Screw, nut and gasket combination

A screw nut and washer technology, applied to nuts, screws, bolts, etc., can solve the problems of multiple installation spaces, multiple installation materials, and long installation time, and achieve the effects of improved fastening effect, low production cost, and good market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

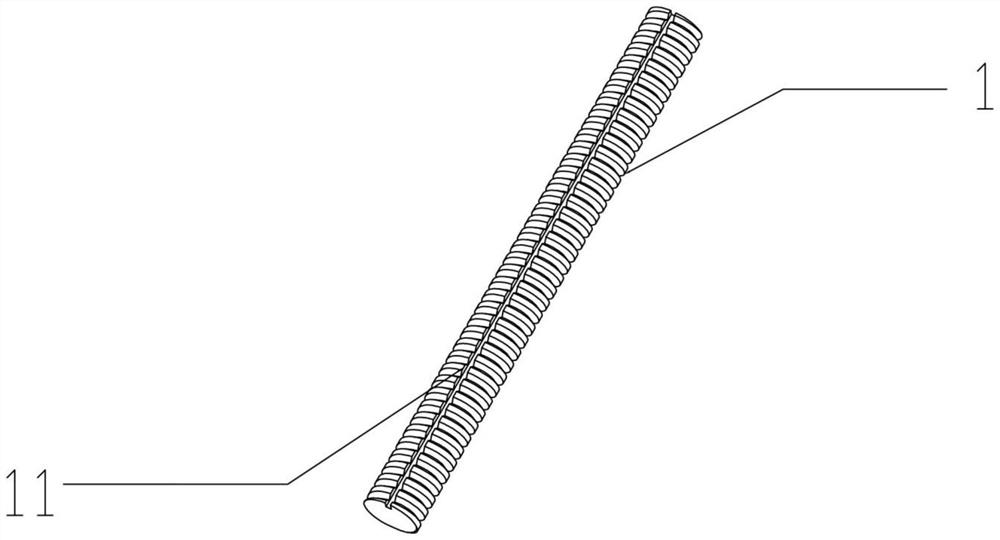

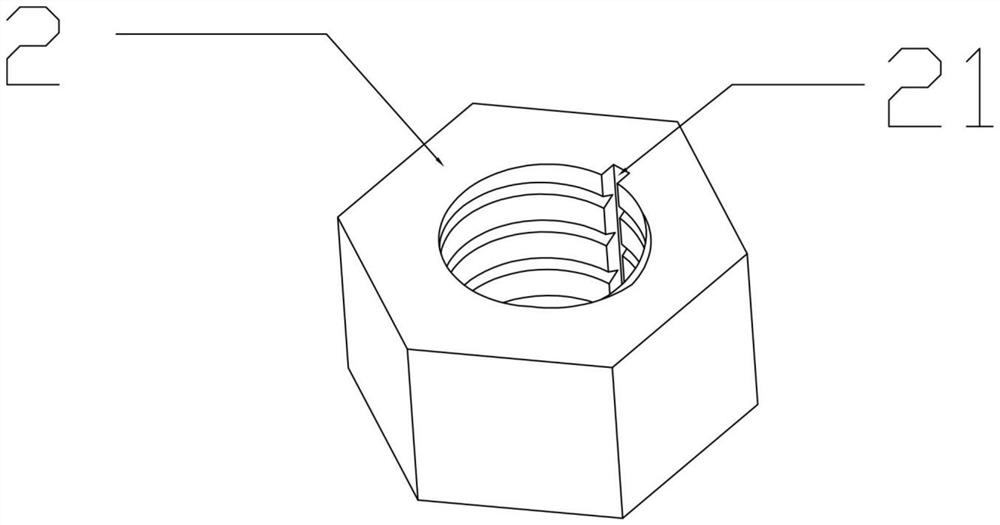

[0020] This embodiment discloses a nut screw washer combination, including a screw 1 , a nut 2 and a washer 3 . The screw 1 is provided with a first groove 11 crossing the threads, and the nut 2 is provided with a second groove 21 crossing the threads.

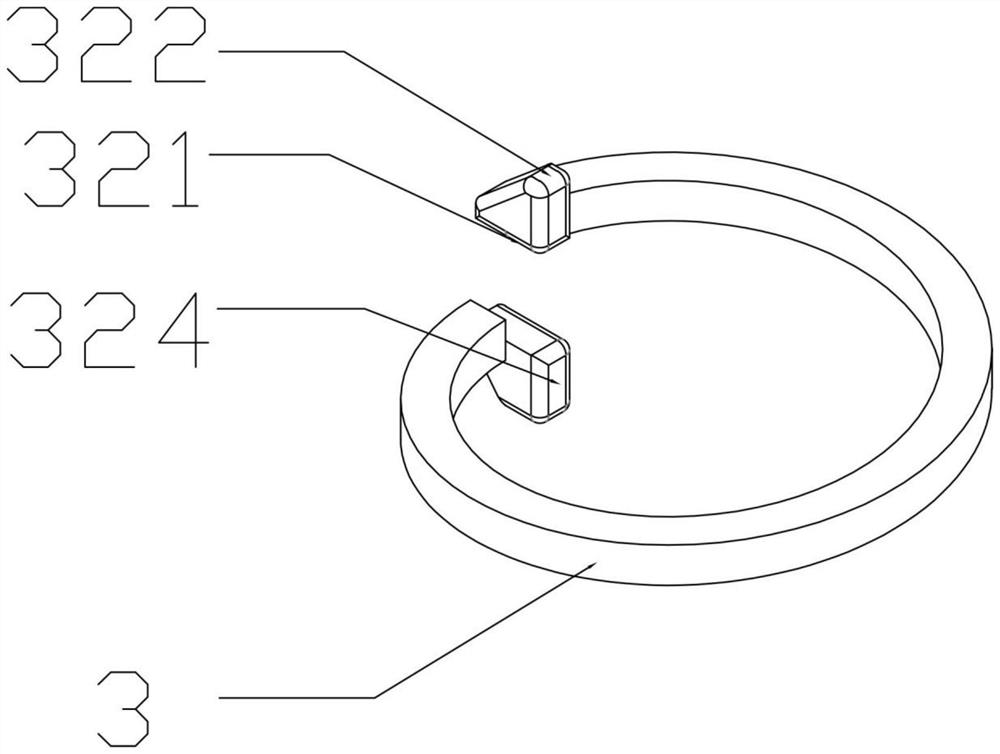

[0021] The gasket 3 includes a ring body 31 and a protruding portion 32, and the ring body 31 is in the shape of an unclosed three-dimensional helix. The protruding portion 32 is fixedly connected to both ends of the ring body 31 . The protruding portion 32 protrudes toward the inner ring of the ring body 31 and both sides in the axial direction of the ring body 31 . like image 3 As shown, the bottom of the protruding portion 32 is a larger end 321, and the top is a smaller end 322. The larger end 321 of the protruding portion is located at half of the ring body, and the smaller end 322 is located at a position away from the ring body 31. There is an inclined part 323 between the larger end 321 and the smaller end 322 near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com