Lifting handle with weighing function

A function and weighing technology, applied in special scales, clothing, measuring devices, etc., can solve the problems of high processing and manufacturing costs, complex assembly process, inaccurate weighing, etc., achieve high weighing accuracy and reduce manufacturing cost. Reasonable cost and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

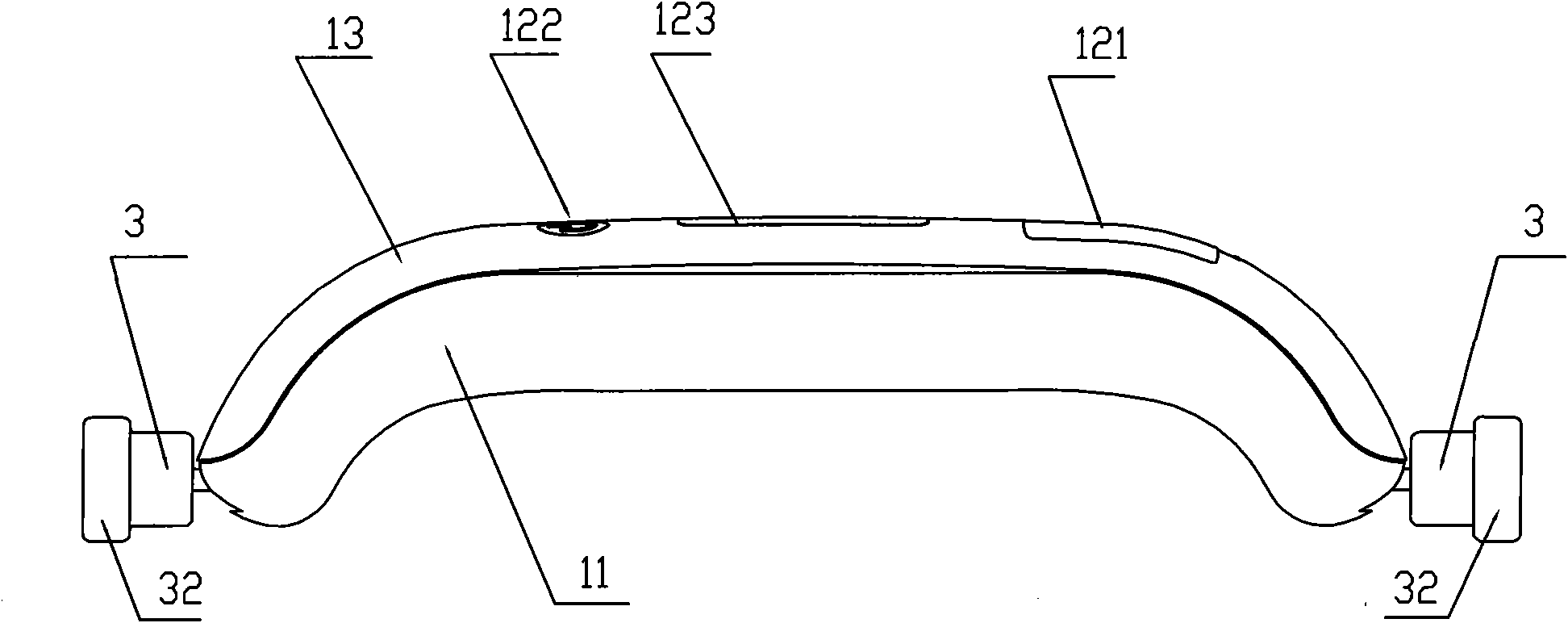

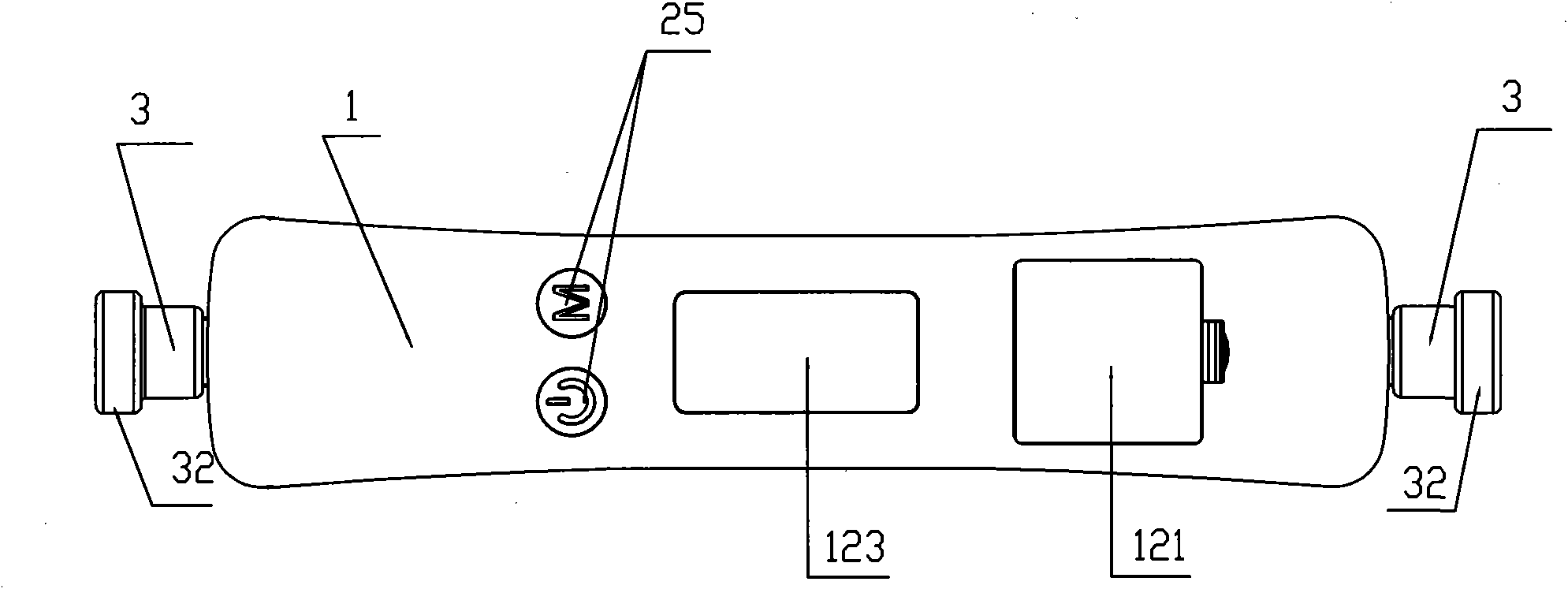

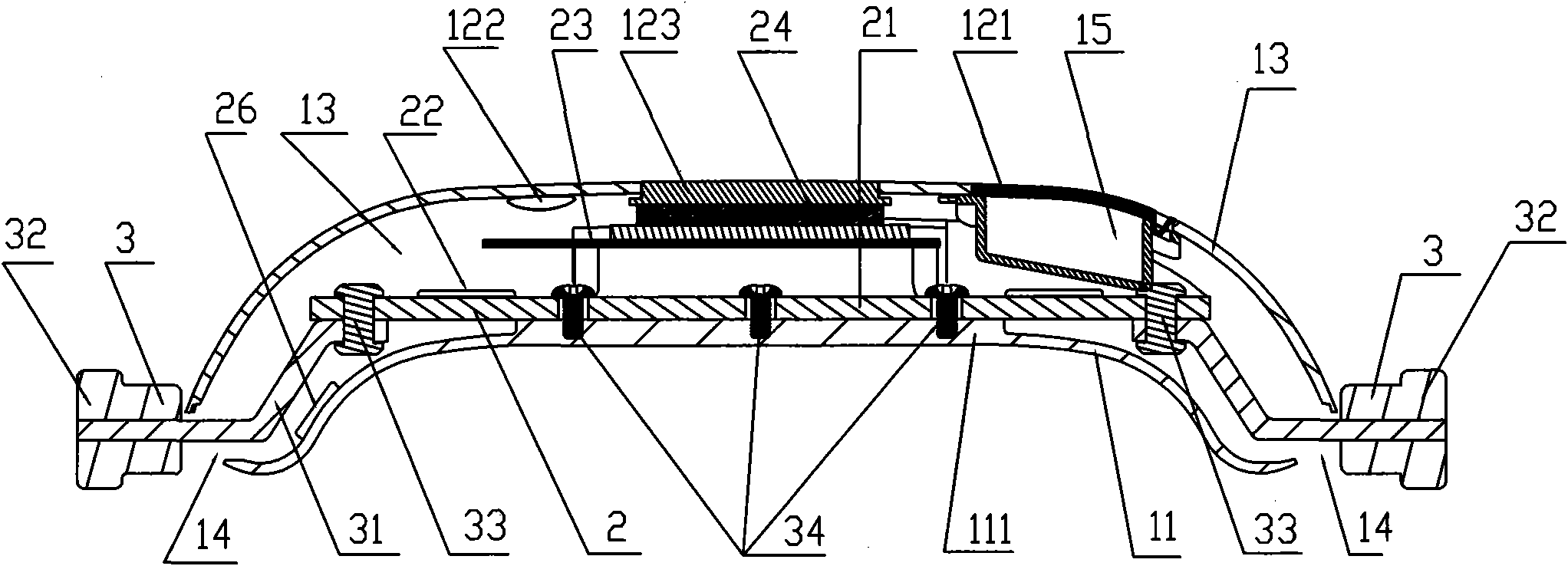

[0027] Example 1: from Figure 1 to Figure 4 It can be clearly seen that the handle with weighing function is composed of a handle body 1 and a weighing sensor 2 arranged therein.

[0028] The handle body 1 is composed of a bottom cover 11 and an upper cover 12. The handle body 1 composed of the bottom cover 11 and the upper cover 12 has a mounting cavity 13 for a weighing sensor. Two ends of the handle body 1 are provided with Mouth 14.

[0029] The bottom cover 11 of the handle is provided with a support 111 for installation of electronic scale circuit board, display screen and function switch.

[0030] The battery compartment 15 with the battery cover 121 provided on the handle loam cake 12 is also provided with a button hole and a liquid crystal display window on the handle surface of the handle loam cake 12 .

[0031] The weighing sensor 2 consists of an elastic body 21 with a length less than the length of the cavity, a strain gauge 22 pasted on the loading end faces o...

Embodiment 2

[0038] Example 2, from Figure 5 It can be seen that this is another embodiment of the carrying handle with weighing function.

[0039] The basic structure of the handle with weighing function is the same as that of Embodiment 1, the only difference being that the two loading ends of the elastic body 21 are respectively equipped with nylon braid 4 through rivets 31 . The nylon braids 4 connected to the two loading ends of the elastic body 21 respectively protrude from the cavity openings 14 at both ends of the handle body 1 .

[0040] The handle with weighing function can be conveniently connected with the belt buckle on the bag by virtue of the nylon braid 4 at its two ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com