Centrifugal concrete pile mold and flat car for shelving centrifugal concrete pile mold

A technology of concrete piles and moulds, applied in moulds, manufacturing tools, reinforced molding, etc., can solve the problems of not being on the same axis, unbalanced production capacity, and increased workload of cranes across workshops, so as to ensure position accuracy and facilitate cooperation Modeling and Optimizing the Effect of Centrifugal Concrete Pile Production Line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

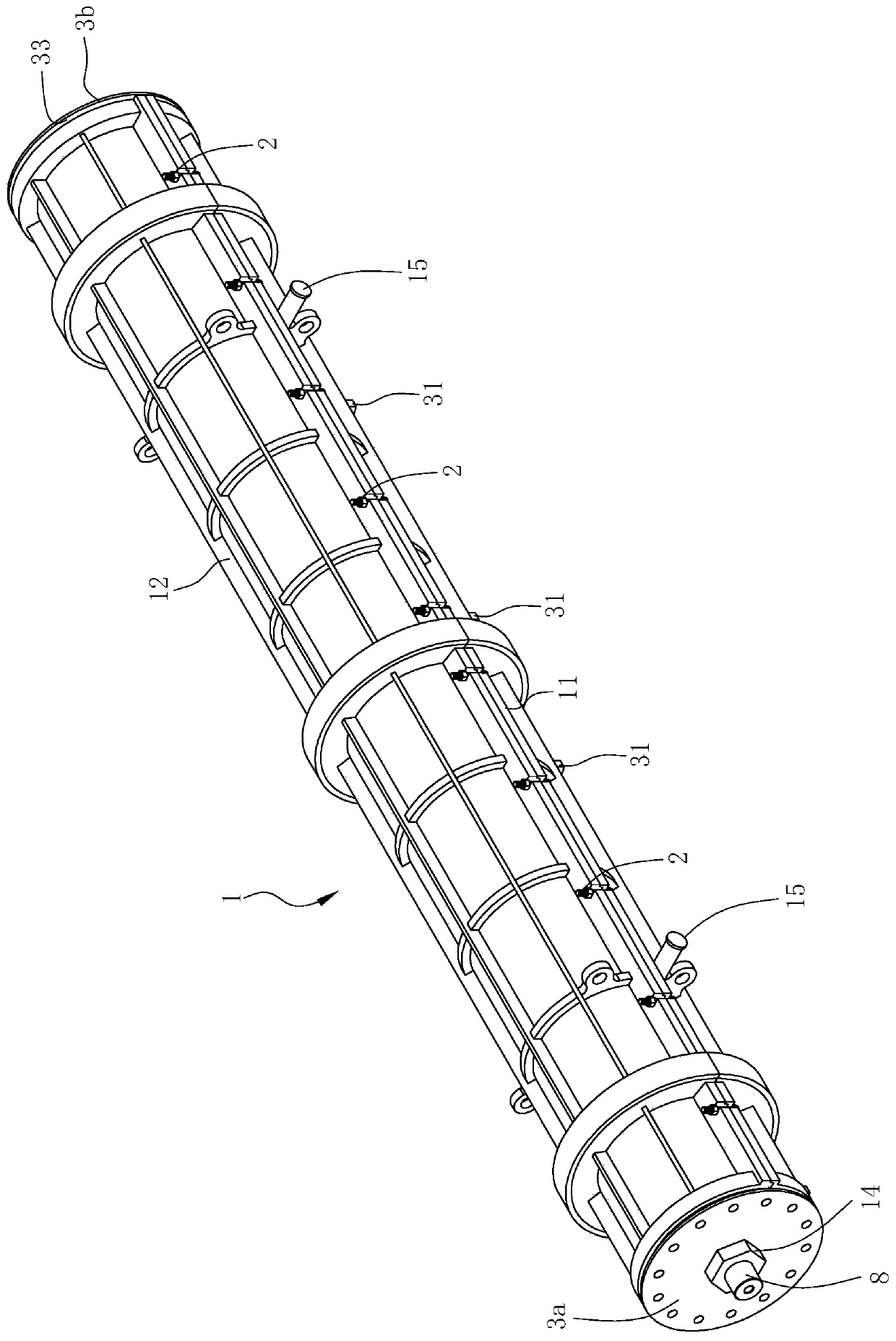

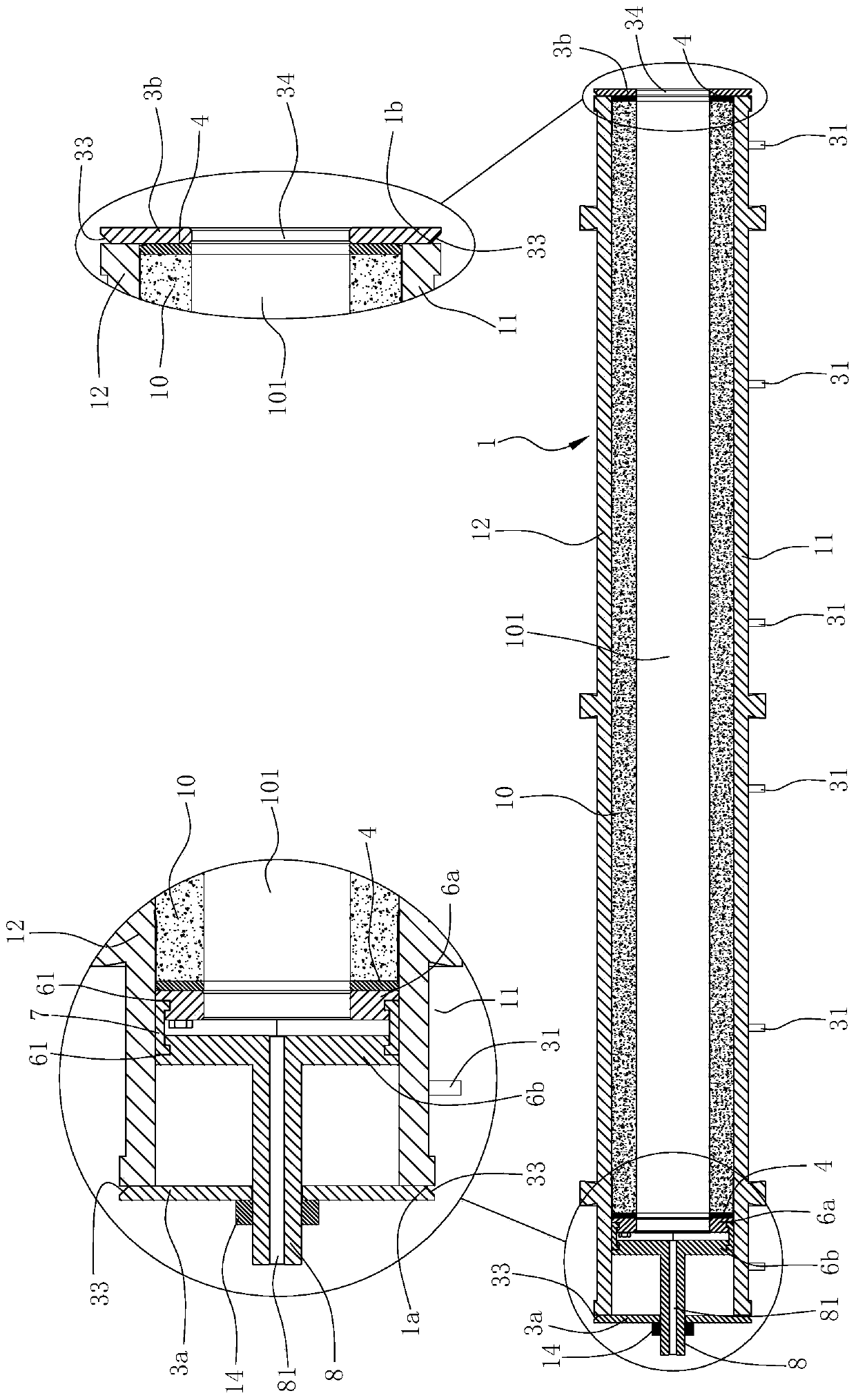

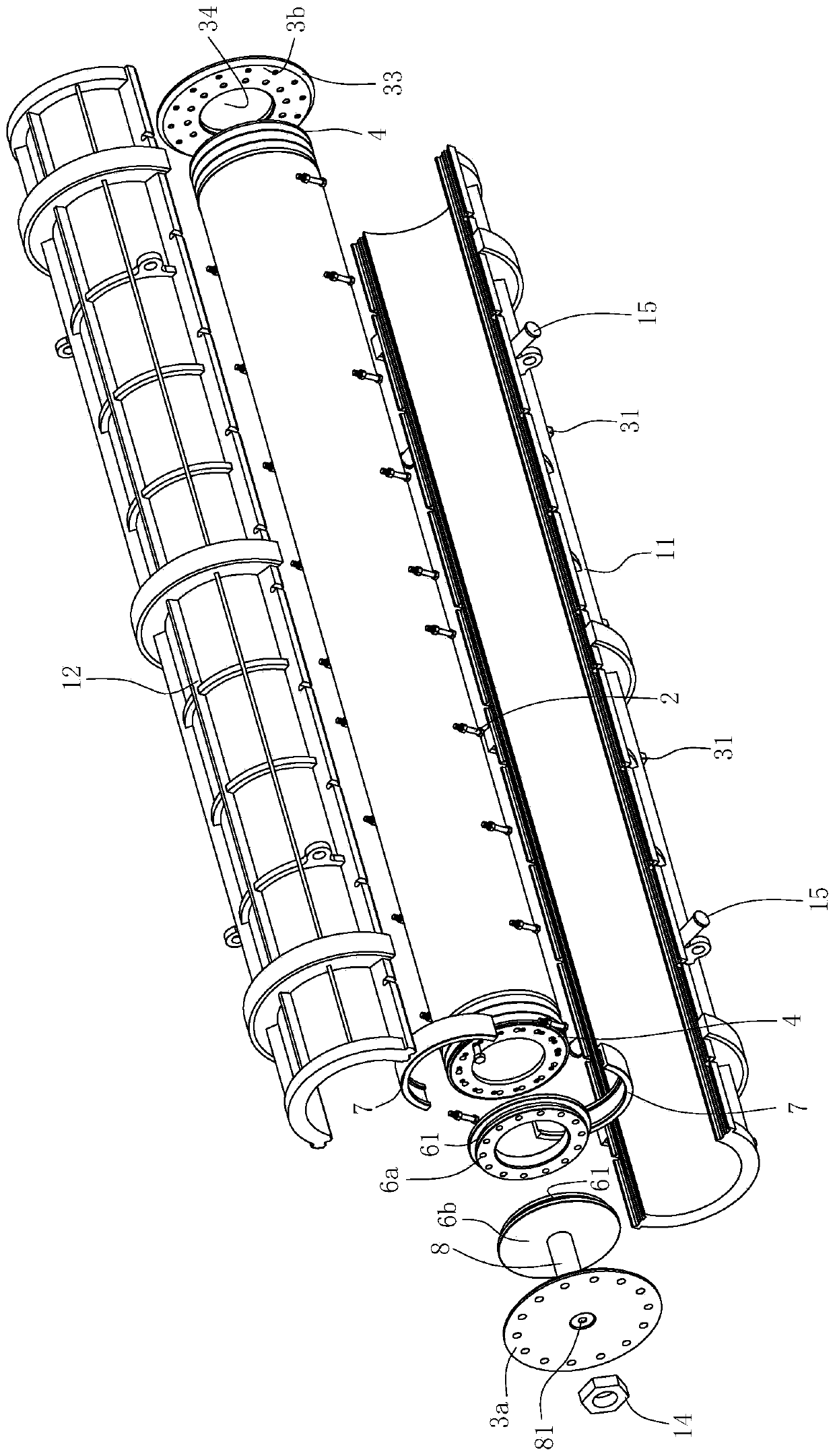

[0036] Such as Figure 1~4 Shown is the first embodiment of the centrifugal concrete pile mold of the present invention.

[0037] A centrifugal concrete pile mold, including a mold body 1 formed by the combination of a lower half mold 11 and an upper half mold 12, and a mold clamping bolt assembly 2 for connecting the lower half mold 11 and the upper half mold 12, and the mold body 1 A front support plate 3a and a rear support plate 3b are respectively fixed on the front end surface 1a and the rear end surface 1b; the peripheral edge of the end surface of the front support plate 3a and the rear support plate 3b which fits with the mold body 1 has an annular wedge-shaped surface 33 .

[0038] The mold is provided with a radially protruding positioning lug 31 that exposes the peripheral surface of the mold body 1 . The positioning lug 31 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com