Non-contact photographing hole-measuring calibration device and method

A non-contact, calibration device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of hole position calculation errors, inability to judge hole accuracy, and inability to satisfy accurate hole measurement, etc., to improve position accuracy , The effect of ensuring position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] At present, there are mainly two types of measuring instruments and measurement methods for the position of holes on skin parts: (1) three-coordinate measuring machine contact measurement; (2) non-contact photographic hole measurement method.

[0059] For the first measurement method, when the measurement scheme has hundreds of group holes attached to large skin parts, the detection time is long, and it is difficult to meet the requirements of high efficiency of production cycle, while the second measurement method has image Identification, data processing, rapid detection and other advantages, so it is becoming the focus of research and the next development direction.

[0060] However, when the existing non-contact photographic hole measuring method is in use, the main body and object of measurement during actual measurement are still holes, which leads to the photographing of the edge profile of the hole in a non-normal direction, and the hole profile will appear ellip...

Embodiment 2

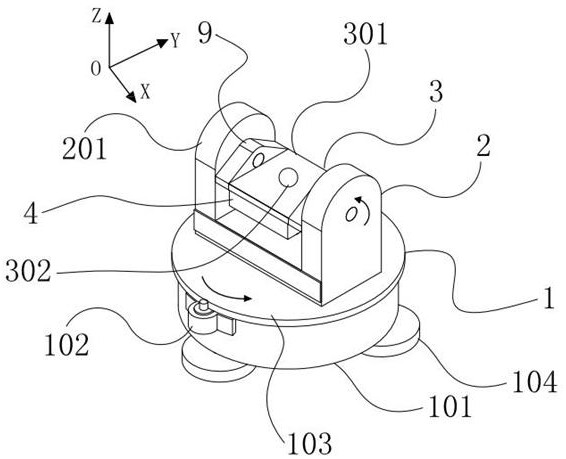

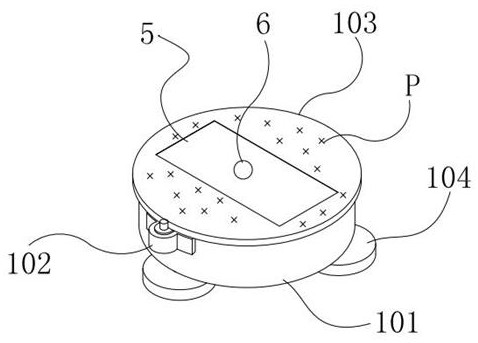

[0068] This embodiment discloses a non-contact photographic hole measuring device. figure 1 - attached Figure 6 , on the basis of Embodiment 1, this embodiment makes further limitations on the calibration device, specifically as follows.

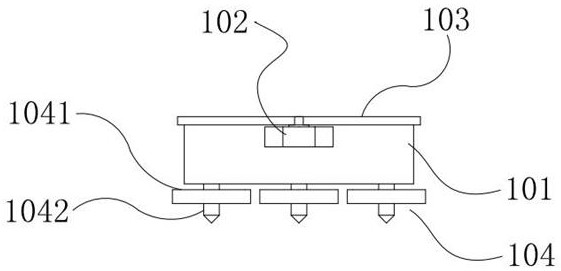

[0069] The base 1 also includes a fine-tuning unit 104, the fine-tuning unit 104 is provided on the lower surface of the base body 101, and the number of the fine-tuning units 104 is three, which are evenly distributed on the lower surface of the base body 101 for adjusting the flatness of the base 1; The fine-tuning unit 104 is an integrated nut and screw structure, including an integrally formed anti-skid nut 1041 and a screw rod 1042, the anti-skid nut 1041 is fixedly sleeved on the screw rod 1042, the diameter of the front and rear sections of the screw rod 1042 is 10mm, and one side of the end is conical. The other end is an M8*10 thread, and the surface of the anti-skid nut 1041 is provided with staggered scratches for anti-skid, the...

Embodiment 3

[0081] Based on the same inventive concept, this embodiment provides a non-contact photoborehole calibration method, which is realized by the non-contact photoborehole calibration device in the above embodiment, and the method specifically includes the following steps:

[0082] Step S101. Leveling the overall reference of the calibration device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com