High-precision electronic belt scale and weighing algorithm of same

An electronic belt scale, high-precision technology, applied in the direction of continuous material flow weighing equipment, weighing, measuring devices, etc., can solve the problem that the single-point calibration method cannot solve random errors, etc., to improve weighing accuracy, The effect of improving measurement efficiency and reducing the impact of random errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

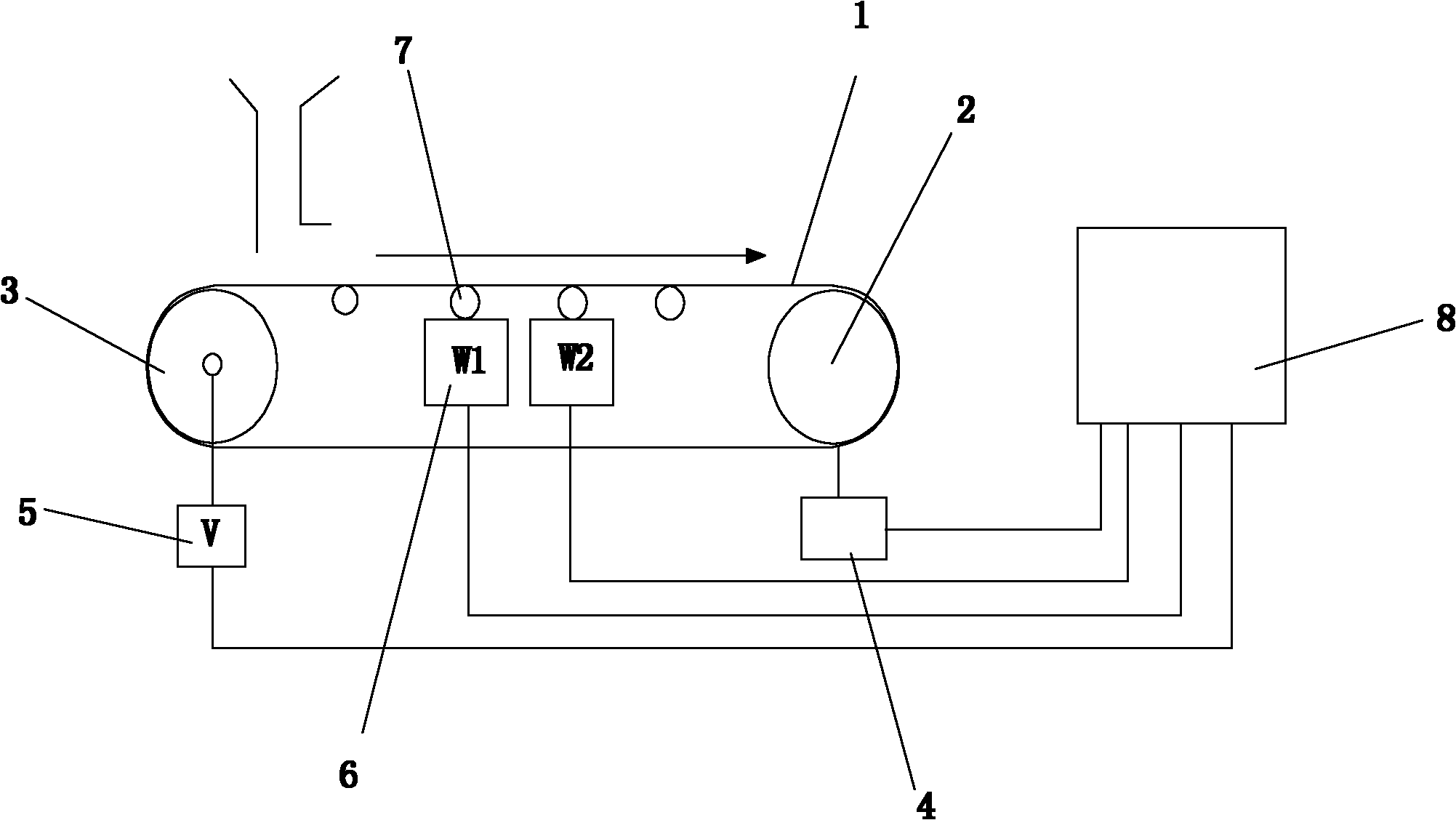

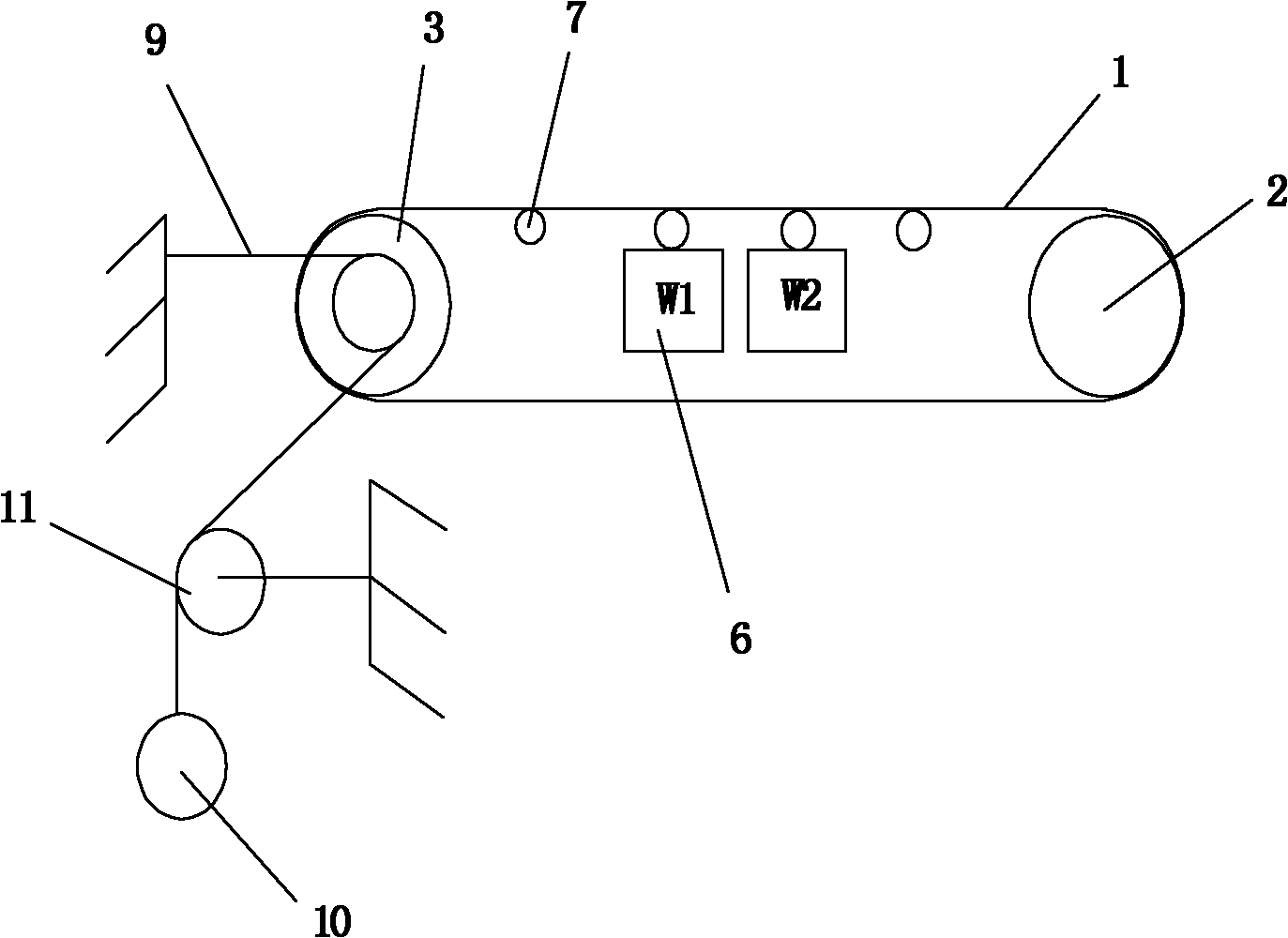

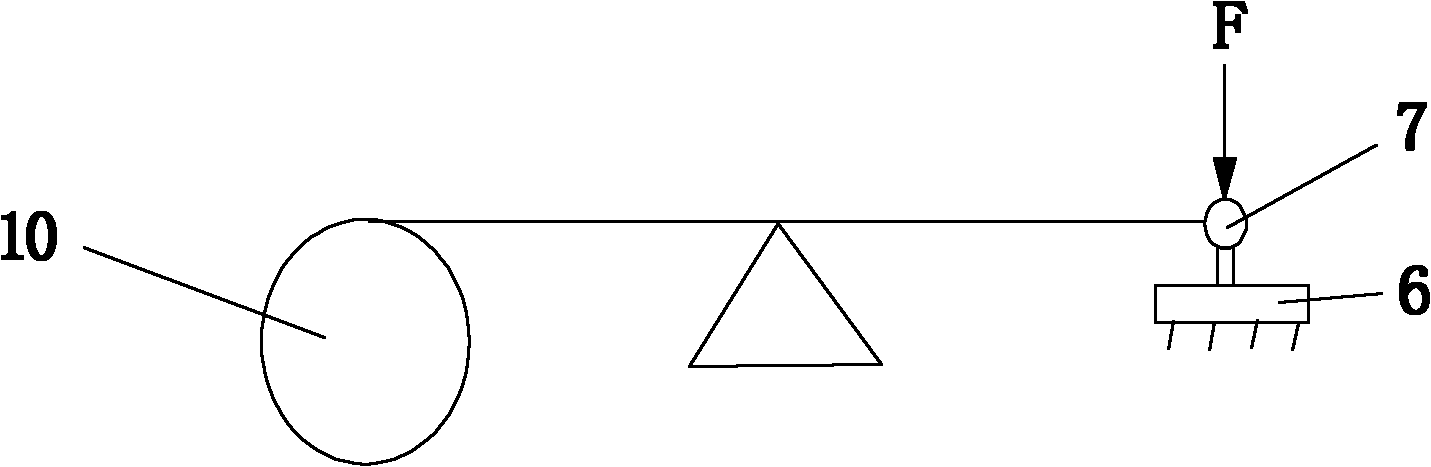

[0014] Such as figure 1 , figure 2 with image 3 The high-precision electronic belt scale shown is mainly composed of idlers, belts 1, and motors 4 installed on a frame (not shown in the figure). The idlers include weighing idlers 7 and main idlers at both ends of the belt 1 2 and the auxiliary roller 3, the main roller 2 is connected with the motor 4, the auxiliary roller 3 is connected with a speed sensor 5, the lower part of the auxiliary roller 3 is provided with a certain rod 11, and a steel rope 9 fixed at one end is passed around in turn The auxiliary roller 3 and the fixed rod 11 are connected with a counterweight 10, and the weighing roller 7 is provided with a weighing sensor 6 underneath. The weighing sensor 6, the motor 4, and the speed sensor 5 are connected with a controller 8 to control A touch screen is connected outside the device.

[0015] Such as Figure 4 As shown, the frame is provided with a photoelectric cell 12 for detecting the direction of the belt 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com