Integrated anti-cheating dynamic weighing method and system

A dynamic weighing and anti-cheating technology, applied in the direction of weighing equipment testing/calibration, weighing, measuring devices, etc., can solve problems such as inability to meet and prevent vehicle cheating, and achieve the effect of improving weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

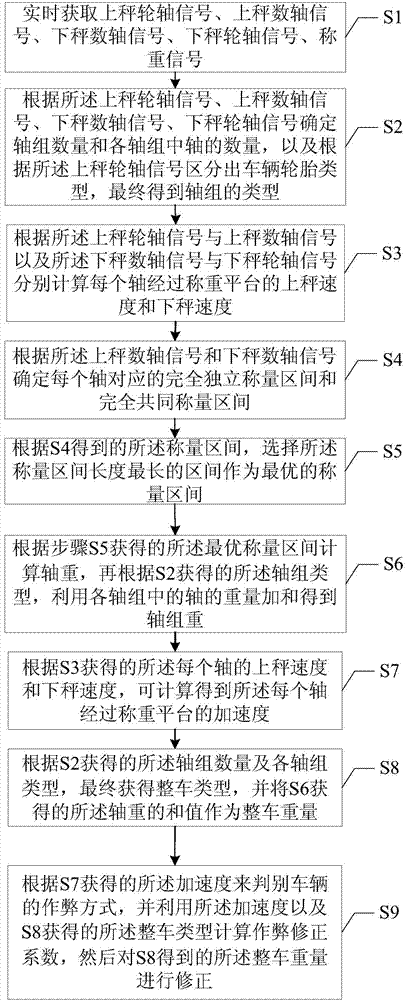

[0076] A kind of conjoined anti-cheating dynamic weighing method in the present invention is described below with an optimal embodiment, and described method comprises the following steps:

[0077] Step 101: Receive the vehicle entry signal, and after receiving the vehicle entry signal, execute step 102, if the vehicle entry information is not received, then wait;

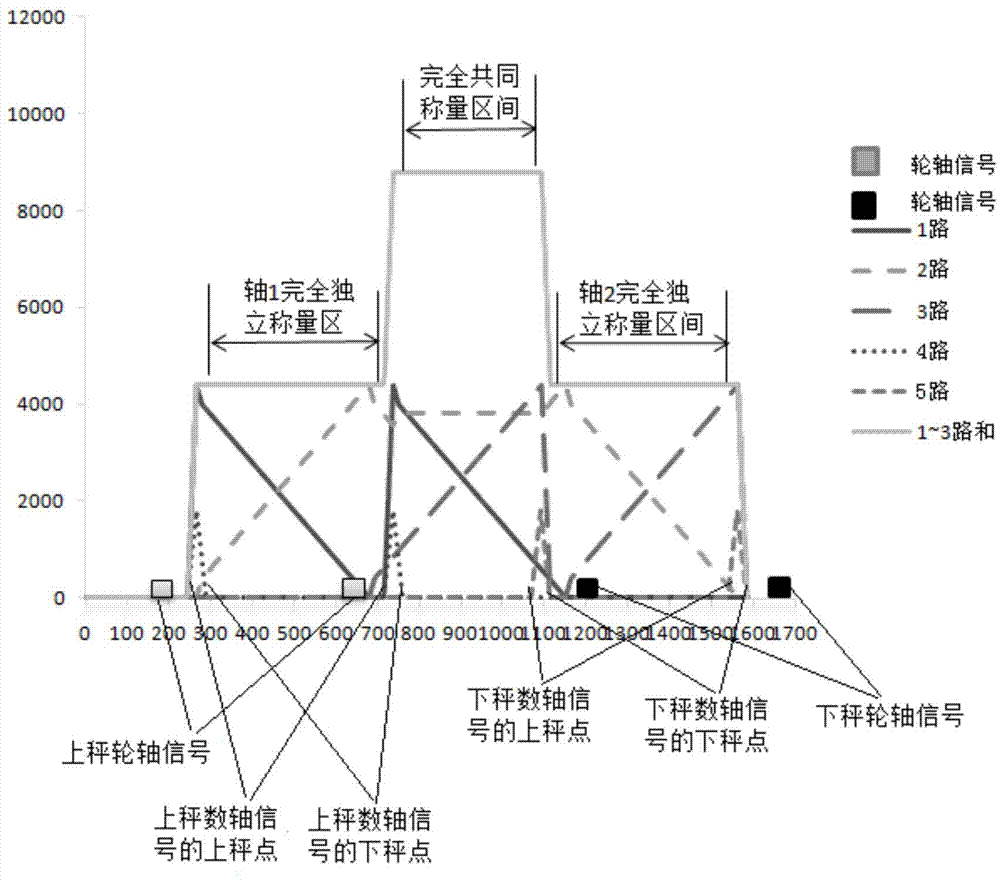

[0078] Step 102: Obtain the upper scale wheel shaft signal, the upper scale number shaft signal, the lower scale number shaft signal, the lower scale wheel shaft signal, and the weighing signal in real time, refer to figure 2 , No. 1, No. 2, No. 3 are weighing signals, No. 4 is the number axis signal of the upper scale, and No. 5 is the number axis signal of the lower scale;

[0079] Step 103: Refer to figure 2 , obtain the shaft group type according to the upper scale wheel shaft signal, the upper scale number shaft signal, the lower scale number shaft signal, and the lower scale wheel shaft signal, refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com