Workpiece fastening and clamping mechanism

A clamping mechanism and workpiece technology, which is applied in workpiece clamping devices, metal processing, manufacturing tools, etc., can solve the problems of reducing production efficiency, increasing time consumption, occupying large funds and equipment resources, etc., and achieves good fastening effect, High-efficiency fastening and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

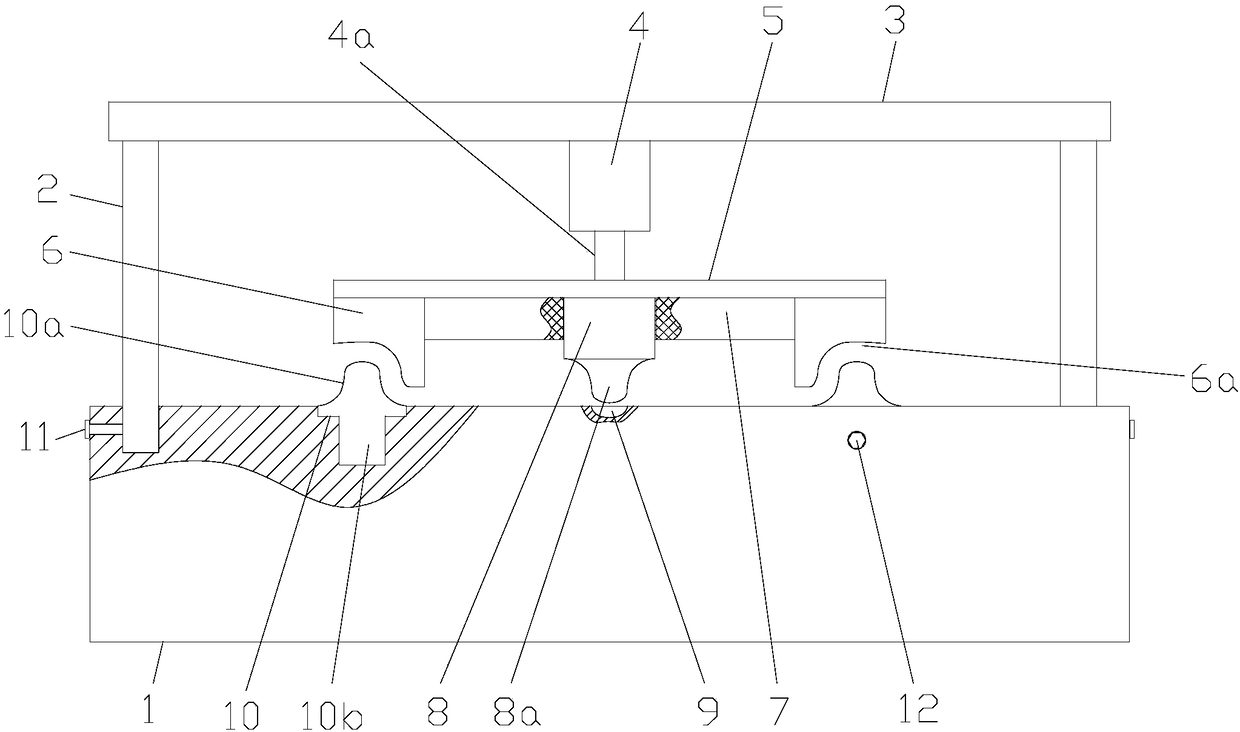

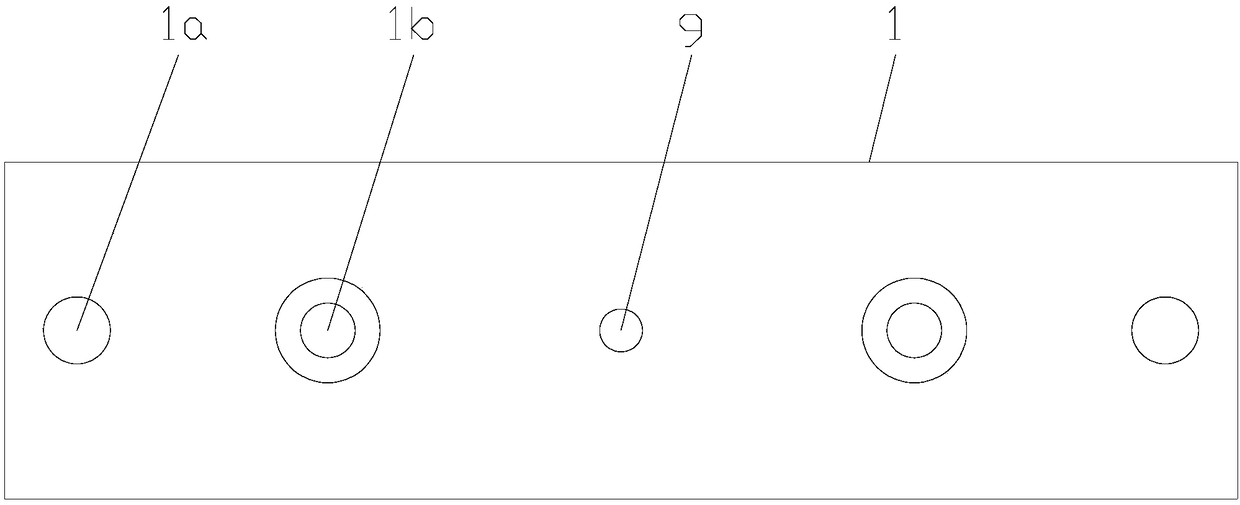

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the working platform of the present invention, as shown in the figure: the workpiece fastening and clamping mechanism of this embodiment includes a working platform 1, a support frame and a pressing assembly for pressing and fastening the workpiece, and the support frame It includes uprights 2 arranged symmetrically on both lateral sides of the working platform and a cross support beam 3 fixed on the top of the two uprights 2, and the pressing assembly includes a lifting cylinder 4, a connecting plate 5, a pressing block I6, a pressing block II8, and a buffer member 7 , the lifting cylinder 4 is fixed on the bottom of the middle of the cross support beam 3, the connecting plate 5 is fixed on the end of the piston rod 4a of the lifting cylinder 4, and the briquetting block I6, briquetting block II8 and buffer member 7 are fixed on the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com