Double-color infrared thermometer applied to testing of cutting temperature of machine tool

A cutting temperature and thermometer technology, applied in the field of thermometers, can solve the problems of complex focusing and aiming methods, easy failures, cumbersome debugging, etc., and achieve simple and convenient focusing and aiming, high safety and rapid response precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

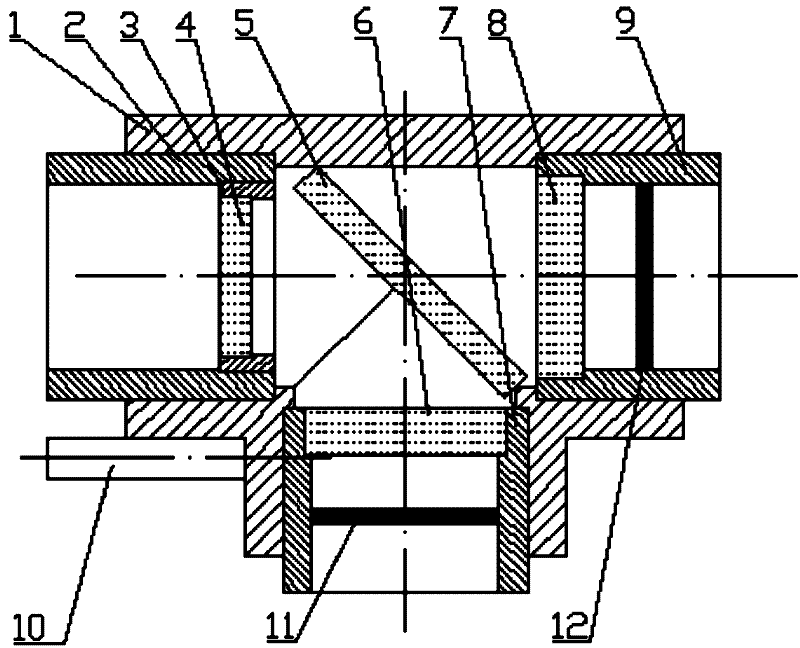

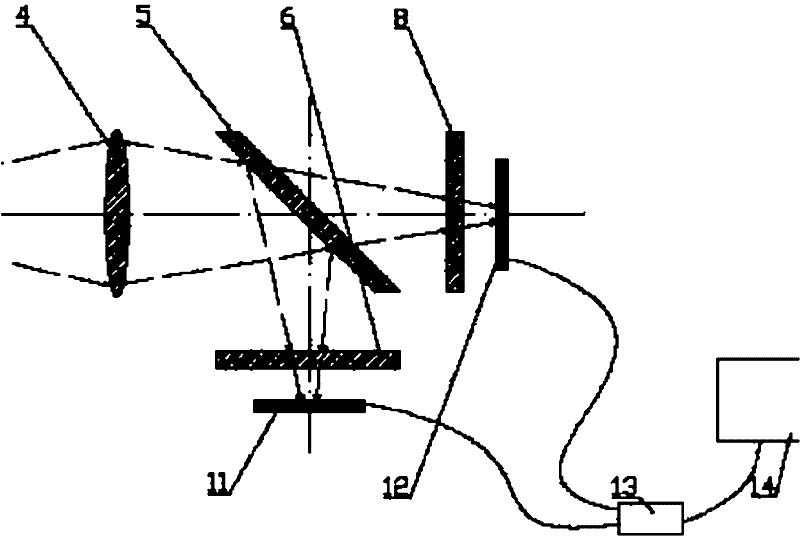

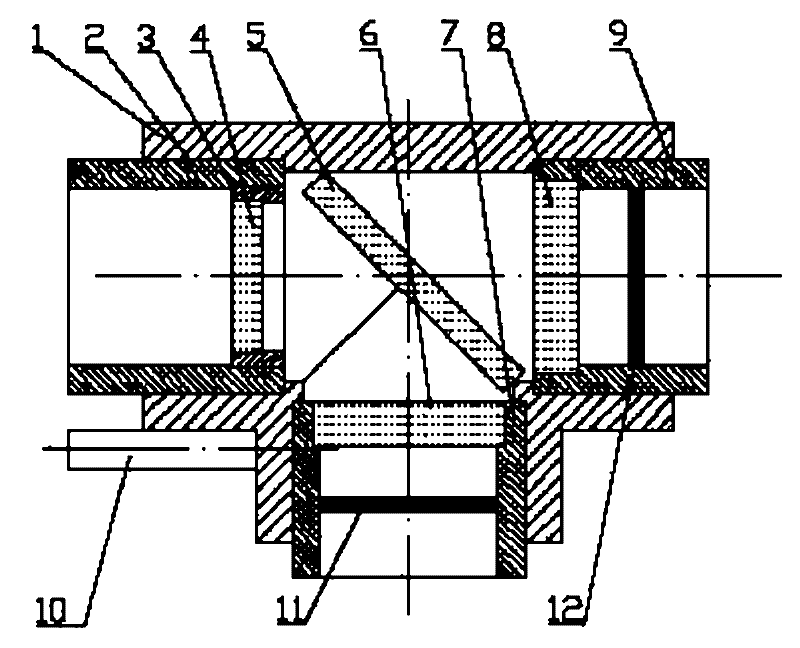

[0017] The structure of the two-color infrared thermometer of the present invention is as follows: figure 1 with figure 2 As shown, it includes a housing 1 , a laser sight 10 , a focusing tube 2 , a convex lens 4 , a beam splitter 5 , an optical filter, an infrared detector, a processor 13 and a display 14 . The housing 1 is a three-way pipe structure. A laser sight 10 is mounted on the casing 1 . The focus tube 2 is installed in one of the two through ports in the shell 1, and is screwed to the shell 1. The inside of the focus tube 2 is equipped with a convex lens 4 through the lens sleeve 3, and the measurement can be adjusted by rotating the focus tube 2. distance. The beam splitter 5 is arranged inside the casing 1 and forms an angle of 45° with the convex lens 4 . A filter sleeve 7 and a filter sleeve 9 are installed in the other two openings of the housing 1 respectively, and the axes of the filter sleeve 7 and the filter sleeve 9 are vertical. The inner ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com