Fuel cell catalyst with function of guiding protons, and prepartion method

A technology of fuel cells and catalysts, which is applied in the directions of catalyst activation/preparation, catalyst carriers, chemical instruments and methods, etc., to achieve the effect of improving catalytic efficiency and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

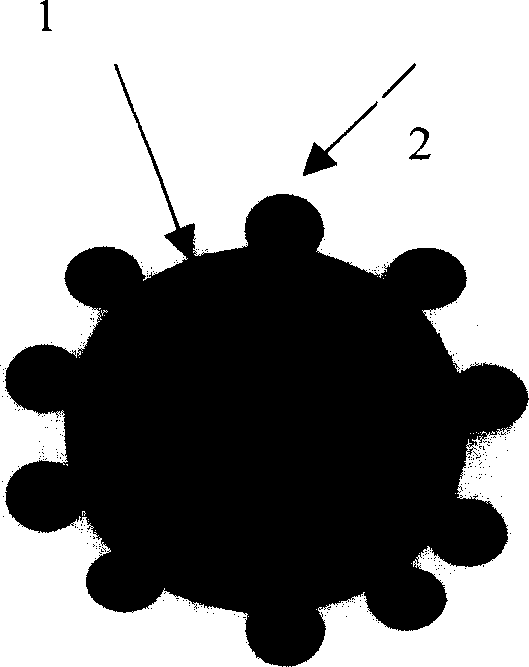

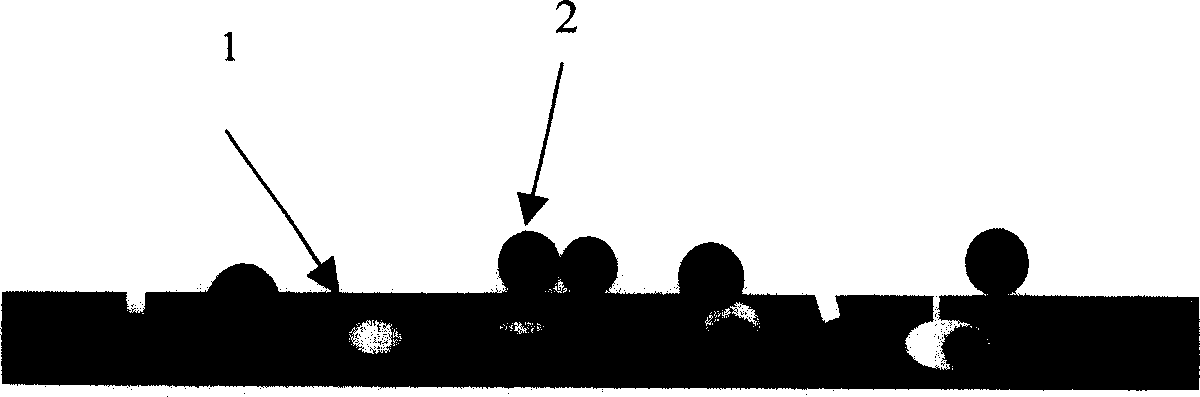

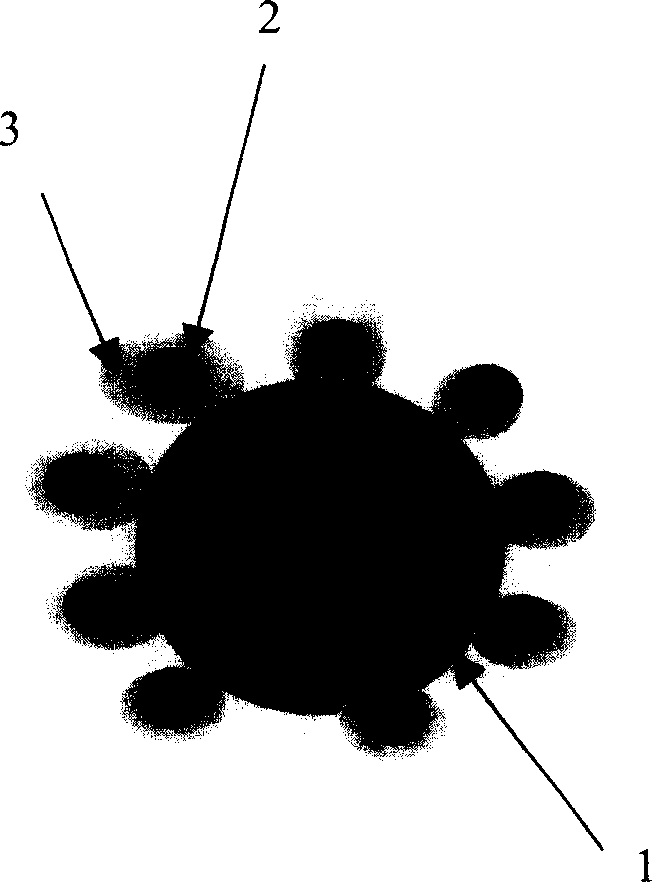

Method used

Image

Examples

Embodiment 1

[0033] Take 2 ml of Nafion solution with a mass concentration of 5% and add it to a mixture of ethanol and water with a mass ratio of 0.5:1, stir for 5 to 10 minutes, then add 32 mg of platinum in H 2 PtCl 6 The solution continued to stir, and the pH of the solution was adjusted to 8 with NaOH, and heated to reflux at 90° C., the solution gradually turned from light yellow to black, and finally dark black, and a stable Pt-containing colloidal solution was obtained. Then weigh 80 mg of carrier XC-72 (the specific surface area is 250 square meters per gram), fully disperse it with the above ethanol and water mixture, add it to the Pt-containing colloid solution, and continue stirring for 3 to 5 hours to obtain Nafion-modified Pt / C catalyst. Among them, the average particle size of Pt particles is 2 nanometers, and the dispersibility is very good.

[0034] Preparation of fuel cell core chip CCM: Add the prepared catalyst to the mixture of deionized water and perfluorosulfonic a...

Embodiment 2

[0037] Take 3 ml of SPEEK solution with a mass concentration of 5%, add it to a mixture of ethanol and water with a mass ratio of 100:1, stir for 5 to 10 minutes, then add 60 mg of platinum in H 2 PtCl 6 The solution continued to stir, and the pH of the solution was adjusted to 13 with NaOH, and heated to reflux at 90° C., the solution gradually turned from light yellow to black, and finally dark black, and a stable Pt-containing colloidal solution was obtained. Then weigh 90 mg of carrier mesoporous carbon microspheres with a pore diameter of 3 to 6 nanometers, fully disperse them with the above ethanol and water mixture, add them to the Pt-containing colloid solution, and continue to stir for 3 to 5 hours to obtain SPEEK-modified Pt / C catalyst. Among them, the average particle diameter of Pt particles is 3.5 nanometers, and the dispersibility is very good. The preparation process of the fuel cell core chip CCM, single cell assembly and test conditions are the same as those...

Embodiment 3

[0039] Take 10 ml of sulfonated polystyrene resin solution with a mass concentration of 5%, add it to a mixture of methanol and water with a mass ratio of 10:1, stir for 5 to 10 minutes, then add 32 mg of platinum in H 2 PtCl 6 The solution continued to stir, and the pH of the solution was adjusted to 8 with NaOH, and heated to reflux at 100° C., the solution gradually turned from light yellow to black, and finally dark black, and a stable Pt-containing colloidal solution was obtained. Then weigh 80 mg of carrier nano-graphite balls, the particle size of which is 40-55 nanometers, fully disperse with the above-mentioned methanol and water mixture, add to the Pt-containing colloidal solution, and continue to stir for 3-5 hours to obtain sulfonated Polystyrene resin modified Pt / C catalyst. Among them, the average particle size of the Pt particles is 3 nanometers, and the dispersibility is very good. The preparation process of the fuel cell core chip CCM, single cell assembly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com