Method for preparing metal colloid at normal temperature

A metal colloid and metal precursor technology, applied in the direction of nanotechnology, can solve the problem of limited platinum sol, and achieve the effect of uniform distribution, small particle size and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

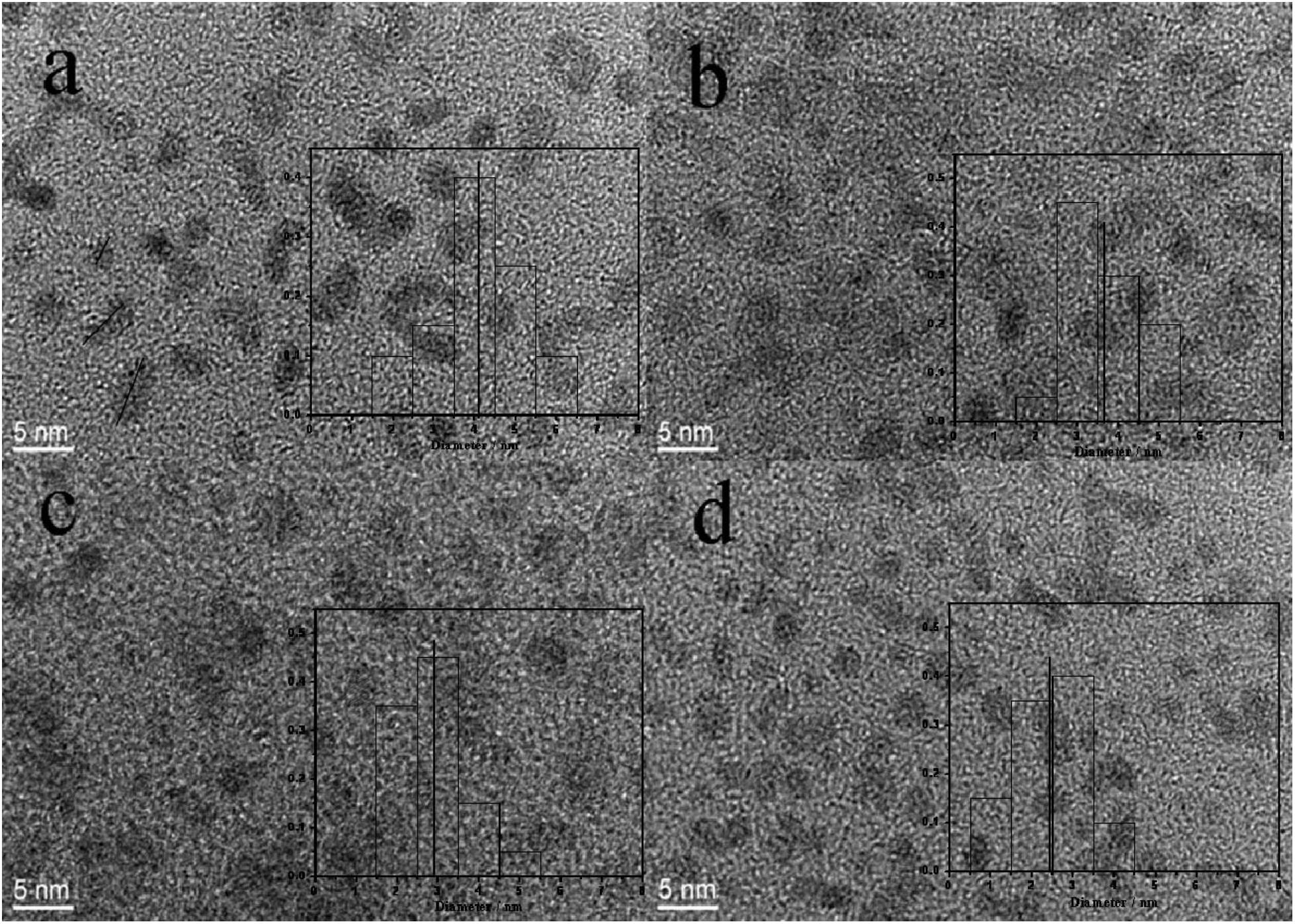

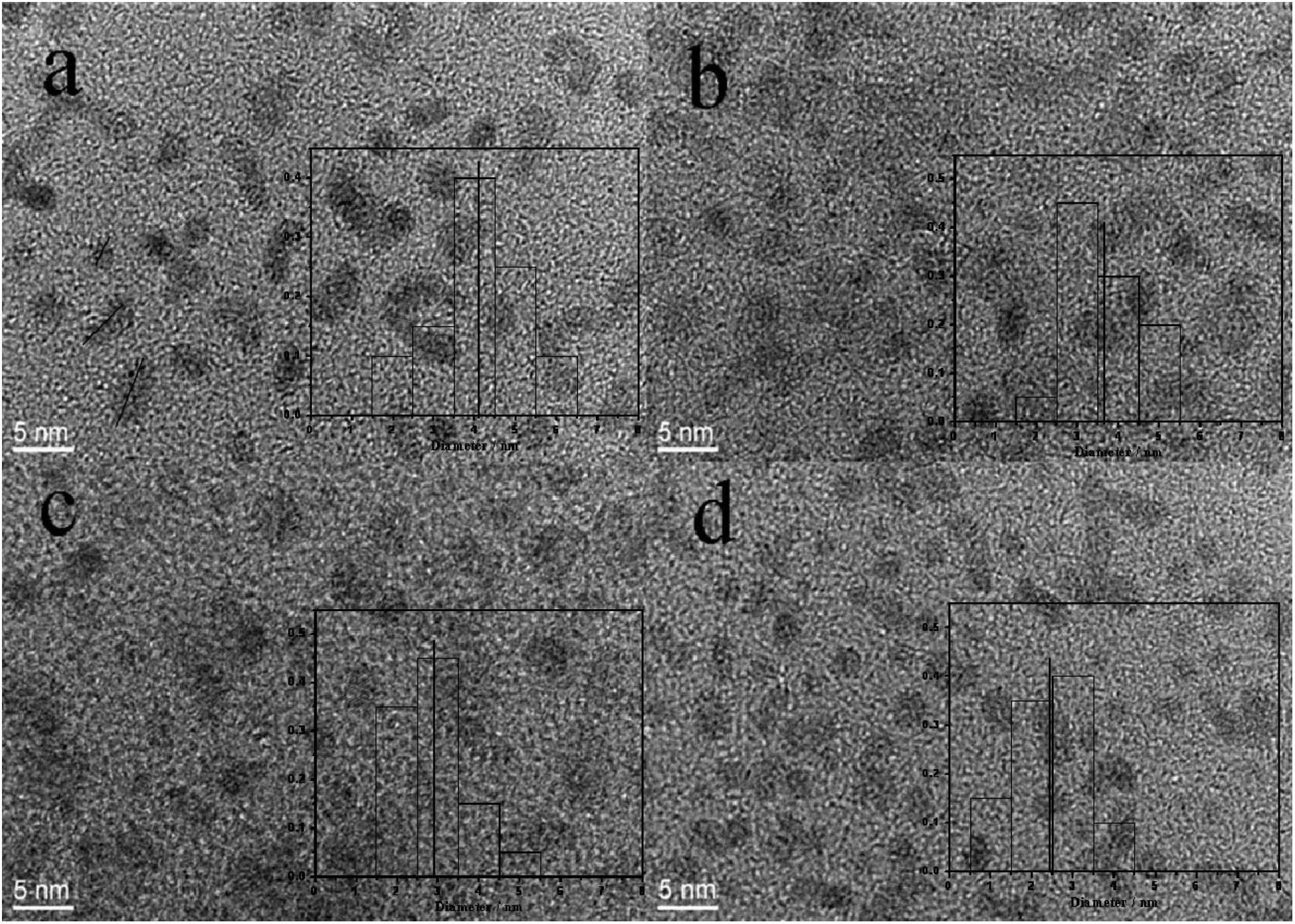

[0011] Embodiment 1: chloroplatinic acid and sodium acetate are dissolved in ethylene glycol respectively, the concentration of chloroplatinic acid is 0.001mol / L, the concentration of sodium acetate is 0.005mol / L, and the molar ratio of sodium acetate and chloroplatinic acid is 5. Mix the solution of sodium acetate with the ethylene glycol solution of chloroplatinic acid, and react at room temperature for 4 hours. The color change during the reaction is: from light yellow to red to brown and finally to black, which proves that platinum ions are reduced to platinum metal , to generate platinum sol, the particle size of platinum is 4nm. figure 1 Middle a is the result of the TEM photo of the prepared platinum sol.

[0012] It can be seen from the figure that the particle diameter of the generated platinum metal is 4nm.

Embodiment 2

[0013] Embodiment 2: chloroplatinic acid and sodium acetate are dissolved in ethylene glycol respectively, the concentration of chloroplatinic acid is 0.001mol / L, the concentration of sodium acetate is 0.010mol / L, and the molar ratio of sodium acetate and chloroplatinic acid is 10. Mix the solution of sodium acetate with the ethylene glycol solution of chloroplatinic acid, and react at room temperature for 4 hours. The color change during the reaction is: from light yellow to red to brown and finally to black, generating platinum sol. The particle size of platinum 3.6nm. figure 1 Middle b is the result of the TEM photo of the prepared platinum sol. It can be seen from the figure that the particle diameter of the generated platinum metal is 3.6 nm.

Embodiment 3

[0014] Embodiment 3: chloroplatinic acid and sodium acetate are dissolved in ethylene glycol respectively, the concentration of chloroplatinic acid is 0.001mol / L, the concentration of sodium acetate is 0.035mol / L, and the molar ratio of sodium acetate and chloroplatinic acid is 35. Mix the sodium acetate solution with the chloroplatinic acid solution, and react at room temperature for 4 hours. The color changes during the reaction process: from light yellow to red to brown and finally to black, and a platinum sol is formed. The particle size of platinum is 2.8nm. figure 1 Middle c is the result of the TEM photo of the prepared platinum sol. It can be seen from the figure that the particle size of the generated platinum metal is 2.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com