Measurement system for a material transfer vehicle

A measurement system and material technology, applied in the field of measurement system, can solve the problems of inaccurate output value and inaccuracy, and achieve the effect of good stability and good weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

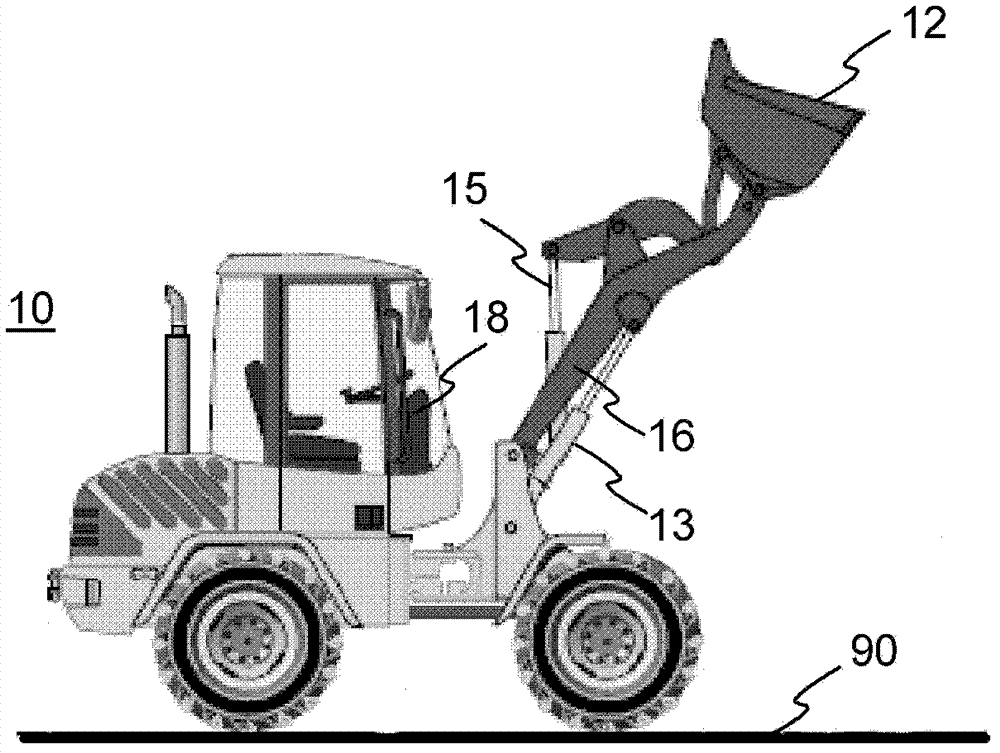

[0028] described in the prior art section above figure 1 .

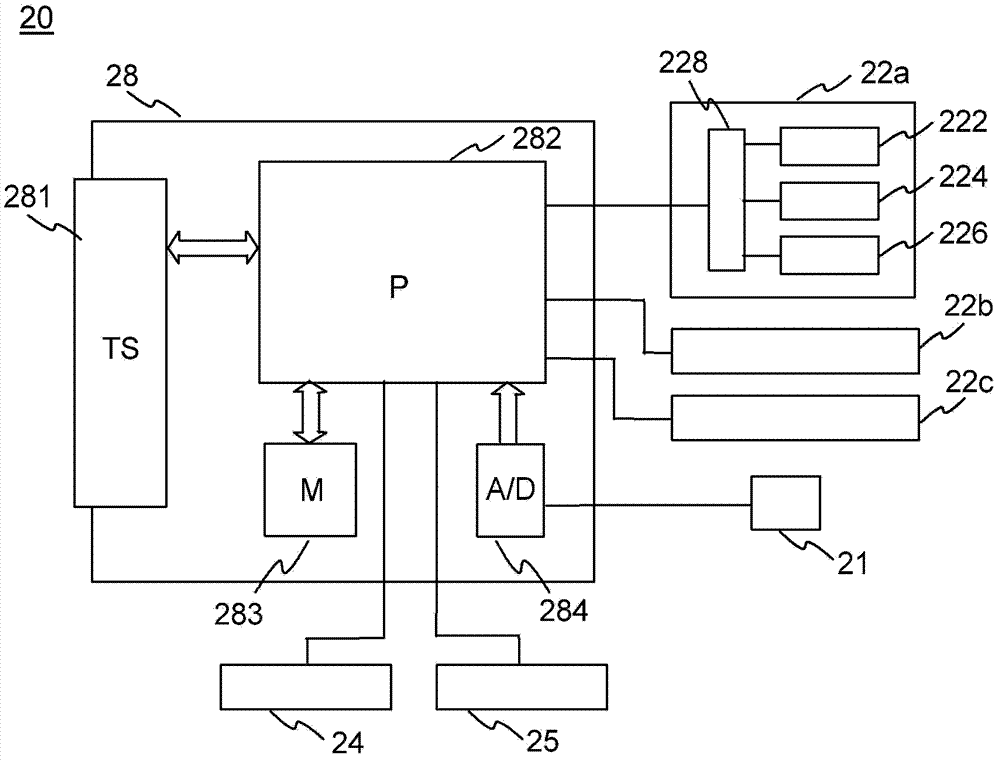

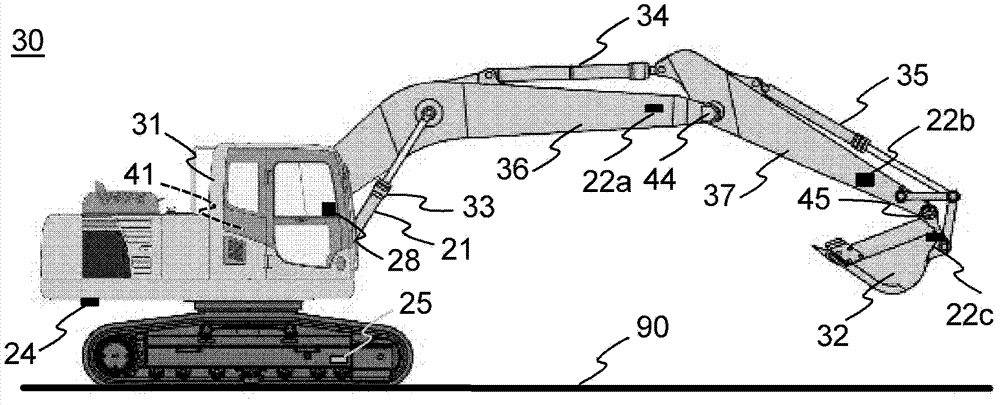

[0029] figure 2A block diagram of a measurement system 20 according to one embodiment of the invention is shown. The system has a first type of sensor unit 21 for weighing the load of the carrier. The first sensor unit can be, for example, a strain gauge transducer or a pressure transducer whose output signal is proportional to the load weight. Strain gauge transducers may be mounted to the boom or at an articulated joint between the cabin / chassis and the boom, between two booms and / or between the boom and the carrier. Pressure transducers are mounted in one or more hydraulic cylinders that move the boom / carrier. In some systems, a pressure sensor may measure air pressure from a pneumatic cylinder. The signal from the first sensor unit is directed to the electronic unit 28 by wireless data transfer or cable, and said signal is further amplified and converted into digital form in an analog-to-digital (A / D) conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com