Glass coated with color multilayer film and its producing method

A multi-layer film and glass technology, which is applied in the field of glass and float-method on-line colored multi-layer film glass, can solve the problems of corrosion of refractory materials in melting furnaces, affecting the service life of melting furnaces, and being uneconomical, so as to improve optical performance, improve Optical properties and chemical stability, effects of stabilizing optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

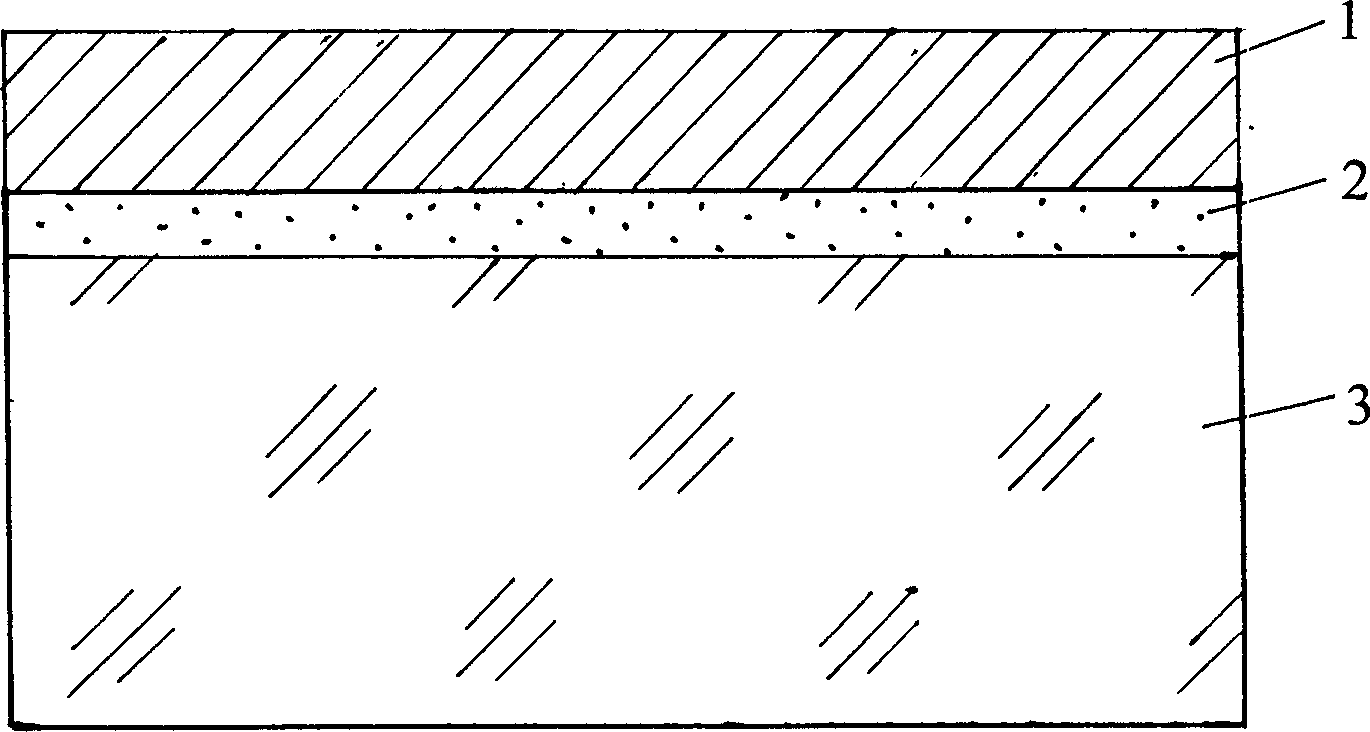

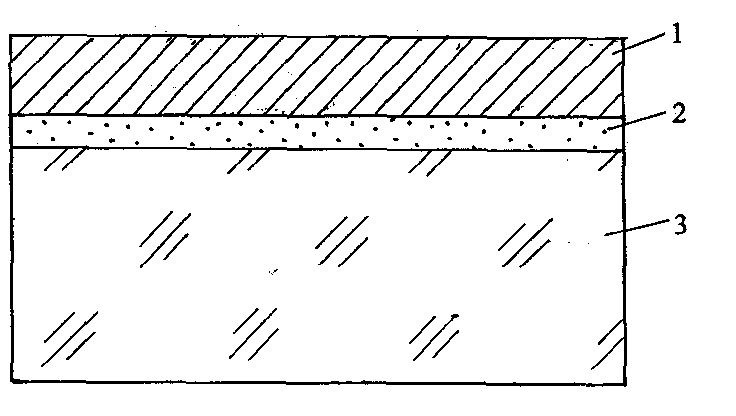

Image

Examples

Embodiment 1

[0036] In the tin tank of the float glass production line, where the temperature of the glass ribbon is 780°C, a copper metal electrode is set as the anode, and the tin liquid is used as the cathode to keep the hydrogen concentration in the tin tank at 5%, and the nitrogen concentration at 95%. The distance between the control electrode and the glass ribbon is 6 mm, the pulling speed of the glass ribbon is 400 m / h, the direct current passing through the electrode is 28.6 amps, and the low-melting point metal lead is sent between the anode and the glass ribbon through the feeding device, so that The metal is electrolyzed into ions and penetrates to the surface of the glass ribbon for 8 microns, and is reduced by hydrogen in the tin bath to form a copper-lead metal film on the surface of the moving hot glass ribbon. A reactor is set above the glass ribbon in the tin bath where the temperature is 650°C, and the coating mixed gas with silane as the main component is sent between th...

Embodiment 2

[0038] In Example 1, the low-melting-point metal lead is replaced by the low-melting-point metal bismuth, and other parameters and processes are kept unchanged, so that brown-red multilayer coated glass can be obtained.

Embodiment 3

[0040] In Example 1, metal electrodes of cobalt, nickel, silver, chromium, and iron are used as anodes instead of metal copper electrodes, and other parameters and processes are kept unchanged to obtain light blue, light green, and golden multilayers respectively. Coated Glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com