Metal nanometertube preparation method

A metal nano and metal technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of few applications, and achieve the effect of large adjustable range, uniform diameter and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

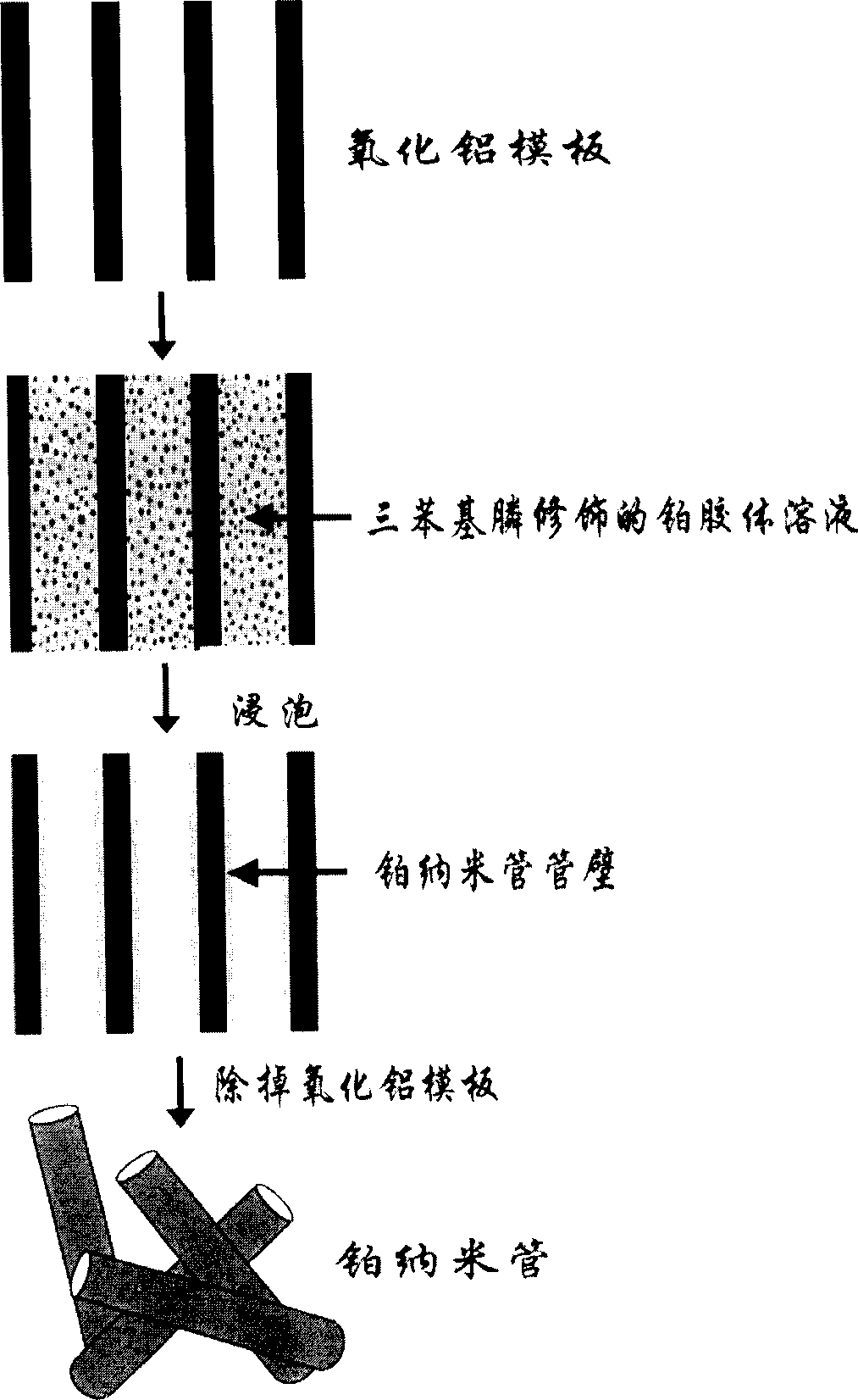

Method used

Image

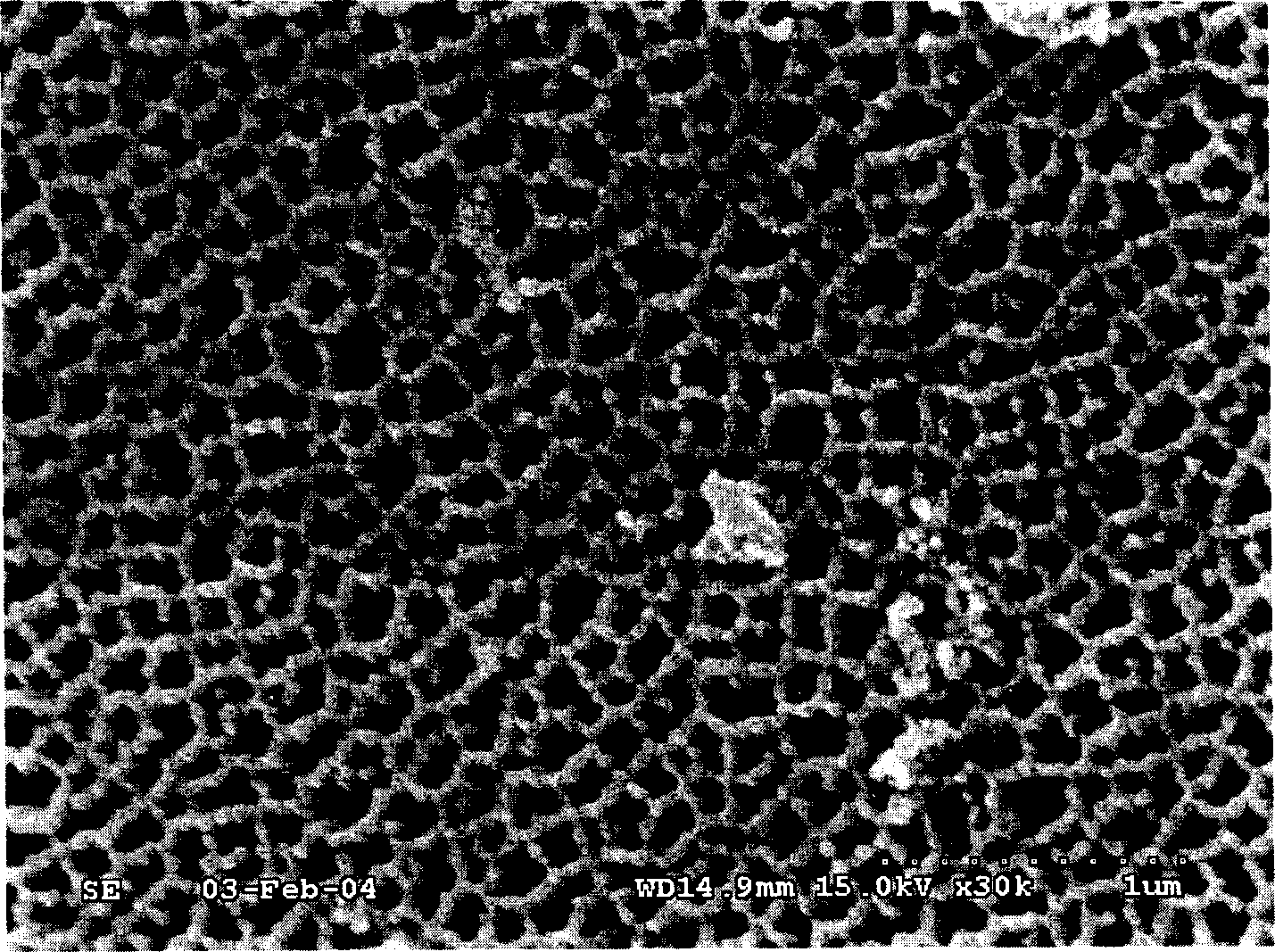

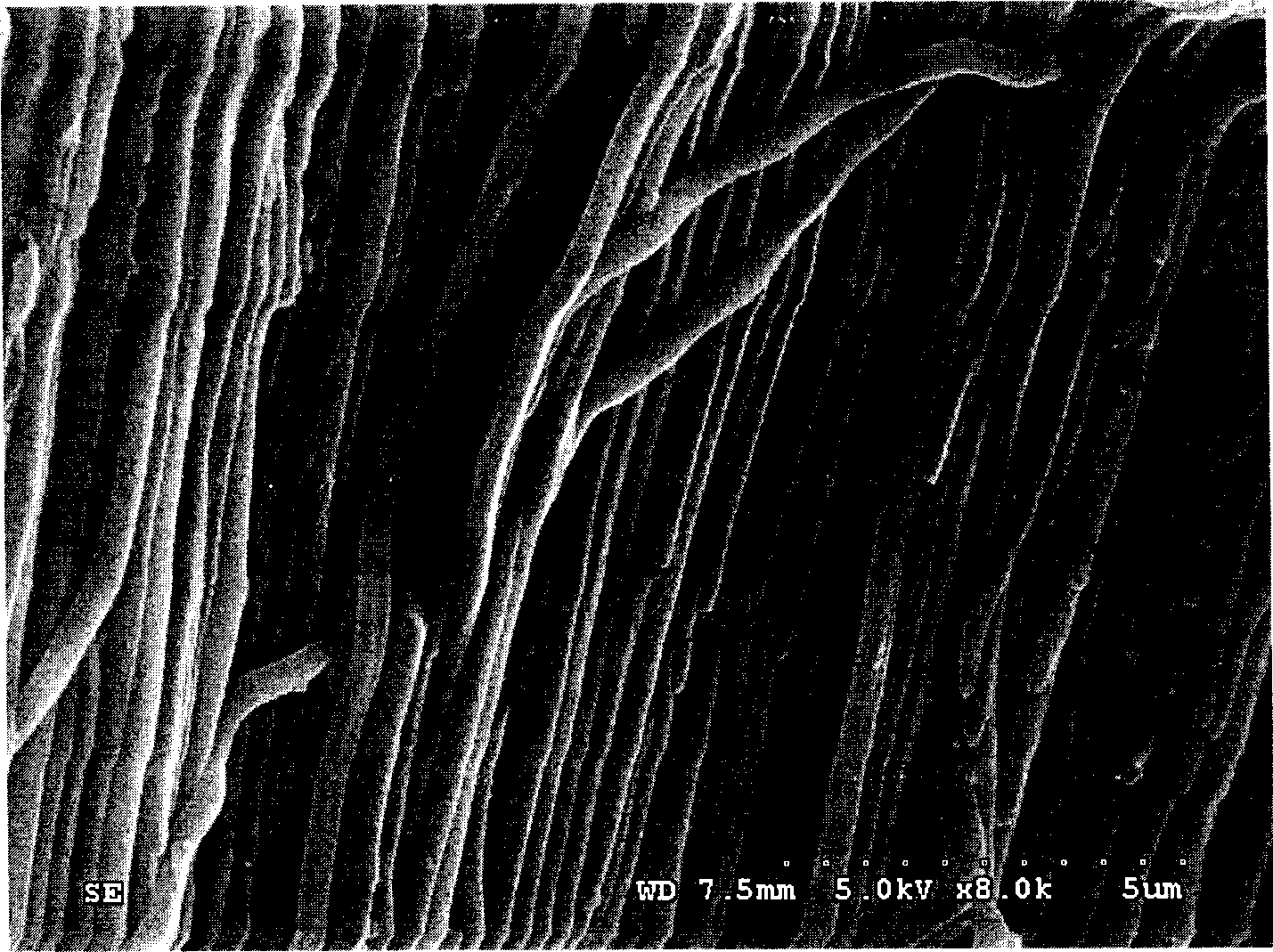

Examples

Embodiment 1

[0021] Add 20ml H into a 250ml two-neck bottle 2 PtCl 6H 2 O ethylene glycol solution, add 20ml NaOH ethylene glycol solution dropwise to chloroplatinic acid ethylene glycol solution under electromagnetic stirring, keep the pH in the range of 7-11.5, and get transparent yellow platinum hydroxide colloidal solution. The system was heated at 180°C for 3 hours under electromagnetic stirring, and N 2 Air flow through the reaction system (N 2 The flow rate is not specifically required) to take away water and organic by-products to obtain a brown-red platinum colloid (3.7mg Pt / ml) solution. This colloid is very stable, and no precipitation is observed after being left for a long time.

[0022] Take 10ml of the prepared platinum colloidal solution and 40ml of ethanol and add it to 50ml of triphenylphosphine toluene solution under stirring. The molar ratio of triphenylphosphine to platinum is 0.5, and the mixed system is a homogeneous brown-red triphenyl Phosphine modified platin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com