A preparation method of acetate propylene ester synthesis catalysts

The technology of propylene acetate and catalyst is applied in the field of preparation of propylene acetate synthesis catalyst, can solve problems such as application limitation, and achieve the effects of large active metal surface area, high activity and selectivity, and concentrated particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] With chloropalladium acid (H 2 PdCl 4 ) and chloroauric acid equivalent to 0.15gAu (HAuCl 4 ) configure 400ml of aqueous solution, add 30ml of 5g / L PVP solution into the above solution, stir for 1hr, and add 6.0g / L of NaBH dropwise 4 Aqueous solution 200ml, PVP-protected metal colloid is obtained after reduction. The metal colloid was loaded on a 1L silica carrier, dried at 110°C for 4 hours, cooled to room temperature, impregnated with an equal volume of aqueous solution containing 15g of KOAc, taken out and dried at 110°C to finally obtain a finished catalyst.

[0022] Catalyst Performance Evaluation:

[0023] Reactor: fixed bed reactor

[0024] Catalyst loading volume: 600ml

[0025] Reactor inlet pressure: 0.7MPa

[0026] Reaction temperature: 140~160℃

[0027] Response time: 500hr

[0028] Mixed gas flow: 7~8Kg / h

[0029] In the evaluation data:

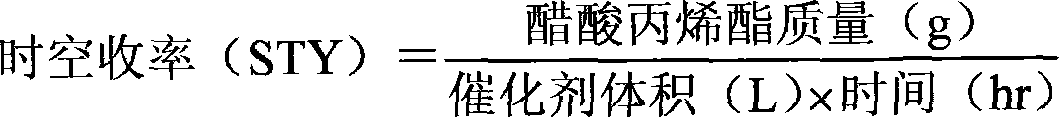

[0030]

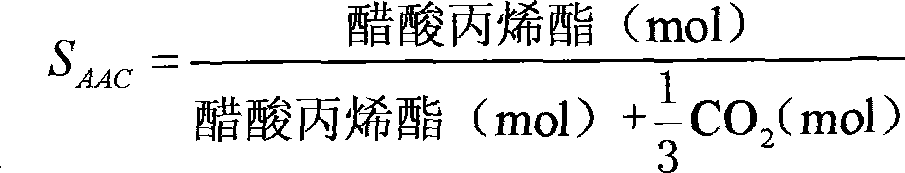

[0031]

[0032] Catalyst activity evaluation is shown in Table 1.

Embodiment 2

[0034] Metal colloid preparation contains the equivalent of 1.5g of chloropalladic acid and the equivalent of 0.15g of copper chloride (CuCl 2 ) preparation aqueous solution, all the other catalyst preparation steps are with embodiment 1.

[0035] The catalyst was tested as in Example 1, and the evaluation results are shown in Table 1.

Embodiment 3

[0037] Metal colloid preparation contains the equivalent of 1.5g of chloropalladic acid and the equivalent of 0.15g of tin chloride (SnCl 2 ) preparation aqueous solution, all the other catalyst preparation steps are with embodiment 1.

[0038] The catalyst was tested as in Example 1, and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com