Automatic magnetic steel surface mounting device

A magnetic steel and surface-mounted technology, applied in the direction of electric components, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of difficult quality assurance, glue shortage and overflow, high labor intensity, etc., to ensure consistency and accuracy, reliable control of the amount of glue, and the effect of reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

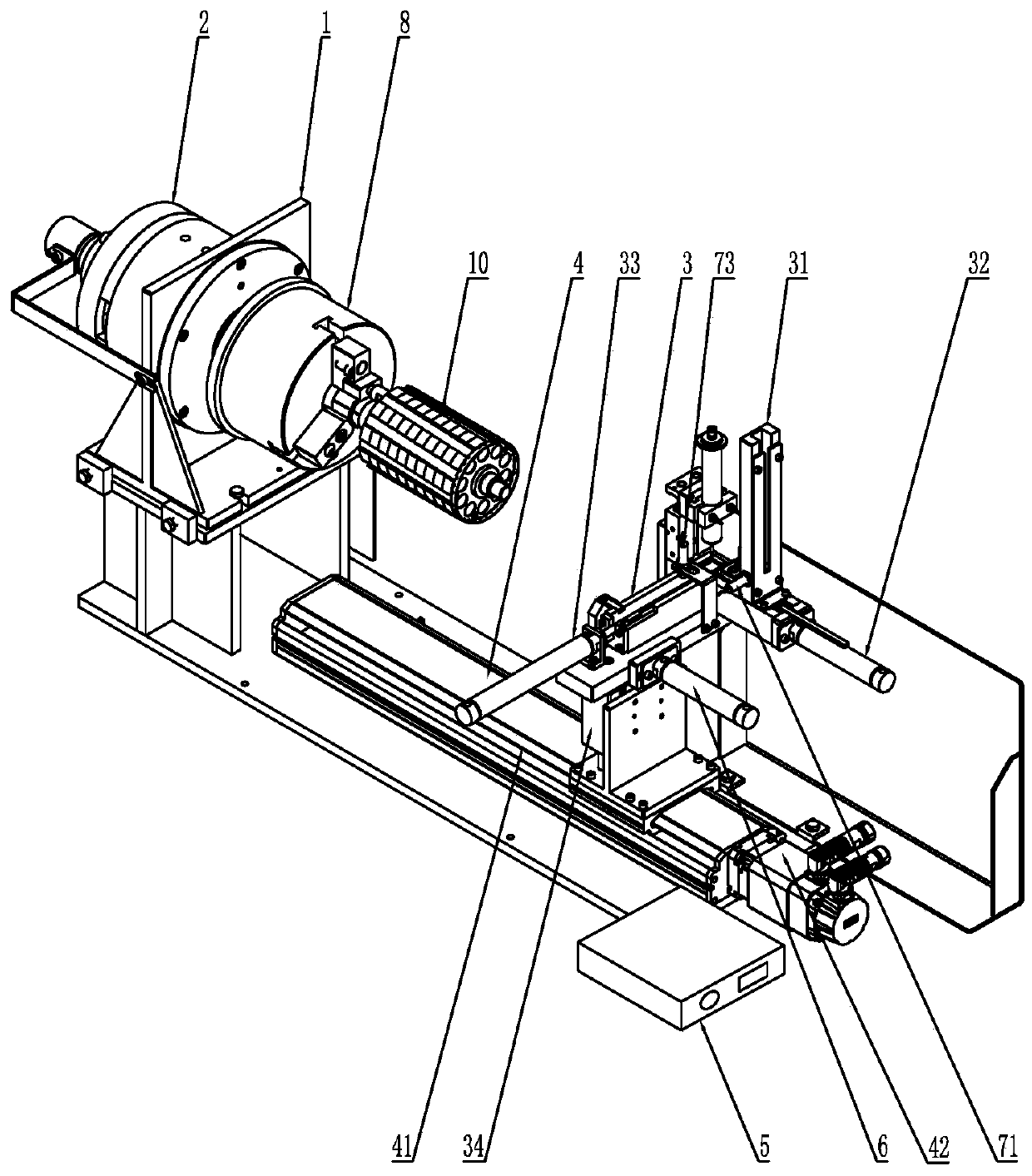

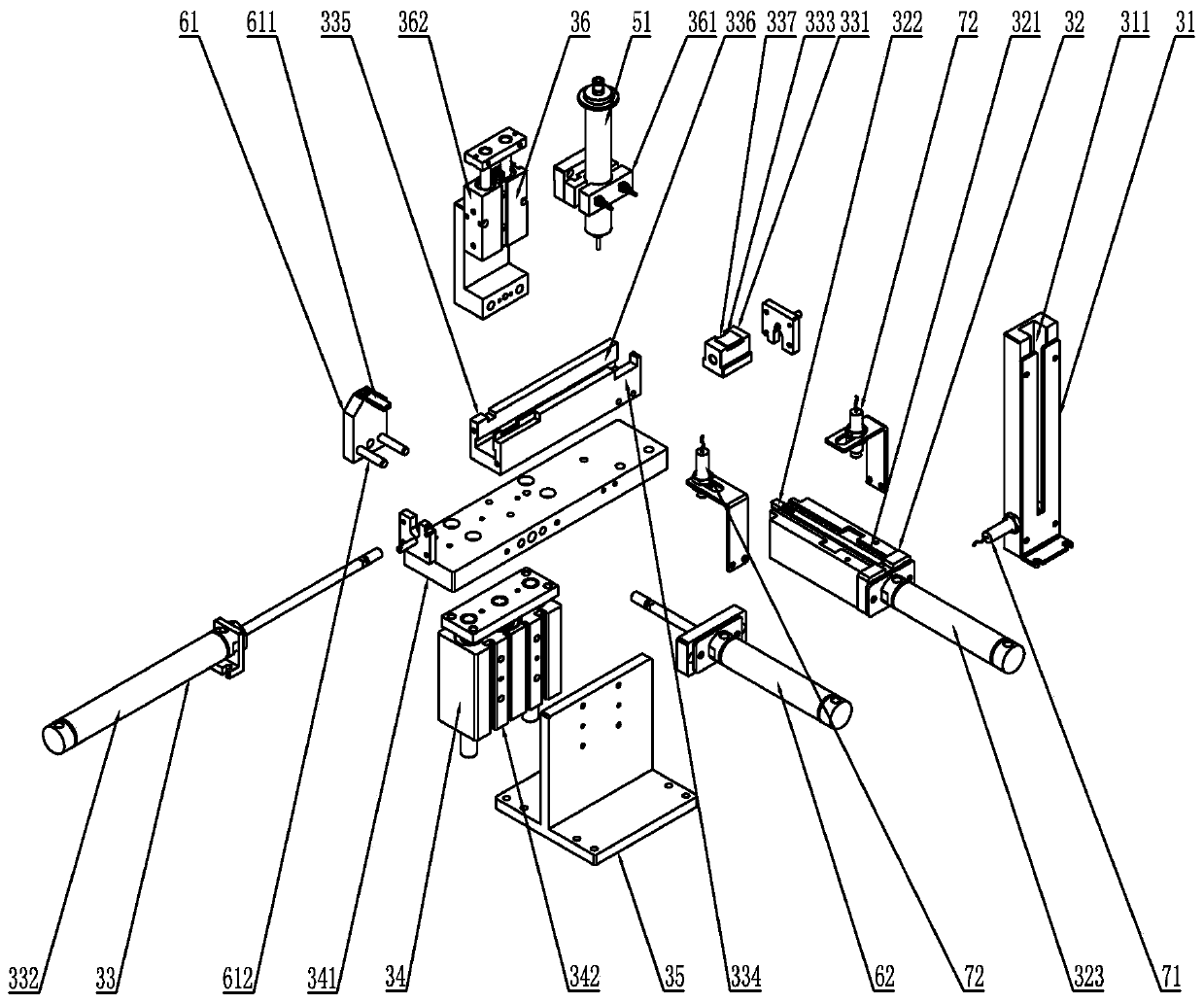

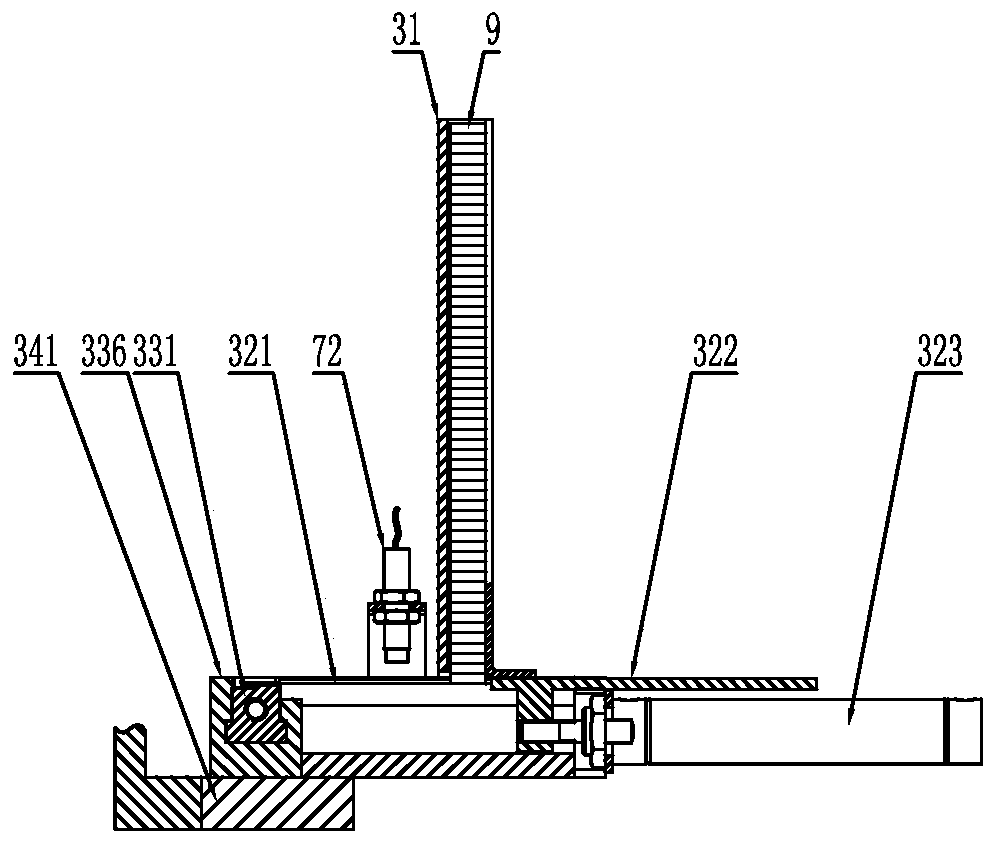

[0030] like Figure 1 to Figure 4 As shown, an automatic surface-mounted magnetic steel equipment includes a motor rotor support structure 1, an angular rotation device 2, a magnetic steel surface-mounted action device 3 and an automatic dispensing device 5, and the angular rotation device 2 can drive the motor rotor 10 in the The motor rotor rotates on the support structure 1, and the angular rotation device 2 includes a power device that provides rotational power, which may specifically be a motor. The magnetic steel surface mount action device 3 includes a storage mechanism 31, a discharge mechanism 32, a first moving mechanism 33 and a lifting and pressing mechanism 34, and the first moving mechanism 33 includes a positioning slider 331 and a positioning slider for driving. Part 331 moves the first power unit 332, the discharge mechanism 32 can take out the magnetic steel from the storage mechanism 31 and send it to the positioning slider 331, and the automatic dispensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com