Dynamic automatic weighing system of kitchen garbage vehicle

An automatic weighing and garbage truck technology, applied in the field of sanitation equipment, can solve the problems of lack of dynamic performance compensation design of weighing pressure, no dynamic weighing performance, poor weighing accuracy, etc., to achieve good dynamic weighing performance, It is suitable for popularization and application, and the calculation error is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

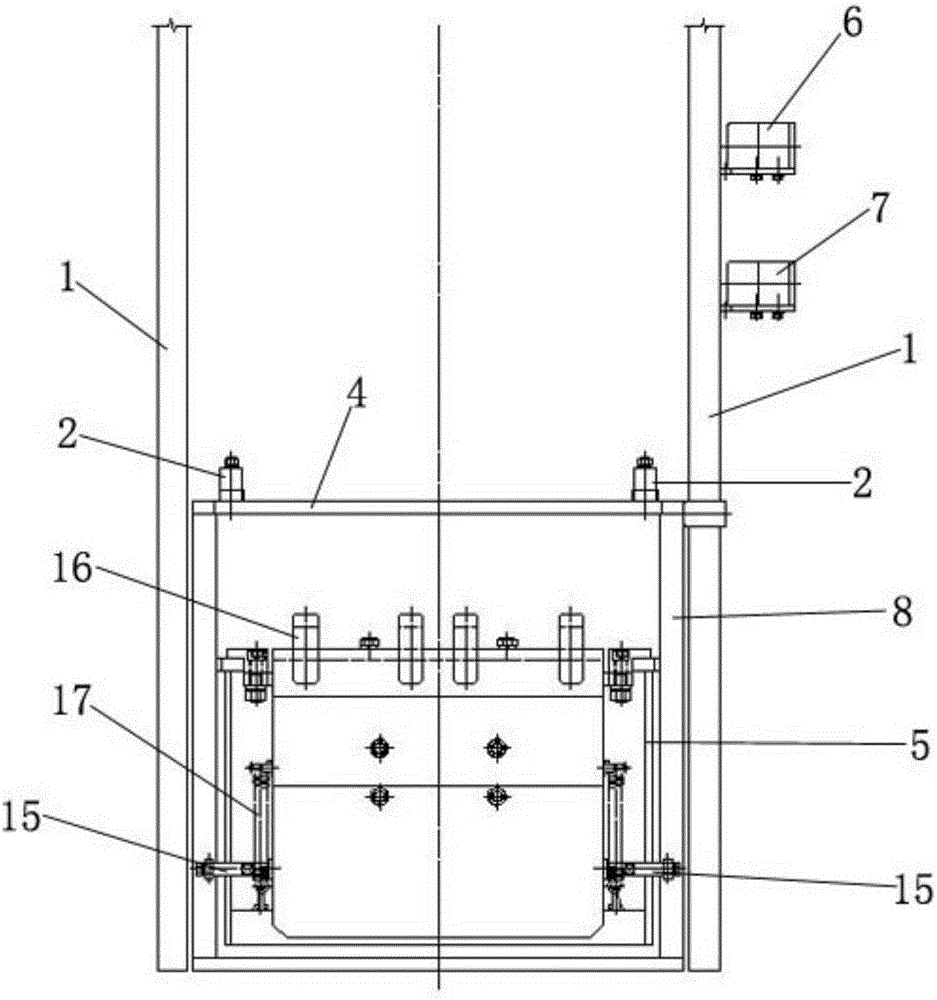

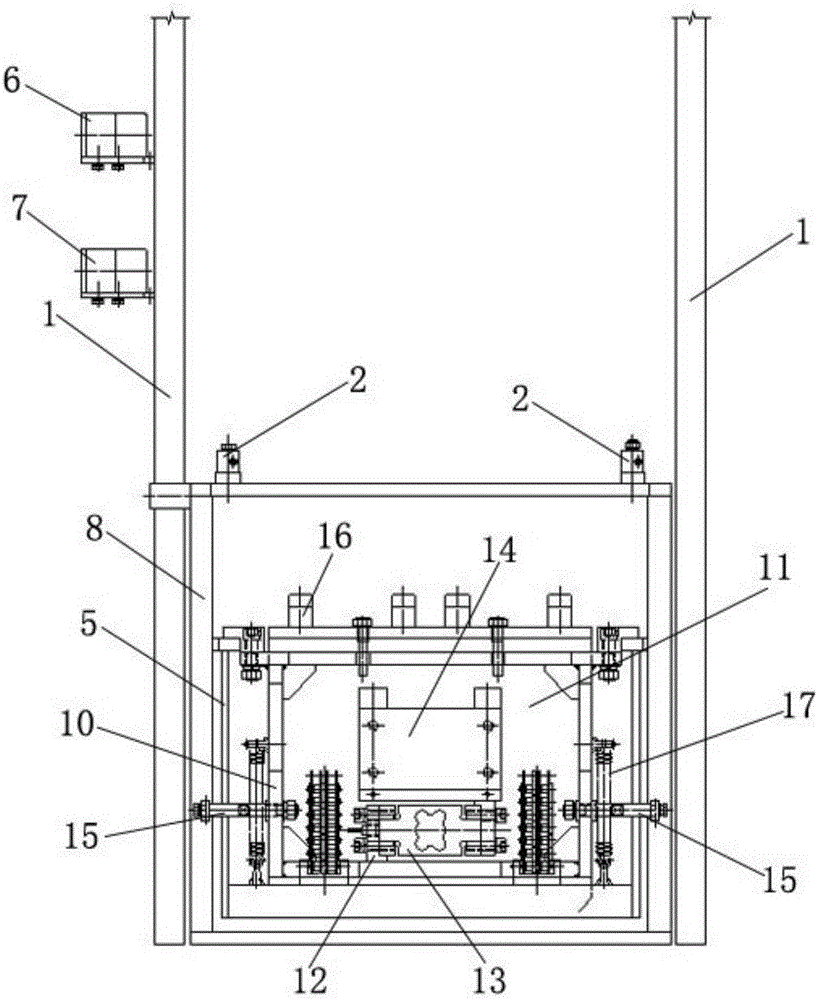

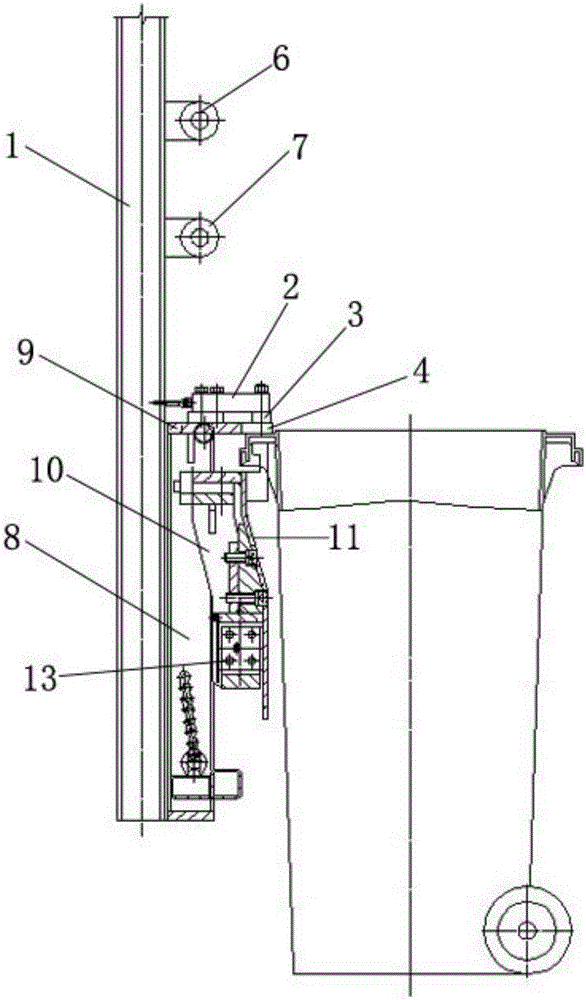

[0024] Such as Figure 1 to Figure 3 The shown dynamic automatic weighing system of the kitchen garbage truck of the present invention includes a lifting track 1, an overturning mechanism, a lifting frame 5, a weighing mechanism, a barrel pressing force compensation mechanism and a data control device. The lifting track 1 is fitted on the body of the garbage truck, and the turning mechanism can be vertically flipped and installed on the lifting track 1 to move vertically. Splash baffles are set around the discharge port. The lifting frame 5 is fixedly installed on the turning mechanism, and the weighing mechanism is installed on the lifting frame 5 to move vertically. The garbage can is hung on the weighing mechanism and moves synchronously with the lifting frame 5 together with the turning mechanism . The weighing mechanism is used to output the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com