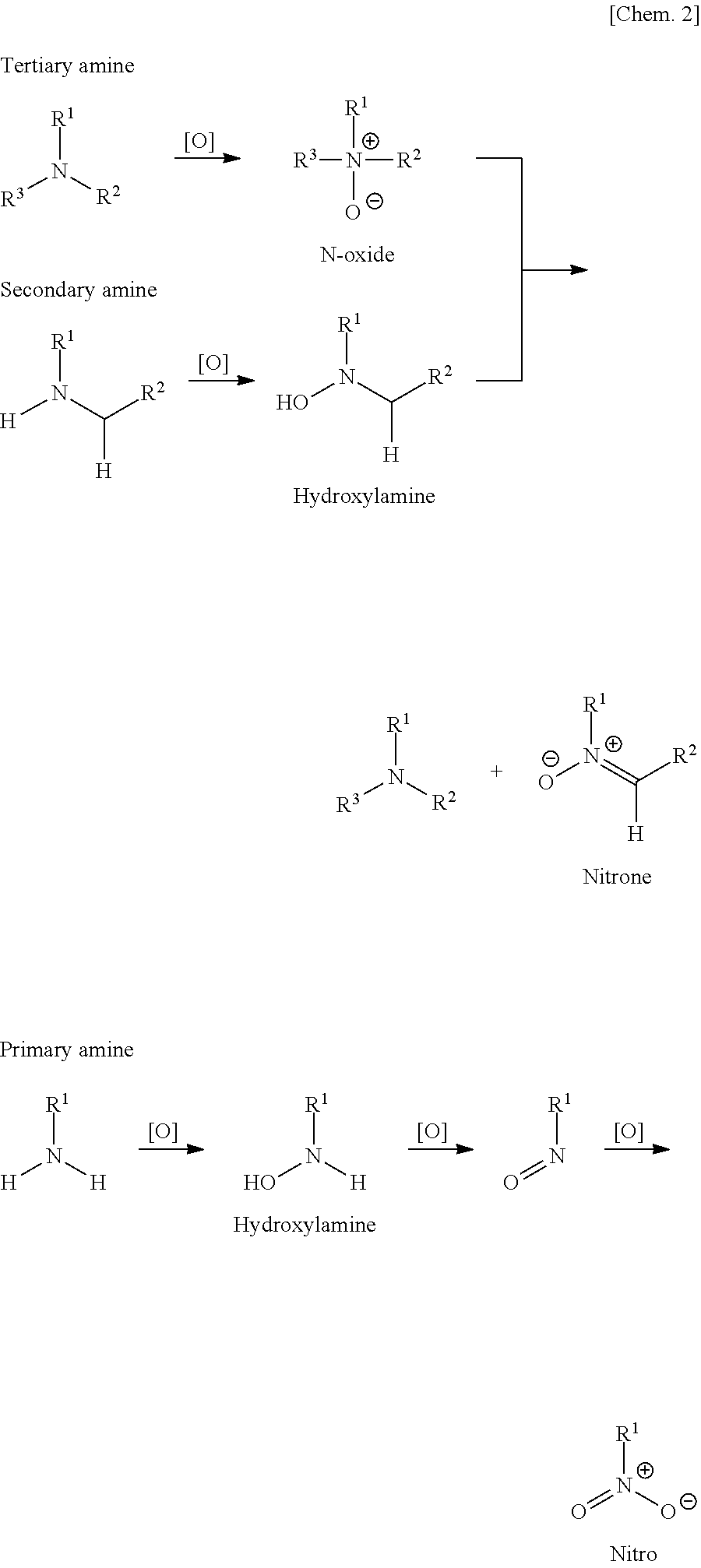

Provided are metal nanoparticle composite body whose multiple properties, such as a good metal nanoparticle control property, high dispersion stability, a good low-temperature firing property, and ease of purifying and separating metal nanoparticles, are intentionally added and controlled so that practical electrical conductivity can be exhibited, a metal colloidal solution in which the metal nanoparticle composite body is dispersed, and methods for producing these. A metal nanoparticle composite body includes a nitrogen-containing compound (A) and a metal nanoparticle (B), in which the nitrogen-containing compound (A) contains an oxidized nitrogen atom. A metal colloidal solution is obtained by dispersing the metal nanoparticle composite body in a medium. A method for producing a metal colloidal solution is characterized in that metal ions are reduced in a medium in the presence of a nitrogen-containing compound (A) containing an oxidized nitrogen atom so as to form metal nanoparticles (B).

Owner:DAINIPPON INK & CHEM INC

Electrically conductive ink, electrically conductive film made from the same, and production methods for electrically conductive ink and electrically conductive film

InactiveUS20100126379A1Excellent hydrogen bonding abilityIncrease stickinessInksNon-conductive material with dispersed conductive materialEngineeringMetal colloids

The electrically conductive ink in accordance with one embodiment of the present invention includes a metal colloid liquid and a saccharide compound, wherein the electrically conductive ink comprises the saccharide compound in an amount equivalent to at least 3% by weight and at a maximum 15% by weight of a solid content of the metal colloid liquid. This way, it is possible to provide an electrically conductive ink making it possible to form an electrically conductive film having a high electrical conductivity and a high adhesiveness to a substrate, to provide an electrically conductive film made from the electrically conductive ink, as well as to provide a production method of the electrically conductive ink and a production method of the electrically conductive film.

Owner:BANDO CHEM IND LTD

Method for preparing metal colloid at normal temperature

The invention discloses a method for preparing a metal colloid at normal temperature, which belongs to the field of preparation of colloids. The method is characterized by comprising the following steps of: mixing a polyol solution with the concentration of a promoter of 0.00002-10mol / L and the polyol solution with the concentration of a metal precursor of 0.00001mol / L-1mol / L, enabling the molar ratio of the promoter to the metal precursor to be 2-100 and reacting at room temperature to prepare metal-sol, wherein the prepared metal-sol has ultrahigh stability, and the particle size of metal is 1-20nm. The metal-sol prepared by the method disclosed by the invention has good stability, and the particle size distribution of metal nanoparticles is uniform. The method disclosed by the invention has a simple process and is suitable for large-scale generation of the metal colloids, protecting agents on the surfaces of the generated nanoparticles are easy to clean, a catalyst prepared by the method disclosed by the invention has high activity, and the method further has good economic benefits and industrial application prospects.

Owner:DALIAN UNIV OF TECH

Glass coated with color multilayer film and its producing method

The glass with coated multilayer color film consists of glass, metal film layer penetrating to 2-15 micron below glass surface and silicon film deposited on the surface of glass. The production process includes ion penetration to form metal film and chemical vapor deposition to form silicon film. In the tin tank in float glass producing line, electric field is applied to high temperature glass belt, so that metal ions migrate into glass belt surface layer before being reduced in reduction atmosphere into metal colloid to form the metal film layer. Then in a reactor, one layer of silicon film is formed on the moving glass belt through chemical vapor deposition. Through altering the kind of penetrated metal, glass in the required color may be produced. The outer silicon film can strengthen the stability and reflecting effect of the metal film, reduce the transmittance of the metal film and raise the surface wear resistance.

Owner:HANGZHOU BLUSR NEW MATERIALS TECH

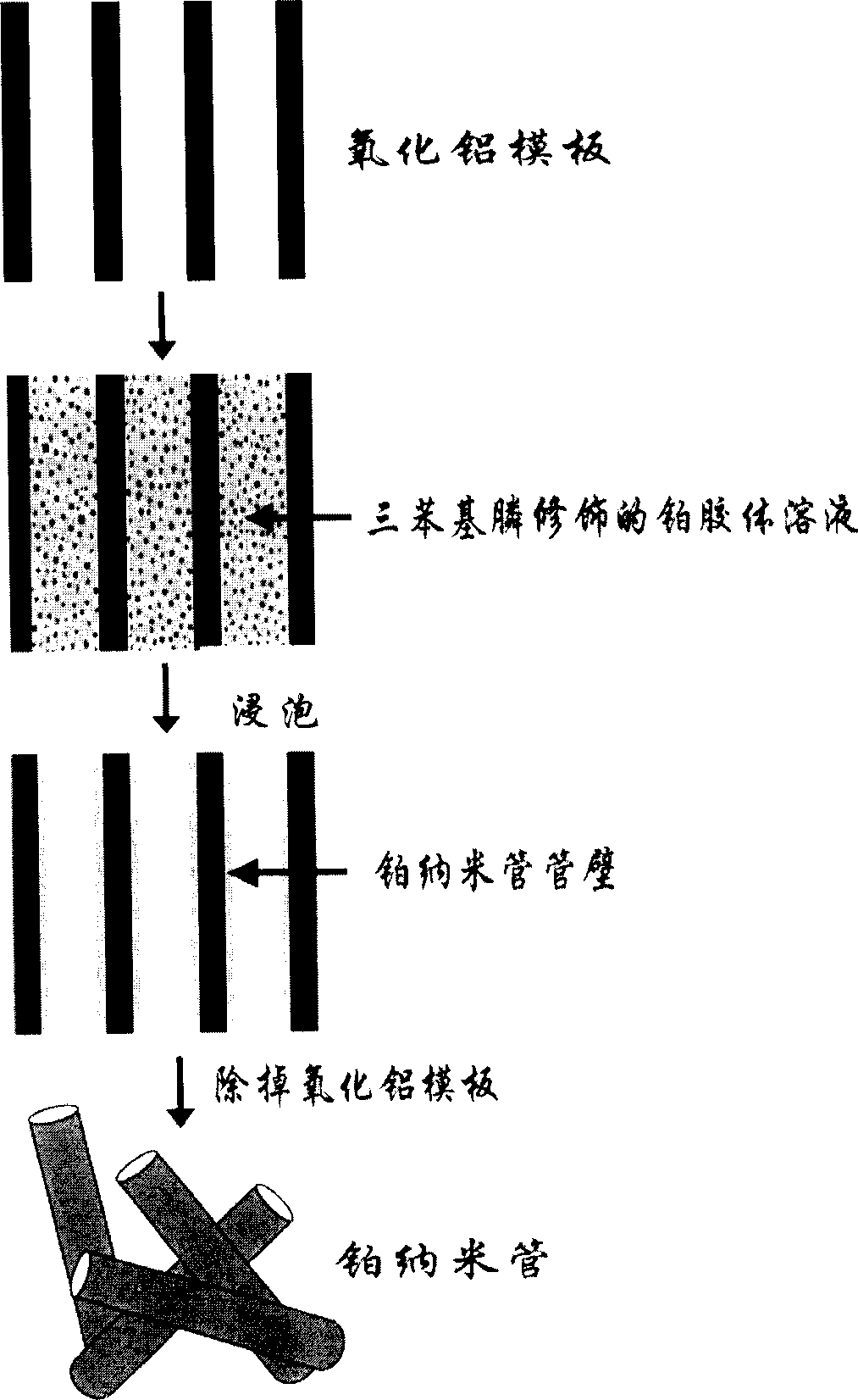

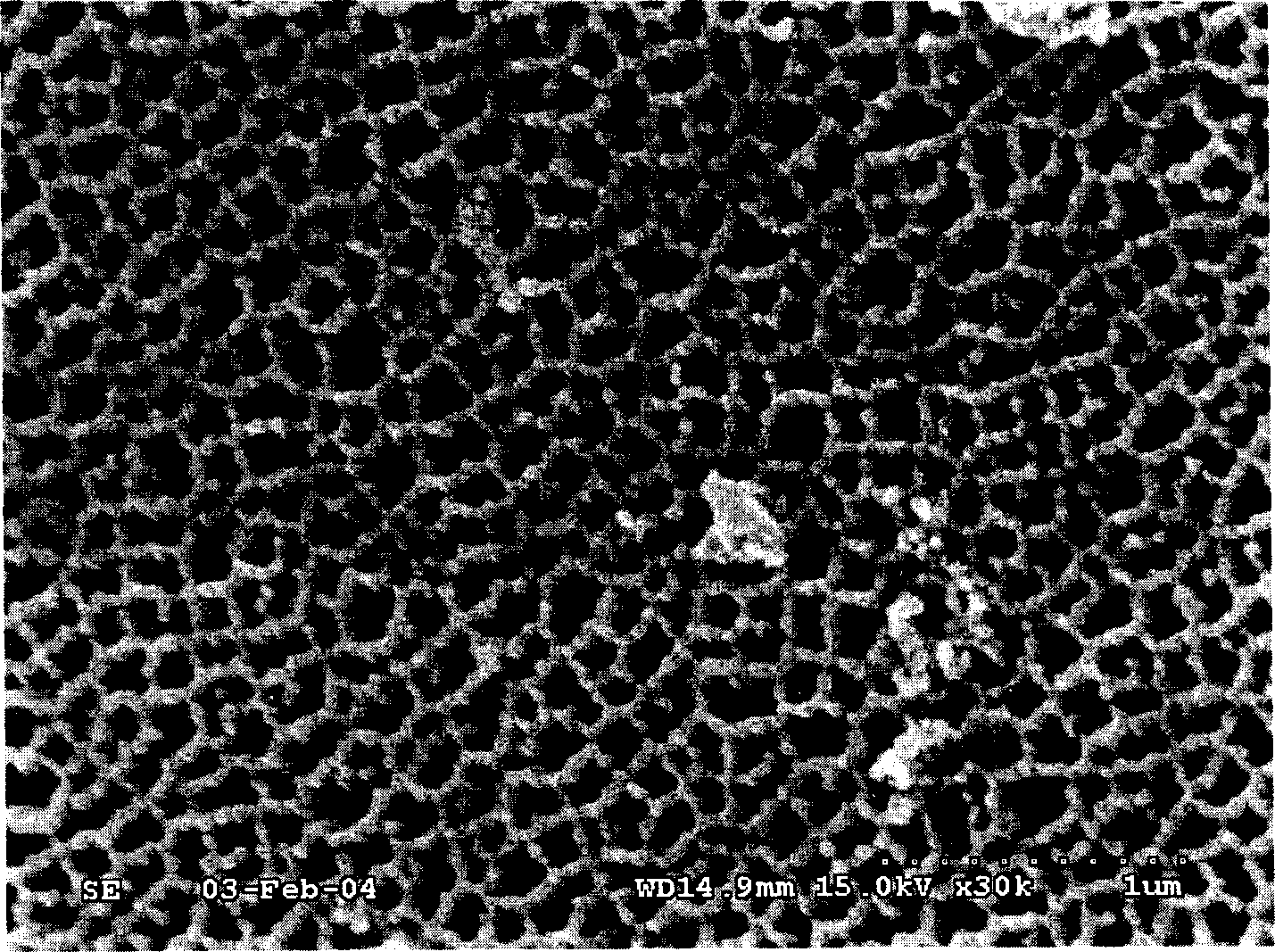

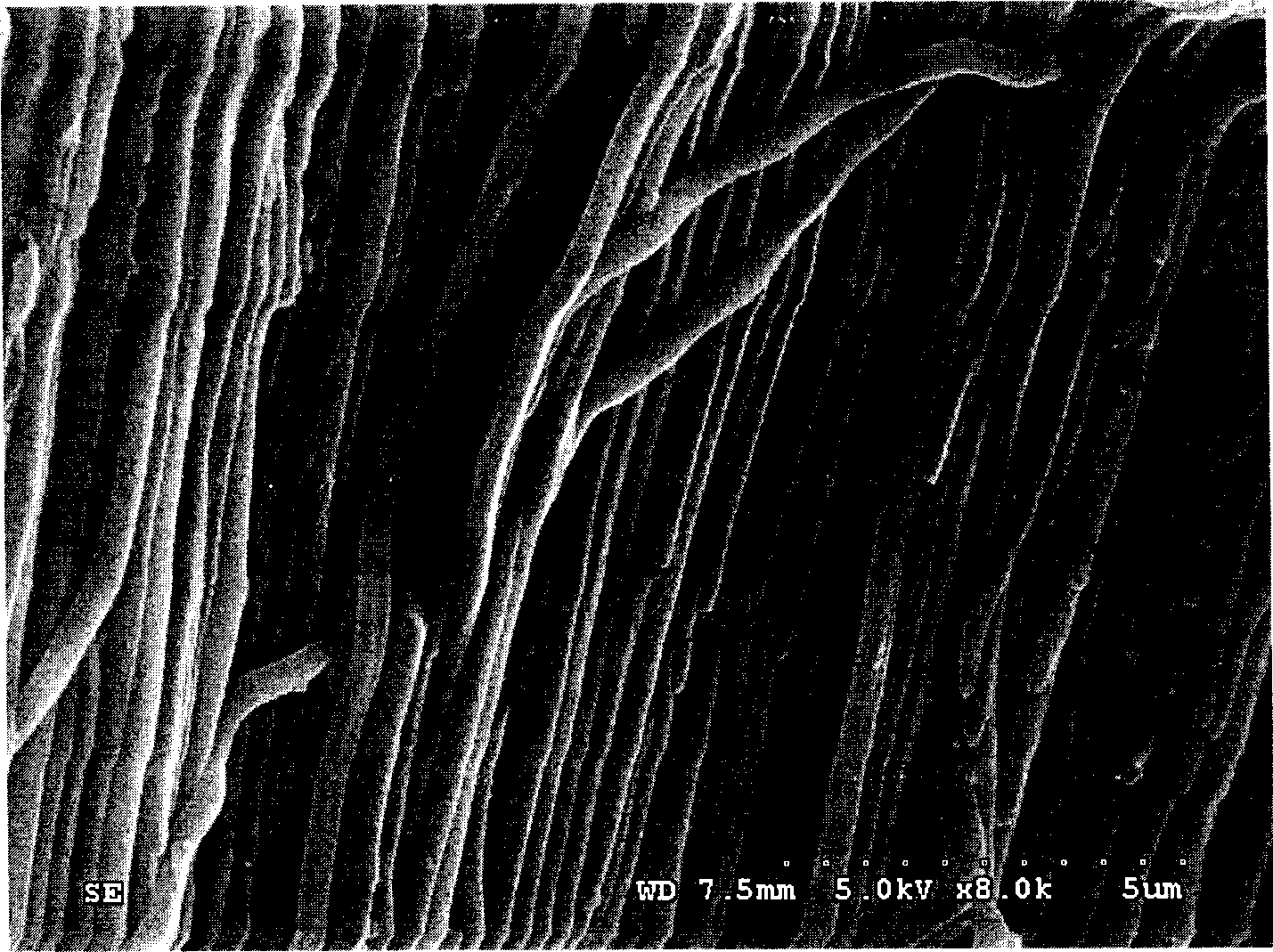

Metal nanometertube preparation method

InactiveCN1769519AEasy to operateLarge adjustment rangeNanostructure manufactureLiquid/solution decomposition chemical coatingSolubilityOrganic solvent

This invention relates to the metal nanometer tube making method, which includes the following steps: fistly making the metal colloid water-solubility solution, then extracting the metal from the water-solubility solution by the organic substance that has the coordination action with the metal, and distributing it in the organic solvent to get the metal colloid solution. The metal will deposit on the substrate when various substrates dips in this solution. If the substrate is the moulding board with the nanometer opening, then the metal will deposit on the inwall of the opening to form the matel nanometer tube. Controlling the dipping time and dipping number can get the nanometer tubes with different thickness. Using the moulding boards with different internal diameter nanometer opening can get the namometer tubes with different diametics. And using this invention can not only obtain the metal namometer tube whose structure and dimension can be controlled, and can obtain the metal nanometer tube array whose height is ordered.

Owner:INST OF CHEM CHINESE ACAD OF SCI

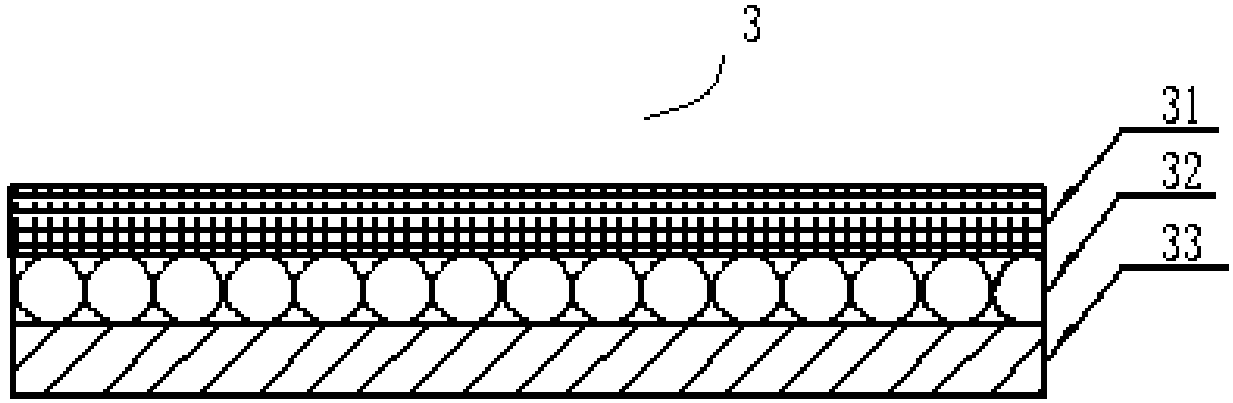

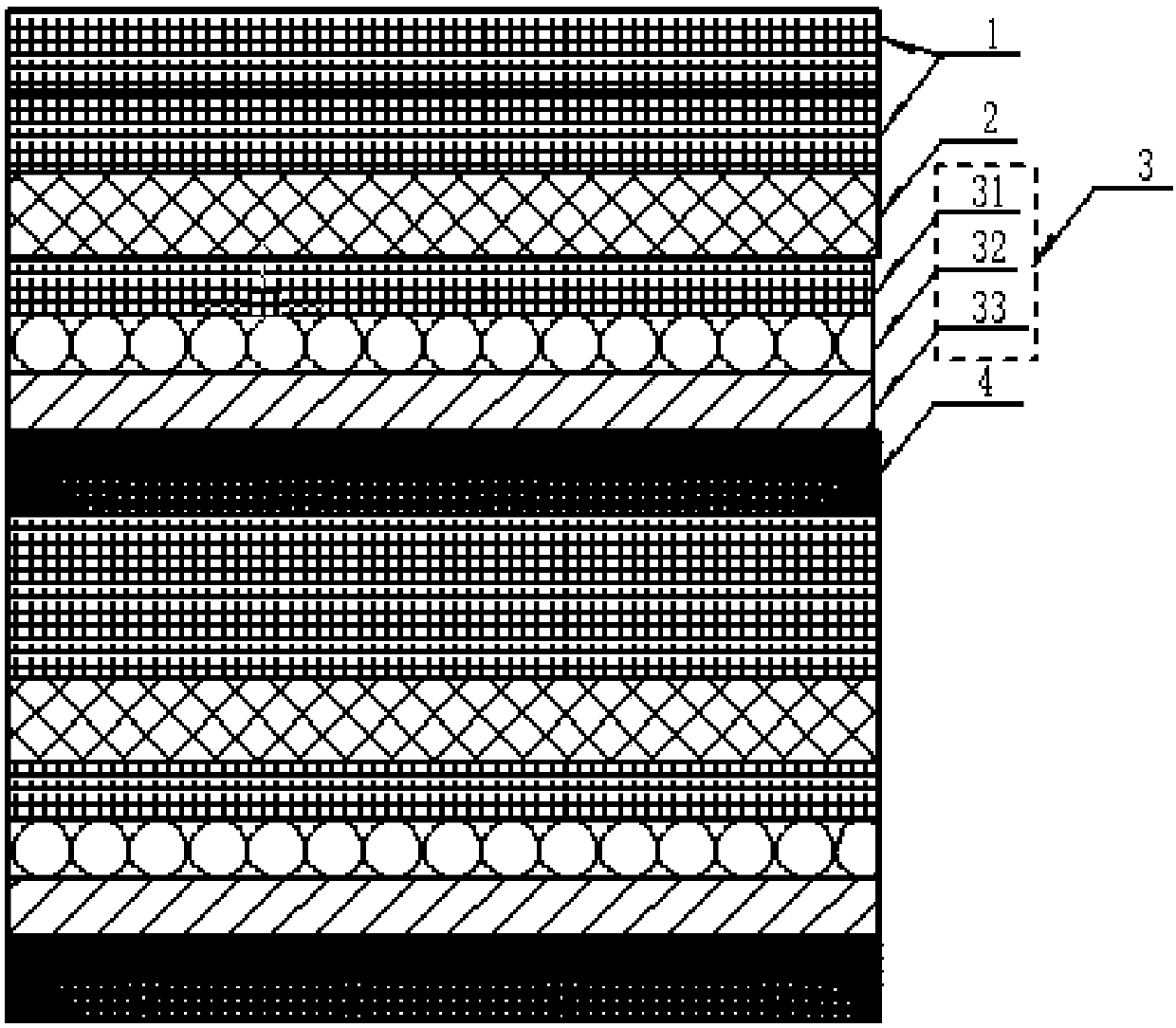

Nickel plated carbon fiber membrane and preparation method thereof as well as shielding structure and preparation method thereof

ActiveCN107815854AGood electromagnetic shieldingHigh electromagnetic shieldingCarbon fibresMagnetic/electric field screeningFiberCarbon fibers

The invention provides a nickel plated carbon fiber membrane and a preparation method thereof as well as a shielding structure and a preparation method thereof. The nickel plated carbon fiber membranecomprises carbon fiber base cloth and a nickel metal layer, wherein metal colloid granules are adhered to the surface of the carbon fiber base cloth; and the nickel metal layer is arranged on the exposed surface of the carbon fiber base cloth and surfaces, far away from the carbon fiber base cloth, of the metal colloid granules. According to the nickel plated carbon fiber membrane, the metal colloid granules are adhered to the carbon fiber base cloth, so that the metal colloid granules have adhesiveness, the nickel metal layer is relatively well adhered to the carbon fiber base cloth, the electromagnetic shielding property of the nickel plated carbon fiber membrane is further improved, the nickel plated carbon fiber membrane is not only relatively good in mechanical property and physicalproperty, but also relatively good in electromagnetic shielding property.

Owner:CRRC QINGDAO SIFANG CO LTD

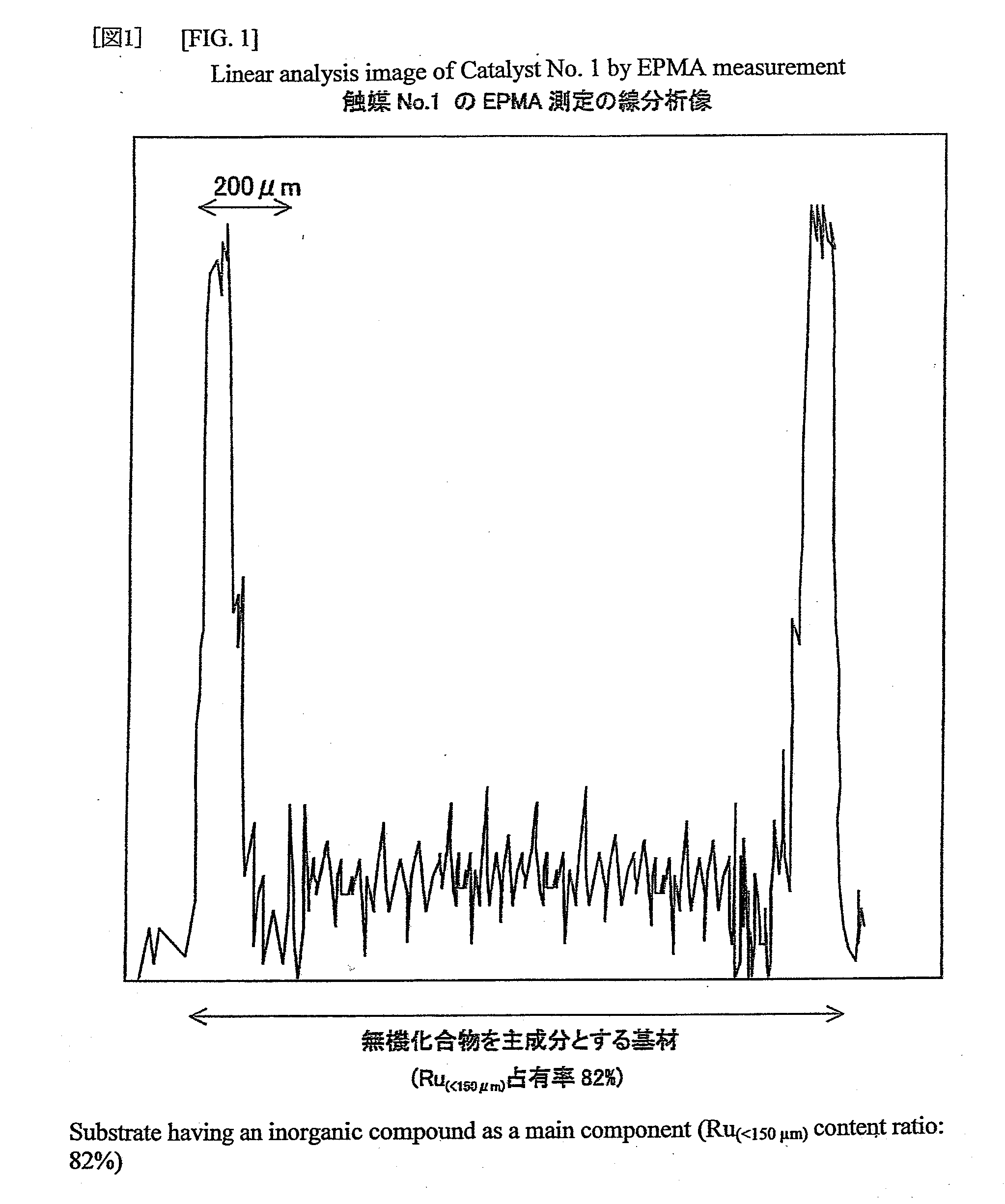

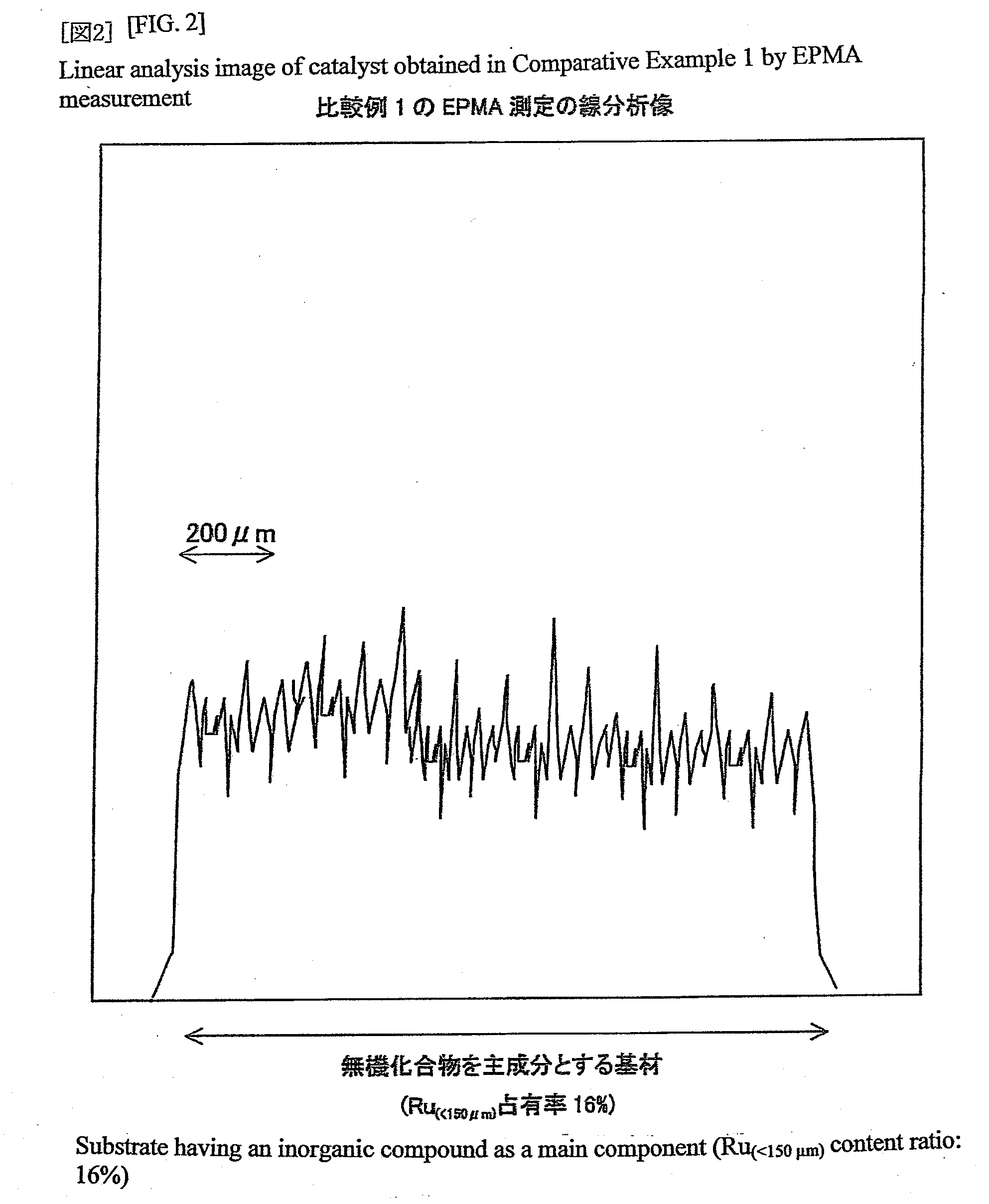

So3 reduction catalyst for purifying an exhaust gas, preparation process thereof, and exhaust gas purifying method using the catalyst

InactiveUS20090022643A1Efficiently reduce amountReduce the amount requiredLayered productsOrganic-compounds/hydrides/coordination-complexes catalystsCombustionSurface layer

To provide an SO3 reduction catalyst for purifying an exhaust gas capable of efficiently reducing the amount of SO3 that is present in a combustion exhaust gas and is a starting substance of S-containing substances such as acid ammonium sulfate causing deterioration of performance of the catalyst or corrosion of apparatuses disposed downstream of the catalyst, or capable of controlling the generation of SO3 in the catalyst itself; a preparation process of the catalyst; and an exhaust gas purifying method using the catalyst.In the catalyst for purifying a combustion exhaust gas containing nitrogen oxides, 50 wt. % or greater of the amount of Ru and / or Ir to be supported is adjusted to fall within a depth of 150 μm from the surface layer of a substrate; and the catalyst is prepared by immersing the substrate in a metal colloid solution of Ru and / or Ir to be supported or an aqueous solution containing at least one compound selected from compounds of Ru and / or Ir to be supported.

Owner:MITSUBISHI HEAVY IND LTD

Fluid for purifying heat engines using stable suspensions of metal colloidal particles, and methods for preparing said fluid

ActiveUS20180304198A1Efficient reductionPromotes homogeneous mixingGas treatmentExhaust apparatusColloidal particleExhaust gas

The present invention describes a fluid which is suitable for the decontamination of heat engines which can carry out both the catalytic reduction of oxides of nitrogen (NOx) contained in exhaust gases and assist in the regeneration of the particulate filter (PF), said fluid being in the form of a stable suspension of colloidal particles, these colloidal particles being dispersed in an aqueous solution containing at least one reducing agent or at least one precursor of a reducing agent for NOx. The invention also describes several embodiments for the preparation of said fluid.

Owner:INST FR DU PETROLE

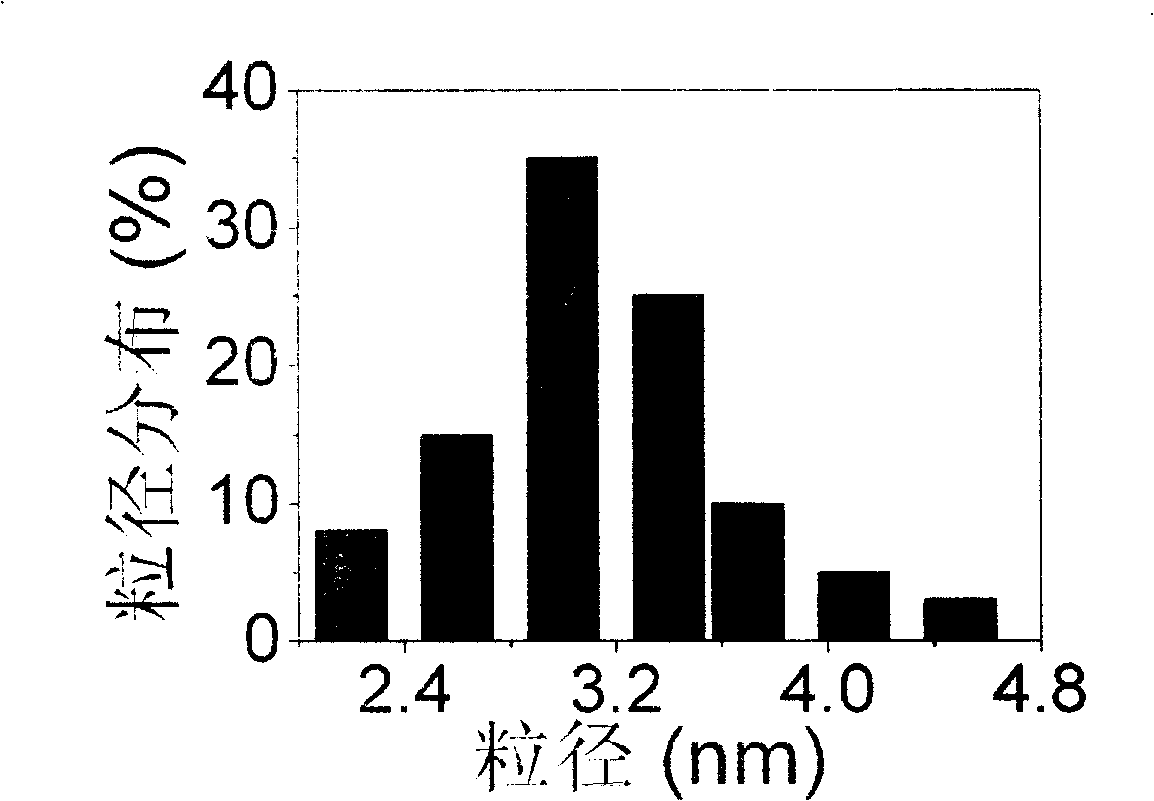

Fuel cell catalyst with function of guiding protons, and prepartion method

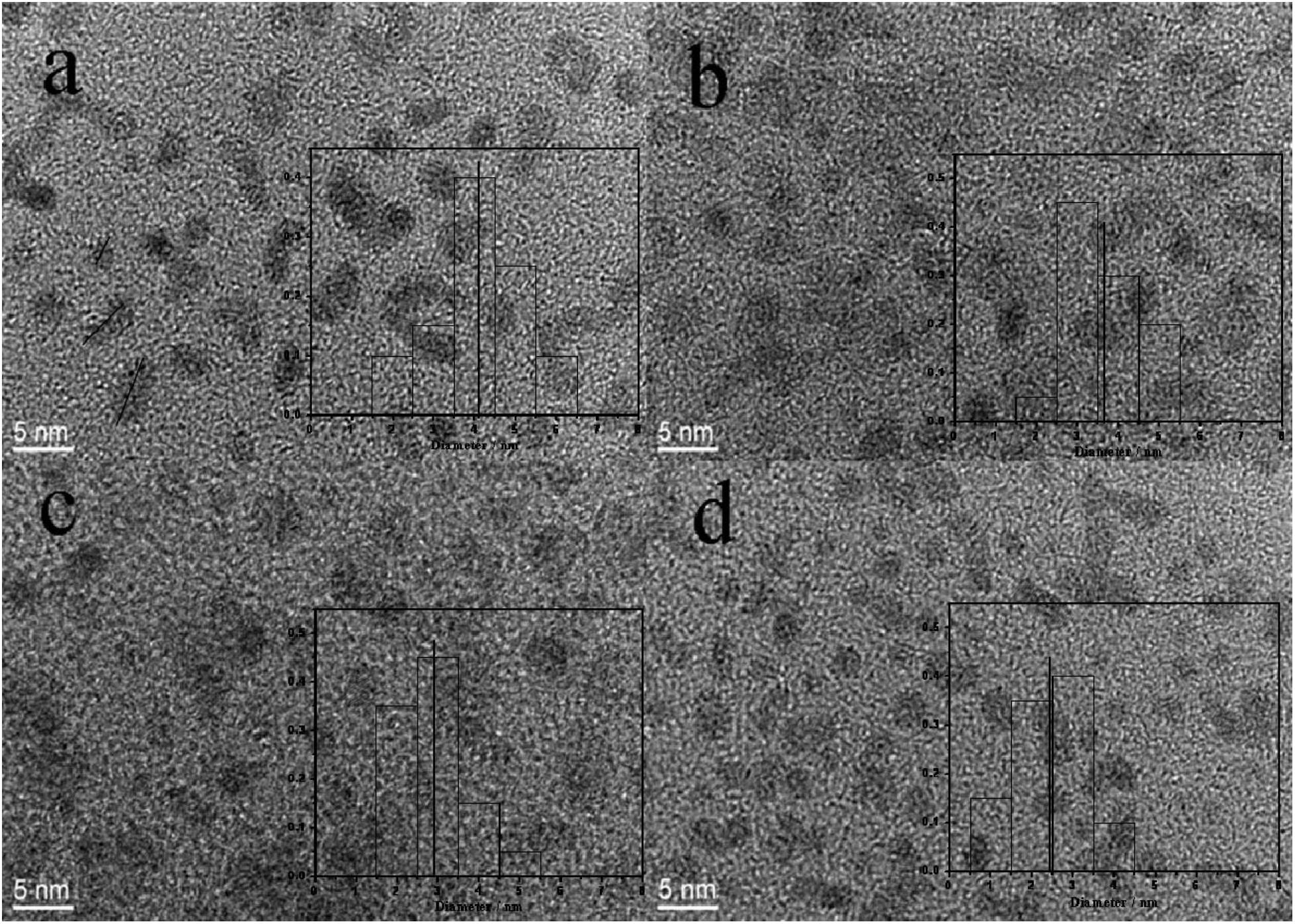

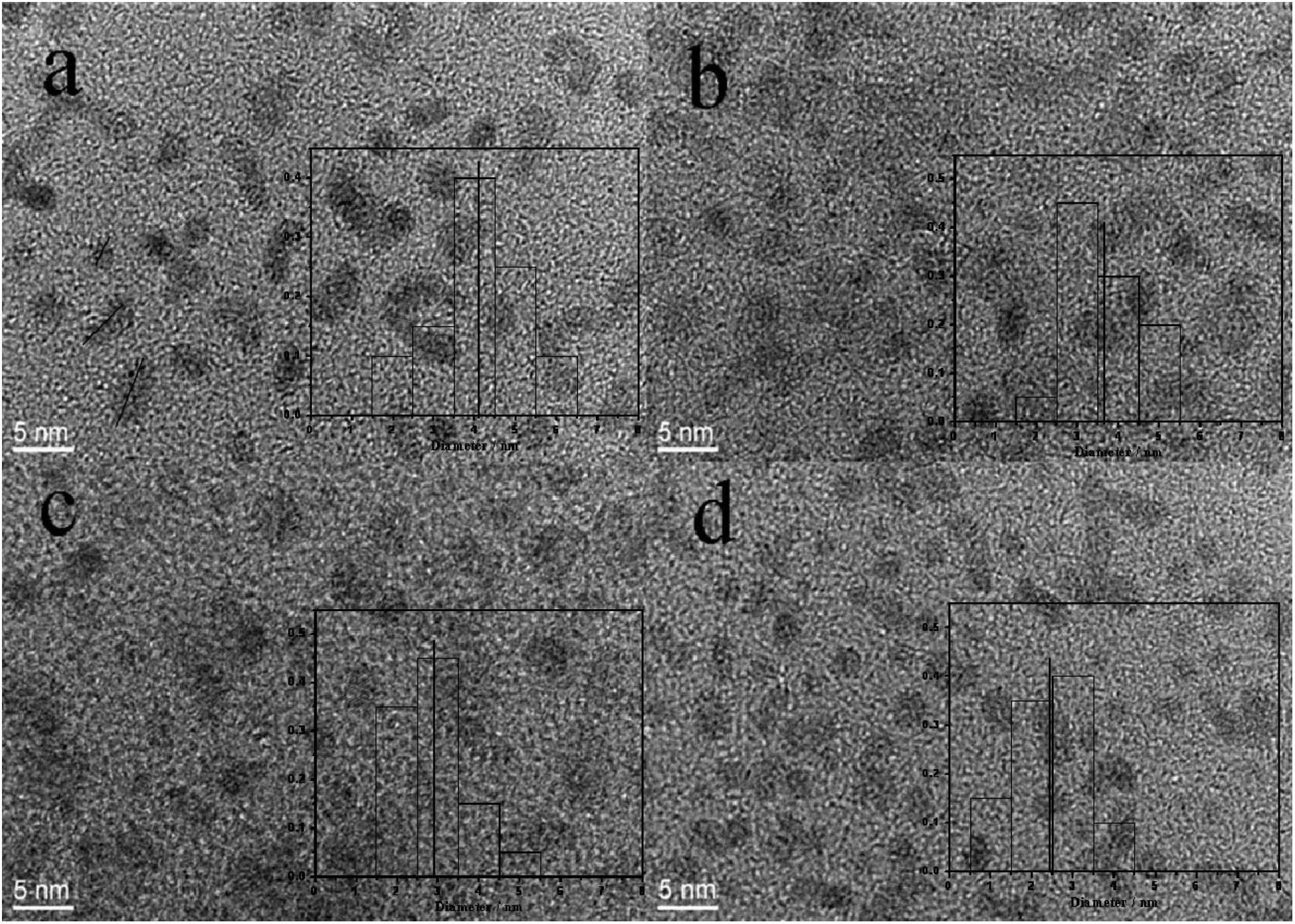

InactiveCN1917260AHigh catalytic efficiencyIncreased durabilityCatalyst carriersCell electrodesNanometreBinding force

Nano fine particles of noble metal in catalyst are modified by high polymer of guiding protons. Inductive the said high polymer can increase steric hindrance of fine particles of noble metal in order to anchor fine particles of noble metal in catalyst on surface of carrier so as to raise use ratio of catalyst. Farther, the high polymer of guiding protons is a better bonding agent also. Better binding force is existed between Nano fine particles of noble metal modified by the high polymer and carrier. The synthesized catalyst possesses function of guiding protons. The method for preparing the catalyst includes steps: preparing colloid of Nano noble metal modified by the said high polymer in advance; then, depositing the prepared colloid on carbon carrier. Average particle diameter of noble metal in catalyst is 2-5 Nano, and diameters are distributed evenly. Battery produced from the catalyst possesses better performance of electric output.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com