Tufted chemical fiber carpet capable of being completely recycled and preparation method thereof

A chemical fiber and carpet technology is applied in the field of fully recyclable tufted chemical fiber carpet and its preparation, which can solve the problems of inconspicuous film fixing effect, no anti-slip effect, waste of leftover materials, etc., and achieves improved pile fixing effect and low cost. , The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a fully recyclable tufted chemical fiber carpet and a preparation method thereof, the method comprising the following steps:

[0039] S1. Selection of chemical fiber yarns: yarns spun from one or more chemical fibers, such as polyester, nylon, acrylic, polyvinyl chloride, polypropylene and other chemical fiber yarns.

[0040] S2. Selection of composite base cloth: use chemical fiber woven or knitted fabric as the base material, lay chemical fiber short fibers on the base material, and then enter the non-woven needle punching machine to form a composite base cloth to obtain a composite base cloth (which is made of chemical fiber woven or Knitted fabric layer and needle-punched chemical fiber non-woven fabric layer) After being rolled up, hot ironing rods are used to carry out ironing treatment to enhance the adhesion of fibers and the flatness of composite base cloth (also can not be ironed).

[0041] The terminology of "non-woven needling processi...

Embodiment 1

[0050] This embodiment relates to a fully recyclable tufted chemical fiber carpet, such as figure 1 shown, including:

[0051] Carpet surface: cut pile layer 1,

[0052] Base fabric layer: composed of base material layer 2 and needle-punched non-woven fabric layer 3; the bottom of needle-punched non-woven fabric layer 3 is a melted and solidified structure formed by melting and solidifying the tufted yarn roots and needle-punched non-woven fabric layer 3 layer.

[0053] The preparation of the fully recyclable tufted chemical fiber carpet comprises the steps:

[0054] 1) Selection of yarn: Select the thickness of 4500DTX polypropylene stock solution dyed BCF yarn.

[0055] 2) Selection of composite base fabric: select polypropylene woven fabric with a weight of 95 g / ㎡ and a density of 114 warp×63 weft as the base material, lay 150 g / ㎡ polypropylene staple fiber on the base material, and then use RY1-4000 non-woven acupuncture Acupuncture is performed on the machine to form ...

Embodiment 2

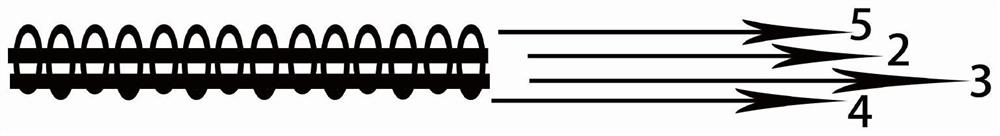

[0060] This embodiment relates to a fully recyclable tufted chemical fiber carpet, such as figure 2 shown, including:

[0061] Carpet surface: including loop pile layer 5,

[0062] Base fabric layer: composed of base material layer 2 and needle-punched non-woven fabric layer 3; the bottom of needle-punched non-woven fabric layer 3 is a melted and solidified structure formed by melting and solidifying the tufted yarn roots and needle-punched non-woven fabric layer 3 layer.

[0063] The preparation of the fully recyclable tufted chemical fiber carpet comprises the steps:

[0064] 1) Yarn selection: 1800D polyester DTY network yarn is used, and the twist direction of the yarn is S twist;

[0065] 2) Selection of composite base fabric: select polyester woven fabric with a grammage of 140 g / ㎡ as the base material, lay 300 g / ㎡ polyester staple fiber on the base material, and then perform acupuncture processing on the RY1-4000 non-woven needle punching machine to form Composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com