Motor and controller integrated system

An integrated system and controller technology, applied in the direction of control drive, connection with control/drive circuit, electromechanical device, etc., can solve the problems of poor cooling effect and motor performance degradation, achieve strong heat dissipation and improve safety The effect of continuous and stable performance and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

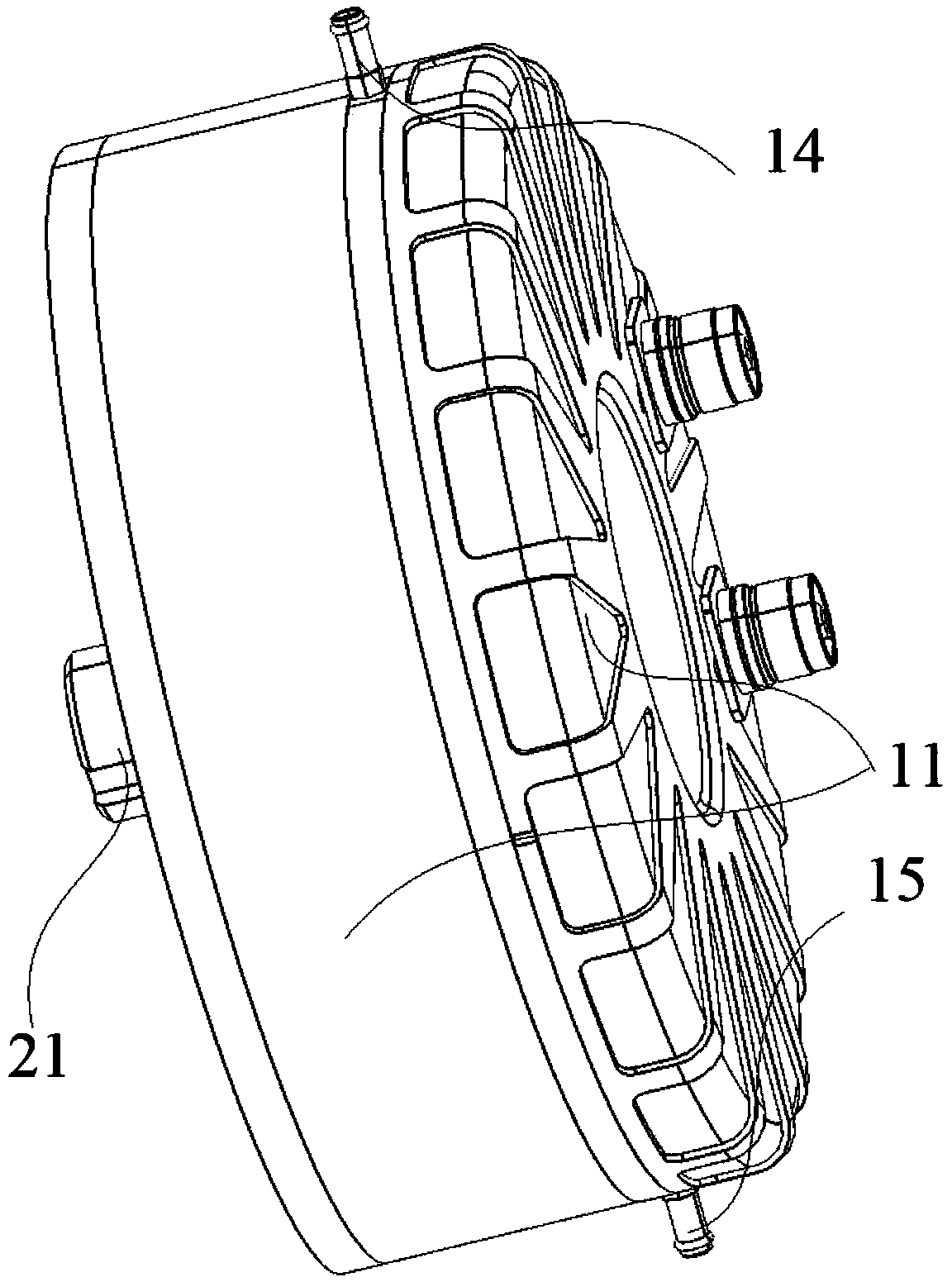

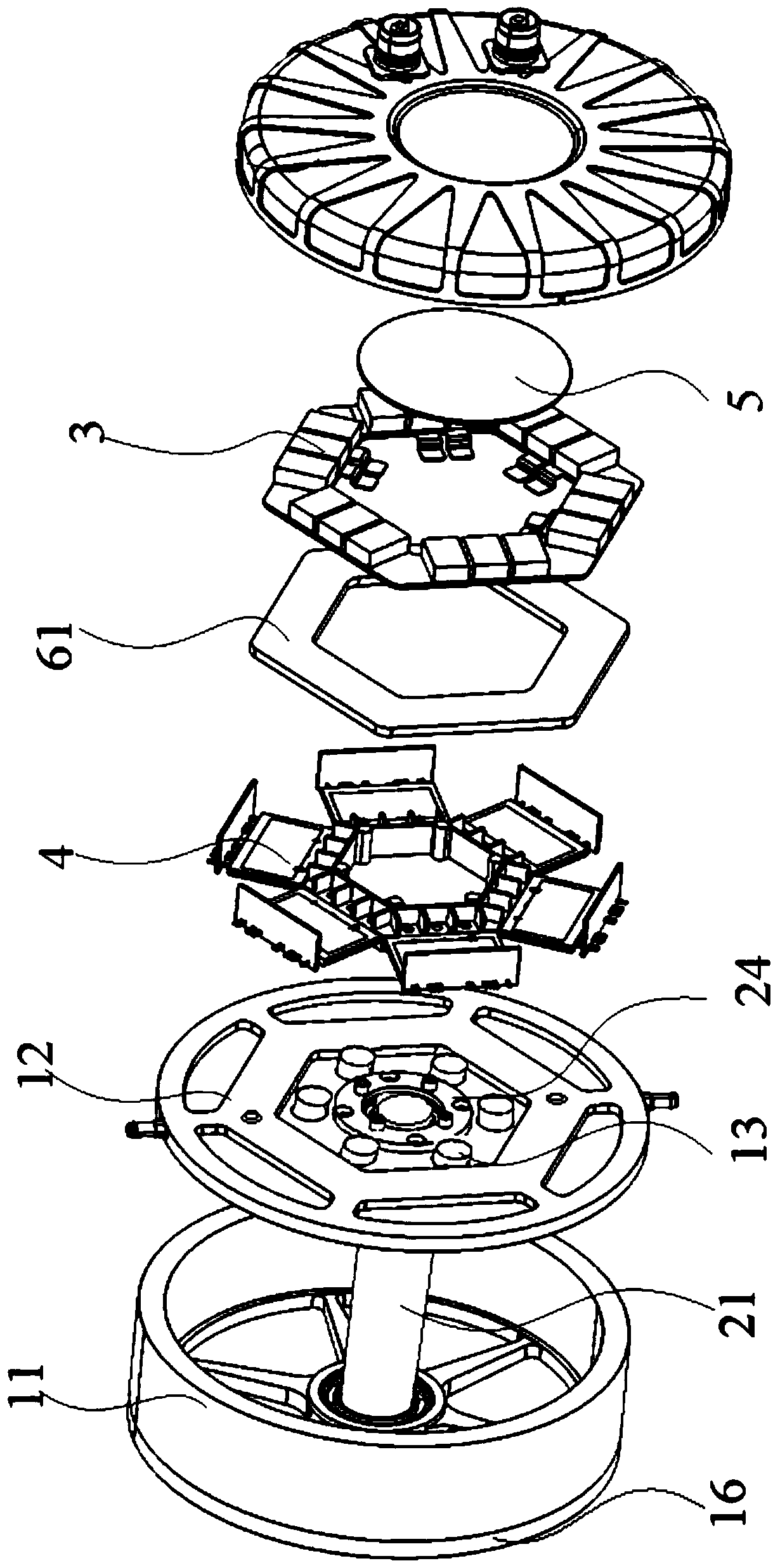

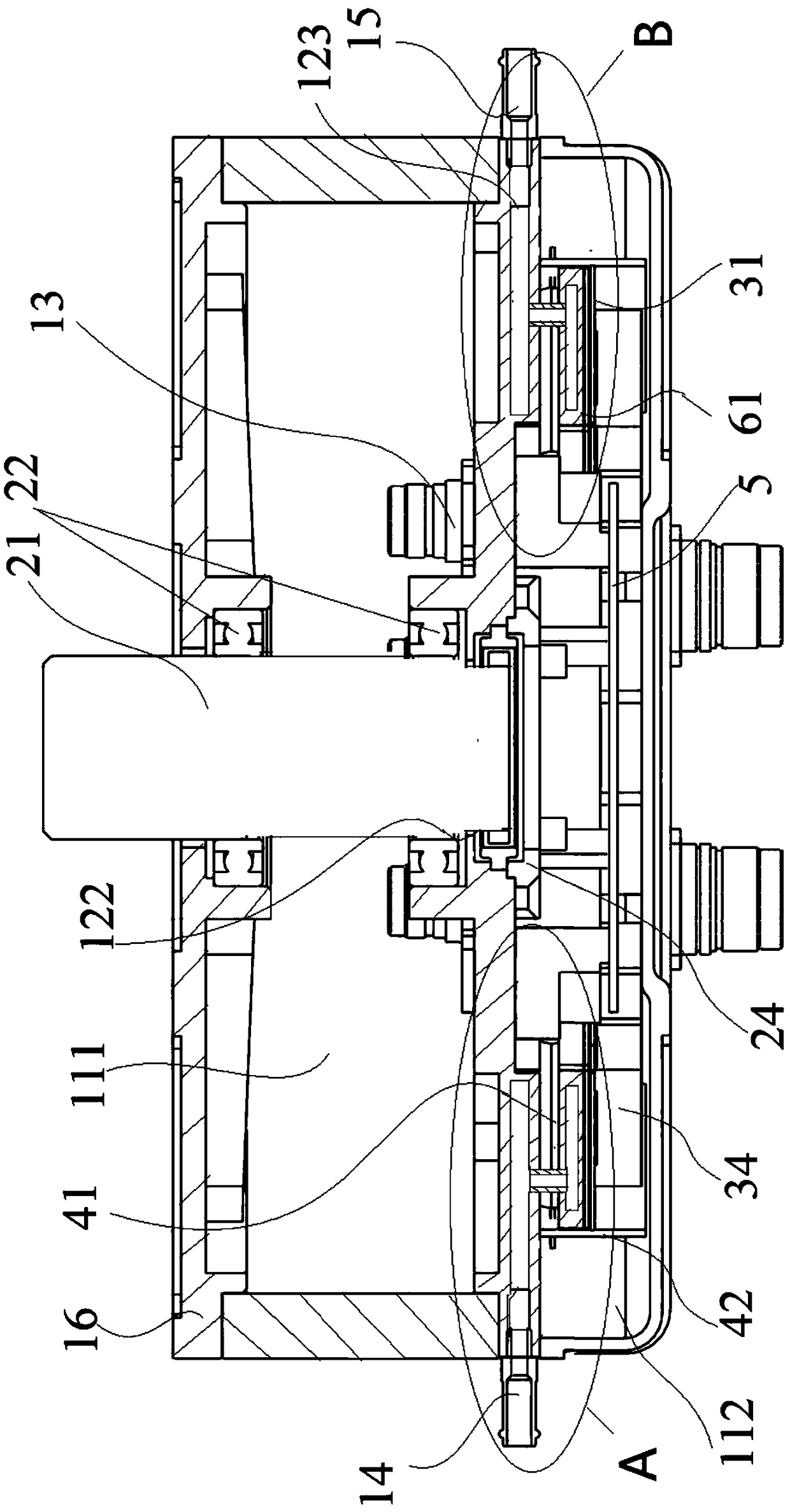

[0064] This embodiment provides an integrated system of a motor and a controller, such as Figure 1 to Figure 9 As shown, it includes: a housing 11, a first end cover 12, a motor body and a controller body. Wherein, the first end cover 12 is arranged in the housing 11, and the inner cavity of the housing 11 is divided into a first cavity 111 and a second cavity 112 with the first end cover 12 as a boundary; the motor body is installed with the first cavity body 111 to convert electrical energy into mechanical energy; the controller body is set in the second cavity 112 to control the action of the motor body.

[0065] like figure 2 and image 3 As shown, the housing 11 includes a second end cover 16 disposed opposite to the first end cover 12 and enclosing a first cavity 111 . As shown in the figure, the motor body has an output shaft 21, a stator (not shown in the figure), a rotor (not shown in the figure) and a coil winding (not shown in the figure).

[0066] Wherein, th...

Embodiment 2

[0088] This embodiment provides an integrated system of a motor and a controller, which differs from the integrated system of a motor and a controller provided in Embodiment 1 in that:

[0089] The power modules 41 can also be three, nine or any multiple of three power modules 41, as long as the power modules 41 are evenly distributed on a circle, in order to cooperate with the commonly used existing three-phase alternating current as the transmission of electric energy Form; at this time, it is ensured that the power modules 41 are evenly distributed on a circle, and at the same time, it is only necessary to ensure that the shape formed by the power conversion assembly 4 adapts to the shape mechanism of the motor body.

[0090] Further, the number of power modules 41 can also be four, five, seven or more, as long as the power modules 41 can be realized as a control source for power output, and convert the direct current input from the input terminal into alternating current ,...

Embodiment 3

[0093] This embodiment provides an integrated system of a motor and a controller, which differs from the integrated system of a motor and a controller provided in Embodiment 1 or Embodiment 2 in that:

[0094] Without considering the number of installed power modules 41 and the influence of the overall shape of the controller body, one, two, three or more power modules 41 can be installed. At this time, it is not necessary to ensure whether the power modules 41 Evenly distributed on the same circle, as long as the connection relationship between the power module 41 , the driving board 42 and the control board 5 is properly ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com