Cross section integrated laser vision fixed weight cutting method for continuously cast bloom and weight fixing device

A cutting method and continuous casting billet technology, applied in the field of metallurgy, can solve problems such as the problem of fixed weight that has not been well solved, the essential problem of not getting involved in fixed weight, and the theoretical accuracy is not thought about, so as to improve production efficiency and economic benefits, Simple structure and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

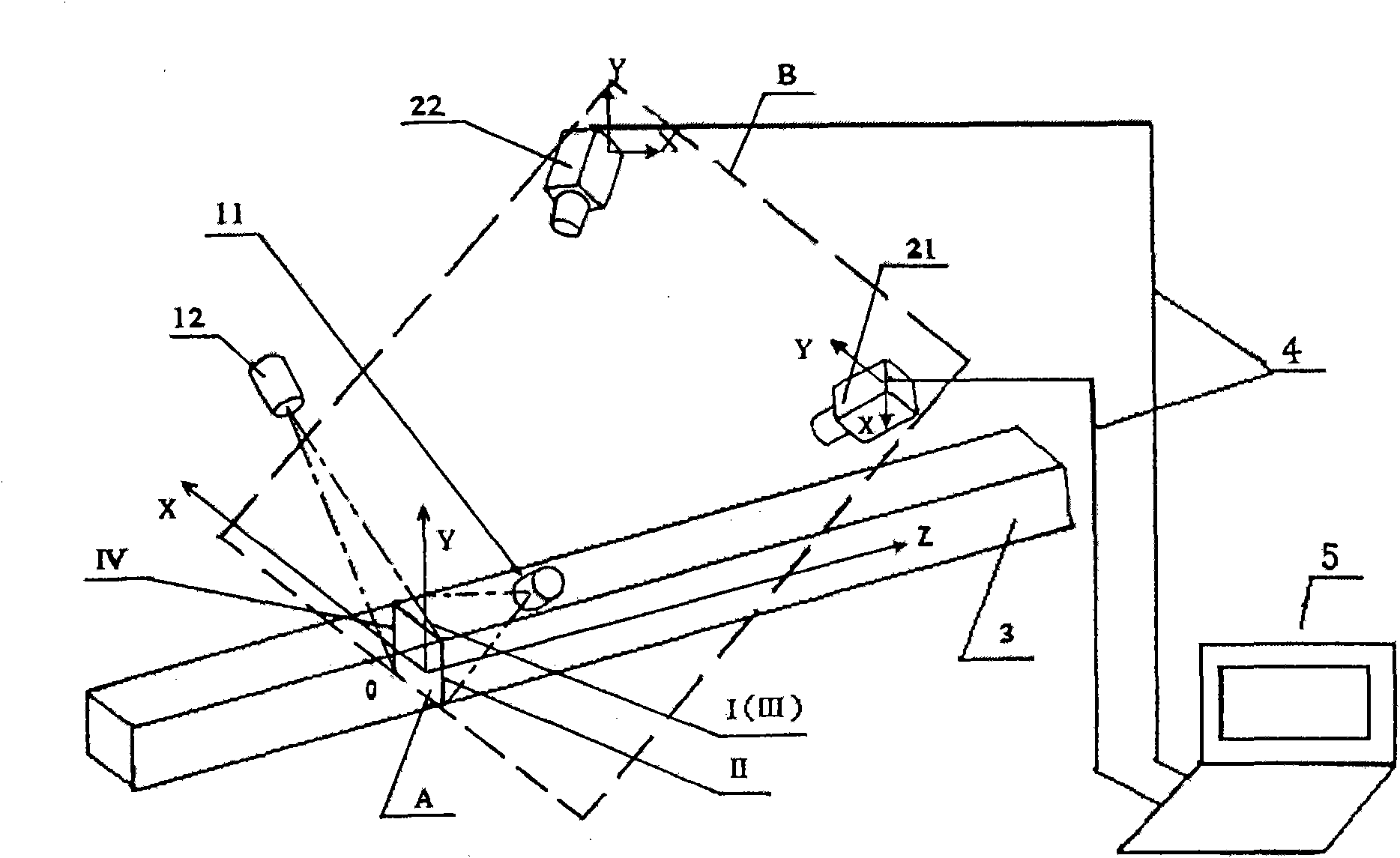

[0047] A cross-sectional integral type continuous casting slab laser vision fixed-weight cutting method, which is carried out according to the following steps:

[0048] ①Laser irradiation and CCD camera imaging

[0049] Using a linear laser to irradiate the laser on the cross-section of the continuous casting slab corresponding to the installation position of the cutting knife to form a light strip located in the same vertical plane A, the vertical plane A is perpendicular to the axis of the continuous casting slab;

[0050] The rear part of the light strip is taken by a CCD camera to form a hologram of the light strip; the light strip curve fitting is performed to obtain the cross-sectional image of the position of the light strip on the continuous casting slab.

[0051] Laser irradiation and CCD camera imaging are carried out in the following steps:

[0052] (1) Installation and adjustment of linear laser

[0053] Installation: on the left and right sides of the continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com