Preparation method of C10+ bicyclo-heavy aromatics selective hydrogenation cracking catalyst

A hydrocracking and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as easy wrapping with each other, achieve low preparation cost, high monocyclic saturation and cracking performance, enhanced effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Catalyst preparation:

[0028] Contains equivalent to 5.0gCe in 45ml 2 Nano-Ce of O 2 Add 0.05g / 100ml of PVP solution 2ml in O ethanol solution, form a stable solution under microwave stirring condition, add the H that is equivalent to 0.05gPt dropwise 2 PtCl 4 solution, keep microwave stirring for 1 hour to form a stable metal colloid solution. The metal colloid was loaded on a 50 g NaY molecular sieve carrier, dried in the shade at room temperature for 48 hours, and dried at 110° C. for 4 hours under anaerobic conditions to obtain a finished catalyst.

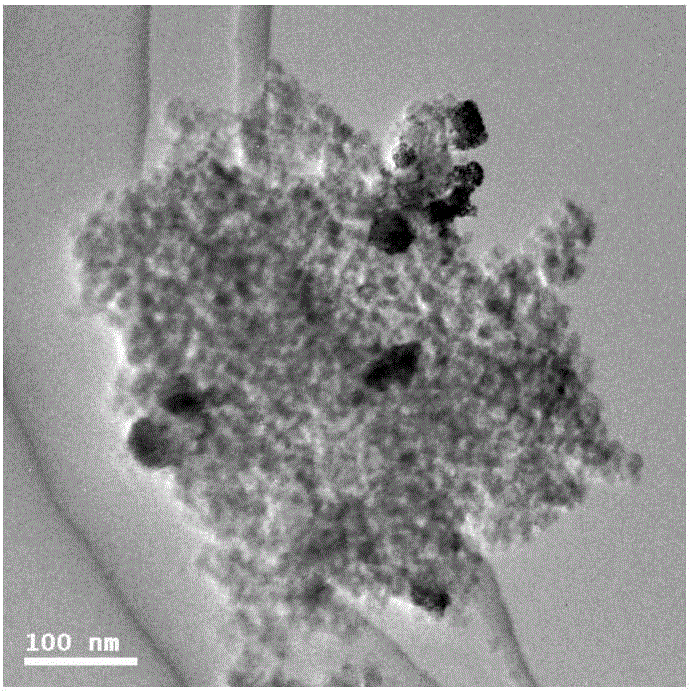

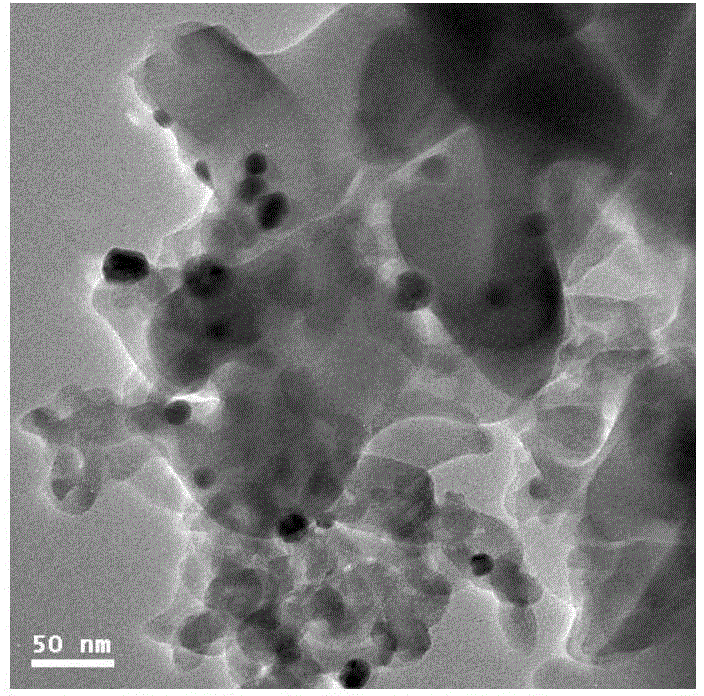

[0029] Catalyst TEM image analysis:

[0030] The catalyst was characterized by transmission electron microscopy, and its structure is detailed in figure 1 It can be seen from the figure that the nano-Pt particles are distributed in the nano-Ce 2 O particle surface.

[0031] Catalyst Performance Evaluation:

[0032] Reactor: fixed bed reactor

[0033] Catalyst loading volume: 50ml

[0034] Reaction pressure: 2...

Embodiment 2

[0040] The carrier adopts NaY-Al 2 o 3 Composite carrier, all the other catalyst preparation steps are the same as in Example 1.

[0041] The catalyst was tested as in Example 1, and the evaluation results are shown in Table 1.

Embodiment 3

[0043] Contains equivalent to 5gCe for the preparation of metal colloids 2 Nano-Ce of O 2 O ethanol solution and H equivalent to 0.03 g Pt 2 PtCl 4 solution, all the other catalyst preparation steps are the same as in Example 1.

[0044] The catalyst was tested as in Example 1, and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com