Integrated IGBT packaging structure based on DBC layout

A packaging structure and layout technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of reducing the IGBT working safety area, high installation process requirements, and large DC loop area, etc. The effect of expanding the working safety area, reducing the stray inductance and improving the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

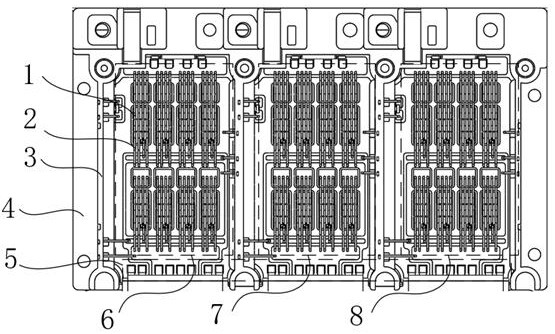

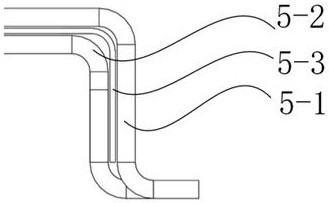

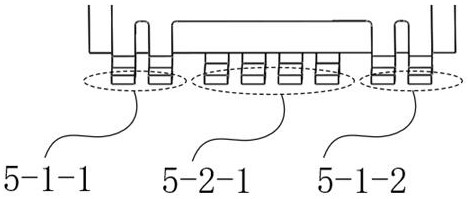

[0030] The integrated IGBT packaging structure based on a DBC layout includes a three-phase DBC structure, the outside of the three-phase DBC structure is fixed with a frame, the front of the three-phase DBC structure is welded with multiple chips, and the back of the three-phase DBC structure is directly welded on On the radiator, the chips in the three-phase DBC structure are connected to each other, and the DC terminals of the three-phase DBC structure are connected with laminated bus bars. The three-phase DBC of the present application is directly welded to the radiator. This process has one less substrate than the traditional process, which greatly reduces the thermal resistance and improves the power density; at the same time, this process is easy to realize automation and improves production efficiency. . A single DBC structure includes a ceramic insulating substrate 000. The front side of the ceramic insulating substrate 000 is provided with an upper bridge IGBT chip 00...

Embodiment 2

[0032] The integrated IGBT packaging structure based on a DBC layout includes a three-phase DBC structure, the outside of the three-phase DBC structure is fixed with a frame, the front of the three-phase DBC structure is welded with multiple chips, and the back of the three-phase DBC structure is directly Soldered on the heat sink, the chips in the three-phase DBC structure are connected to each other, and the DC terminals of the three-phase DBC structure are connected with laminated bus bars. The DBC structure includes a ceramic insulating substrate 000. The front side of the ceramic insulating substrate 000 is provided with an upper bridge IGBT chip 001, an upper bridge diode chip 002, a lower bridge IGBT chip 016, a lower bridge diode chip 017, an NTC temperature sensor 005 and multiple surfaces. Copper foil; the upper bridge IGBT chip 001 and the upper bridge diode chip 002 are connected by surface copper foil, the upper bridge diode chip 002 and the upper bridge IGBT chip 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com