Fixed-weight loading equipment

A loading device and fixed weight technology, applied in the direction of measuring device, loading/unloading, conveyor control device, etc., can solve the problems of increasing the wear and running resistance of the bearing plate, low measurement accuracy, large drift, etc., and improve the weighing accuracy. , The effect of safe and reliable operation and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

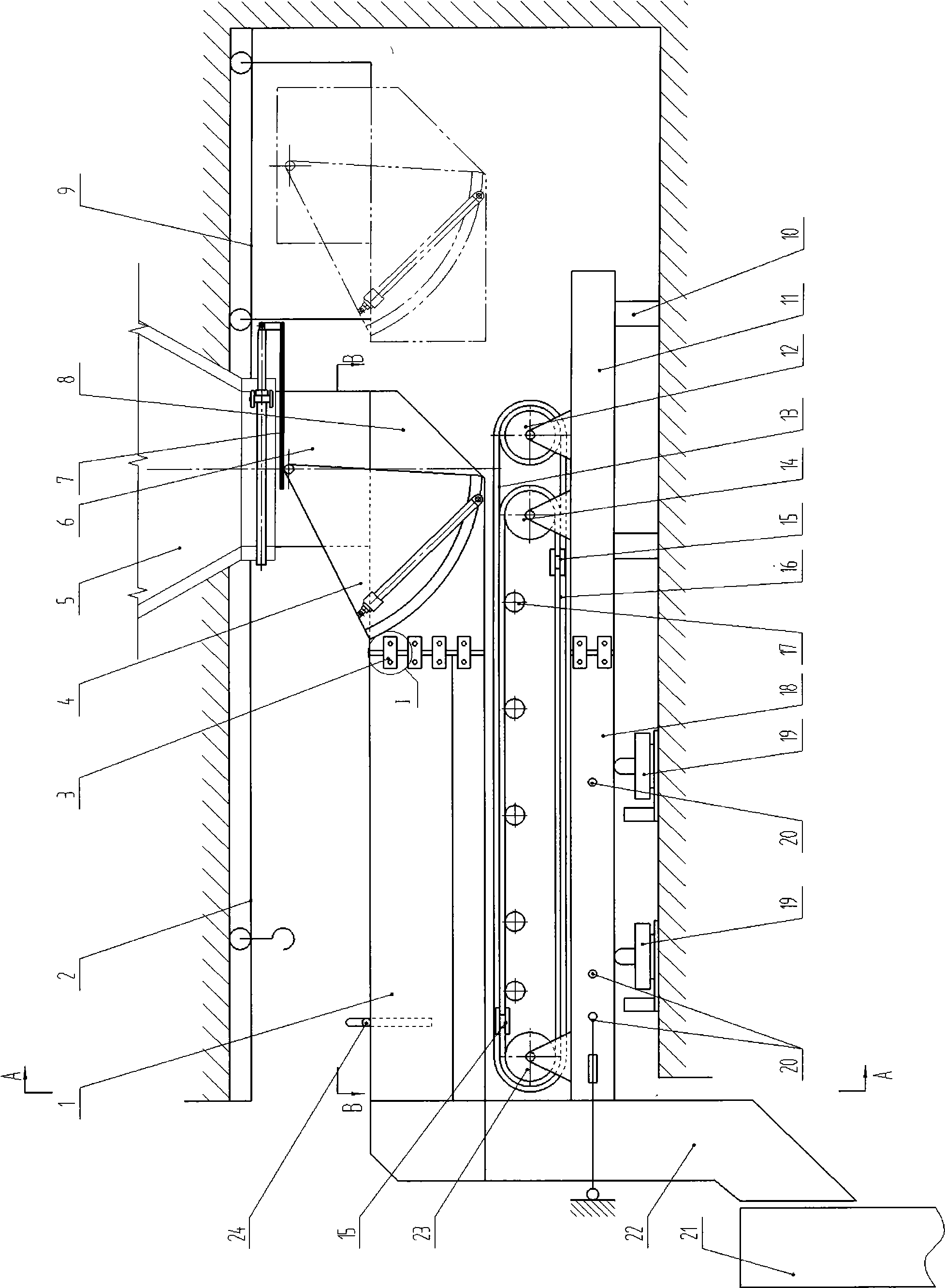

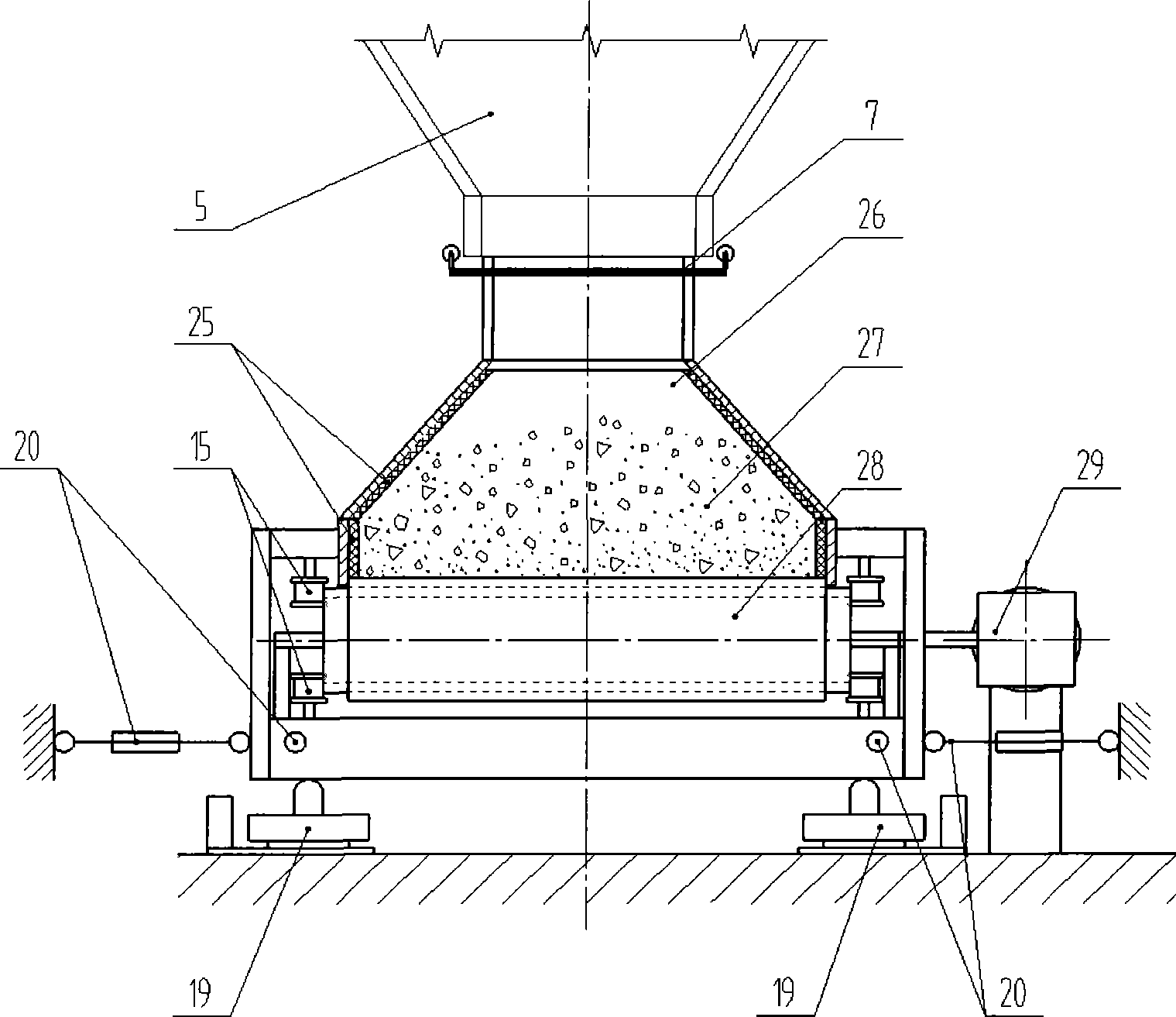

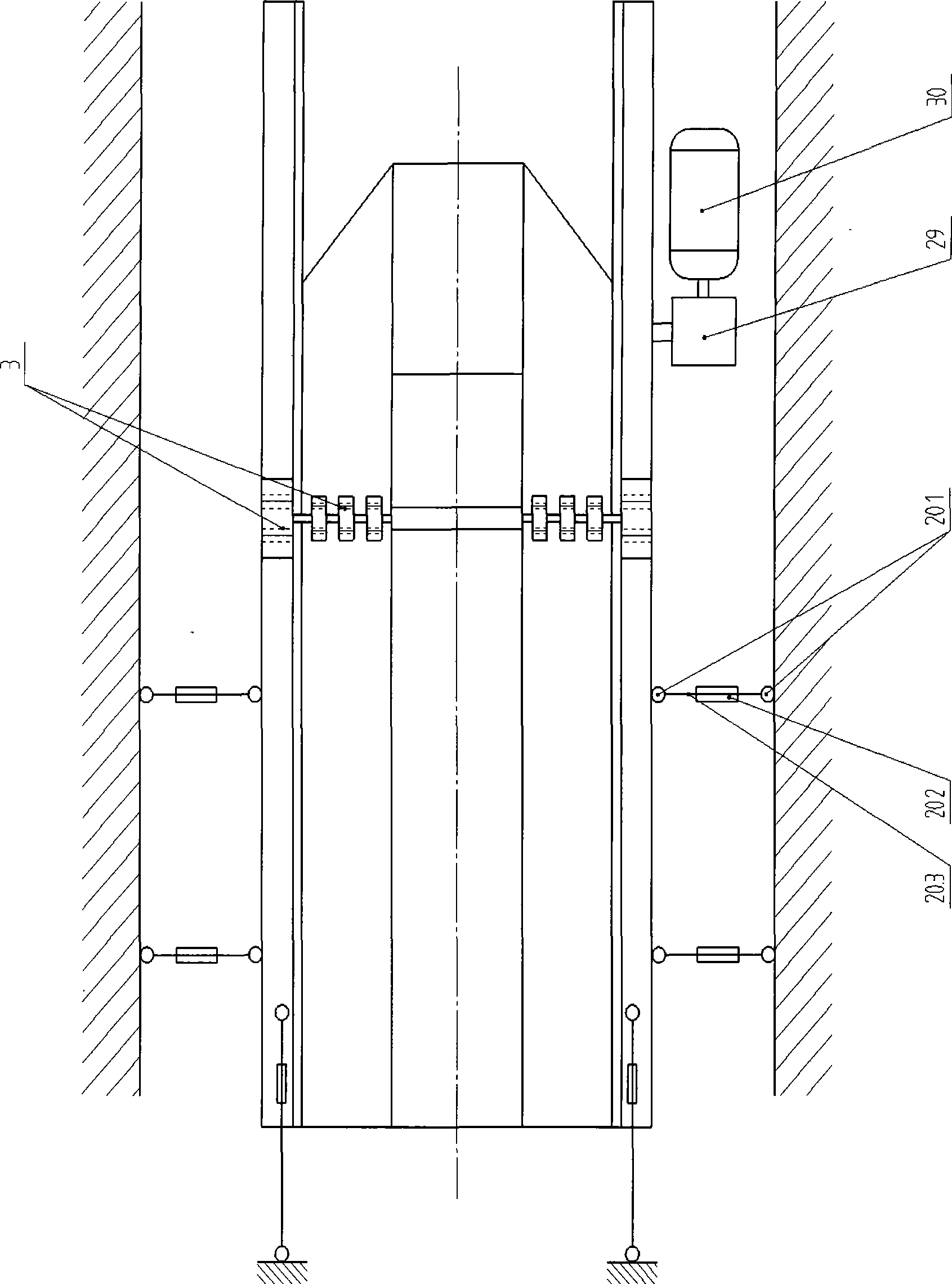

[0039] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 As shown, the receiving part support 11 is fixed on the foundation by the legs 10, the weighing part support 18 is provided with a weighing sensor 19, and the weighing part support 18 and the receiving part support 11 are provided with a conveying device 28 and a conveying device 28 It consists of a driving roller 14, a redirecting roller 23, a tension roller 12, a belt 13 and a tape 16. The belt 16 is wrapped around the driving roller 14 and the redirecting roller 23. The belt 13 is wrapped on the outside of the tape 16, and is wrapped around the tensioning roller. On the roller 12 and the redirecting roller 23, a number of groups of idlers 17 are arranged between the driving roller 14 and the redirecting roller 23. Above the conveying device 28, a weighing part guide groove 1 and a receiving part guide groove 8 are provided, between the weighing part bracket 18 and the receiving part bracket 11, and the weigh...

Embodiment 2

[0047] Same as Embodiment 1, the difference is that the conveying device 28 is composed of the driving roller 14, the redirecting roller 23 and the adhesive tape 16. The adhesive tape 16 surrounds the driving roller 14 and the redirecting roller 23, eliminating the armor belt 13 and the tension roller. 12, such as figure 2 , image 3 , Figure 4 , Figure 6 , Figure 7 Shown.

Embodiment 3

[0049] Same as embodiment 2, the difference is that the conveying device 28 is composed of the driving roller 14, the redirecting roller 23 and the armor belt 13. The armor belt 13 surrounds the driving roller 14 and the redirecting roller 23, eliminating the tape 16 and tensioning. The roller 12 and the anti-deflection wheel 15 are only installed on both sides of the lower section of the armor belt 13 near the roller approach point, such as image 3 , Figure 5 , Figure 6 , Figure 7 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com