Method for preparing catalyst for removing CO by selective oxidation

A catalyst and selective technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problems of complex catalyst preparation process and improve metal dispersion and uniformity, large active metal surface area, and reduced metal particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] With RuCl containing equivalent to 0.8gRu 3 solution 45ml, add 20ml of 10g / L PVP solution to the above solution, stir for 1hr, add 6.0g / L NaBH dropwise 4 20ml of aqueous solution, after reduction, PVP-protected ruthenium metal colloid was obtained. Load the metal colloid on a 100g alumina carrier, and dry it at 110°C for 4hrs to finally obtain 0.8% Ru / Al 2 O3 catalyst.

[0029]Catalyst Performance Evaluation:

[0030] Reactor: fixed bed reactor

[0031] Catalyst loading volume: 50ml

[0032] Airspeed: 5000h -1

[0033] Gas volume composition: CO = 1%, CO 2 = 20%, O 2 = 2%, the rest is H 2

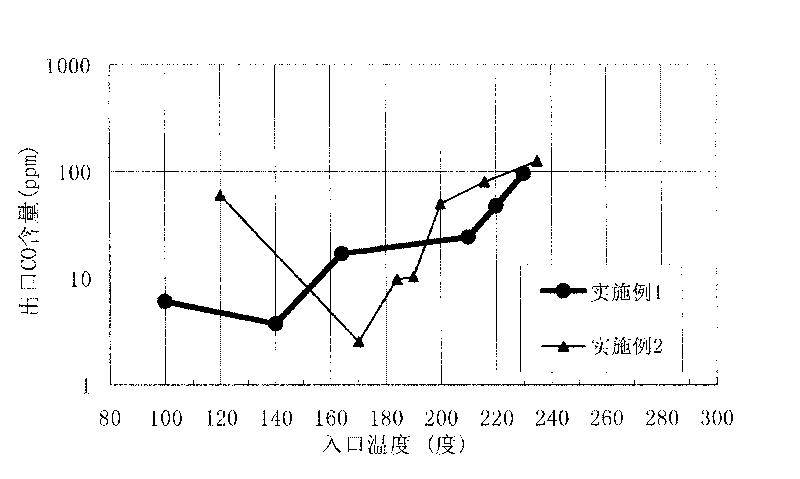

[0034] Catalyst activity evaluation see figure 1 and Table 1.

Embodiment 2

[0036] Metal colloids are formulated with RuCl equivalent to 1.6 g Ru 3 solution, all the other catalyst preparation steps are the same as in Example 1.

[0037] This catalyst is tested with the method as in embodiment 1, and its evaluation result sees figure 1 and Table 1.

Embodiment 3

[0039] The metal colloid is prepared with a chloropalladium acid solution equivalent to 0.8gPd, and the rest of the catalyst preparation steps are the same as in Example 1.

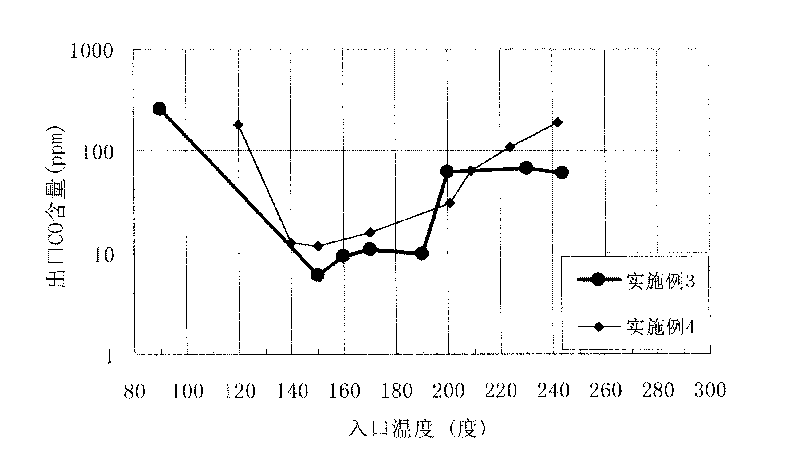

[0040] This catalyst is tested with the method as in embodiment 1, and its evaluation result sees figure 2 and Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com