Nickel plated carbon fiber membrane and preparation method thereof as well as shielding structure and preparation method thereof

A technology of nickel-plated carbon fiber and production method, which is applied in the directions of carbon fiber, fiber treatment, fiber chemical characteristics, etc., to achieve the effect of good electromagnetic shielding performance, good mechanical and physical properties, and enhancing electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

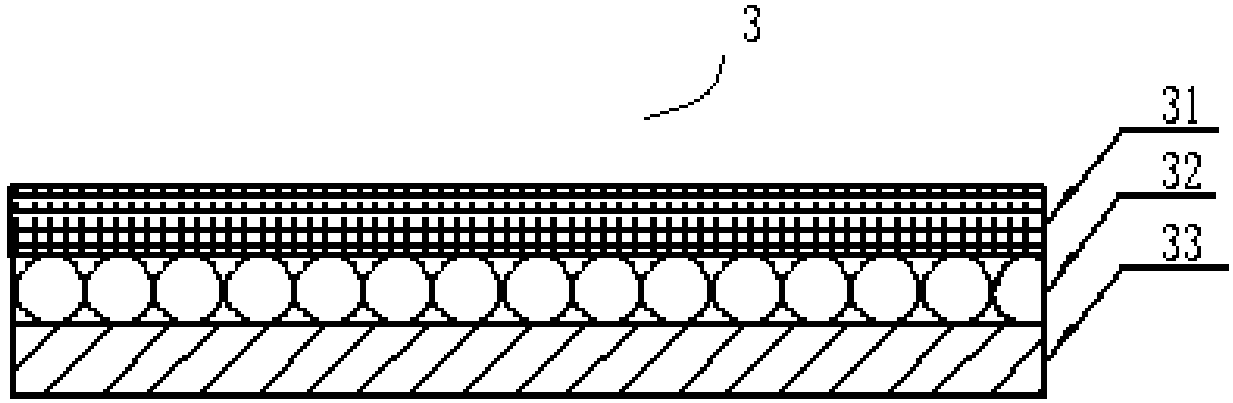

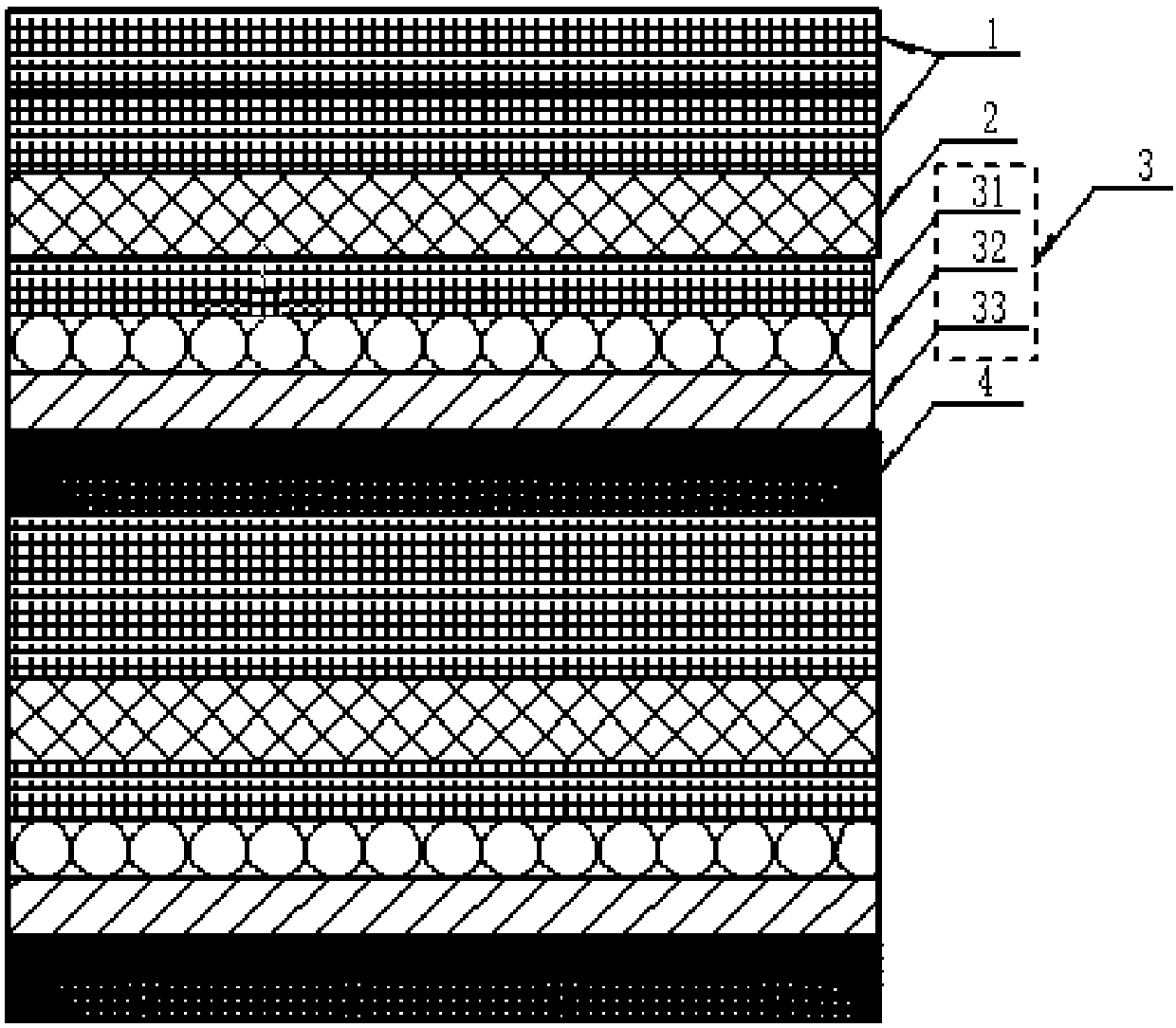

[0093] In order to improve the reliability and firmness of the bonding of each layer of the shielding structure, in one embodiment of the present application, the above-mentioned preparation method further includes: performing thermocompression molding on the above-mentioned pre-shielding unit or forming a plurality of stacked above-mentioned pre-shielding units The unit is thermocompressed to form the shielding structure described above.

[0094] In one embodiment, the above-mentioned thermocompression forming process includes: setting an adhesive between adjacent structural layers that are pre-heated and press-formed to form a pre-heated and pressed structure. When the shielding structure only includes one shielding unit, only Adhesives need to be provided between the various structural layers in the pre-shielding unit. When the shielding structure includes multiple shielding units, adhesives need to be provided between the two shielding units; Pressing: curing the adhesive ...

Embodiment 1

[0105] The fabrication steps of the shielding structure include:

[0106] Soak the carbon fiber base cloth (grade 3k, t700, 200g surface density) in acetone for 30 minutes, clean the surface of the carbon fiber base cloth with distilled water, and then wash it in HF and H 2 SO 4 The molar ratio is 4:6 in the 10% (volume concentration) mixed dilute solution soaking 10min, then wash with distilled water, carbon fiber base cloth in SnCl 2 The mass concentration is 5% dilute HCl acid solution for 30min, and SnCl 2 The temperature of the dilute HCl acid solution is 30 ℃ (that is, the soaking temperature), and then cleaned with distilled water, and the carbon fiber base cloth is placed in 0.025% (mass ratio) of PdCl 2 The activation treatment is carried out in the dilute acid solution, the treatment time is 20min, and the PdCl 2 The temperature of the dilute acid solution is 30°C (that is, the soaking temperature), and the two dilute acid solutions are dilute hydrochloric acid so...

Embodiment 2

[0111] Soak the carbon fiber base cloth (grade 6k, t700, 300g surface density) in acetone for 30 minutes, clean the surface of the carbon fiber base cloth with distilled water, and then dry it in HF and H 2 SO 4 The molar ratio is 4:6 in the 10% mixed dilute solution soaked for 10min, and then washed with distilled water, the carbon fiber base cloth in SnCl 2 The mass concentration is 5% dilute HCl acid solution for 30min, and SnCl 2 The temperature of the dilute HCl acid solution is 30 ℃ (that is, the soaking temperature), and then cleaned with distilled water, and the carbon fiber base cloth is placed in 0.025% (mass ratio) of PdCl 2 The activation treatment is carried out in the dilute acid solution, the treatment time is 20min, and the PdCl 2 The temperature of the dilute acid solution is 30°C (that is, the soaking temperature), and the two dilute acid solutions are dilute hydrochloric acid solutions.

[0112] The plating solution includes 50 parts of nickel sulfate, 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com