Patents

Literature

61results about How to "Automation for convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

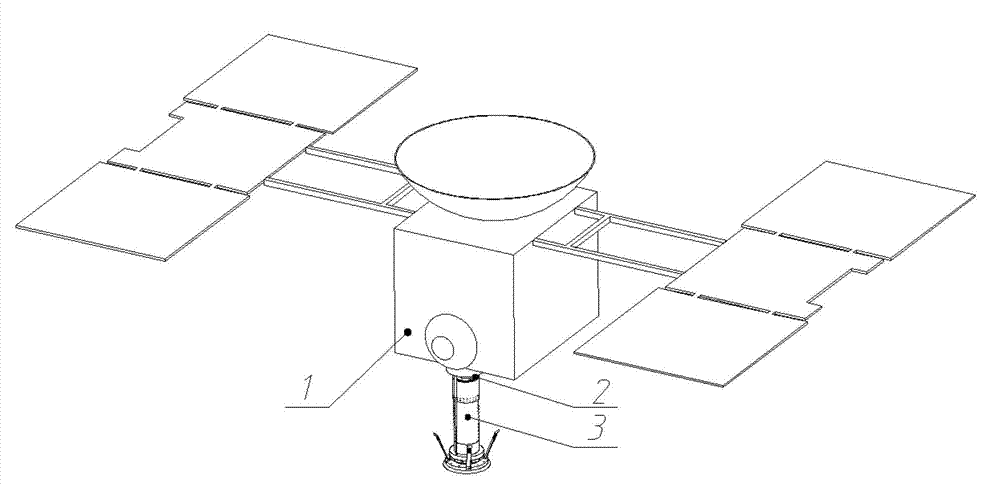

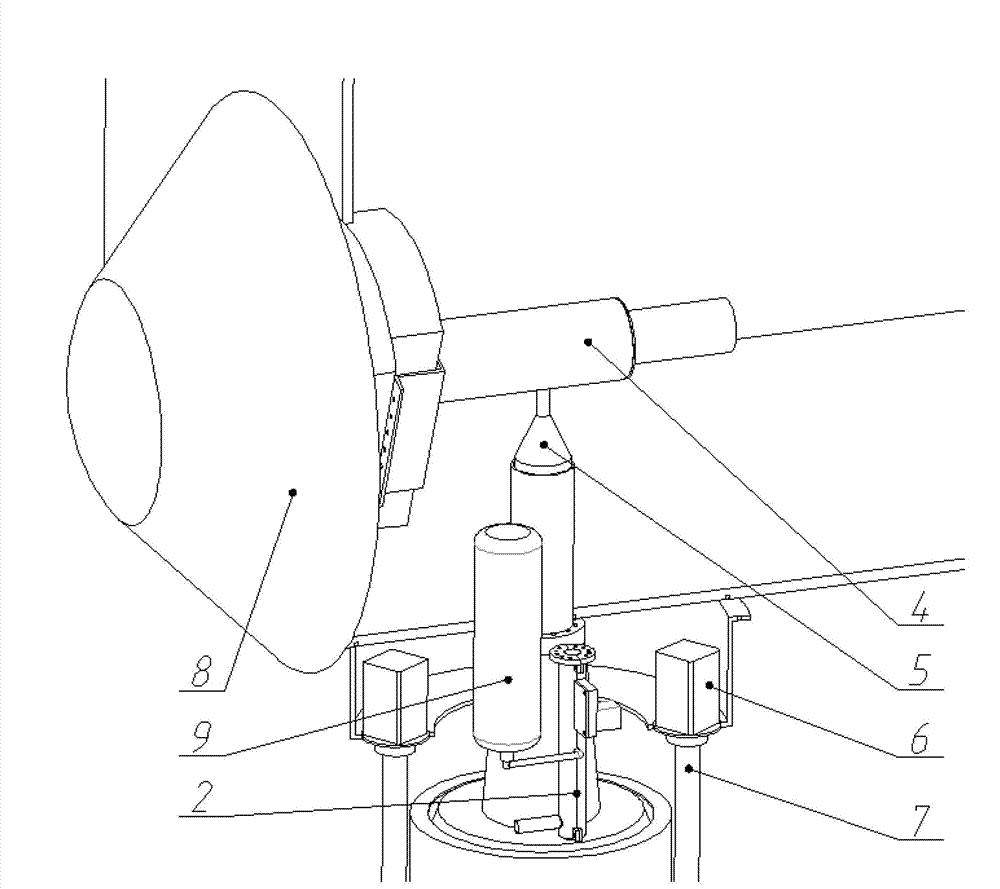

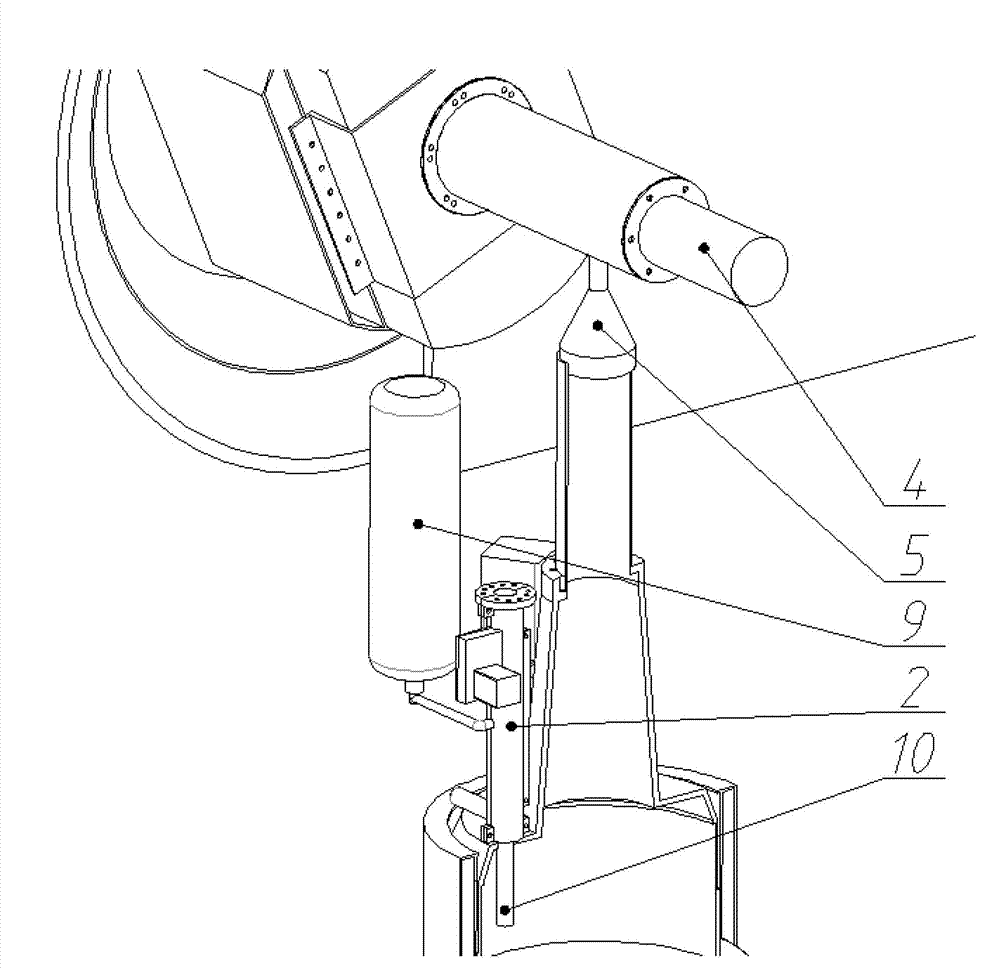

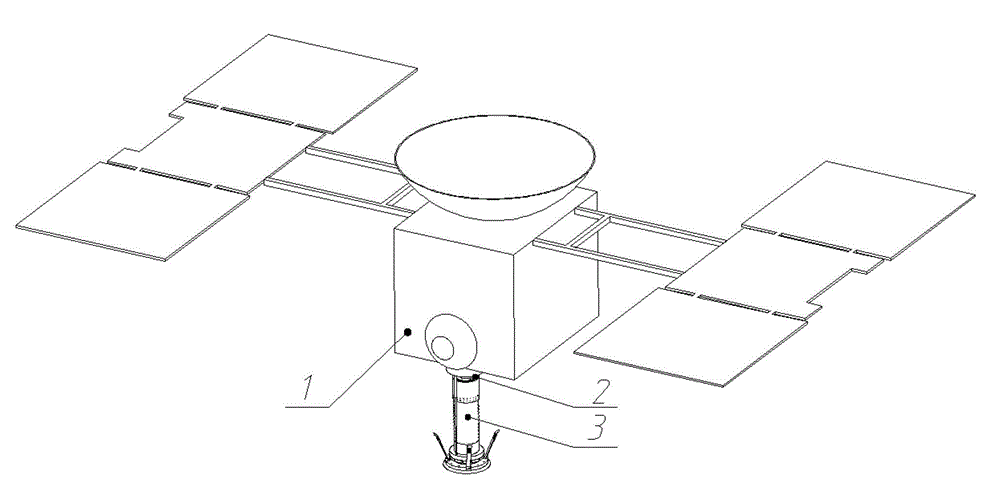

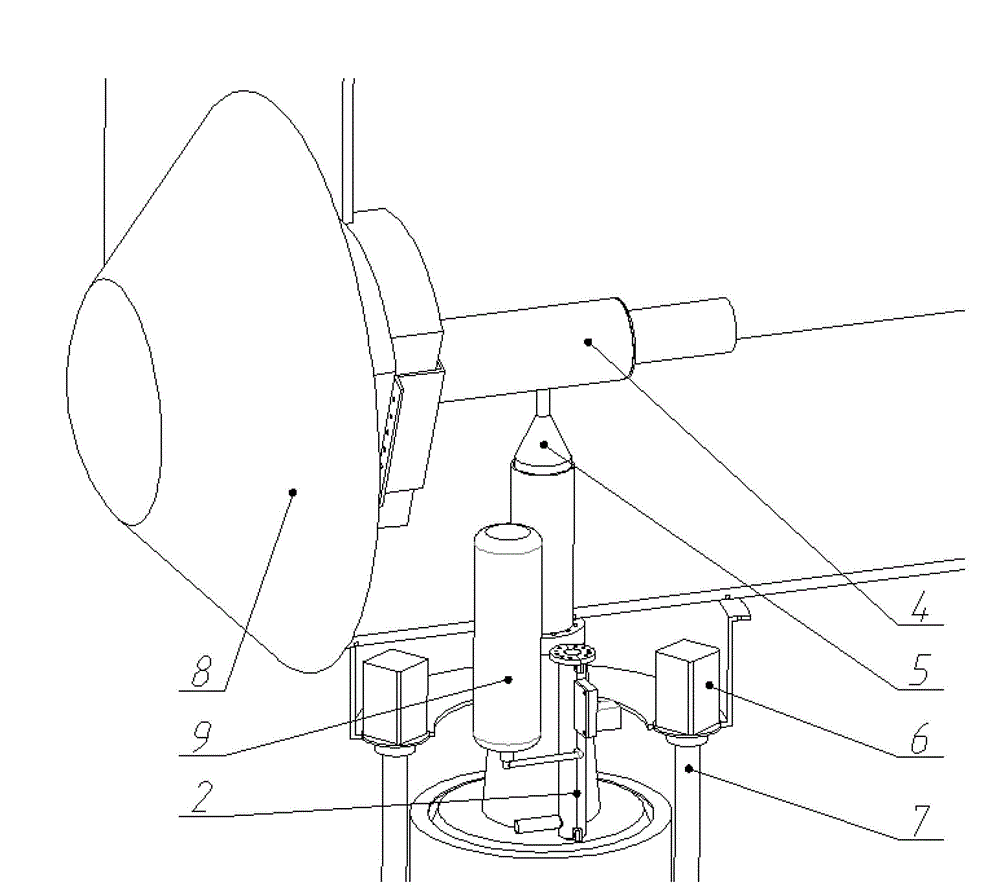

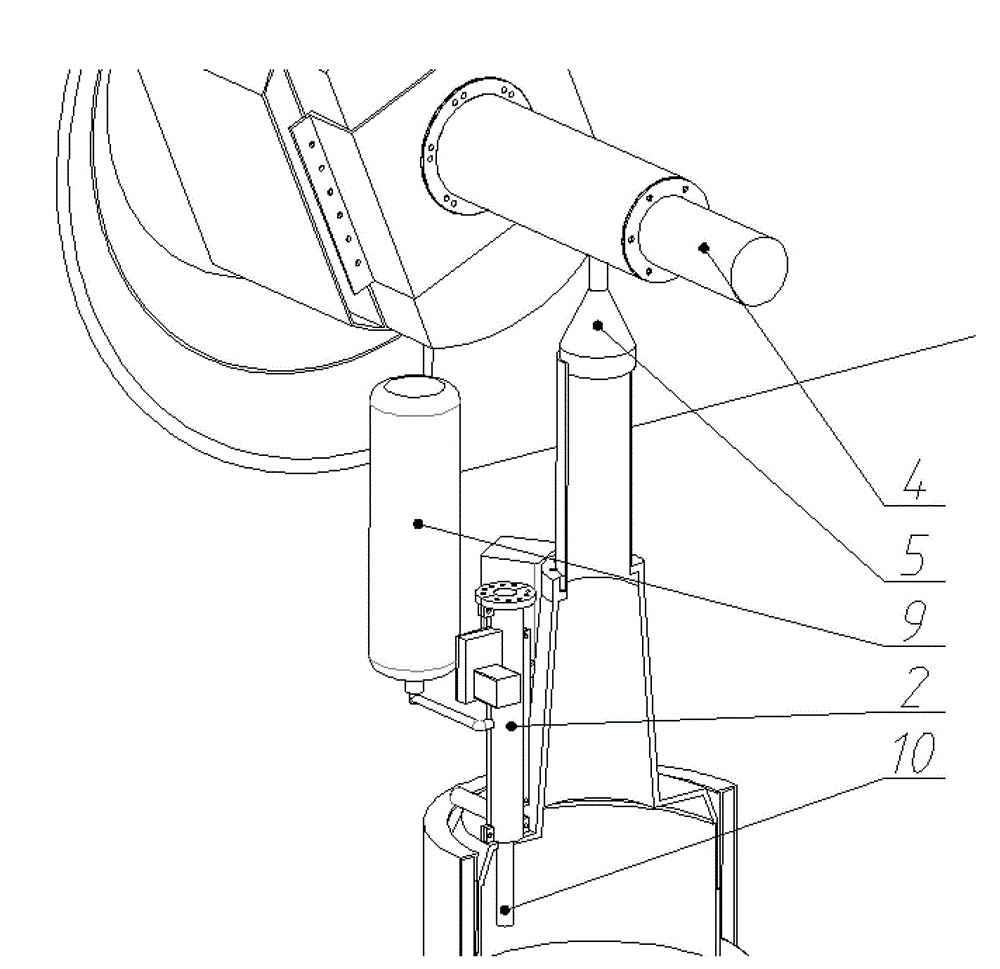

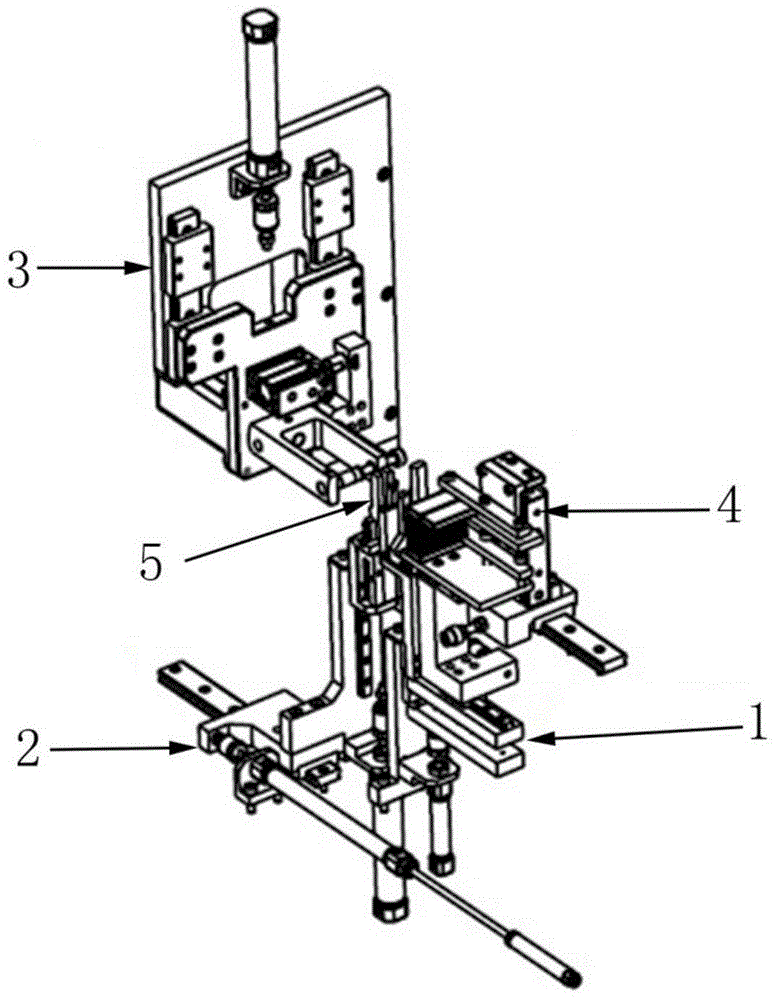

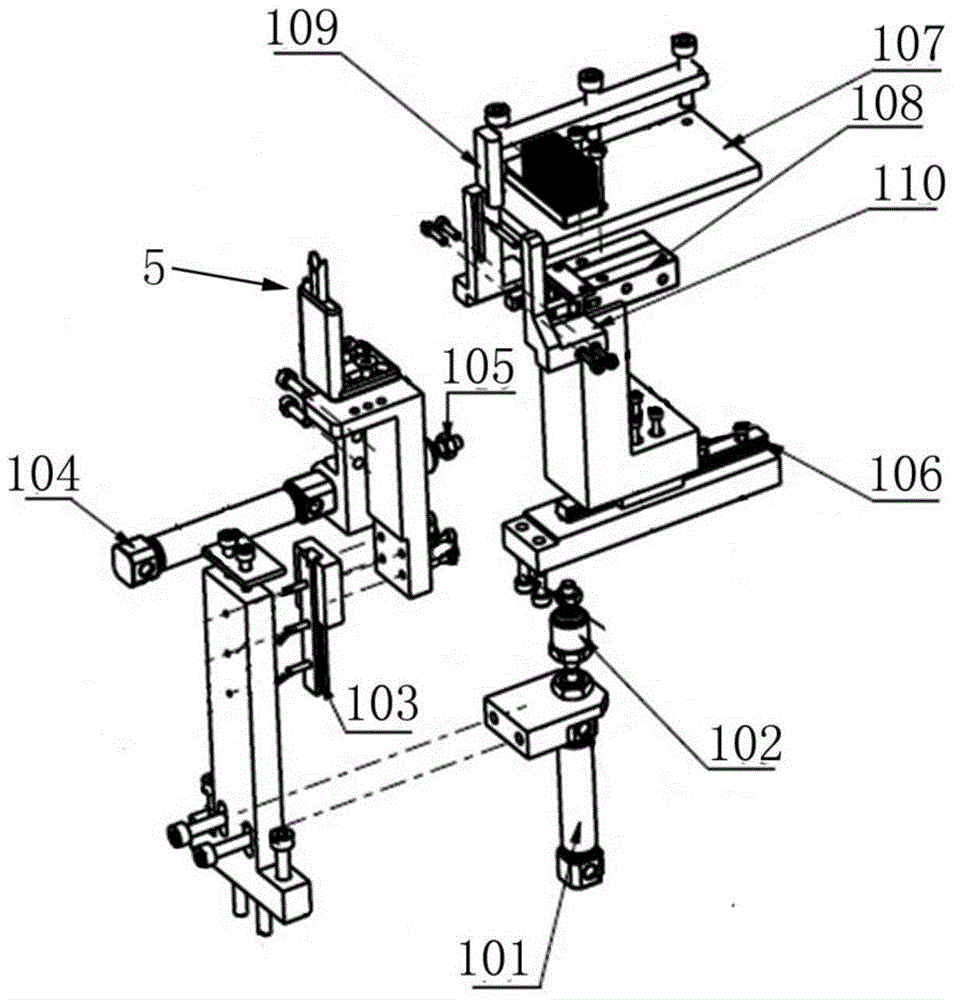

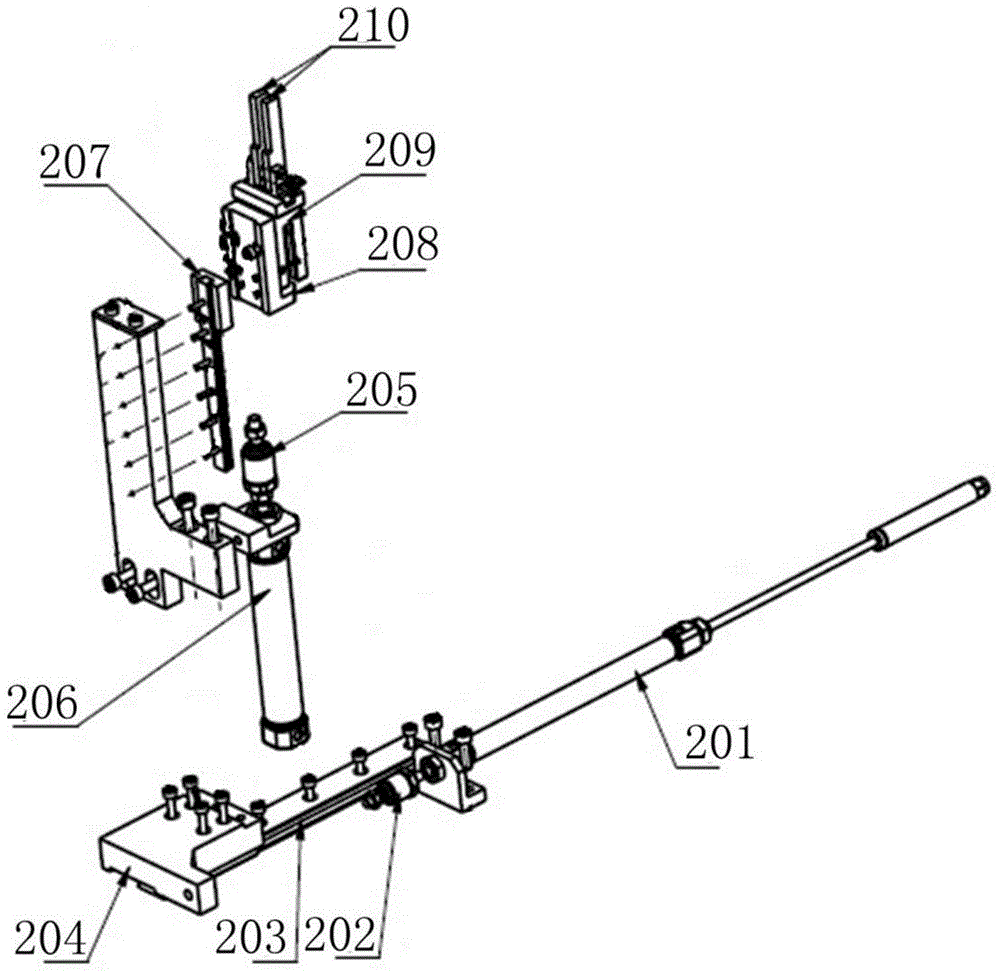

Deep-space asteroid sample collection detector

ActiveCN102879219ALight in massThe overall structure is simple and reliableWithdrawing sample devicesMotor driveEngineering

The invention discloses a deep-space asteroid sample collection detector which comprises a detector housing, a sampling device, a protection device, a recovery device, a heat insulation material, and a control unit; when the asteroid detector lands, mechanical grippers on the protection device are unfolded; a motor-driven lead screw allows a flexible extending material to extend to a limit length so as to be used as a conveying pipeline for dust particle samples and be used for protection of the detector; then the sampling device launches ejection balls which bump the asteroid surface through the pipeline of the protection device; the sputtered dust particles are introduced into the recovery device of the detector through the conveying pipeline of the protection device, and are packaged isolatedly. The invention is an integrated device with the functions of asteroid sample collection, recovery, and packaging, and protection of the detector itself during the sampling process is also considered.

Owner:ZHEJIANG UNIV

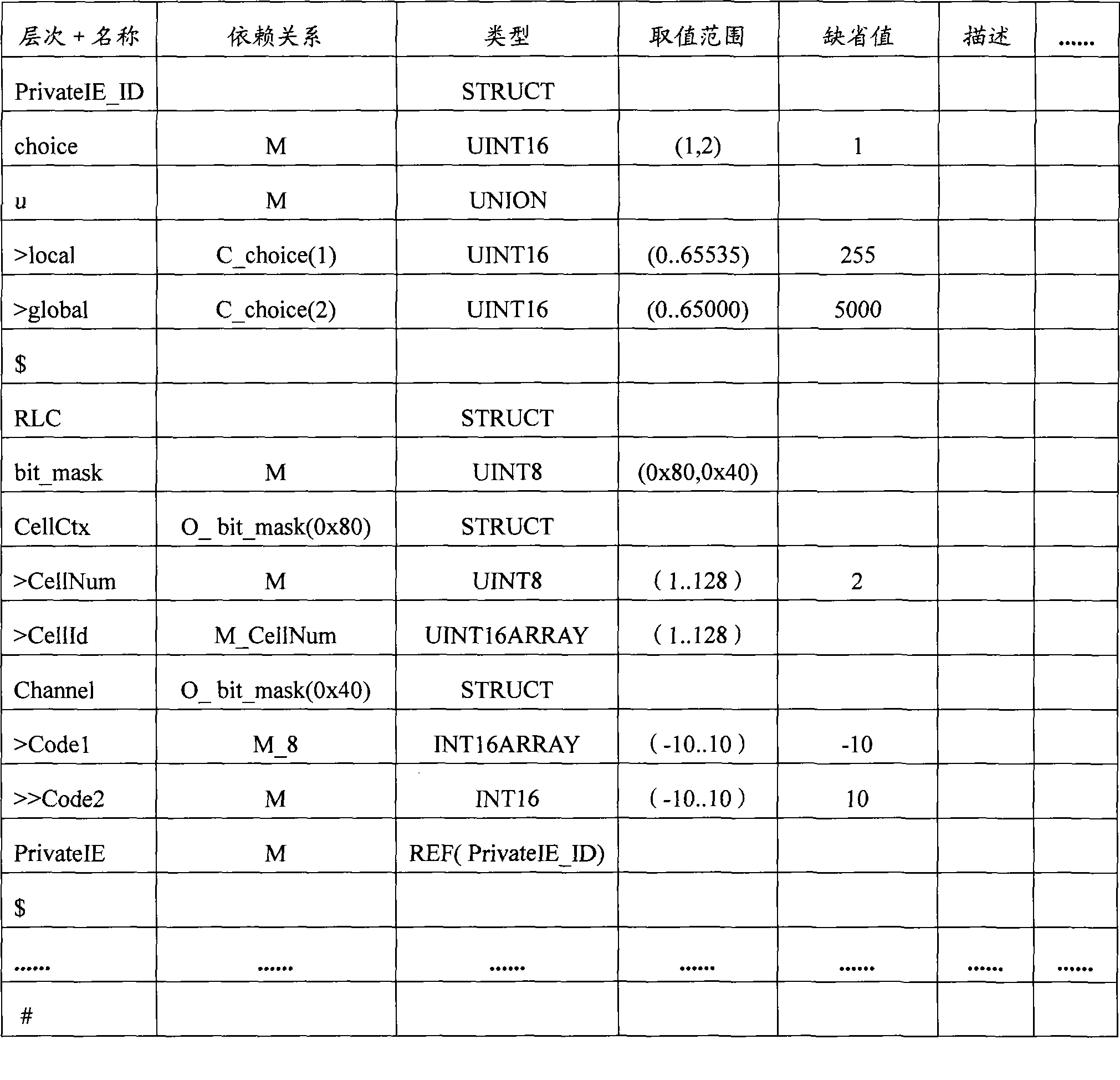

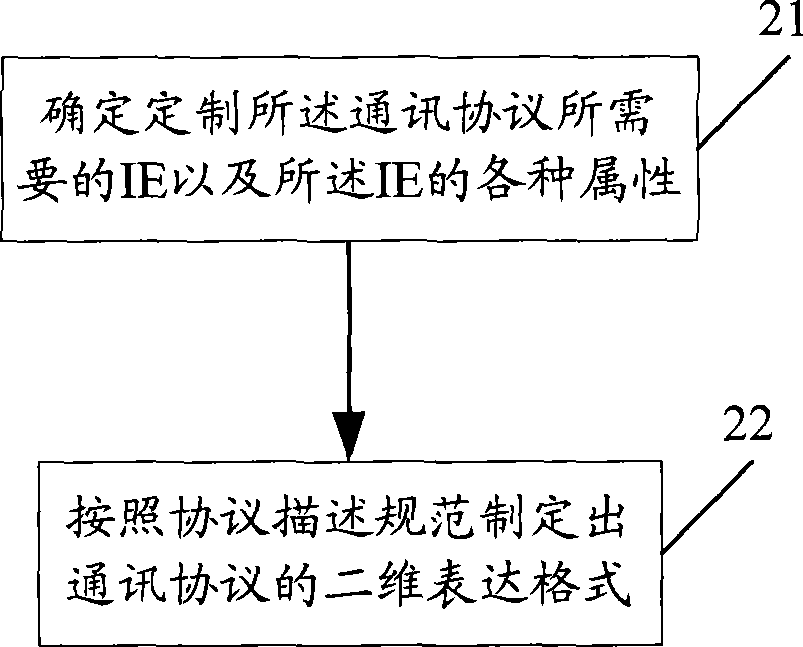

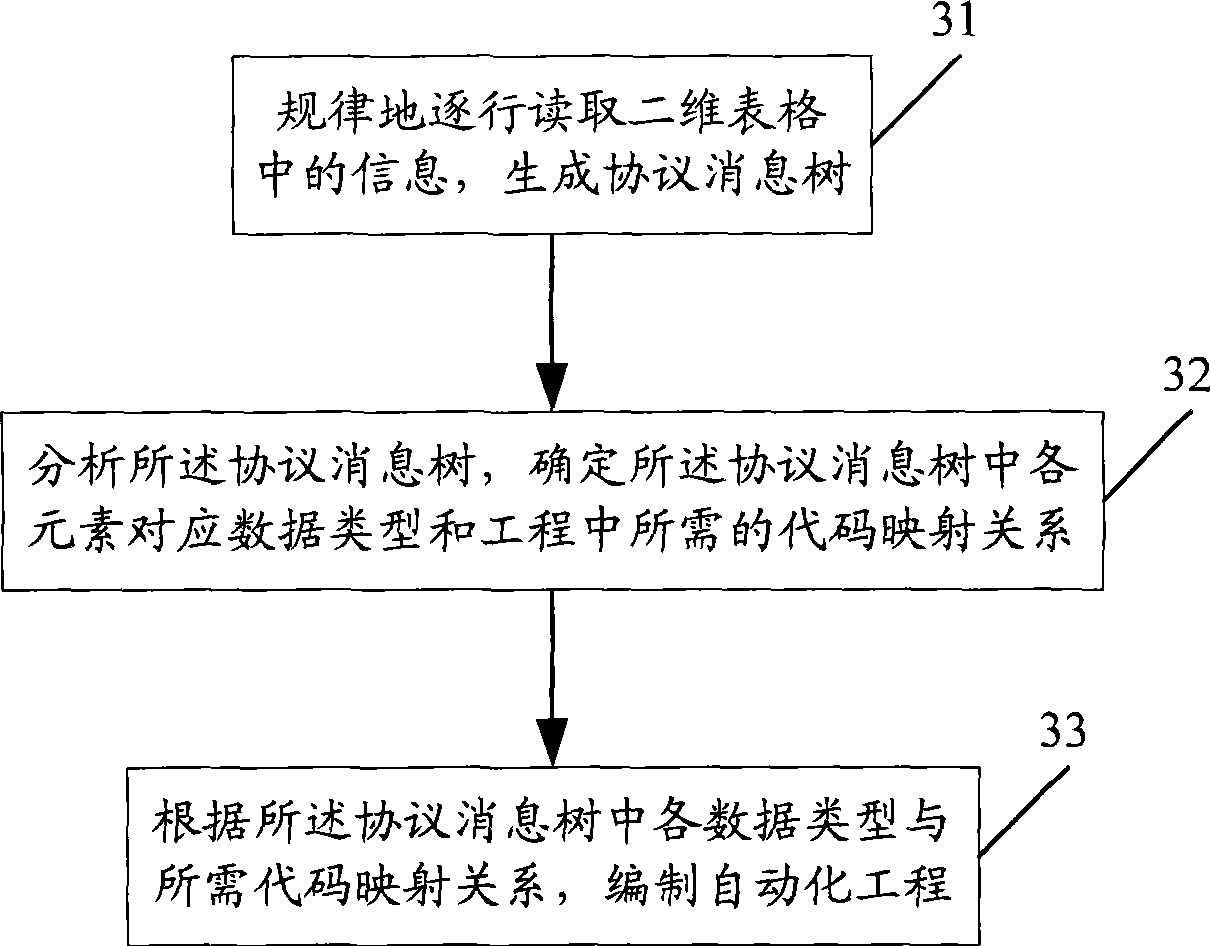

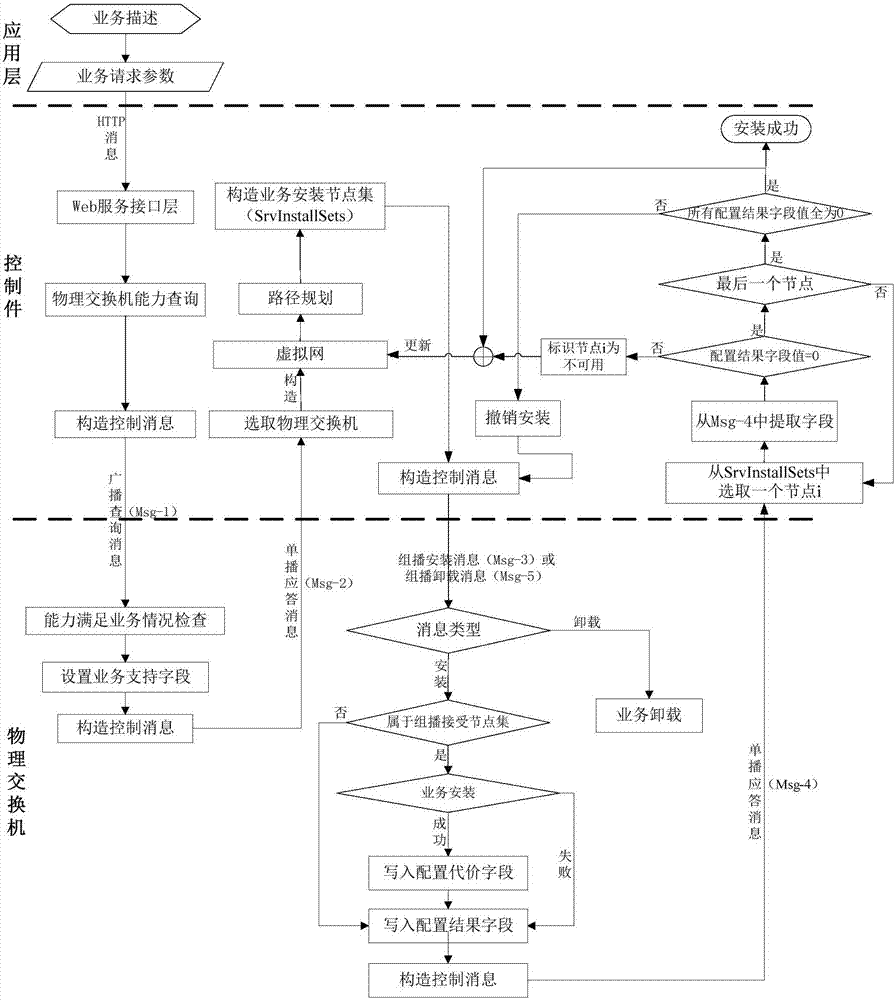

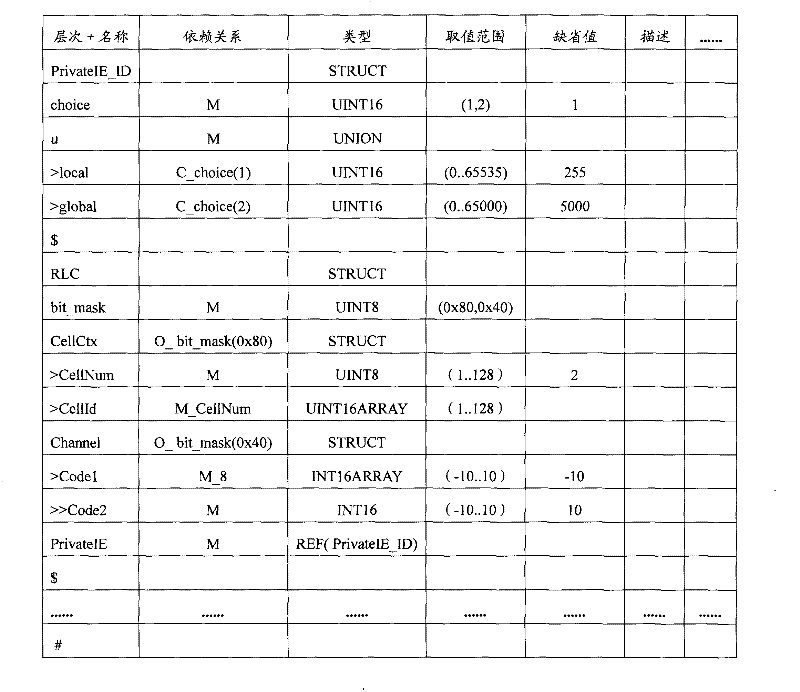

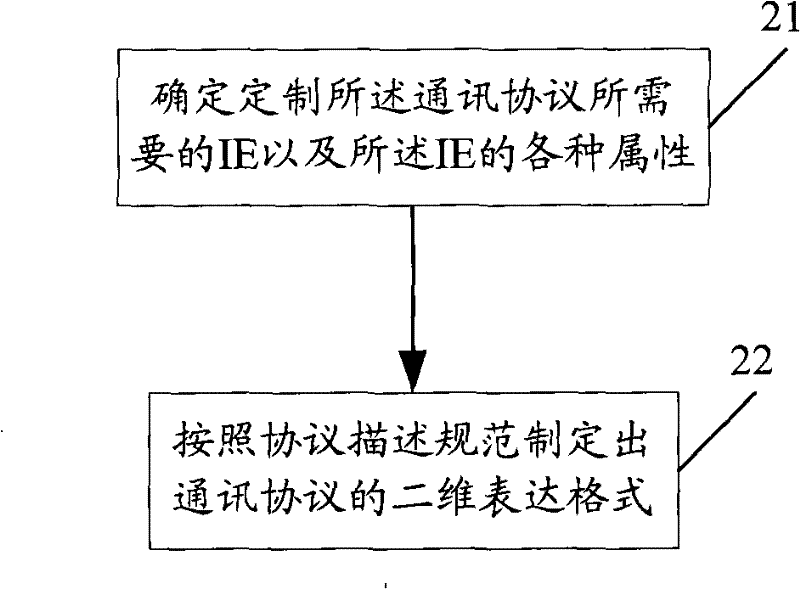

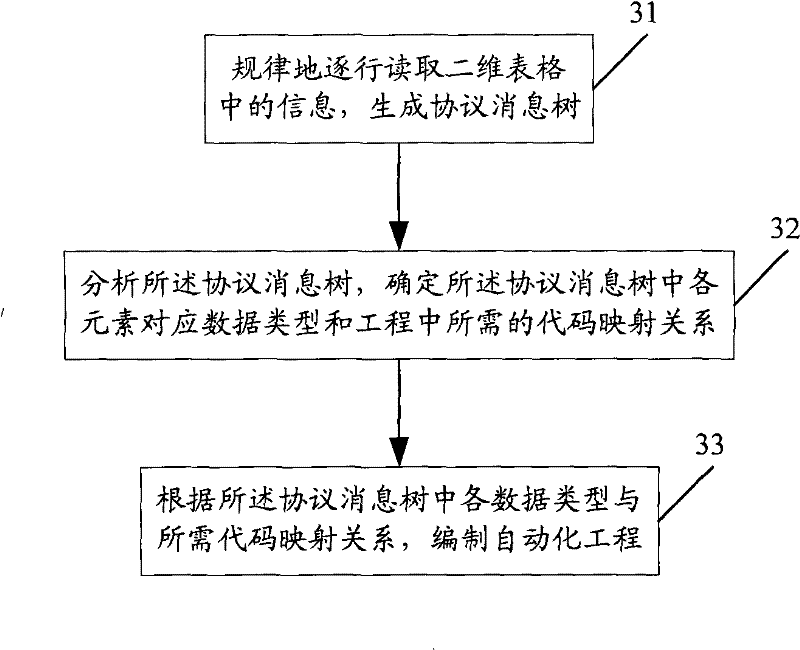

Method and apparatus for customizing communication protocol, method and apparatus for converting communication protocol description

ActiveCN101370003AAutomation for convenienceThe description method is intuitiveTransmissionComputer hardwareCommunications protocol

The invention discloses a method for customizing communication protocol which comprises: determining information element IE needed by customized communication protocol and all kinds of attributes of the IE, matching the IE and attribute of IE to two-dimension relation according to level of IE and dependence relation of IE, matching different attributes of same IE to same row of two-dimensional relation, matching same attribute of different IE to same list of two-dimension relation. The communication protocol needed to be customized can be intuitively and regularly represented through IE, IE level, dependence relation of IEs and other attribute of IE because the communication protocol is described by adopting two-dimension relation, further program code aiming at the communication protocol is developed more easily, automation of the communication protocol is easy. The invention also discloses a device for customizing communication protocol, method and device for converting communication protocol description.

Owner:DATANG MOBILE COMM EQUIP CO LTD

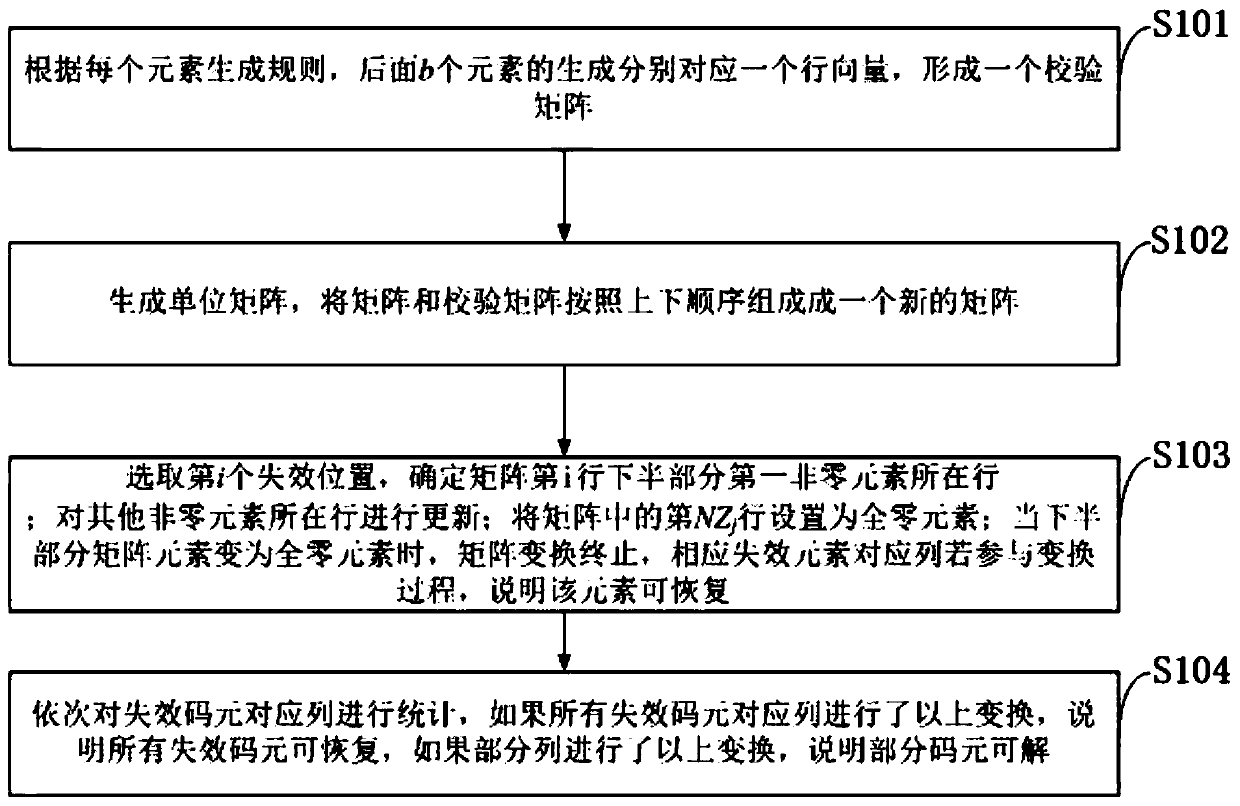

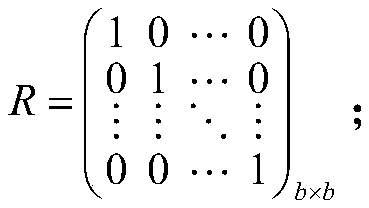

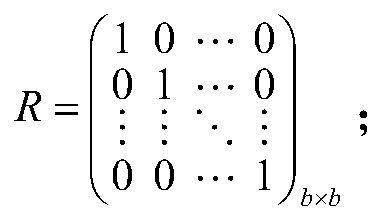

Efficient erasure code lightweight automatic decoding method in finite field and intelligent terminal module

ActiveCN110837436AEliminate inversionAutomation for convenienceRedundant data error correctionComplex mathematical operationsDirect computationInformation processing

The invention belongs to the technical field of information processing, and discloses an efficient erasure code lightweight automatic decoding method in a finite field, and an intelligent terminal module. The method comprises the steps: forming a check matrix according to each element generation rule; generating a unit matrix, and forming a new matrix by the matrix and the check matrix according to an up-down sequence; selecting the ith failure position, and determining a first non-zero element at the lower half part of the ith column of the new matrix; updating the row where other non-zero elements are located; setting the NZj row in the matrix as an all-zero element; when the matrix elements of the lower half part become all-zero elements, ending matrix transformation, wherein thecorresponding columns of the corresponding failure elements can be recovered if participating in the transformation process; and calculating the failure code elements in sequence. The failure code elements can be obtained through direct calculation, the thought is concise, code implementation of software and hardware is facilitated, matrix inversion operation on a finite field is eliminated, thecalculation workload required by decoding is greatly reduced, and the operation efficiency is improved.

Owner:CHENGDU UNIV OF INFORMATION TECH

A Deep Space Asteroid Sample Collection Probe

ActiveCN102879219BLight in massThe overall structure is simple and reliableWithdrawing sample devicesMotor driveEngineering

Owner:ZHEJIANG UNIV

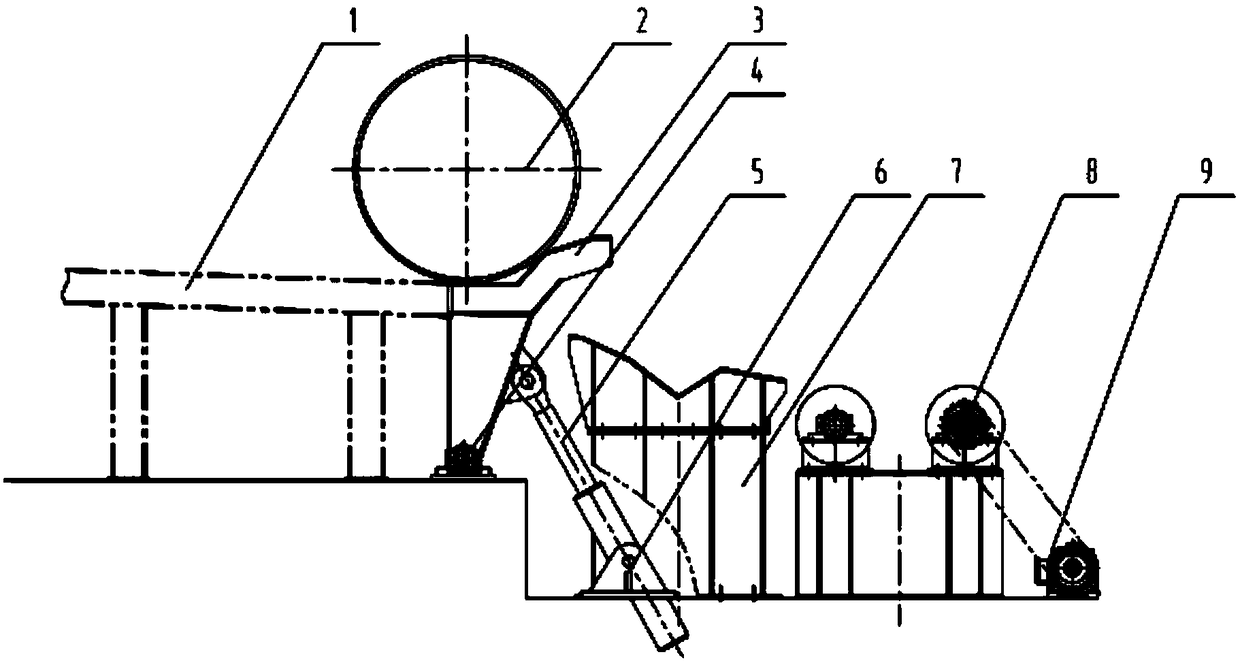

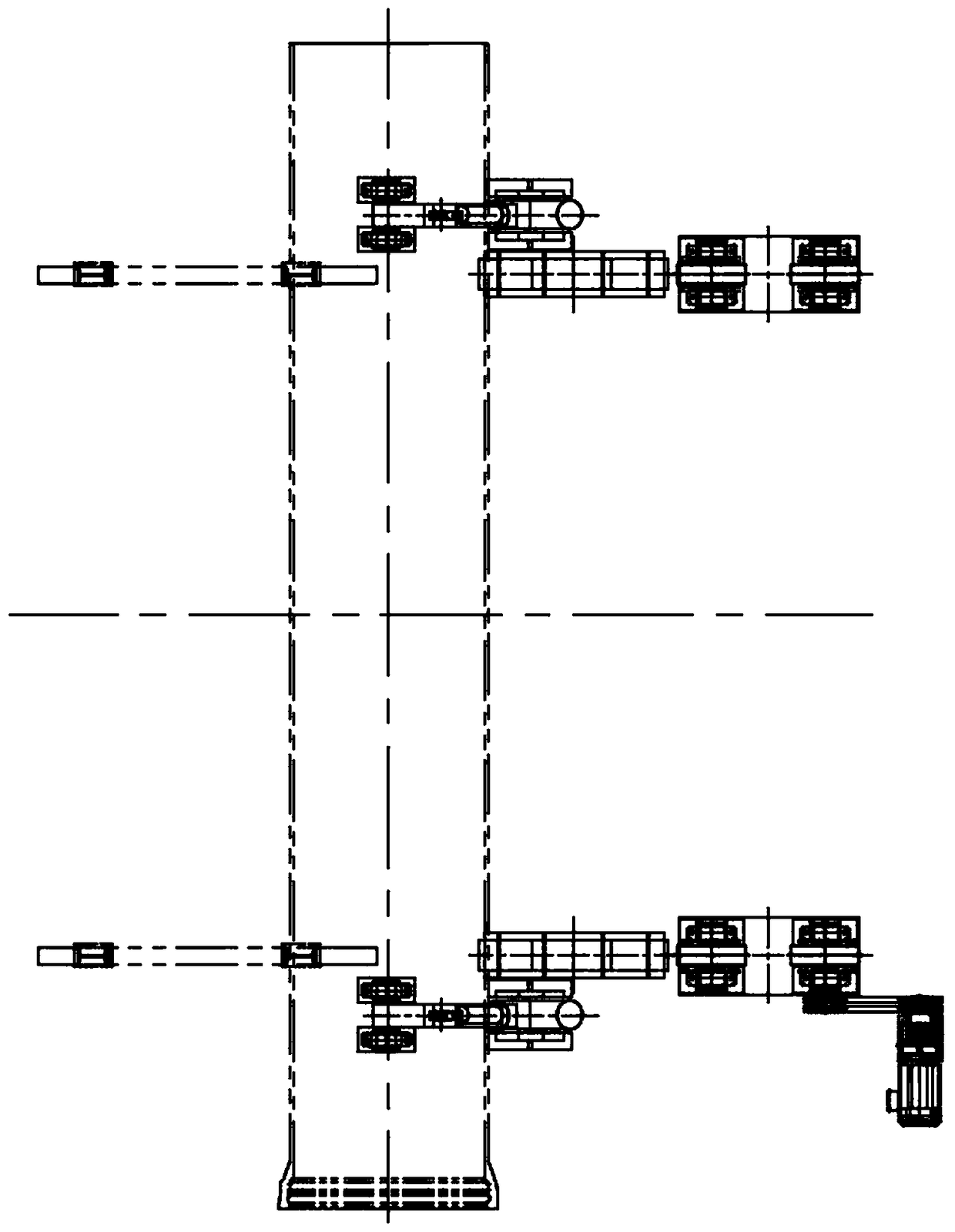

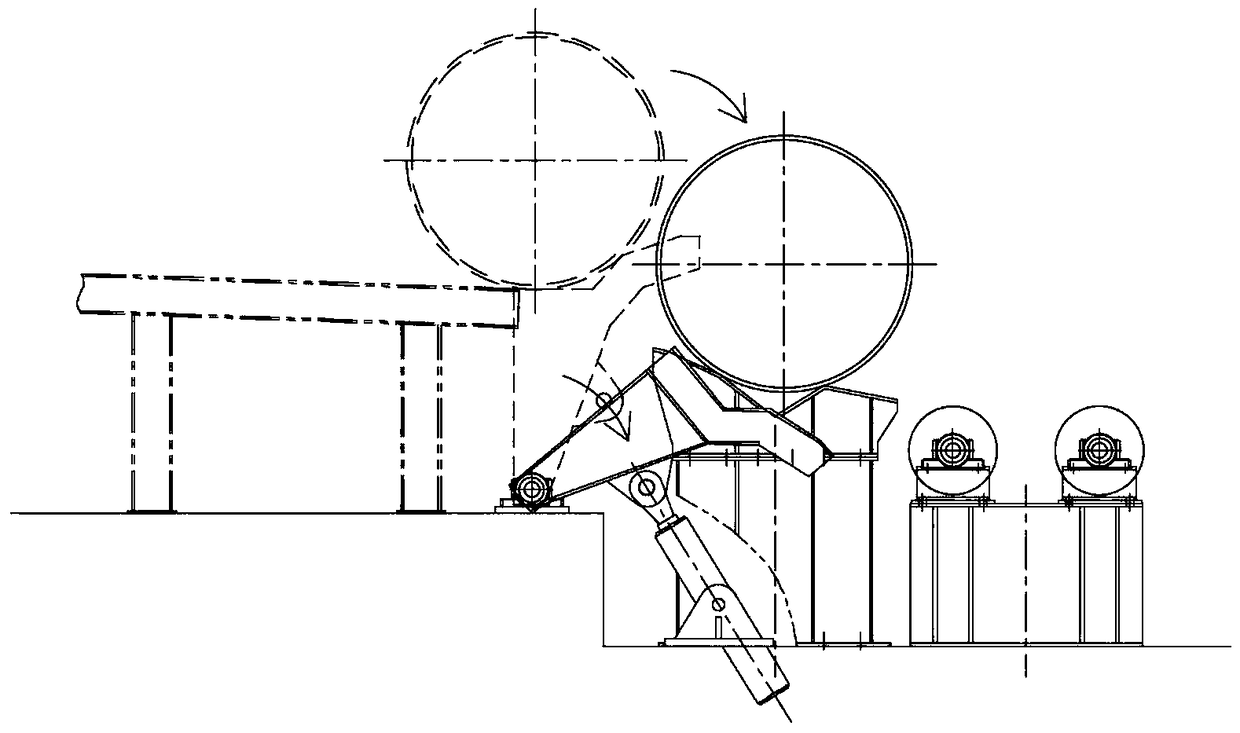

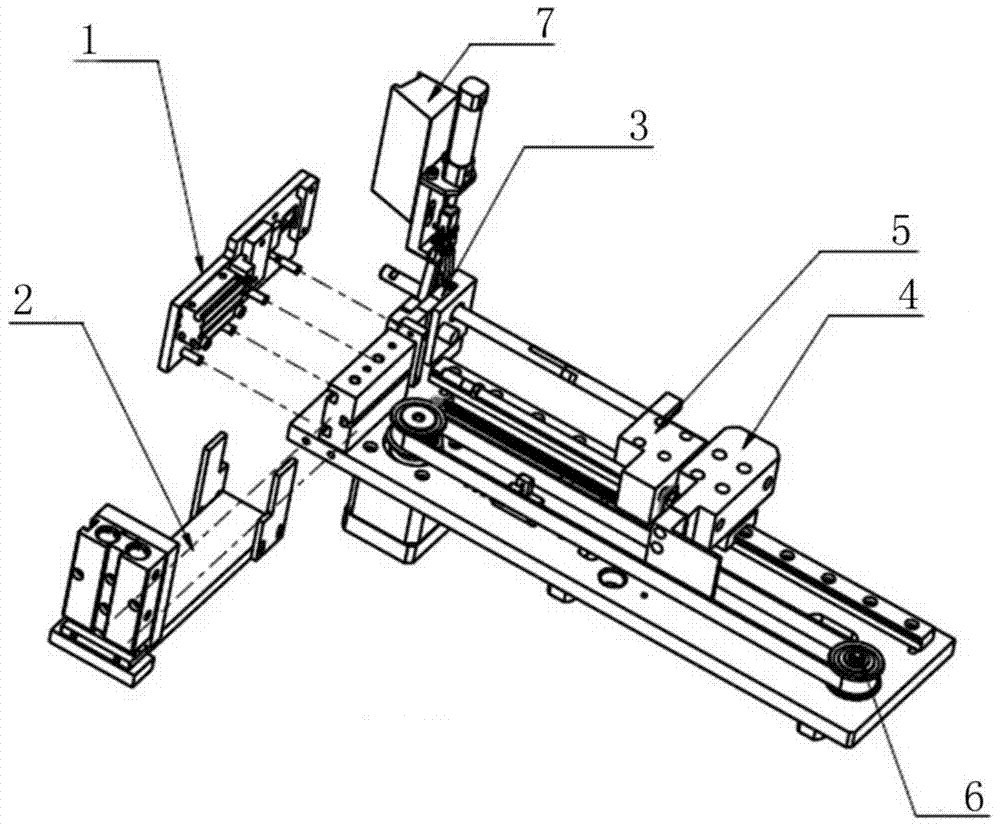

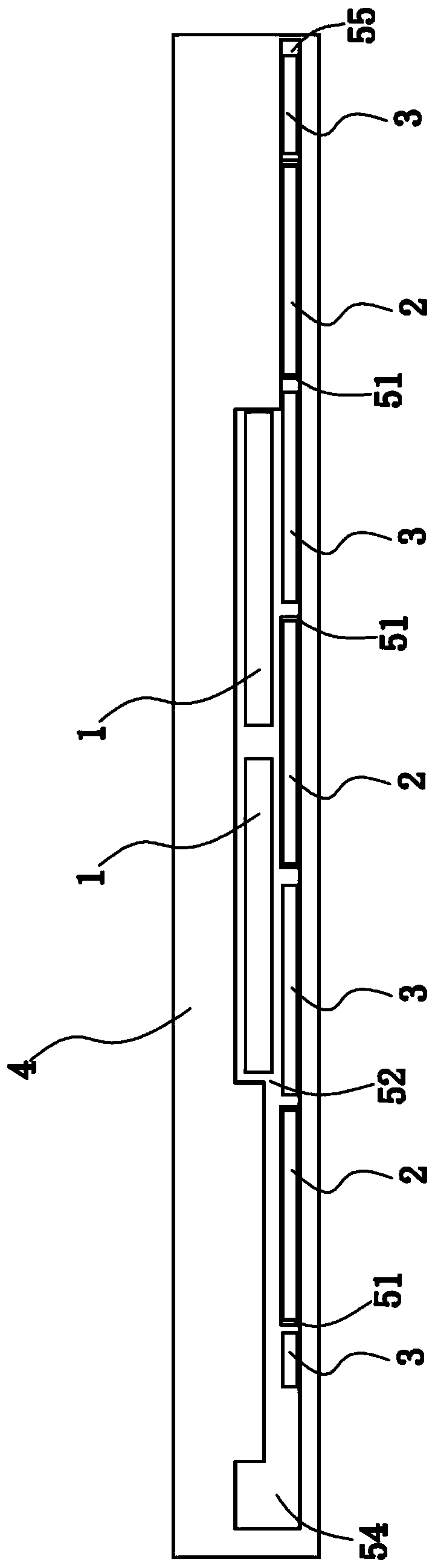

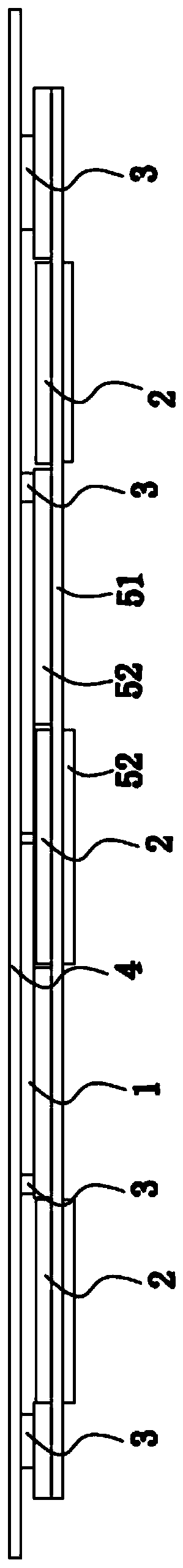

Baffle tube material stirring swing arm device

InactiveCN108726163AThe overall structure is simple and reliableAutomation for convenienceConveyorsConveyor partsHydraulic cylinderPulp and paper industry

The invention discloses a baffle tube material stirring swing arm device. The device comprises a non-driving rail and a baffle stirring swing arm device, the baffle stirring swing arm device is arranged at the right end of the non-driving rail, a hydraulic cylinder is connected with the left side of the baffle stirring swing arm device, the hydraulic cylinder is connected with the ground through ahydraulic cylinder hinge supporting seat, a base is arranged on the right side of the baffle stirring arm device, a V-shaped supporting member is arranged on the base, a traction wheel group is arranged on the right side of the base, and a power device matched with the traction wheel group is arranged on the traction wheel group. The baffle tube material stirring swing arm device has a simple andreliable structure, automated achievement and equipment maintenance are easy, the non-driving rail in a buffering area is provided with tilting angle to help the baffle tube to stop at a tube receiving position of the baffle stirring swing arm device, and a single hydraulic cylinder is adopted to provide power.

Owner:XINXING HEBEI ENG & RES INC

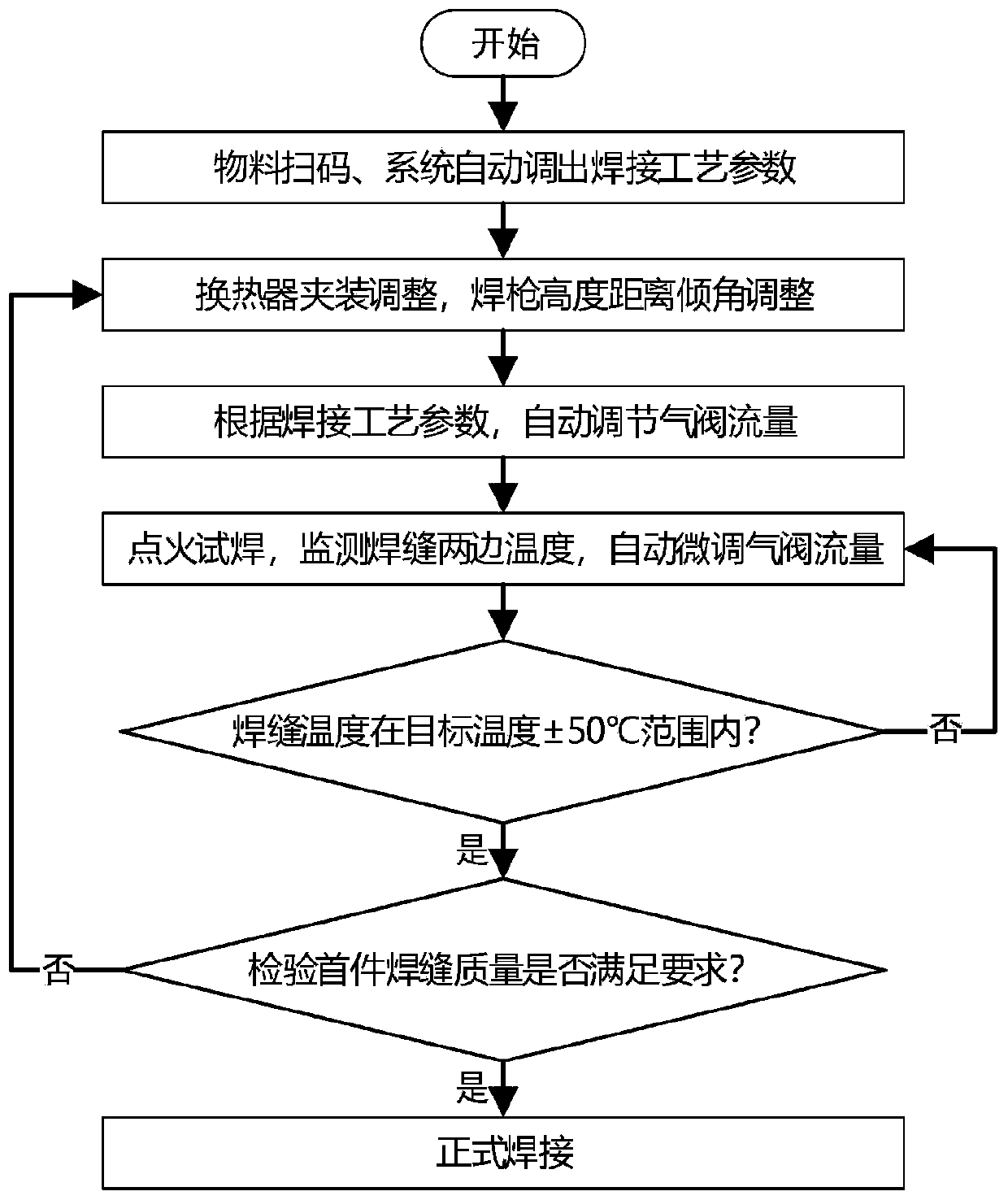

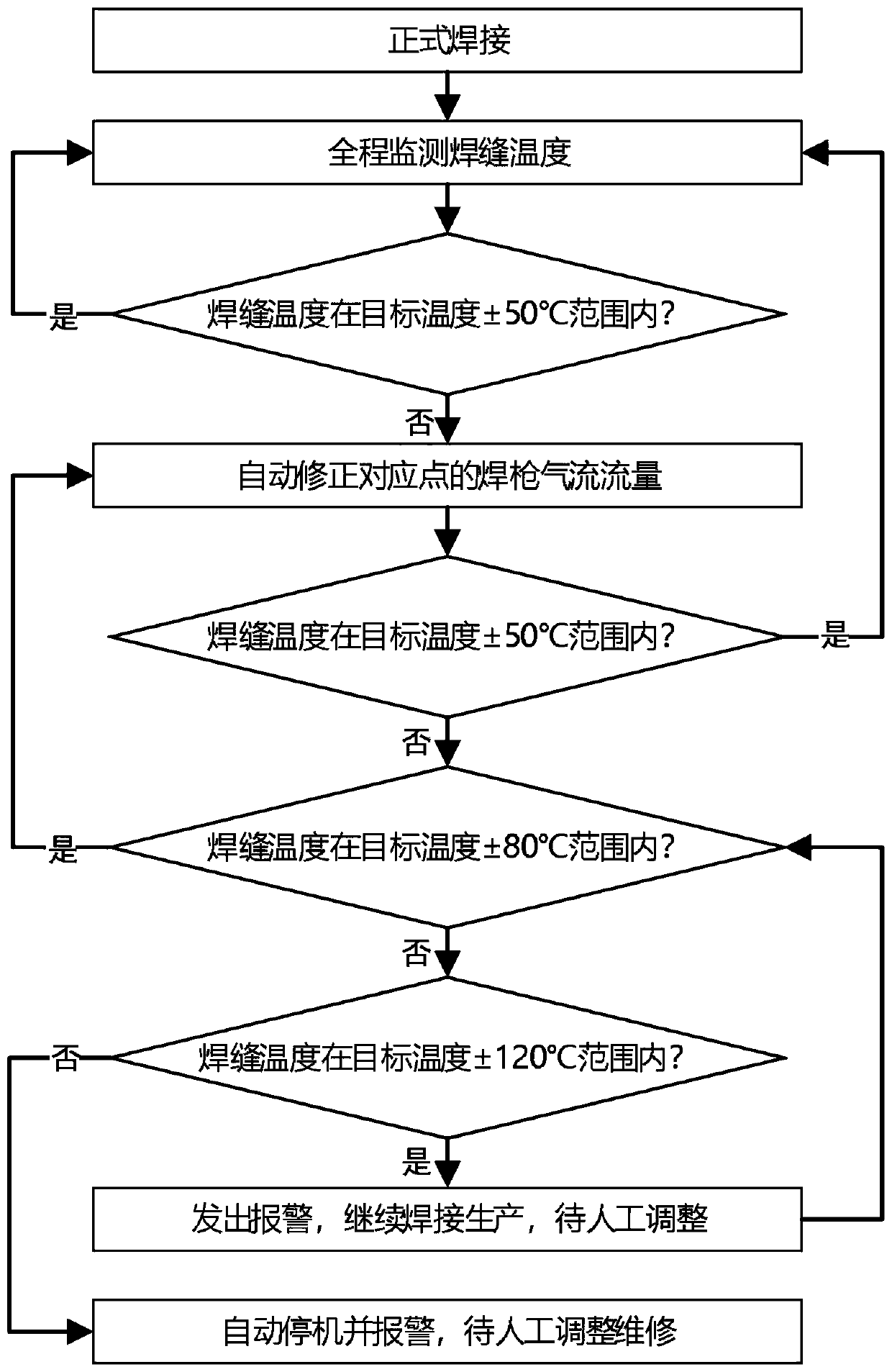

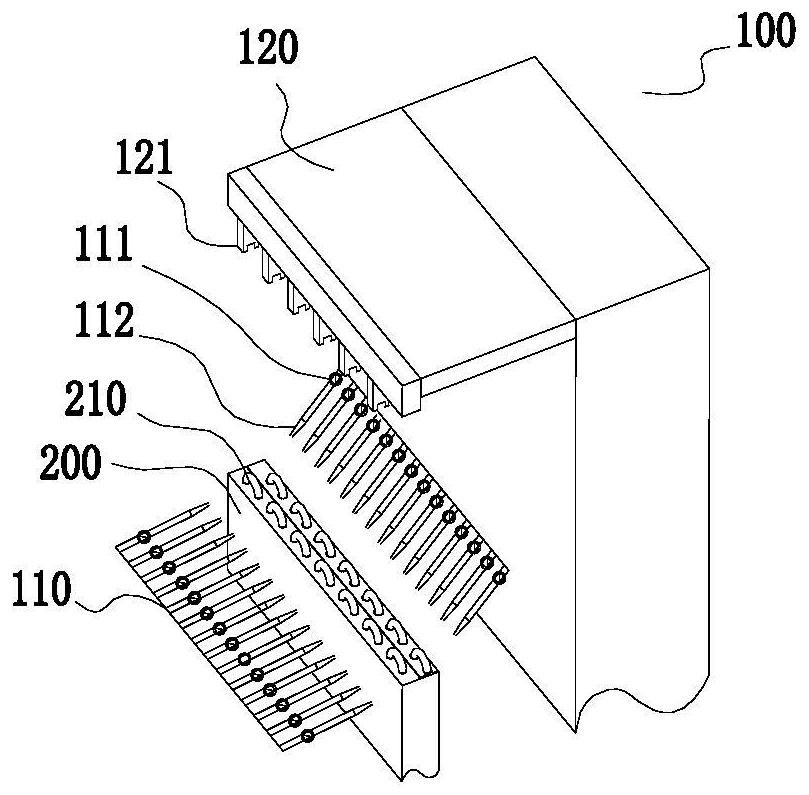

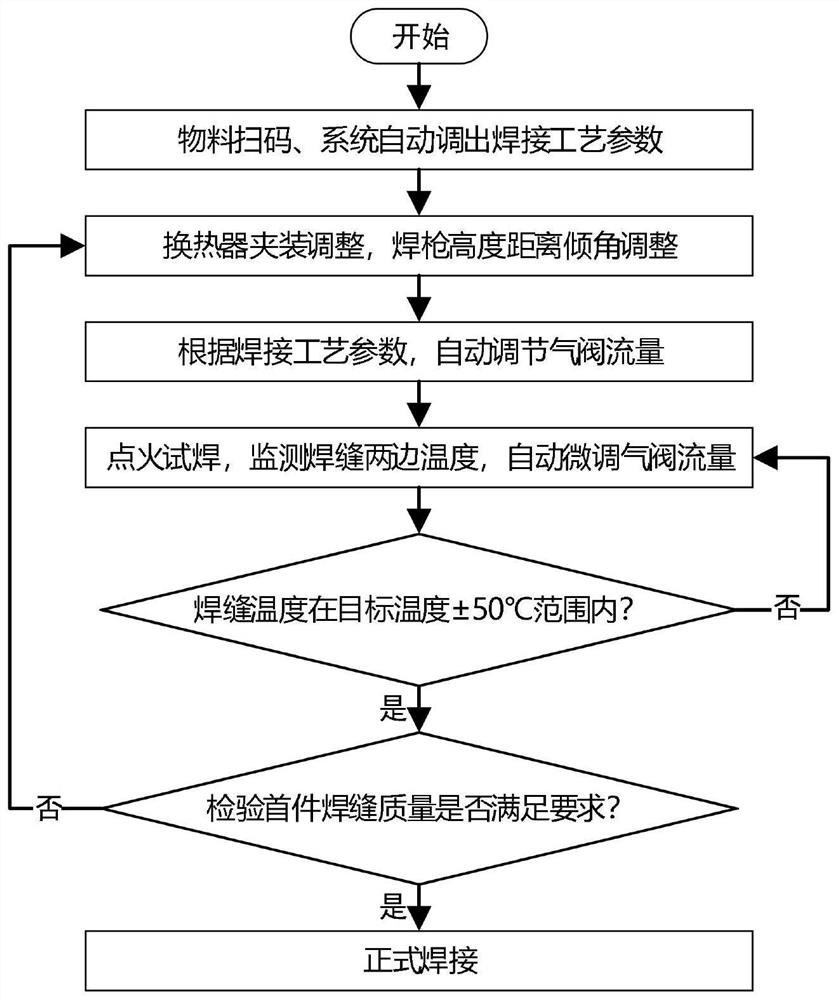

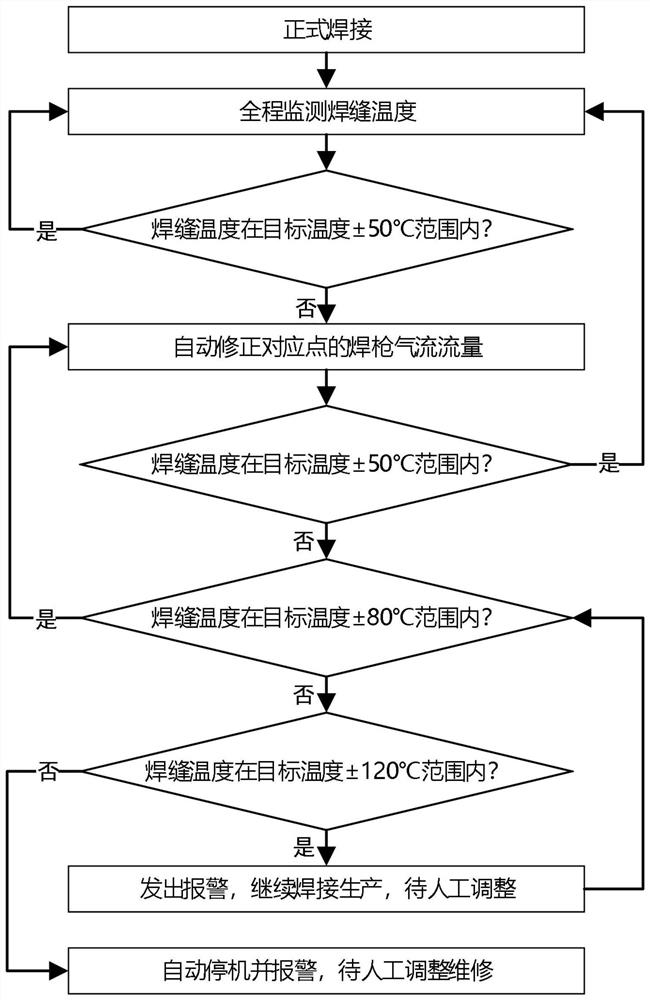

Welding temperature control method

ActiveCN110788440AAutomation for convenienceAvoid human errorHeat exchange apparatusMetal working apparatusWeld seamProcess engineering

The invention provides a welding temperature control method, The method comprises an automatic welding equipment, wherein the automatic welding equipment comprises a welding gun, a temperature controlsystem and an identification system, the identification system is used for identifying identification information of a piece to be welded, the temperature control system is used for calling out corresponding welding process parameters according to the identification information, the gas flow of the welding gun is automatically set based on the welding process parameters, the welding process parameter comprises the target temperature of a welding seam, pipe diameter, wall thickness and other automatically set welding parameters; and the temperature control system comprises a temperature monitoring head, wherein the temperature monitoring head is used for monitoring the real-time temperature of the weld seam, and when the difference value between the real-time temperature and the target temperature exceeds a first threshold value, the temperature control system adjusts the gas flow of the welding gun, so that the difference value between the real-time temperature and the target temperature is smaller than the first threshold value. The welding parameters are automatically called out through identification information, automatic implementation is facilitated, human errors are avoided, automatic shutdown caused by temperature abnormity is avoided, and lot-size problems are eradicated.

Owner:NINGBO AUX ELECTRIC +1

Software definable network business configuration method

ActiveCN107294773AAutomation for convenienceNetworks interconnectionControl layerCentralized management

Conventional network business disposition is very complex, so an operator needs to plan a service path in advance, and manually configures strategies for each node on the service path; different from the conventional network, the software definable network business configuration method comprises the following steps: on one aspect, a control layer possesses a global network resource view, thus easily planning the service path according to the service requests; on the other aspect, the control layer uses a southbound interface to gather and manage physics switch nodes in the data layer, thus automatically configuring the physics switch node strategies.

Owner:山东合能科技有限责任公司

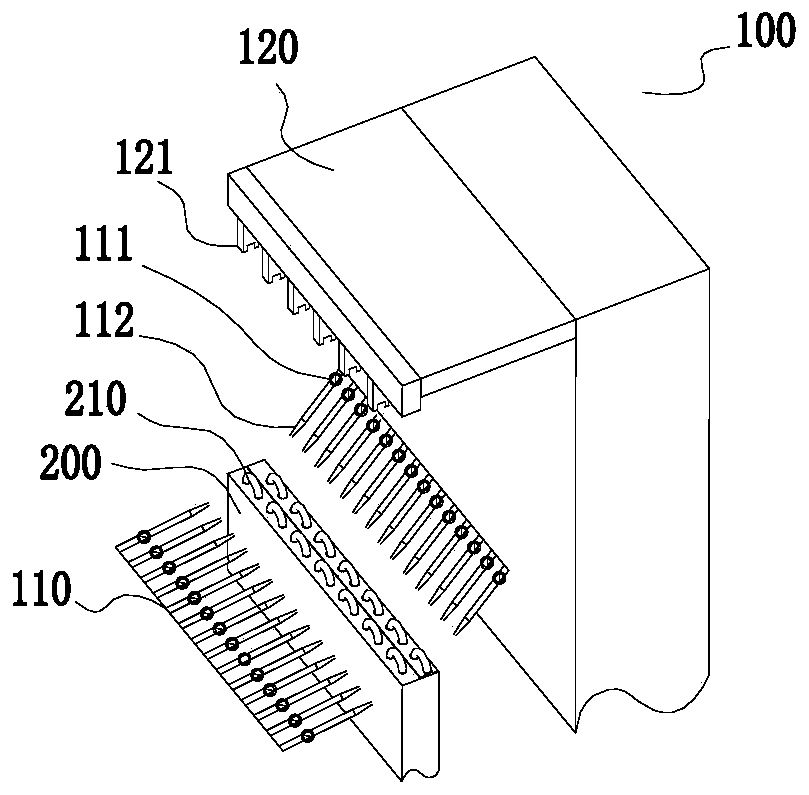

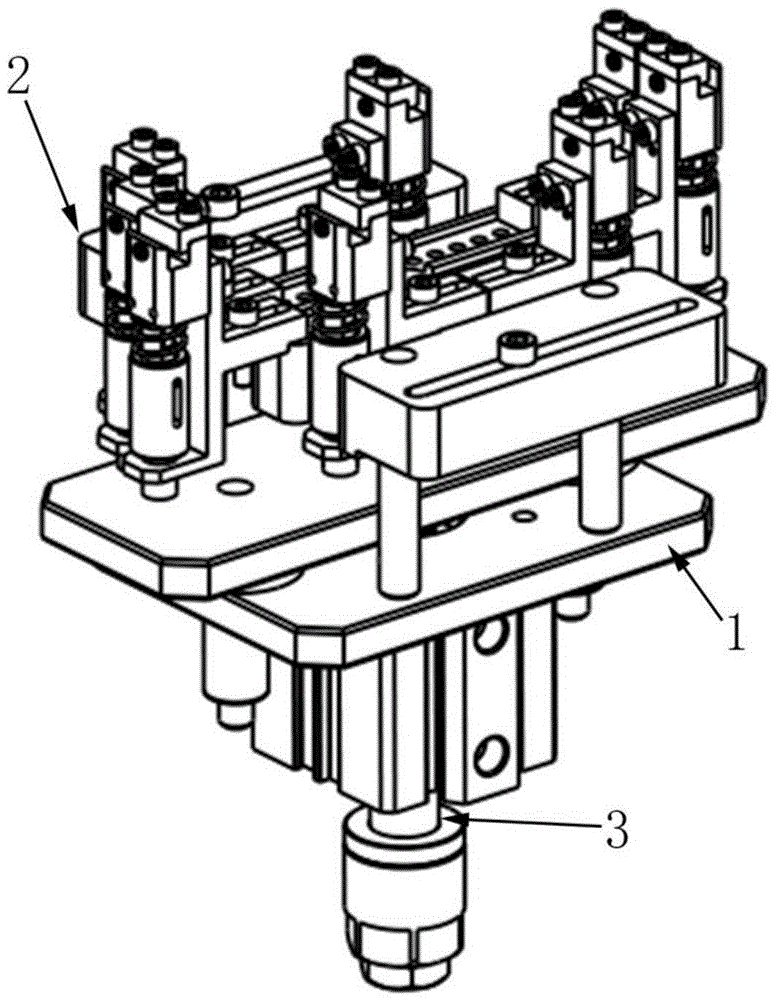

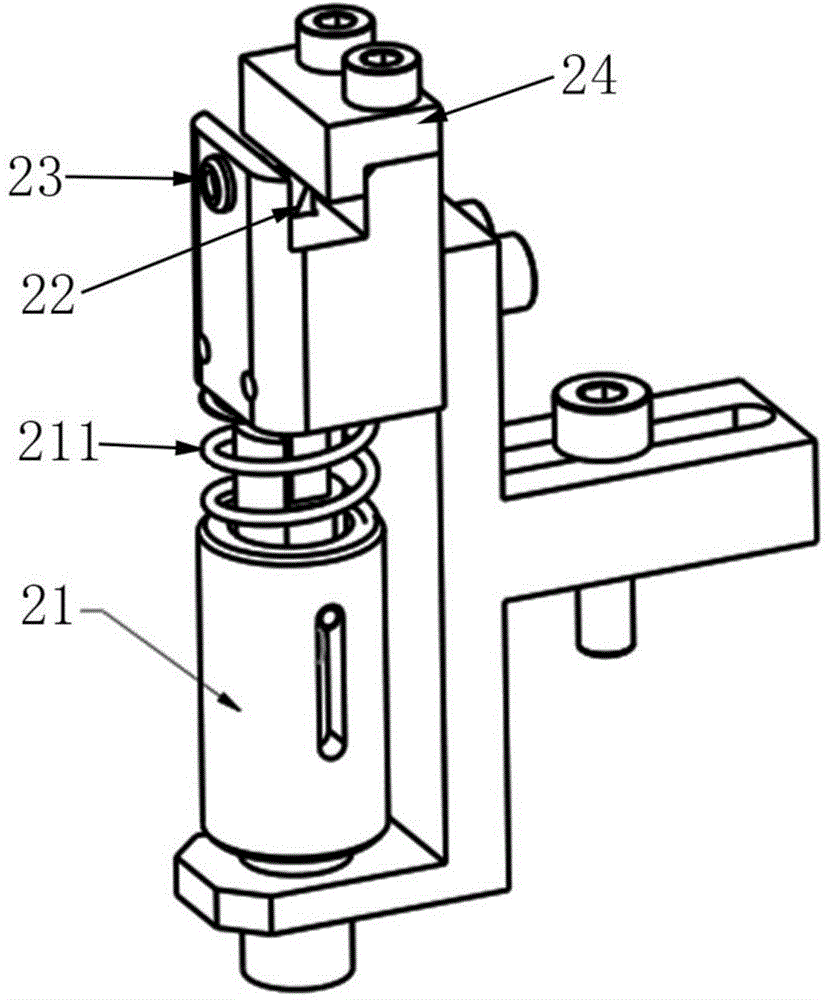

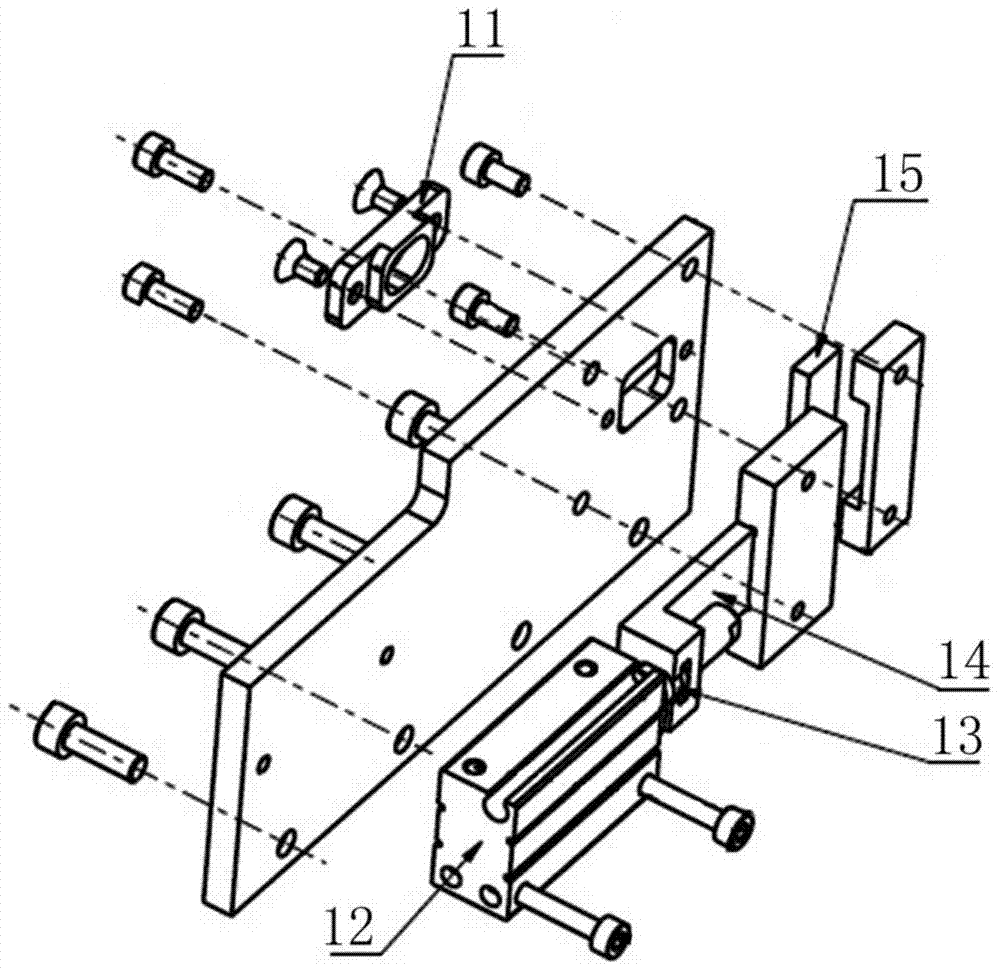

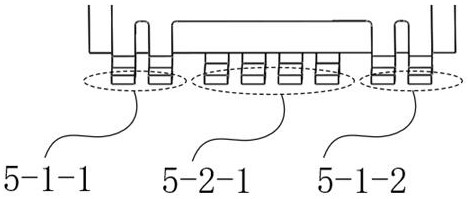

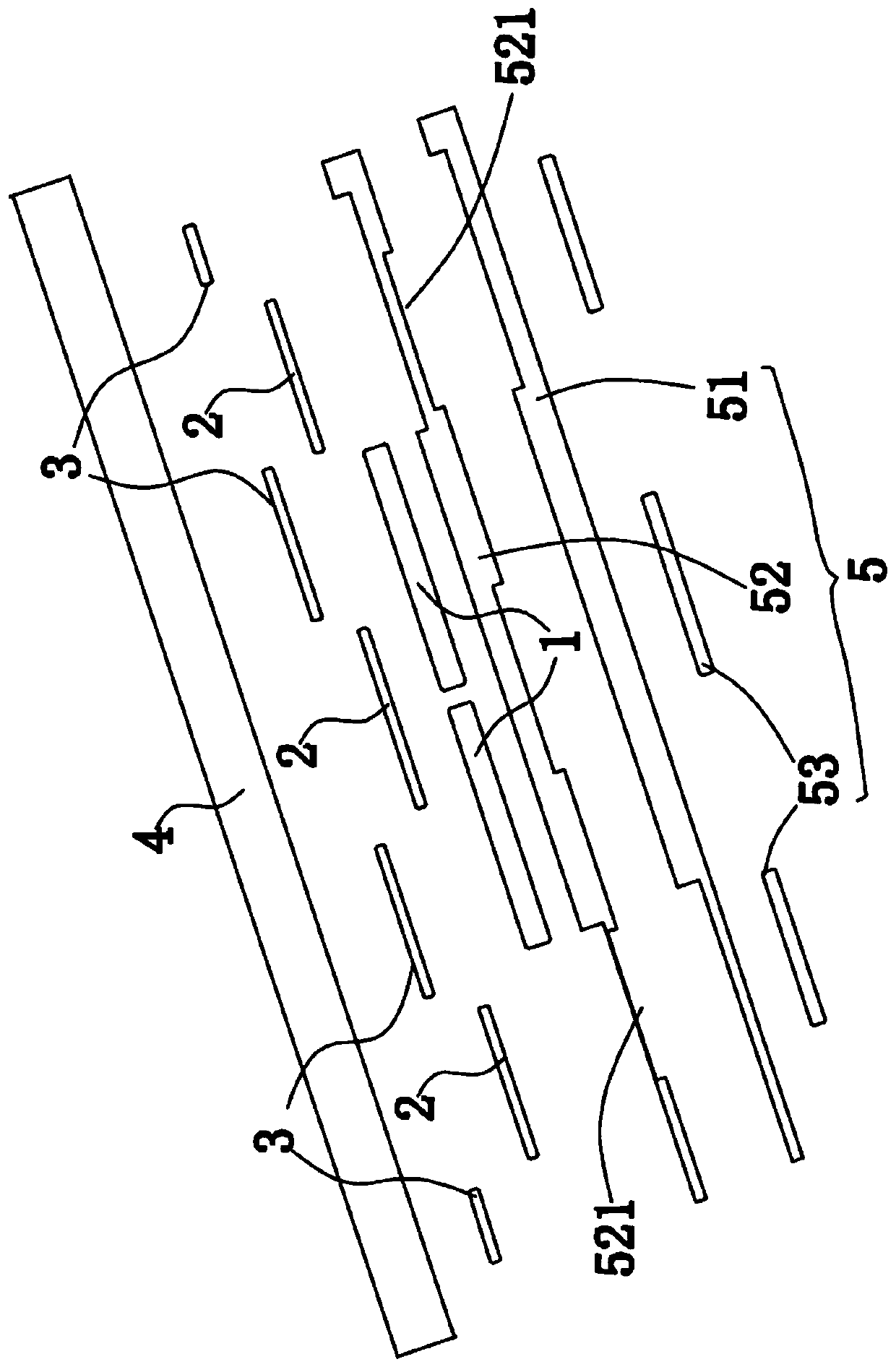

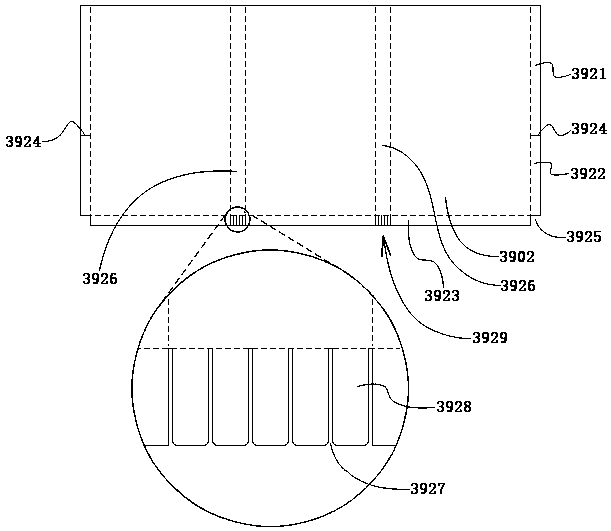

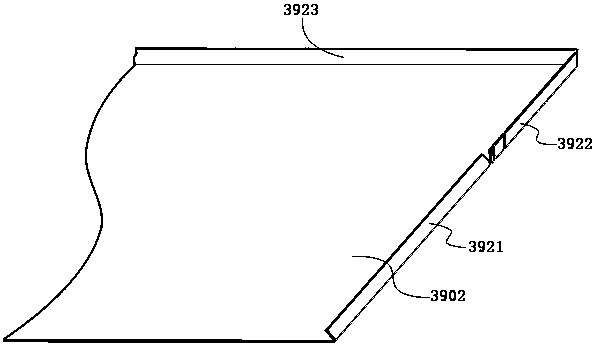

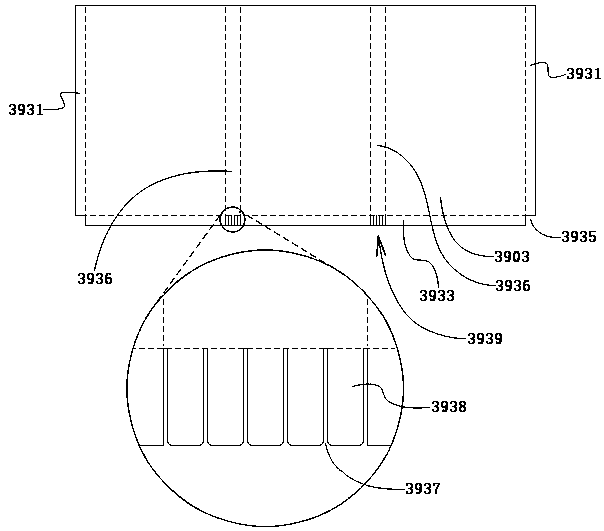

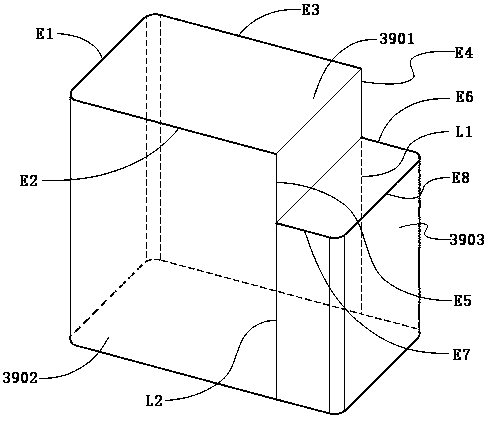

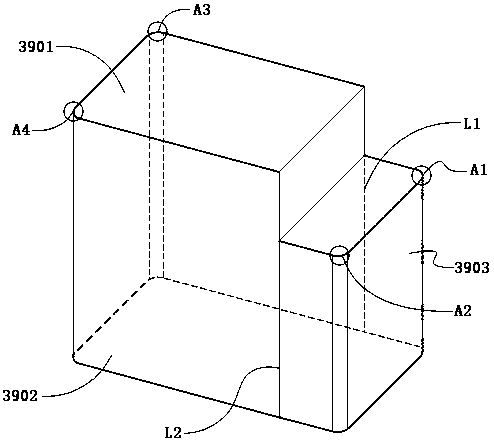

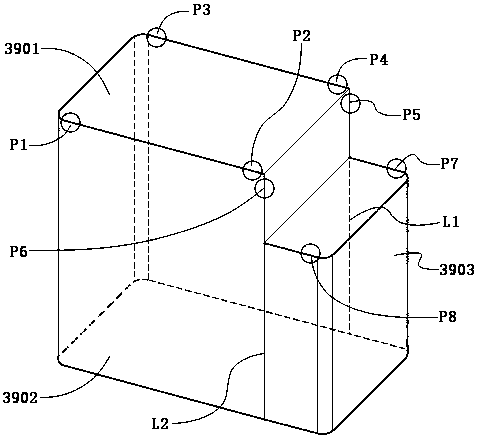

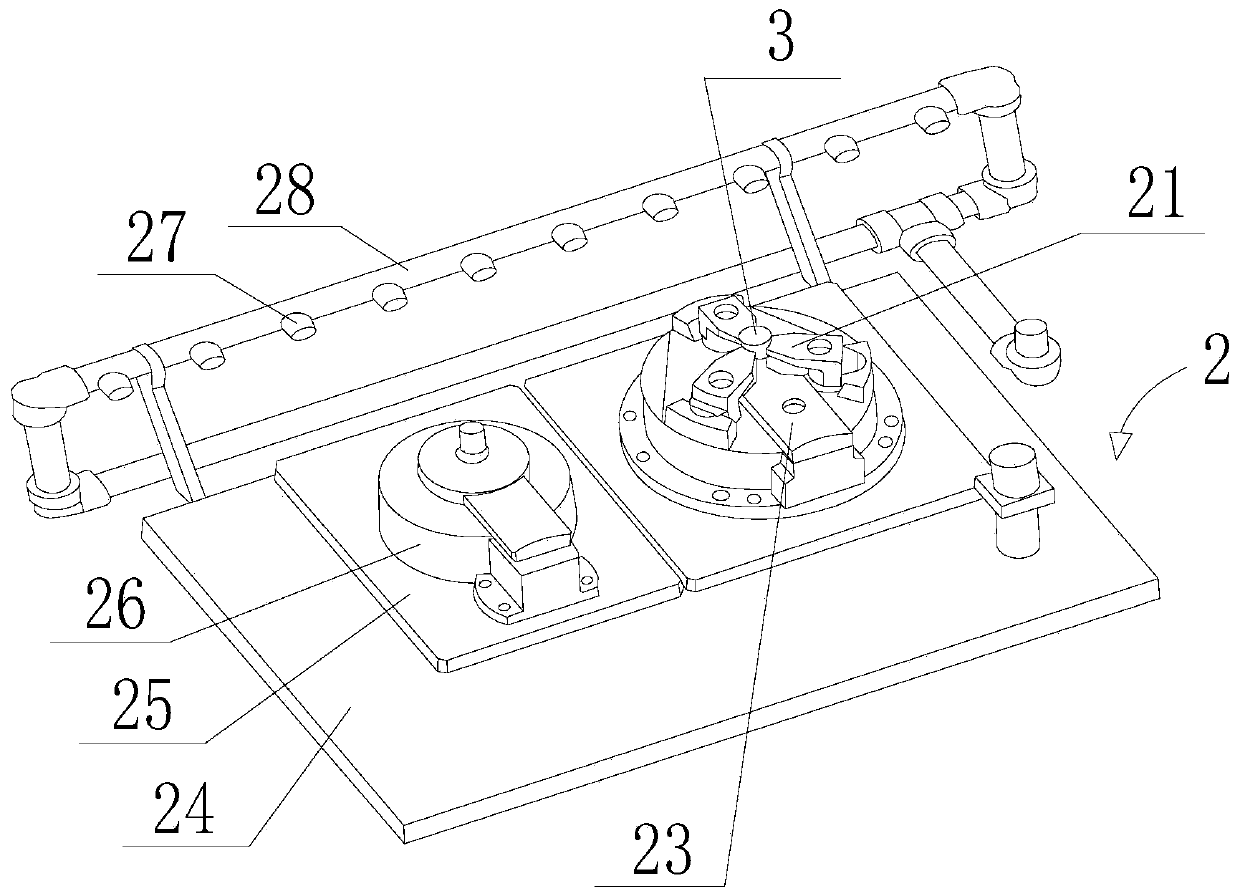

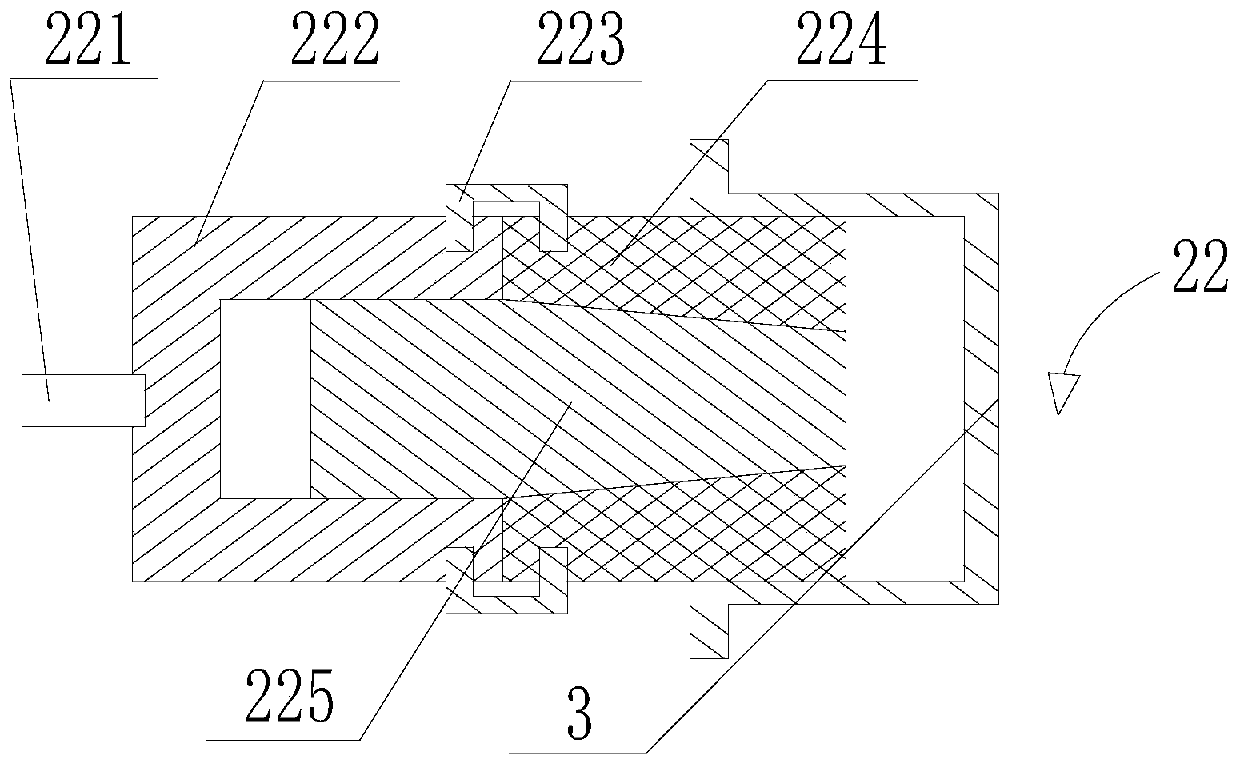

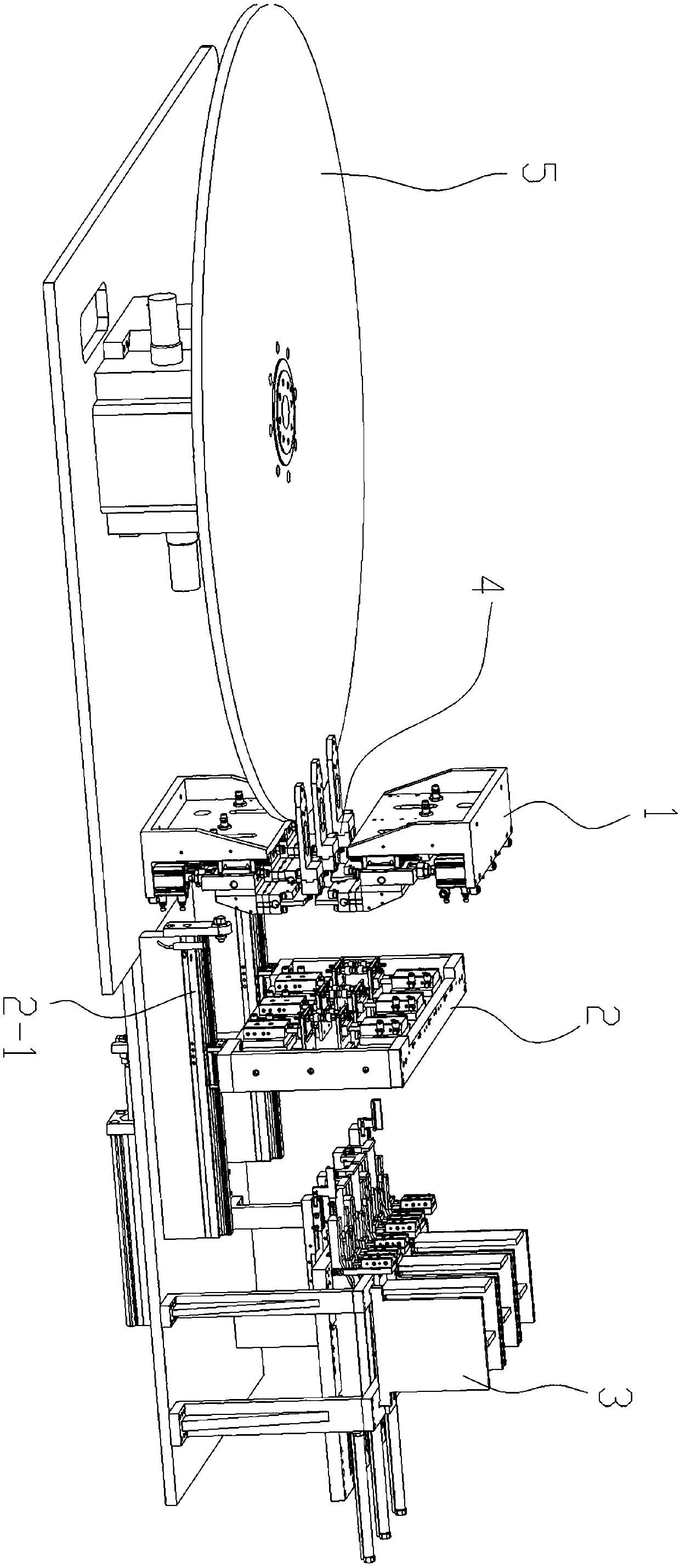

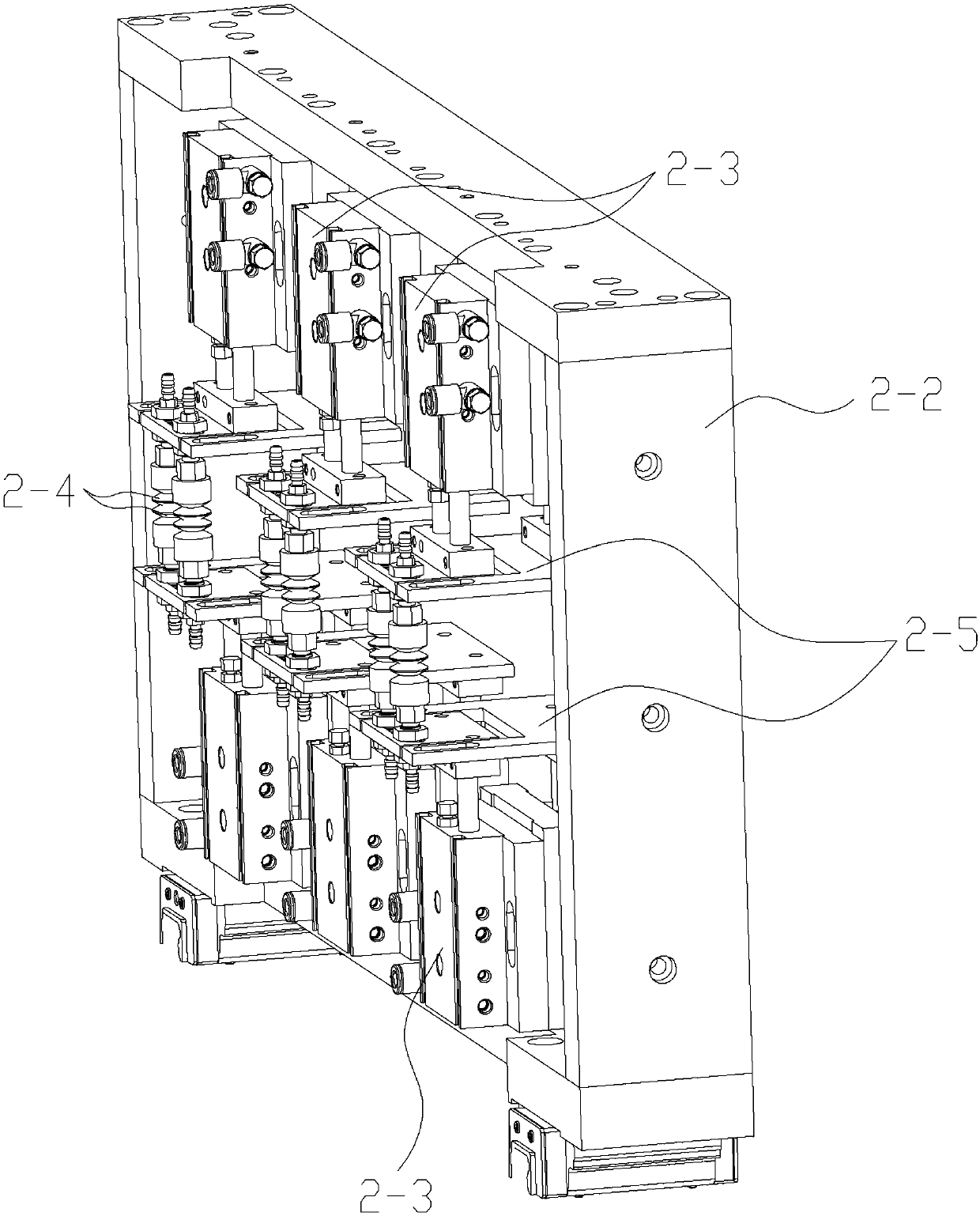

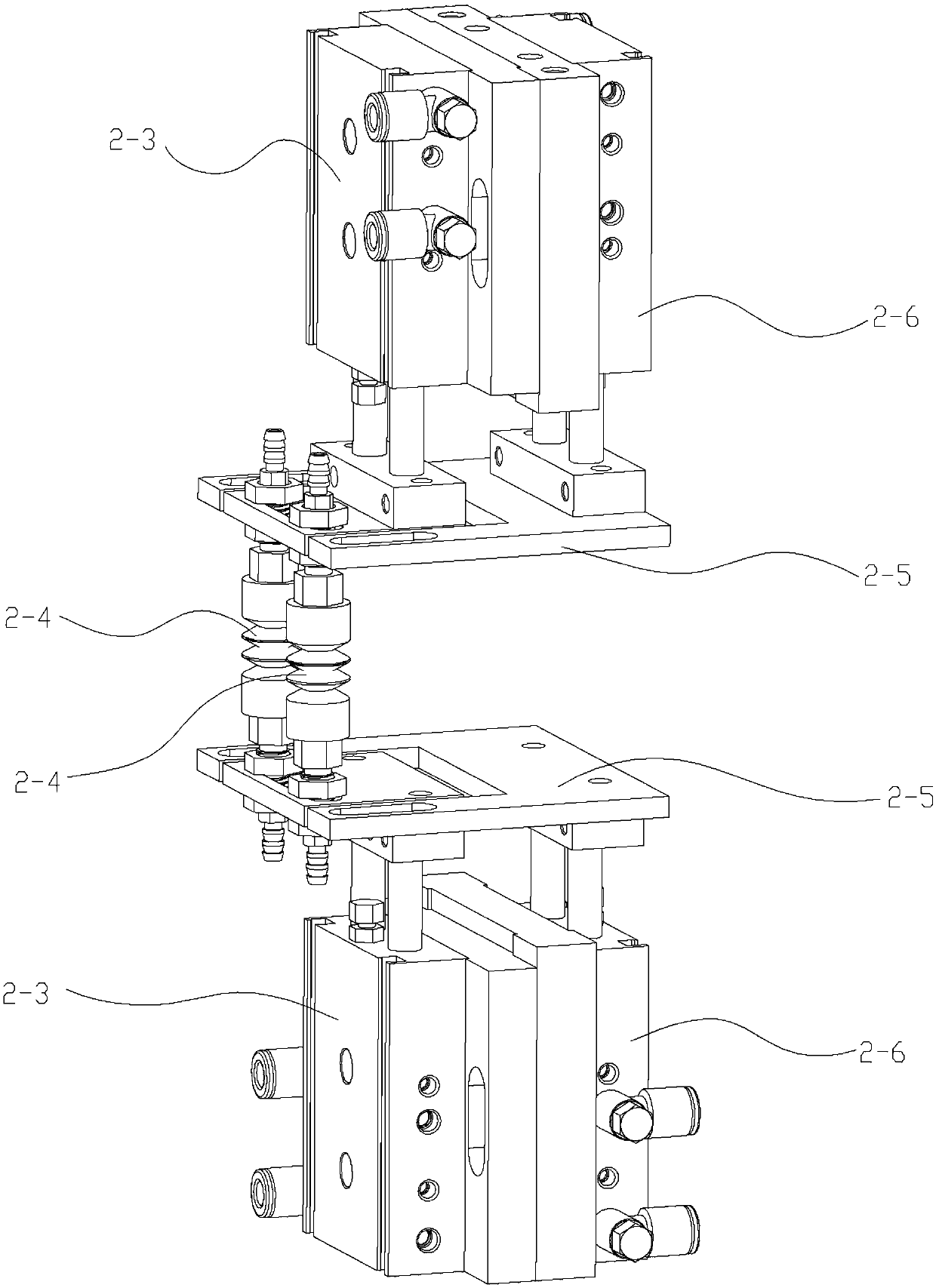

Varnished wire pre-cutting mechanism for T1 ring wire winding machine

The invention provides a varnished wire pre-cutting mechanism for a T1 ring wire winding machine. The varnished wire pre-cutting mechanism comprises a base, multiple pre-cutting devices arranged on the base and an air cylinder arranged below the base and connected with the pre-cutting devices. The pre-cutting devices are used for pre-cutting part of varnished wires in the diameter direction of the varnished wires. By the adoption of the varnished wire pre-cutting mechanism for the T1 ring wire winding machine, the length of a head wire of each varnished wire and the length of a tail wire of the vanished wire can be different, part of the varnished wires are cut in the diameter direction of the varnished wires, and great convenience is provided for automatic conduction of following processes such as the wire twisting process and the T2 ring winding process.

Owner:ZHUHAI HENGNUO SCI & TECH CO LTD

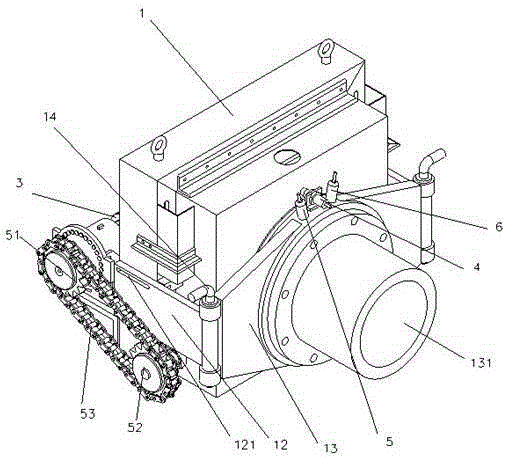

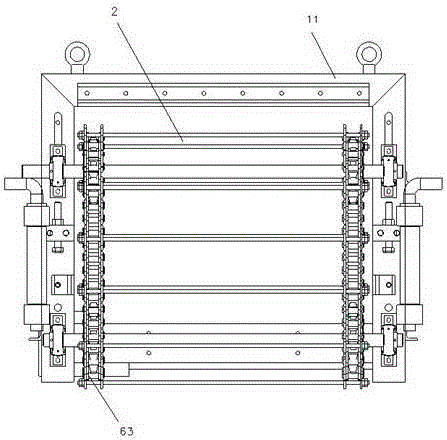

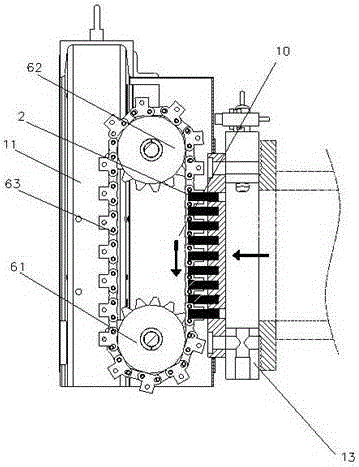

Linear cutter device for catalyst extruder

ActiveCN105252733AEasy to cut offRealize chain controlMetal working apparatusEngineeringDriving mode

The invention discloses a linear cutter device for a catalyst extruder. The linear cutter device comprises a frame, cutters and a cutter driving device. The frame is installed on the catalyst extruder, a catalyst conveying channel is arranged in the frame, and catalysts extruded by the catalyst extruder can enter the catalyst conveying channel conveniently. The cutters are movably arranged in the frame. The cutter driving device is connected with the cutters in a driving mode and can drive the cutters to move so as to cut the catalysts in the catalyst conveying channel. According to the linear cutter device, the catalysts extruded by the catalyst extruder can be well cut, the cutting efficiency can be improved, and automation realization of the catalyst extruder is promoted.

Owner:CHANGZHOU FANQUN DRY EQUIP CO LTD

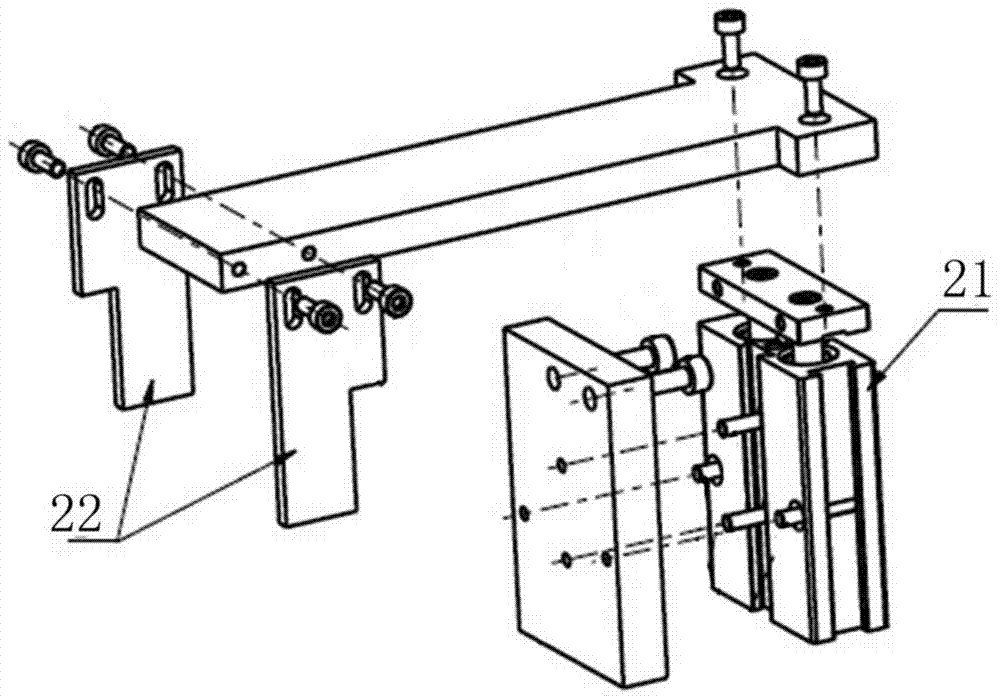

A tail-breaking mechanism of a winding machine

The invention proposes a tail-cutting mechanism of a winding machine, which includes a frame, a wire tail pressing assembly, and a moving magnetic ring assembly and a clamping magnetic ring assembly installed on the frame. By adopting the wire breaking mechanism of the winding machine of the present invention, the enameled wire can be broken at the pre-broken position, and a wound T1 ring with different lengths of the head and tail wires can be obtained, which brings convenience to the automatic realization of the subsequent process.

Owner:ZHUHAI HENGNUO SCI & TECH CO LTD

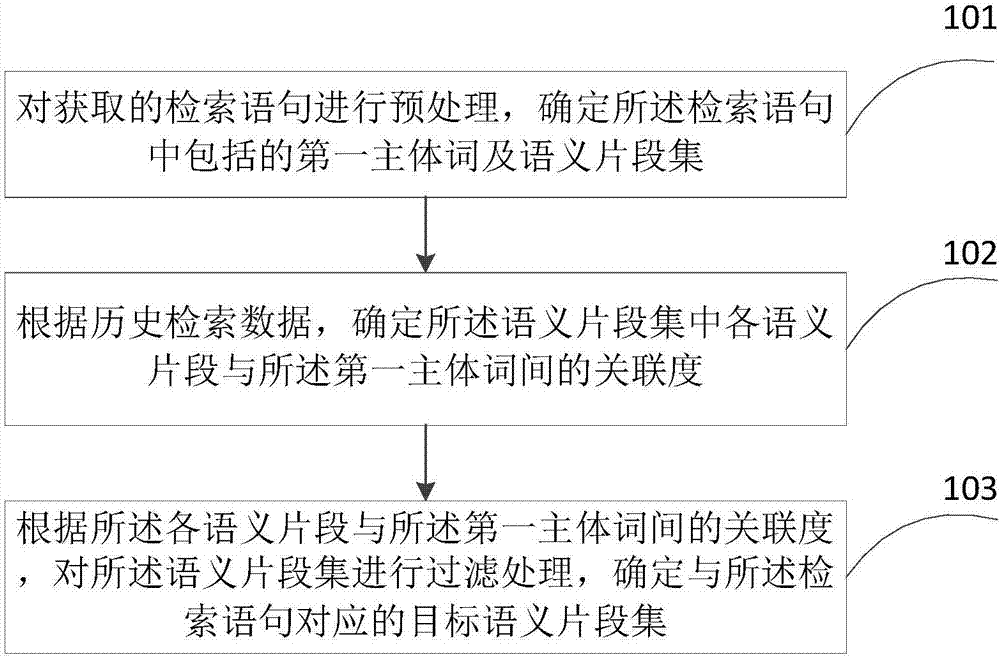

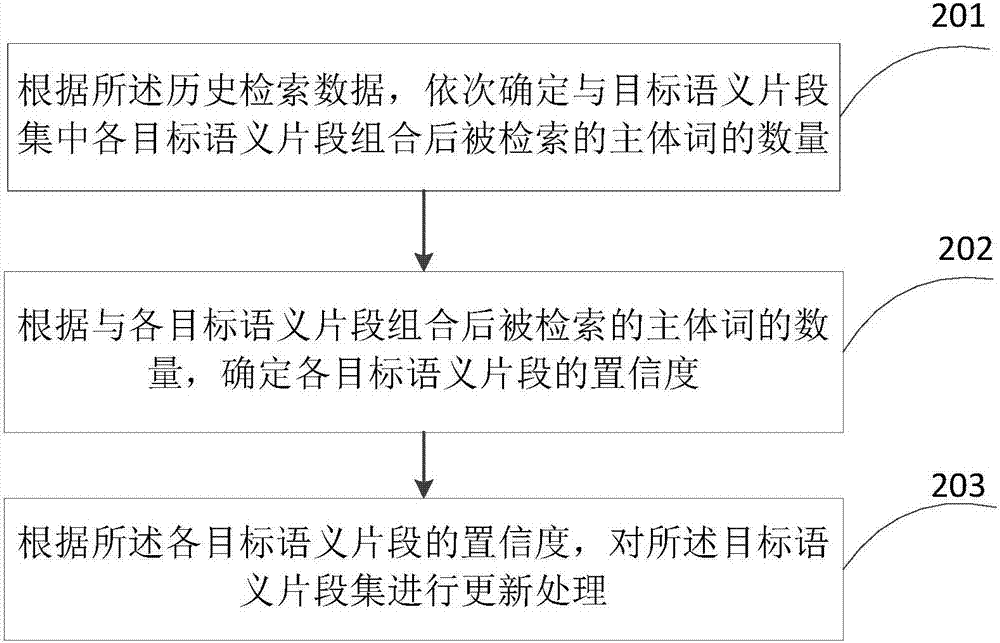

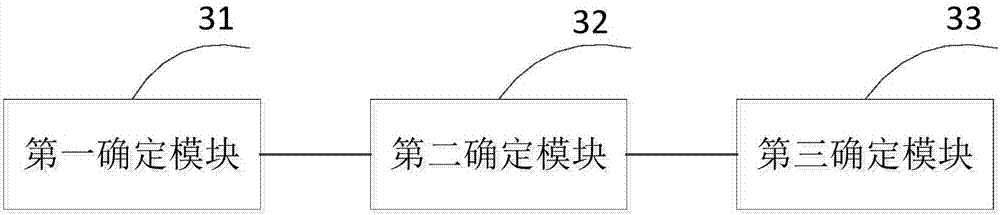

Method and device for obtaining semantic segments of queries based on artificial intelligence and terminal

ActiveCN107357830AFlexible accessEasy to identifySemantic analysisKnowledge representationUser needsGranularity

The invention puts forward a method and device for obtaining semantic segments of queries based on artificial intelligence and a terminal. The method comprises the following steps: pre-processing obtained queries and determining first subject words and semantic segment sets of queries; determining degrees of relevancy among all semantic segments of the semantic segment sets and the first subject words according to retrieval of historical data; filtering the semantic segment sets according to degrees of relevancy among all semantic segments and the first subject words and determining target semantic segment sets corresponding to queries. Therefore, target semantic segment sets corresponding to queries are obtained. There is no need to use manpower to edit and extract templates, which saves manual resources and is conducive to realization of automation. The mode of obtaining semantic segments is flexible and can adaptively mine all granularities of semantic segments. Therefore, recognition effect of semantic segments is enhanced and therefore retrieval results of query can better meet needs of users and improve user experience.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

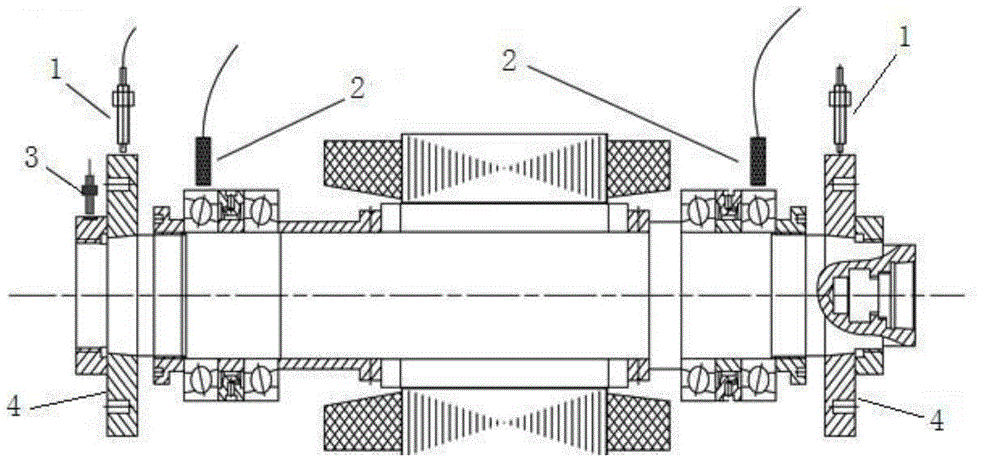

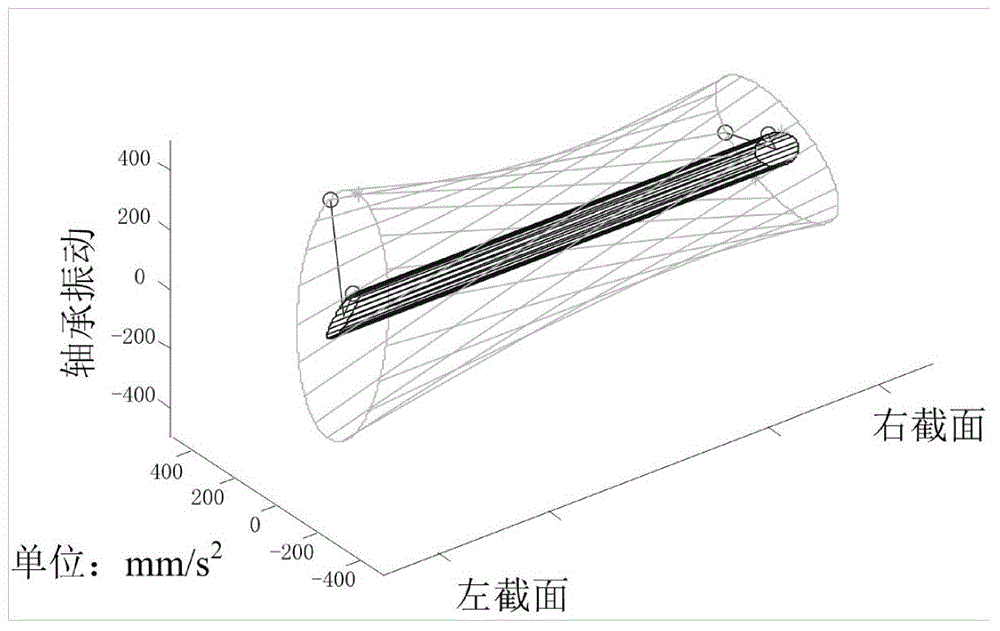

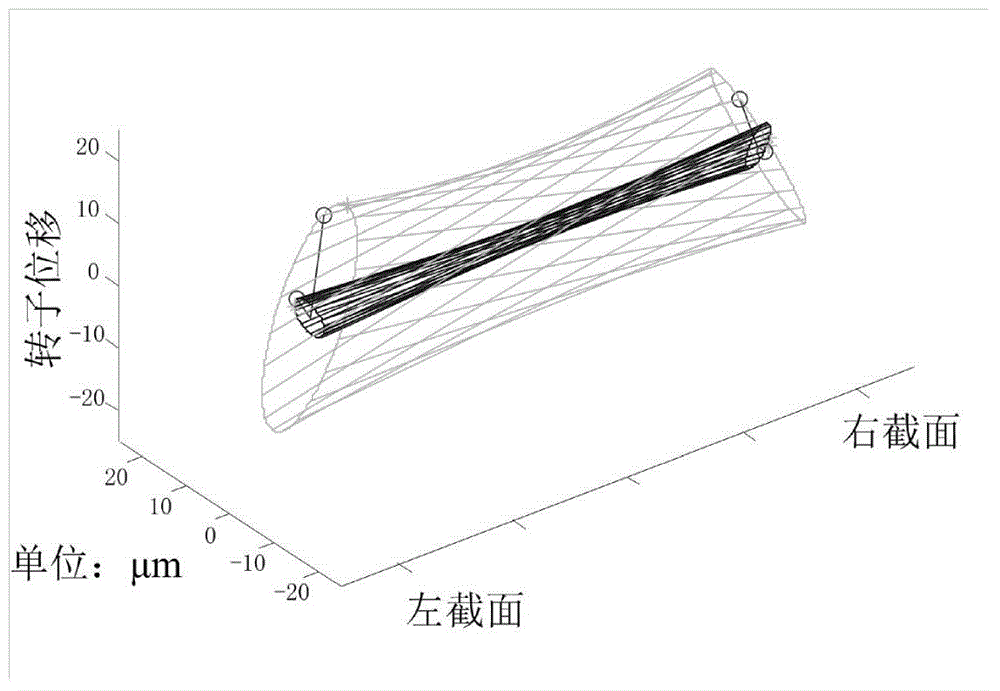

Dynamic balance suppression method for spatial vibration of high-speed rotor bearing system

InactiveCN104460728AHigh rotation accuracyImbalance Vibration Energy SuppressionMechanical oscillations controlVibration controlWeight coefficient

The invention discloses a dynamic balance suppression method for spatial vibration of a high-speed rotor bearing system. On the basis of testing spatial vibration of the high-speed rotor bearing system, the incidence relation between the displacement and vibration motion track area and the amount of unbalance is given, an optimized objective function involving rotor displacement and bearing vibration is established, synchronous suppression of rotor displacement and bearing vibration is achieved in combination with an optimization method, both promotion of rotor rotation precision and suppression of unbalance vibration energy are taken into consideration, and the proportions of displacement and vibration suppression effects in different directions and on different sections are controlled through configuration of weight coefficients. The dynamic balance suppression method overcomes the defects that according to traditional vibration suppression methods, rotor displacement or bearing vibration is seldom taken into comprehensive consideration, most of vibration tests are implemented only in a single direction or on a single section, and consequently it is unable to attend to everything at once occasionally. Compared with the traditional methods, the dynamic balance suppression method has the advantages that the vibration control effect of the rotor bearing system can be optimal, and the service life of the system can be prolonged effectively while the running accuracy of the system is guaranteed.

Owner:XIDIAN UNIV

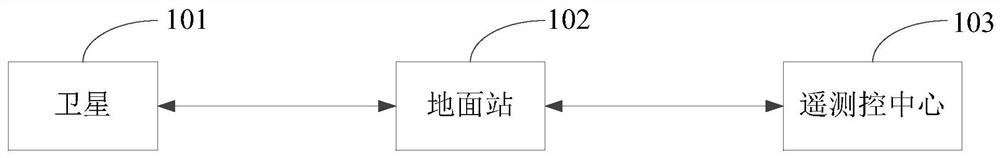

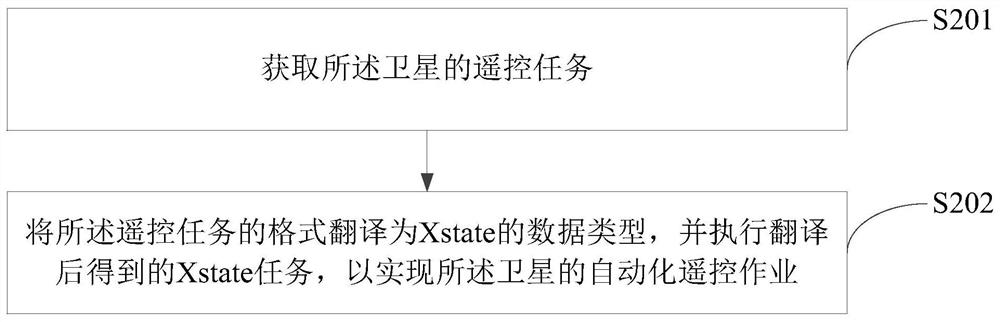

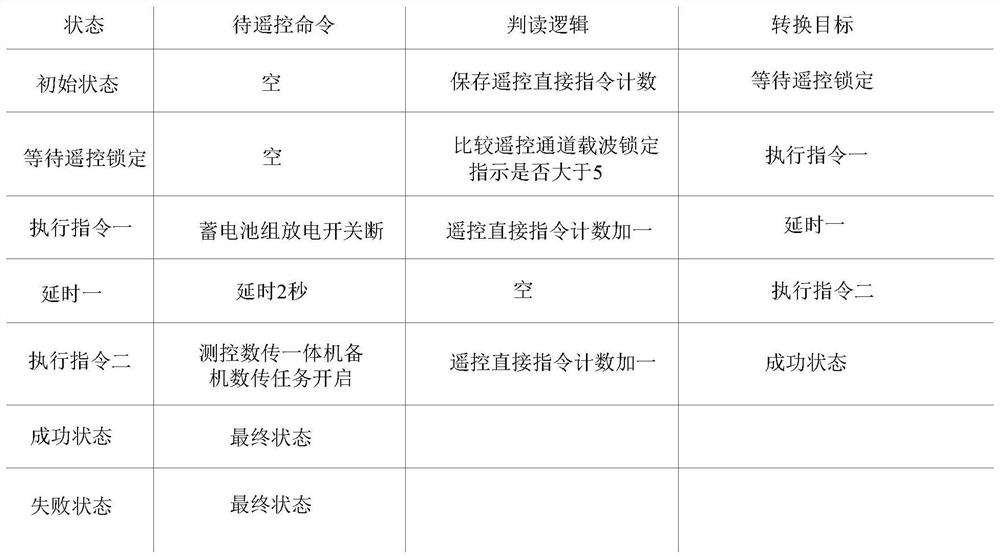

Satellite remote control method, device and equipment based on Xstate and storage medium

ActiveCN113364515AReduce management costsImprove automationRadio transmissionControl engineeringComputer science

The invention relates to a satellite remote control method and device based on Xstate, equipment and a storage medium. The method comprises the steps of obtaining a remote control task of a satellite, wherein the remote control task is described through a state machine, the remote control task comprises a plurality of states, and the states comprise a command to be remotely controlled, interpretation logic of received data and a conversion target of the states; and translating the format of the remote control task into the data type of the Xstate, and executing the Xstate task obtained after translation so as to realize the automatic remote control operation of the satellite. According to the method, remote control tasks of satellites are described through a state machine, instruction sending of the satellites, control of observation stations and interpretation of received data (telemetering data of the satellites and the states of the observation stations) are automatically achieved by operating the state machine, and automation of satellite remote control operation is achieved. Moreover, an operator on duty can understand, compile and change a remote control task more easily by adopting the state machine, and the realization of satellite remote control operation automation is simplified, so that the management cost of satellite in-orbit operation is reduced.

Owner:北京和德宇航技术有限公司

Wire twisting mechanism for T1 ring wire winding machine

The invention provides a wire twisting mechanism for a T1 ring wire winding machine. The wire twisting mechanism comprises a wire head clamping assembly, a wire tail clamping assembly, a T1 ring fixing assembly and a wire twisting assembly. The T1 ring fixing assembly is located between the wire head clamping assembly and the wire tail clamping assembly and the wire twisting assembly is arranged above the wire head clamping assembly. By the adoption of the wire twisting mechanism for the T1 ring wire winding machine, two varnished wires needing to be wound around a T2 ring can be automatically twisted before the vanished wires are wound around the T2 ring, and great convenience is provided for automatic conduction of following processes such as the T2 ring winding process.

Owner:ZHUHAI HENGNUO SCI & TECH CO LTD

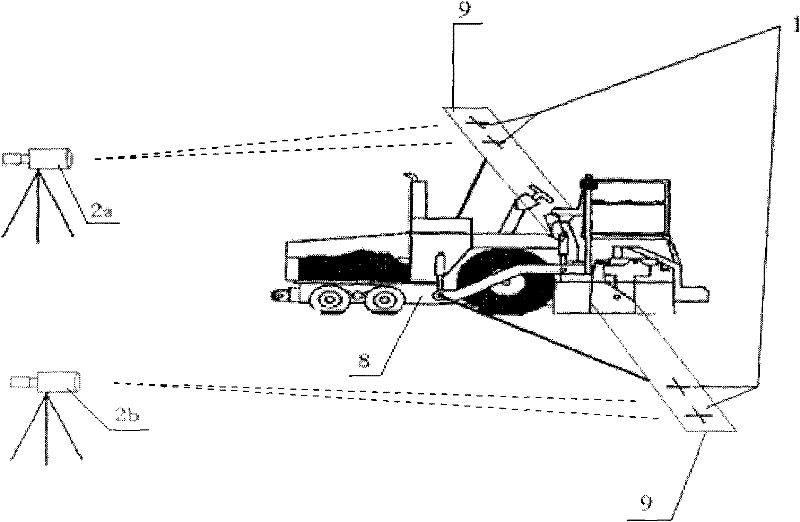

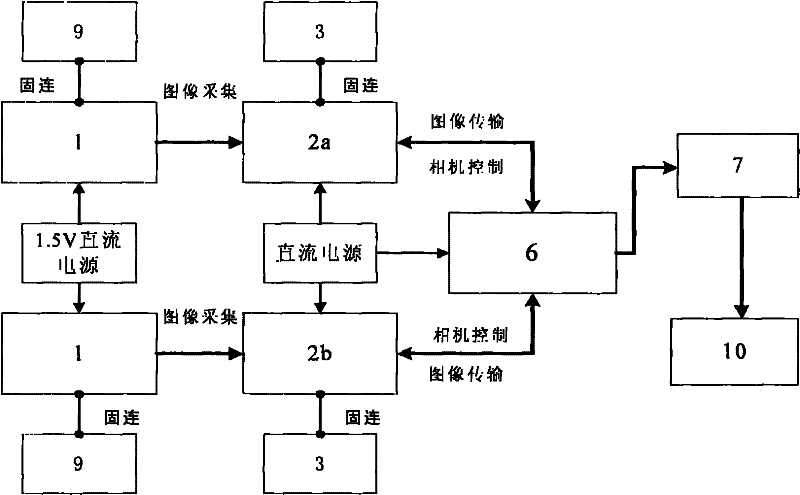

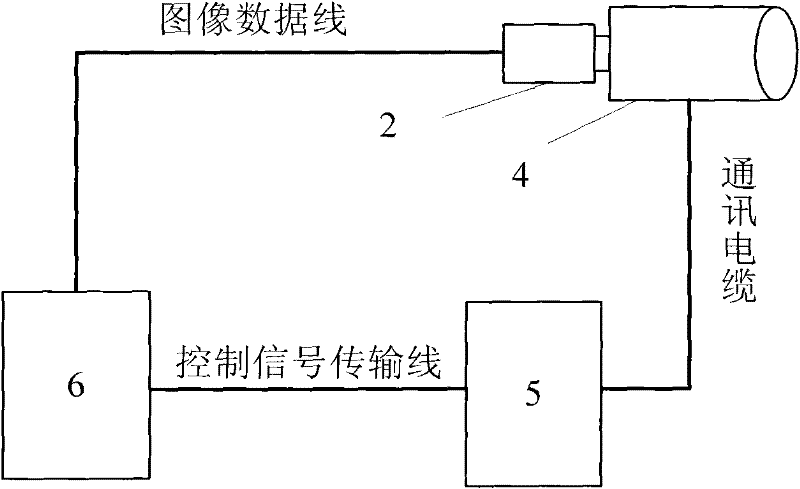

Camera measurement based automatic leveling system and method of spreading machine

InactiveCN101718072BReasonable priceLow pricePhotogrammetry/videogrammetryRoads maintainenceControl systemControl engineering

The invention discloses camera measurement based automatic leveling system and method of a spreading machine. The method comprises the steps of: firstly, establishing a leveling system formed by four manual cooperation marks fixed on an ironing plate of the spreading machine and a camera measurement system, obtaining offsets of the manual cooperation marks fixed on the ironing plate of the spreading machine relative to the initial position through rapid and accurate measurement of a camera system, thereby obtaining offset of the ironing plate of the spreading machine relative to the initial position; and secondly, feeding the measurement result back to a control system of the spreading machine, thereby realizing the rapid and automatic leveling the spreading machine. The camera measurement based automatic leveling system and the method of the spreading machine have the advantages of non-contact, full site, high accuracy, easy automatic implementation and the like. The invention is simultaneously suitable for the field of other machines of a leveling machine and the like, and can improve the leveling quality and the automation of the leveling machine.

Owner:NAT UNIV OF DEFENSE TECH

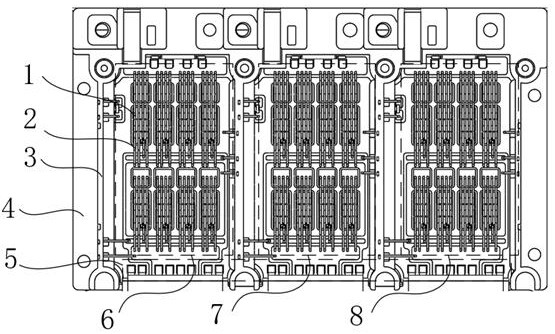

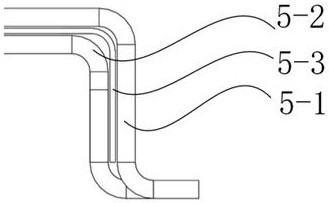

Integrated IGBT packaging structure based on DBC layout

ActiveCN111627899AReduce thermal resistanceImprove power densitySemiconductor/solid-state device detailsSolid-state devicesBusbarEngineering

The invention belongs to the field of semiconductor packaging and power modules, in particular to an integrated IGBT packaging structure based on DBC layout. The structure comprises a three-phase DBCstructure. A frame is fixed outside the three-phase DBC structure, a plurality of chips are welded on the front surface of the three-phase DBC structure, the back surface of the three-phase DBC structure is directly welded on the radiator, the chips in the three-phase DBC structure are connected with one another, and a laminated busbar is connected to a direct-current terminal of the three-phase DBC structure. The three-phase DBC is directly welded to the radiator, and compared with a traditional process, one layer of substrate is omitted in the process, so that the thermal resistance is greatly reduced, and the power density is improved; and meanwhile, the process is convenient to realize automatically, and the production efficiency is improved.

Owner:成都森未科技有限公司

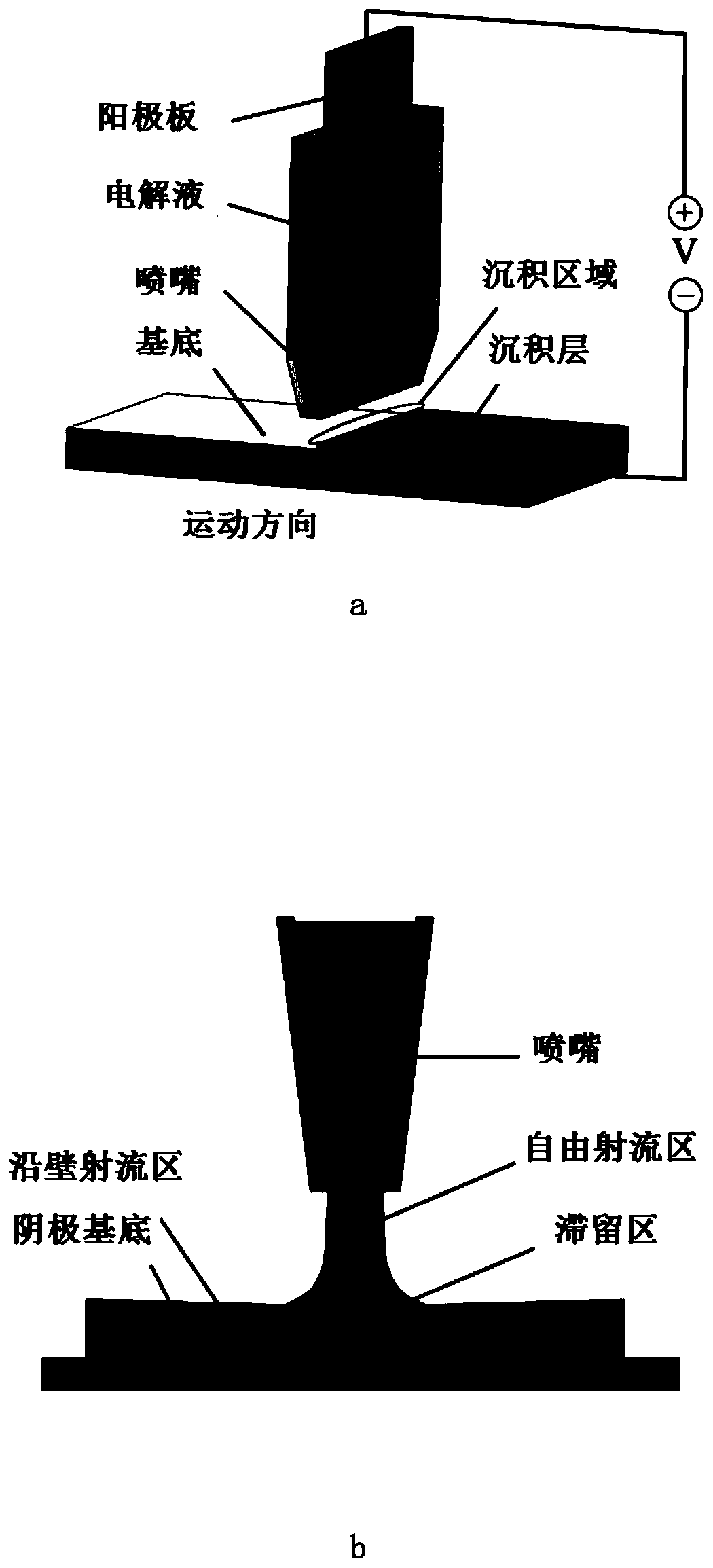

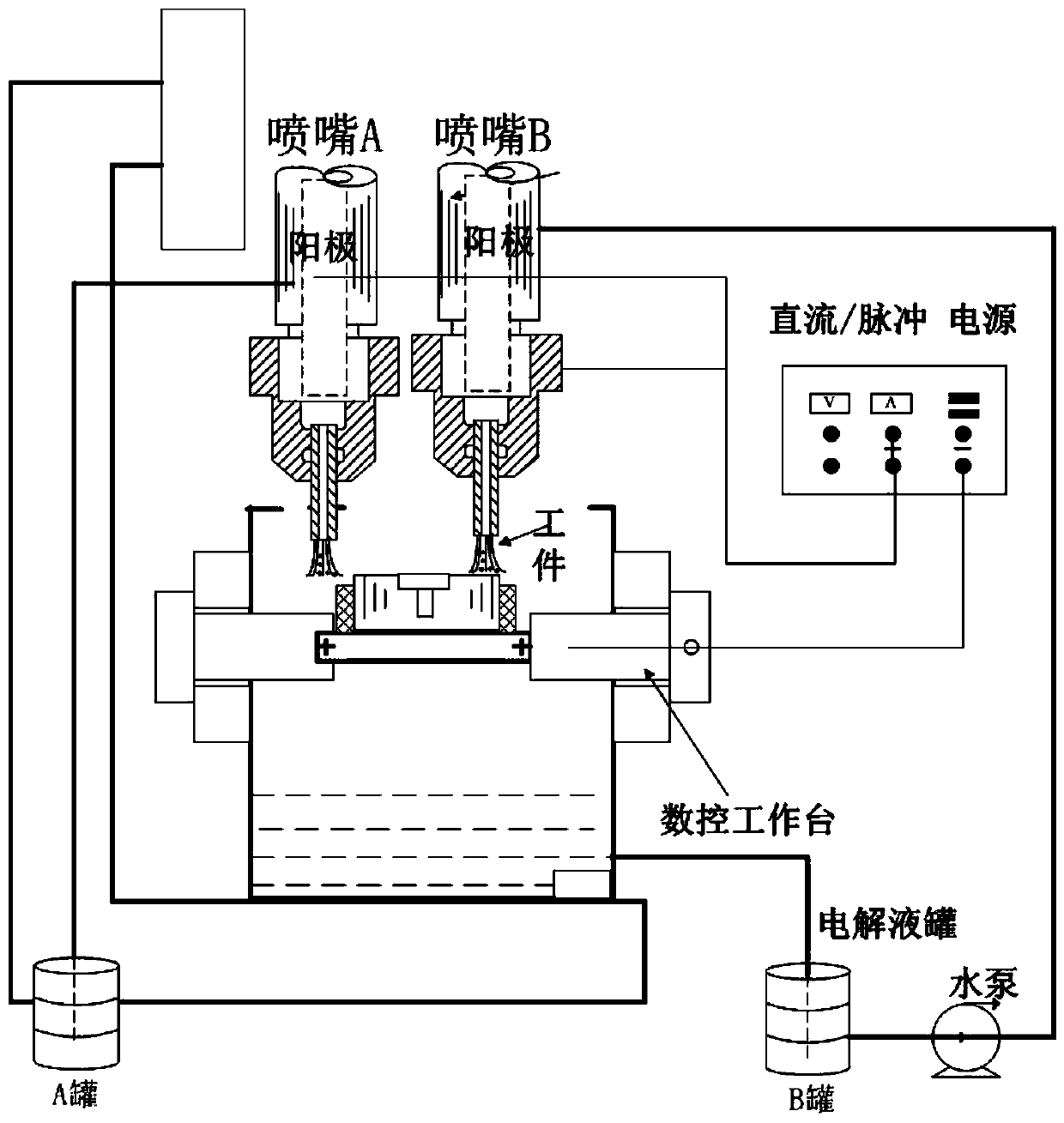

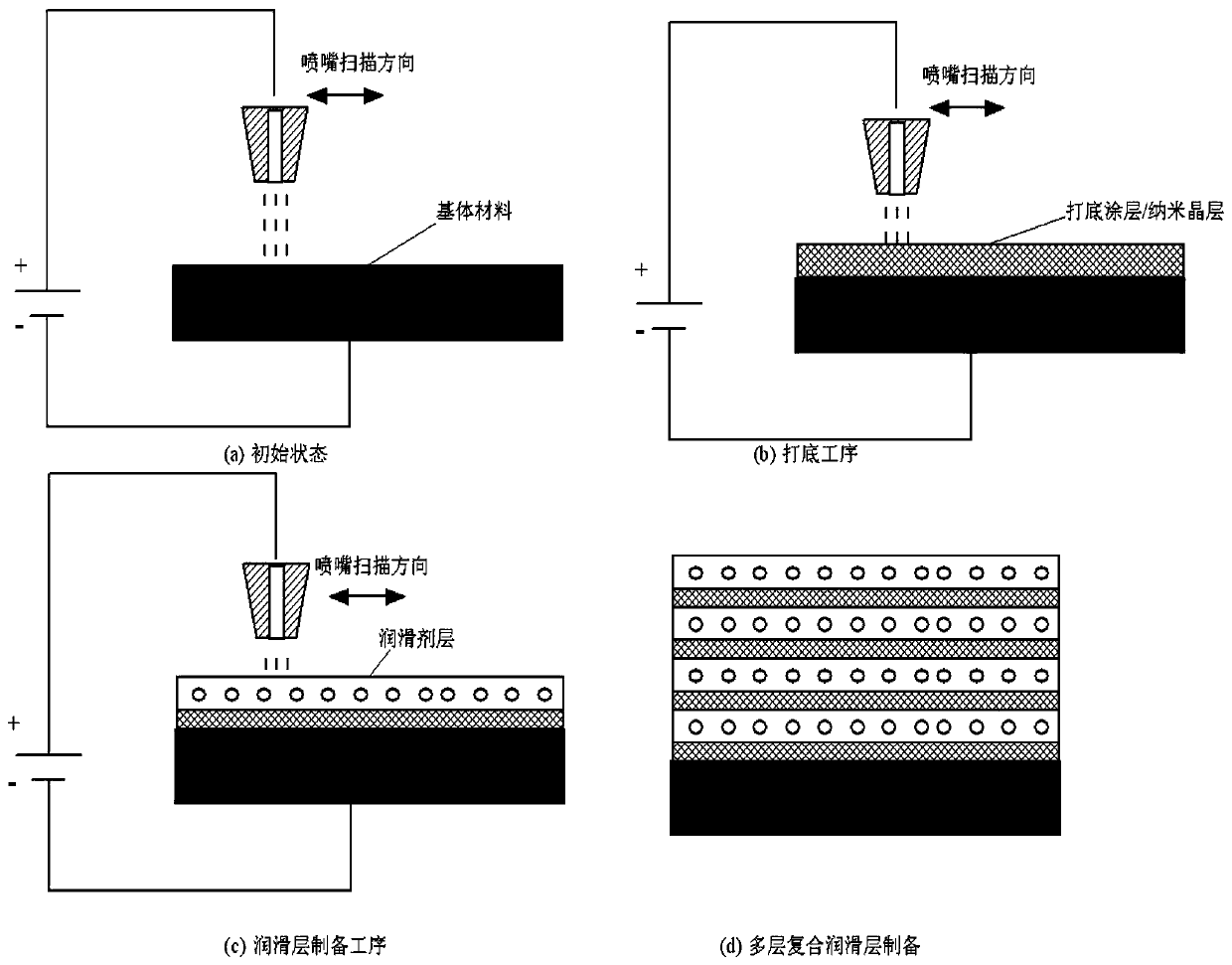

Processing method of solid lubricating coating for surface texture

InactiveCN110885995AExtend your lifeImprove carrying capacityElectrolytic coatingsGraphiteMechanical property

The invention discloses a processing method of a solid lubricating coating for a surface texture. By alternating deposition of a nanocrystalline coating and a lubricating texture coating, a multi-layer graphite coating structure is generated, the lubricating coating can be packaged by the multi-layer graphite coating structure through the nanocrystalline coating with good mechanical property and morphology, so that the service life and the bearing capacity of the coating are improved. Meanwhile, the number of layers of the multi-layer lubricating layer is designed corresponding to the number of layers of bearing friction, so that the lubricating layer is exposed out of a fresh-time layer material to correspond to new friction after being worn, the persistence of the friction reduction effect is ensured, the use effect and the service life of a friction reduction texture are prolonged, and excessive wear and failure of a friction reduction layer are avoided.

Owner:XUZHOU NORMAL UNIVERSITY

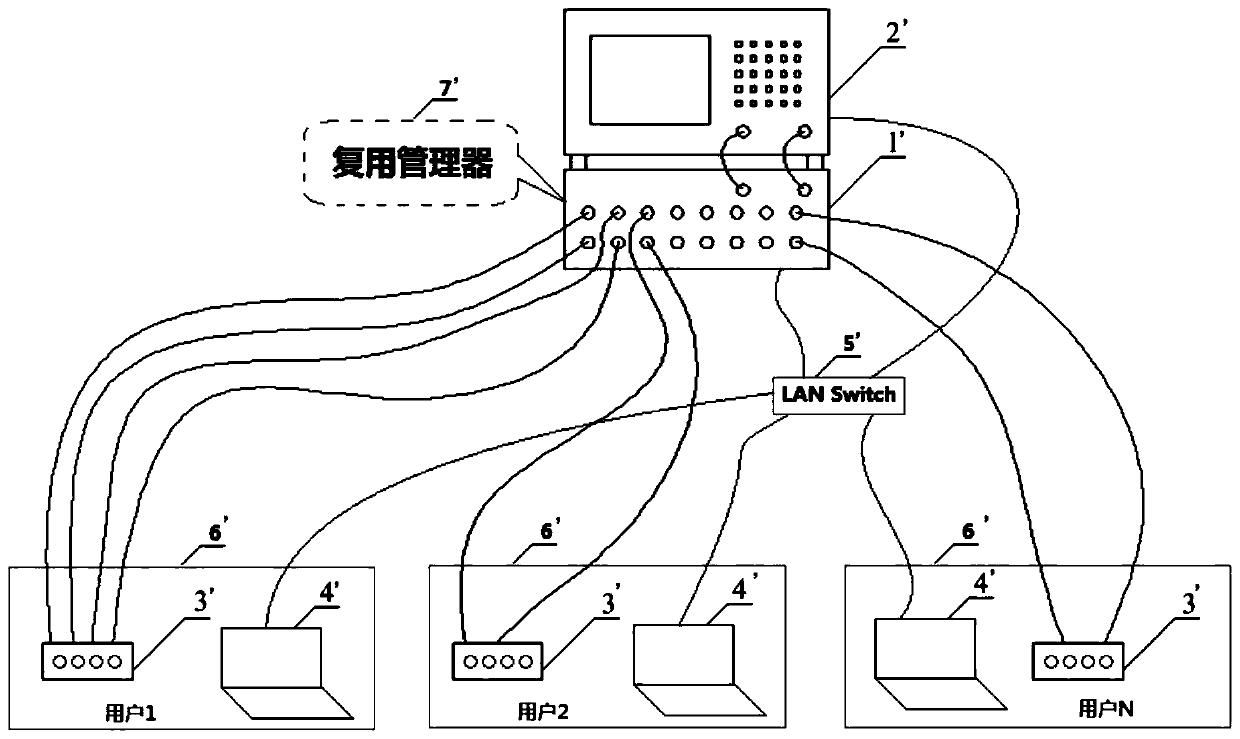

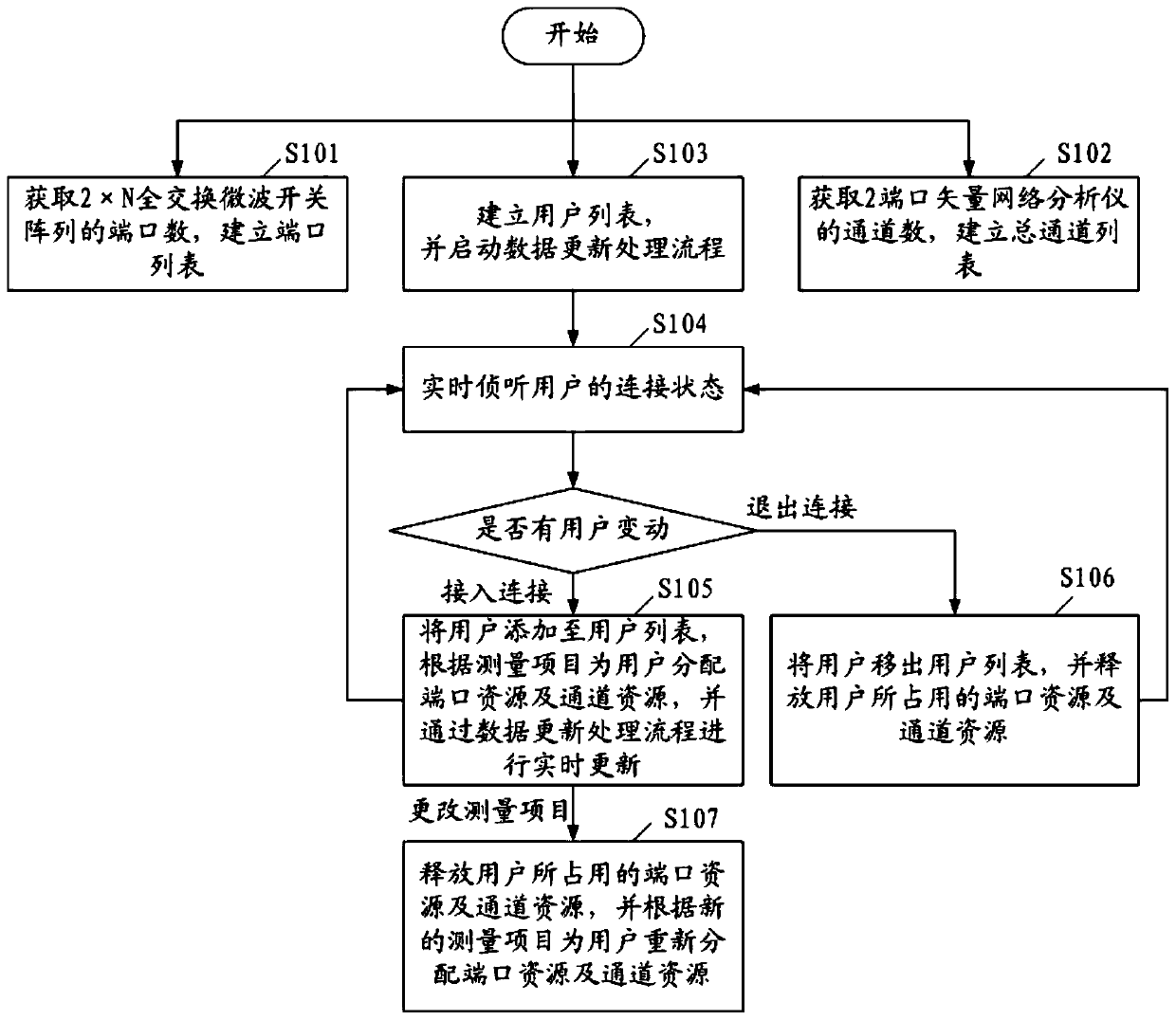

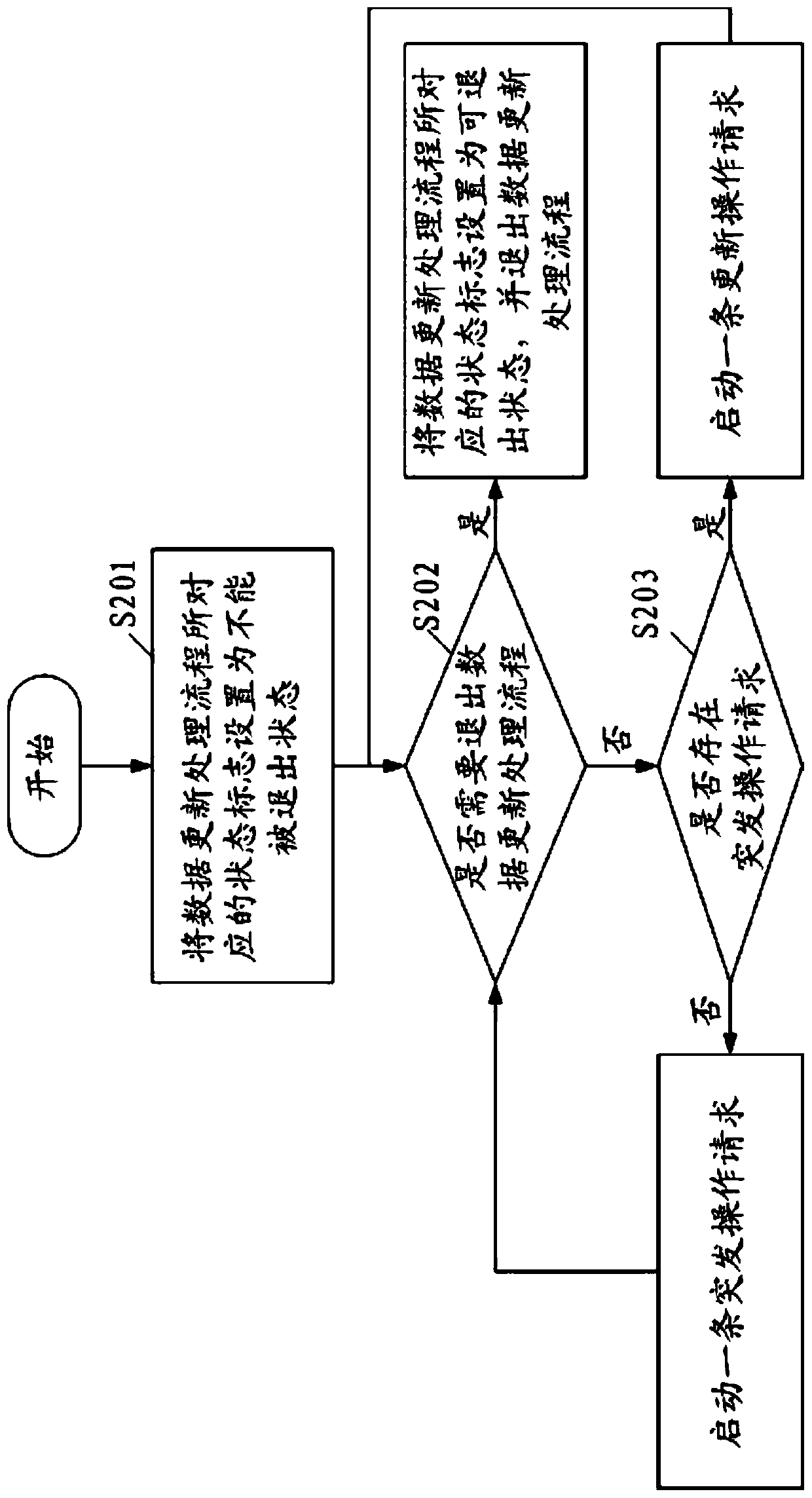

Multi-user multi-port expansion method and system based on vector network analyzer

ActiveCN110376450AIncrease flexibilityQuick matchElectrical testingElectromagentic field characteristicsMulti portComputer science

The invention discloses a multi-user multi-port expansion method based on a vector network analyzer, and the method comprises the following steps of establishing a port list; establishing a total channel list; establishing a user list, and starting a data updating processing flow; monitoring the connection state of a user in real time, adding the user to the user list when the user accesses the connection, distributing port resources and channel resources for the user according to the measurement items, and updating in real time through the data updating processing flow; and when the user quits the connection, moving the user out of the user list, and releasing the port resources and the channel resources occupied by the user. The invention also discloses a multi-user multi-port expansionsystem based on the vector network analyzer. By adopting the invention, reasonable expansion of port resources and network analyzer channel resources can be realized, and the multi-user multi-port expansion method and system based on the vector network analyzer has the advantages of strong real-time property, high precision, good flexibility, rapidness and convenience.

Owner:南京冉亚电子技术有限公司

High stability shading adhesive tape and processing method thereof

PendingCN109943241AMake up for the defect of poor weather resistanceAvoid degummingFilm/foil adhesive release linersOne-hotPeel force

The invention discloses a high stability shading adhesive tape and a processing method thereof. The high stability shading adhesive tape comprises at least one shading tape, at least one hot melt adhesive parallel to the extension direction of the shading adhesive and transparent double faced adhesive tapes located on the outer sides of two ends of the hot melt adhesive. One adhesive sides of theshading adhesive, the hot melt adhesive and the double faced adhesive tape are covered by a supporting film while the other adhesive faces are covered by a handle film, and the peeling force of the handle film is greater than that of the supporting film. According to the scheme, the high stability shading adhesive tape integrates the shading adhesives and the hot melt adhesive effectively into anintegrated structure, and a plurality of adhesives can be attached by one-time operation, so that the efficiency is high. The defect that the weather resistance of the shading adhesives is poor is supplemented by means of the characteristics of the hot melt adhesive fully, so that stable bonding is guaranteed, and the probability of degumming the shading adhesives is avoided. By adding the doublefaced adhesive tape, the hot melt adhesive at constant temperature clings to a to-be-adhered element stably during attachment, and the position precision is guaranteed, thereby providing guarantee tobonding the hot melt adhesive in a follow-up process, and the pasting difficulty is reduced.

Owner:ZAIXIAN ELECTRONICS SUZHOU

Refrigerator inner container preparing method

The invention discloses a refrigerator inner container preparing method. The refrigerator inner container preparing method comprises U-shaped large surrounding plate preparing, U-shaped small surrounding plate preparing, Z-shaped bottom plate preparing, square-shaped surrounding plate riveting, surrounding plate and bottom plate riveting and riveting line gluing. Surrounding plate and bottom plateriveting comprises bottom plate pre-riveting, four-circular-bead riveting, synchronous vertical edge and end edge riveting, synchronous side edge and end edge riveting and step-by-step short side edge riveting. In bottom plate pre-riveting, synchronous nail riveting is conducted on a plurality of point positions selected on an edge corner line where a Z-shaped bottom plate and a square-shaped surrounding plate are combined. In four-circular-bead riveting, four circular beads are riveted through two steps. In synchronous vertical edge and end edge riveting, synchronous riveting is conducted ontwo vertical edge corner lines and a high-end edge corner line. In synchronous side edge and end edge riveting, synchronous riveting is conducted on two long side edge corner lines and a low-end edgecorner line. In step-by-step short side edge riveting, two short side edge corner lines are riveted step by step. By means of the method, automatic production equipment conveniently achieves automatic production.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Method for preparing refrigerator liner by U-shaped large and small surrounding plates and Z-shaped baseplate

ActiveCN108106313AOptimize layoutAutomation for convenienceDomestic cooling apparatusLighting and heating apparatusVertical edgeEngineering

The invention discloses a method for preparing a refrigerator liner by U-shaped large and small surrounding plates and a Z-shaped baseplate. The method comprises seven steps in sequence: mouth-shapedsurrounding plate riveting, baseplate pre-riveting, four-round-angle riveting, vertical edge and end edge synchronous riveting, side edge and end edge synchronous riveting, short side edge step-by-step riveting and riveting line gluing. In the mouth-shaped surrounding plate riveting, two end lines of the U-shaped large surrounding plate and the U-shaped small surrounding plate are riveted to forma mouth-shaped surrounding plate. In the baseplate pre-riveting, multiple points are selected on combined corner lines of the Z-shaped baseplate and the mouth-shaped surrounding plate for synchronousriveting. In the four-round-angle riveting, four round angles are riveted by two steps. In the vertical edge and end edge synchronous riveting, two vertical corner lines and high end corner lines aresynchronously riveted. In the side edge and end edge synchronous riveting, two long side corner lines and low end corner lines are synchronously riveted. In the short side edge step-by-step riveting,two short side corner lines are riveted step by step. The riveting method is convenient for automatic production equipment to realize automatic production.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Preparation method of 2-amino-5-sulfydryl-1, 3, 4-thiadiazole

The invention discloses a preparation method of 2-amino-5-sulfydryl-1, 3, 4-thiadiazole, and particularly relates to a method for producing 2-amino-5-sulfydryl-1, 3, 4-thiadiazole by using a microreactor, the reaction temperature is 80 to 100 DEG C, the reaction time is 0.5 to 1 hour, and the reaction pressure is 100 to 160 psi. The method comprises the following steps: S1, preparing a raw material solution; S2, building equipment: carrying out reaction by using a silicon carbide reactor; S3, carrying out cyclization reaction; and S4, post-treatment: carrying out suction filtration, water washing and drying on the reaction liquid to obtain a product. According to the invention, the traditional preparation method of 2-amino-5-sulfydryl-1, 3, 4-thiadiazole is converted into a Flow mode, and the reaction time is shortened and the reaction yield is improved by strengthening the reaction process and accurately controlling the temperature. Meanwhile, the mode is beneficial to realizing automatic production of products and meeting the industry development requirements.

Owner:南京硕达生物科技有限公司

Method and apparatus for customizing communication protocol, method and apparatus for converting communication protocol description

ActiveCN101370003BAutomation for convenienceThe description method is intuitiveTransmissionComputer hardwareCommunications protocol

Owner:DATANG MOBILE COMM EQUIP CO LTD

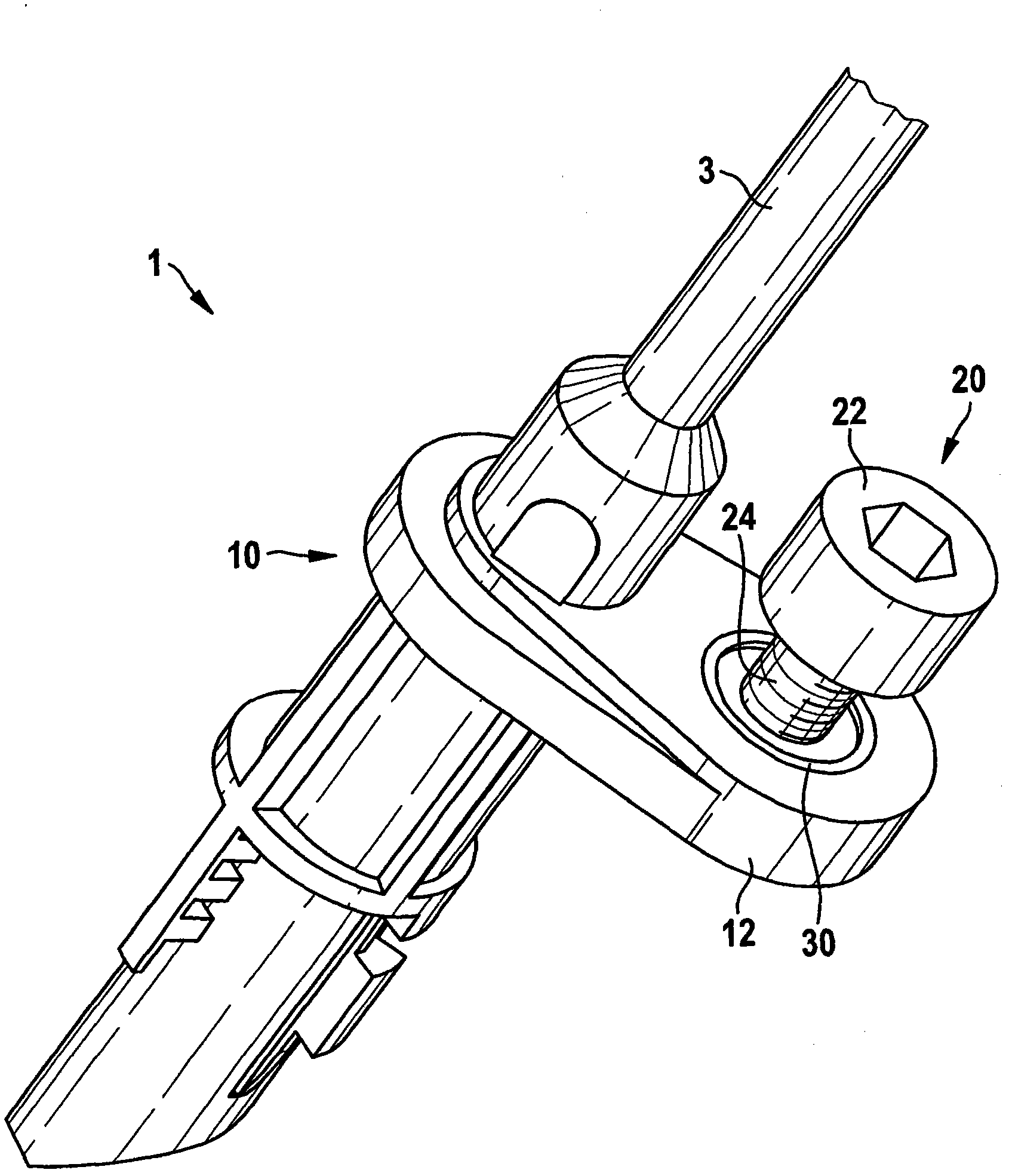

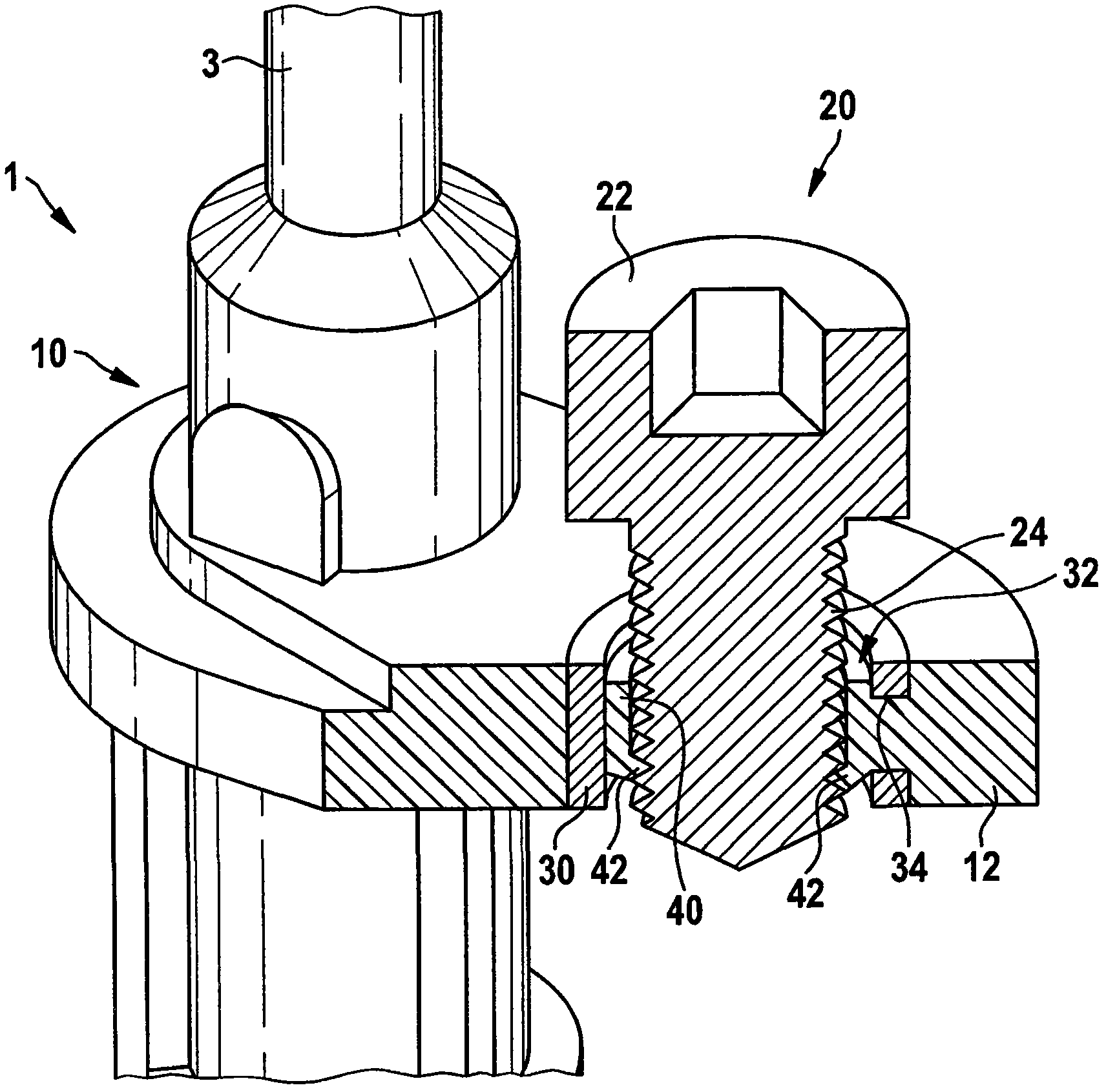

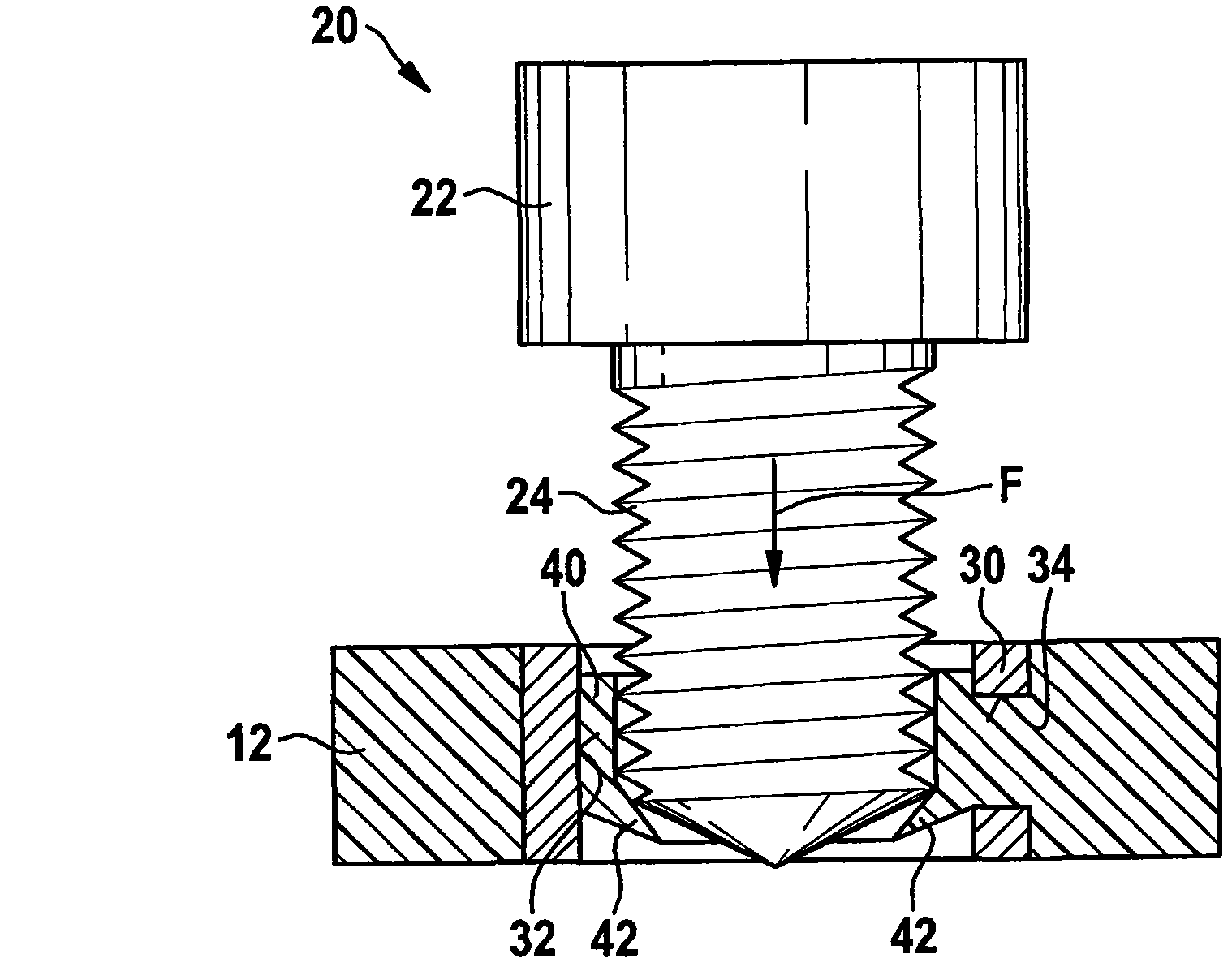

Structure of a build-in screw in a bushing and corresponding sensor housing

An improved structure of a build-in screw (20) in a bushing (30) comprises a bushing (30) made of metal and an elastic material (40) at an inner region (32) forming a flexible area (42) in which a thread shank (24) of said screw (20) is pressed in by deforming said flexible area (42), so that said screw (20) and said metal bushing (30) are captively connected.

Owner:ROBERT BOSCH GMBH

A kind of welding temperature control method

ActiveCN110788440BAutomation for convenienceAvoid human errorHeat exchange apparatusMetal working apparatusTemperature controlWeld seam

The invention provides a welding temperature control method, which includes automatic welding equipment, the automatic welding equipment includes a welding torch, a temperature control system and an identification system, the identification system identifies the identification information of the parts to be welded, and the temperature control system according to the The identification information calls out the corresponding welding process parameters, and automatically sets the gas flow of the welding torch based on the welding process parameters. The welding process parameters include the target temperature of the weld, and also automatically adjust the welding parameters such as pipe diameter and wall thickness. Parameters The temperature control system includes a temperature monitoring head for monitoring the real-time temperature of the weld, and when the difference between the real-time temperature and the target temperature exceeds a first threshold, the temperature control system adjusts the gas flow of the welding torch to Making the difference between the real-time temperature and the target temperature smaller than the first threshold. Automatically call out welding parameters through identification information, which is conducive to automation, avoids human errors, automatically stops when the temperature is abnormal, and eliminates batch problems.

Owner:NINGBO AUX ELECTRIC +1

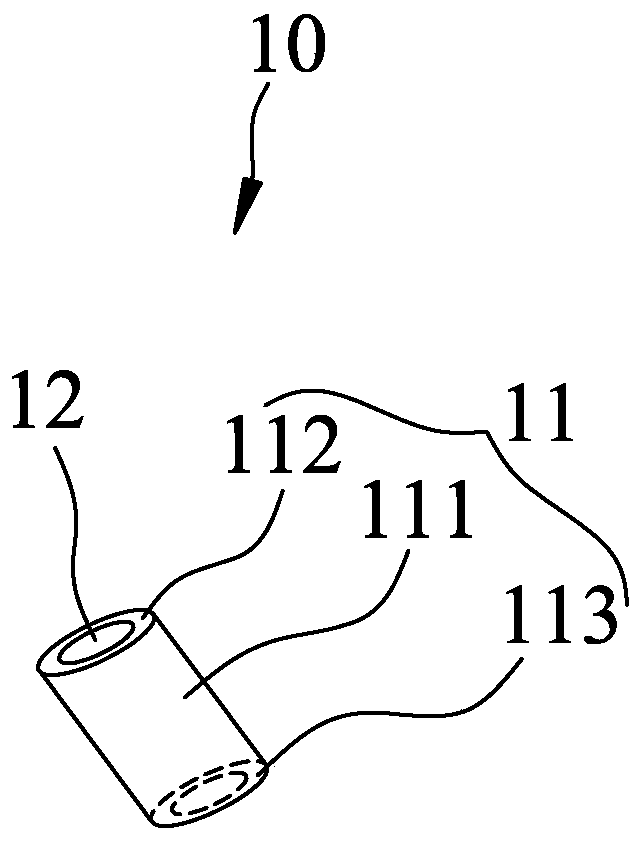

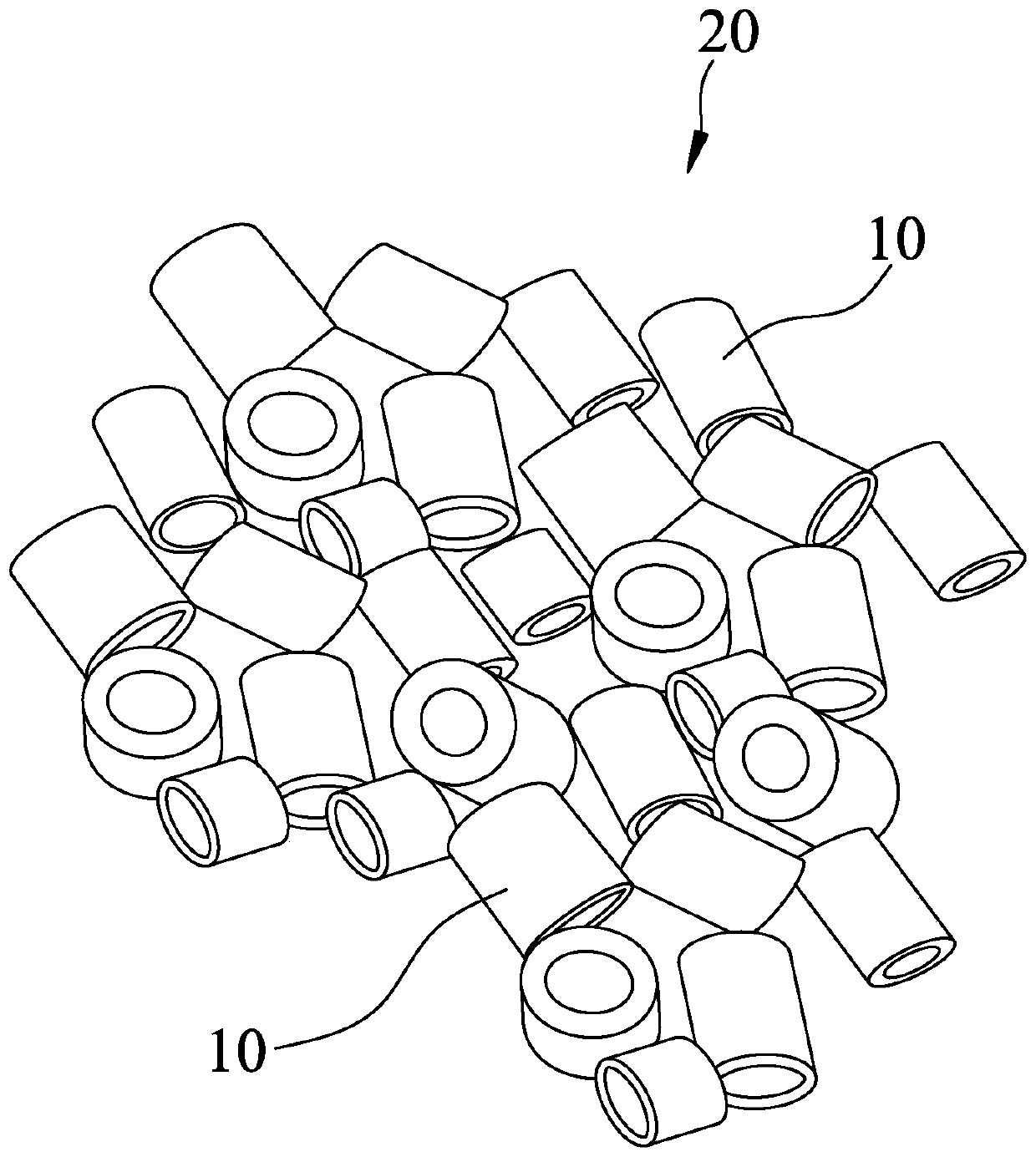

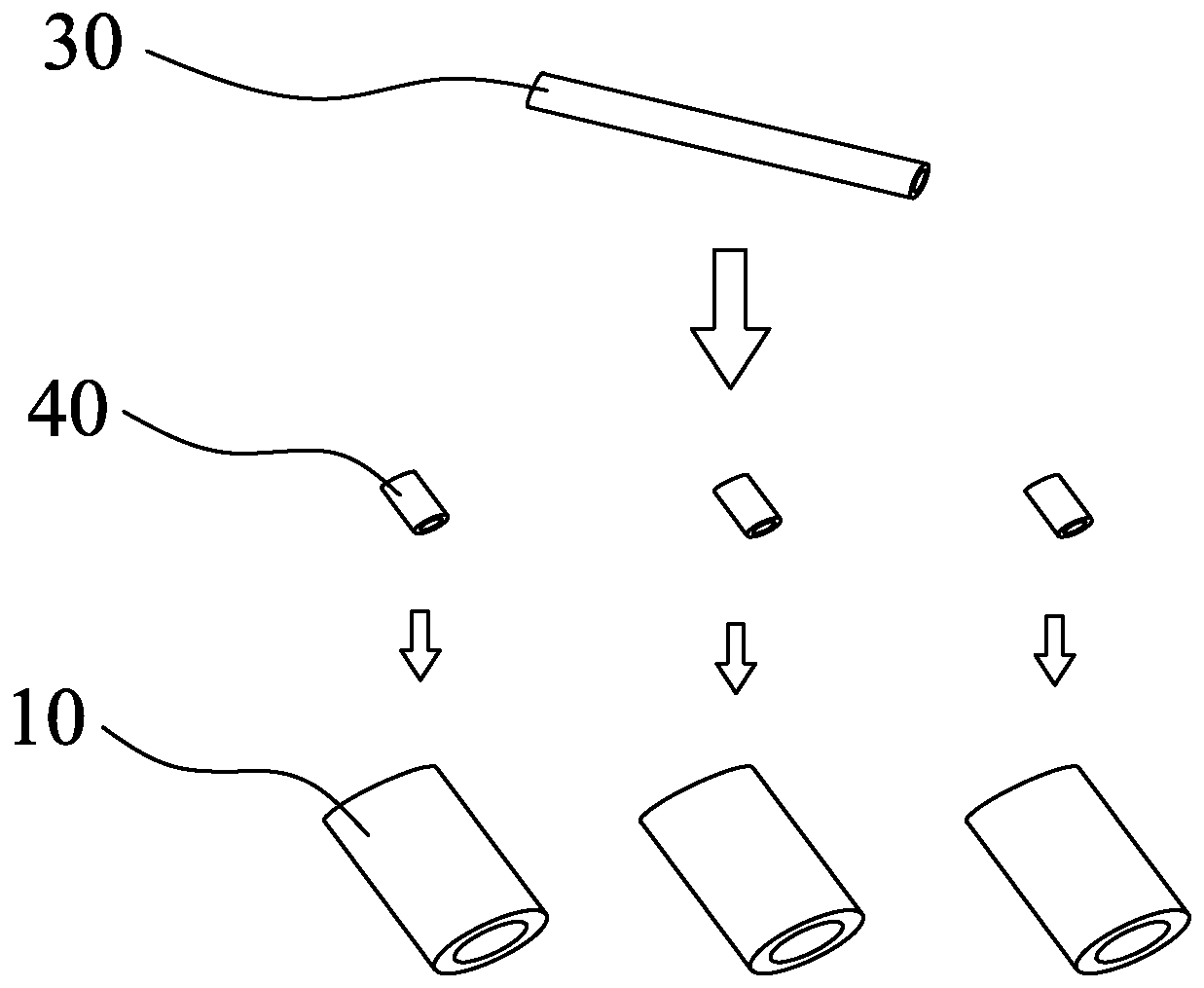

Improved foaming particle, molded body and production process of improved foaming particle

InactiveCN109795050AImprove molding efficiencyAutomation for convenienceCoatingsElastomerUnit volume

The invention discloses an improved foaming particle, a molded body and a production process of the improved foaming particle. The improved foaming particle comprises a cylindrical elastomer, whereina through hole is formed in the middle position of the cylindrical elastomer, and the cylindrical elastomer is prepared by foaming and molding extruded cylindrical particle with holes. Compared with the prior art, the improved foaming particle, the molded body and the production process enrich the types of foaming particles, the weight of the particles per unit volume can further be reduced, and the cushioning performance of products can be improved to a certain extent.

Owner:晋江国盛新材料科技有限公司

Electrolyte for coating electrode material surface of lithium battery and coating method

InactiveCN106299238AGood effectSimple processFinal product manufactureLi-accumulatorsPlasticizerNickel–lithium battery

The invention relates to the technical field of lithium batteries, in particular to an electrolyte for coating an electrode material surface of the lithium battery and a coating method. The electrolyte comprises the raw materials of lithium trifluoromethanesulfonimide, a plasticizer, a surfactant, an antioxidant and a stabilizer, wherein the plasticizer comprises fluorobenzene and ethyl acetate. The coating method comprises the steps of (1) evenly coating the positive and negative surfaces of a positive pole piece with a positive electrode active material which is 50-70 microns thick and evenly coating the positive and negative surfaces of a negative pole piece with a negative electrode active material which is 50-70 microns thick; (2) evenly coating the positive and negative surfaces of the positive pole piece and the negative pole piece with the electrolyte separately until the coating thickness is 15-25 microns, carrying out lamination and reversely sealing the tops to obtain a naked battery core; and (3) finally carrying out formation treatment on the naked battery core to prepare the lithium battery core. According to the electrolyte and the coating method, electrolyte pollution and liquid leakage are not formed; the throughput yield is 5% higher than that of a conventional electrolyte; meanwhile, the electrolyte provided by the invention is simple in operation, safe and environment-friendly and is of great significance in promotion of application and development of the lithium battery.

Owner:四川赛尔雷新能源科技有限公司

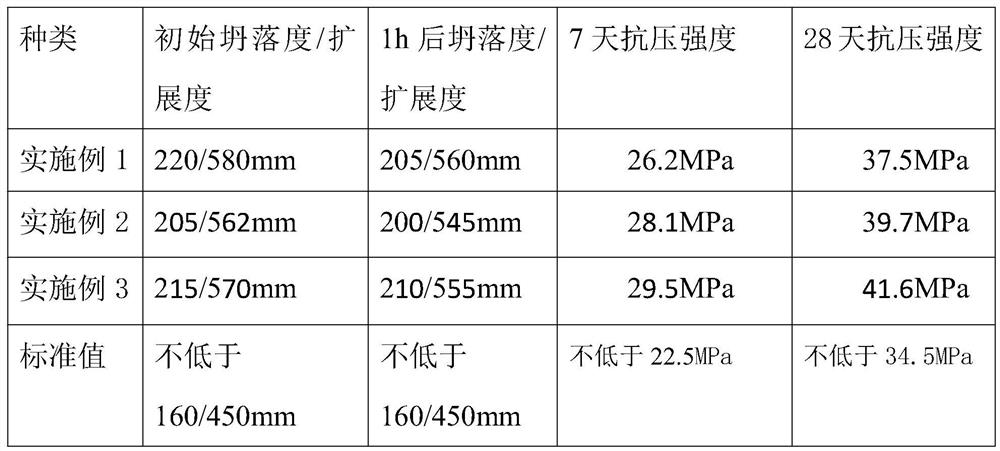

A kind of activator and preparation method of copper smelting waste slag applied in concrete

The invention discloses an activator for application of copper smelting waste residues in concrete and a preparation method of the activator, wherein the activator comprises modified polyoxyethylene ether rich in sulfonic acid groups, trifluoromethanesulfonate and alkylol amine, and the form of the activator is solid powder. The preparation method of the activator has the advantages of mild process conditions, simple and easily-controlled equipment, high production efficiency, zero emission and no pollution; the produced novel activity-excited solid powder additive is convenient to package andtransport, and is easy to mix, grind and add with copper smelting waste residues. When the copper smelting waste slag activated by the activator is applied to concrete, the activity of the copper smelting waste slag is improved; on the premise of ensuring the workability, strength and durability of the concrete, mineral powder and fly ash in the concrete can be replaced, the use amount of cementis reduced, waste is turned into wealth, and the problems of shortage of admixture supply and unstable quality required by green treatment of copper smelting waste residues and concrete production aresolved.

Owner:湖南振海新材料科技有限公司

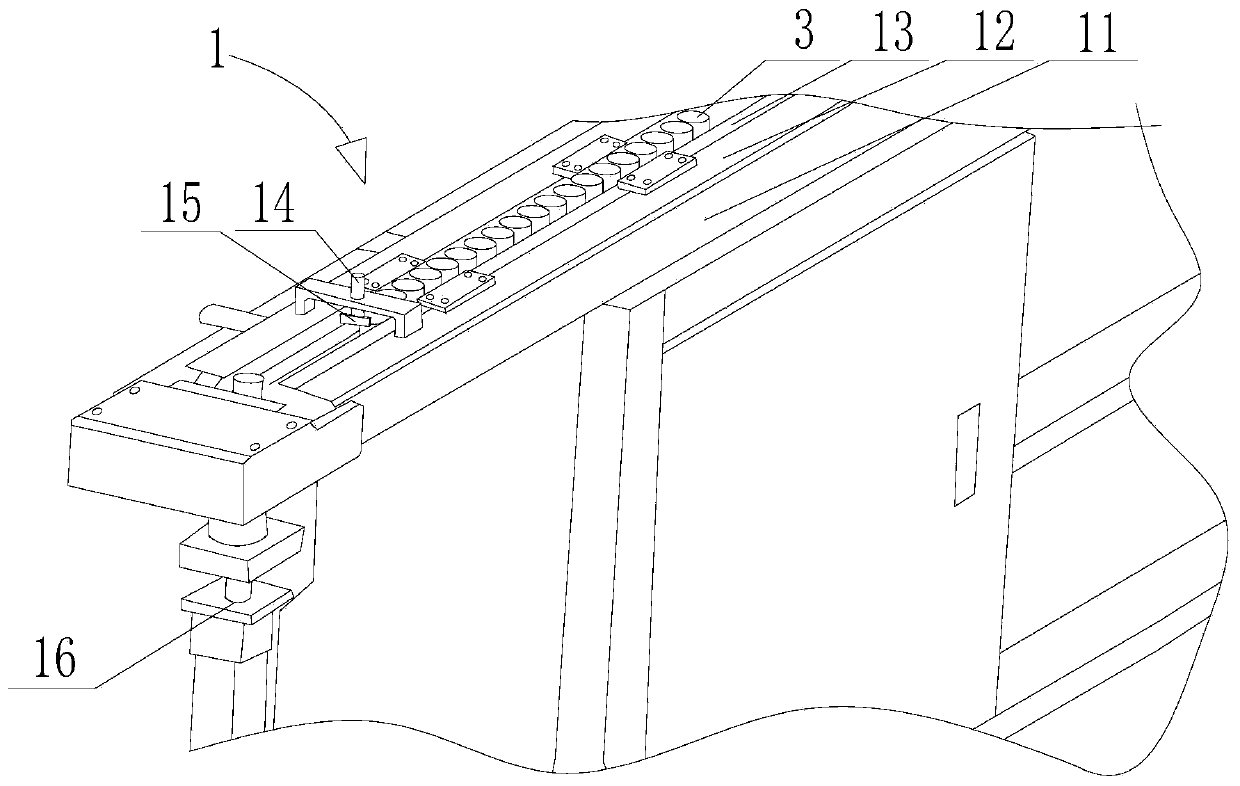

Automatic processing technology of vvt valve sleeve

ActiveCN108274201BReduce processing stepsReduce processing timeMeasurement/indication equipmentsLarge fixed membersRobot handEngineering

The invention discloses a VVT valve sleeve automatic machining technology. The VVT valve sleeve automatic machining technology comprises the following steps that (1), a VVT valve sleeve is transportedto a robot hand-grabbing position by a feeding device; (2), the robot grabs the positioning surface, close to a clamp, of the VVT sleeve to prepare for clamping; (3), the clamp blows to clean the positioning surface and the VVT valve sleeve; (4), the VVT valve sleeve is installed on the positioning surface of the clamp by the robot; (5), the VVT valve sleeve is pressed by grippers of the robot, and the VVT sleeve is fixed on the positioning surface by a clamping mechanism on the clamp; (6), whether the VVT valve sleeve is installed in place or not is detected by the clamp through gas detection; and (7), after confirming that the VVT valve sleeve is installed in place, the VVT valve sleeve is subjected to tool machining by a tool, and the tool is mounted on a machine tool. All steps are completed centrally in a machining center. The clamp comprises a front face machining station and a back face machining station, the clamp further comprises an air blowing device, and the air blowing device comprises a pipeline and a jet opening formed in the pipeline. The VVT valve sleeve automatic machining technology solves the problems of low efficiency and high cost caused by an existing automatic machining technology.

Owner:四川融至精密机械有限公司

Suction nozzle mounting instrument for soft packaging bag

InactiveCN110774665AIncrease success rateSimple structureBag making operationsPaper-makingMechanical engineeringFood products

The invention relates to a suction nozzle installation instrument for a soft packaging bag. The suction nozzle installation instrument aims at solving the defects of low success rate and low efficiency in installing a suction nozzle on the soft packaging bag in the prior art. According to the scheme, the suction nozzle installation instrument comprises a soft packaging bag feeding device, a soft packaging bag opening device for forming and opening of a bag opening of the soft packaging bag which is fed by the soft packaging bag feeding device, a nozzle loading device for placing the suction nozzle on the bag opening of the soft packaging bag, and an edge sealing device for sealing the suction nozzle and the bag opening of the soft packaging bag. The soft packaging bag opening device comprises a frame, a set of sucking discs and sucking disc driving mechanisms, the sucking discs and the sucking disc driving mechanisms are each arranged in pairs and oppositely arranged, and the sucking disc driving mechanisms are arranged on the frame; the sucking disc driving mechanisms are used for driving the paired sucking discs to move towards each other or towards the opposite direction; and the soft packaging bag feeding device is used for conveying the soft packaging bag to the positions between the paired sucking discs. The suction nozzle installation instrument is mainly used in the suction nozzle installation field of soft packaging bags for food such as liquid beverage or gel jellies.

Owner:深圳市聚能自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com