Automatic processing technology of vvt valve sleeve

A processing technology and valve sleeve technology, which is applied in the field of VVT valve sleeve automatic processing technology, can solve the problems of high cost and low efficiency, and achieve the effects of high tool life, high service life, and high processing dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

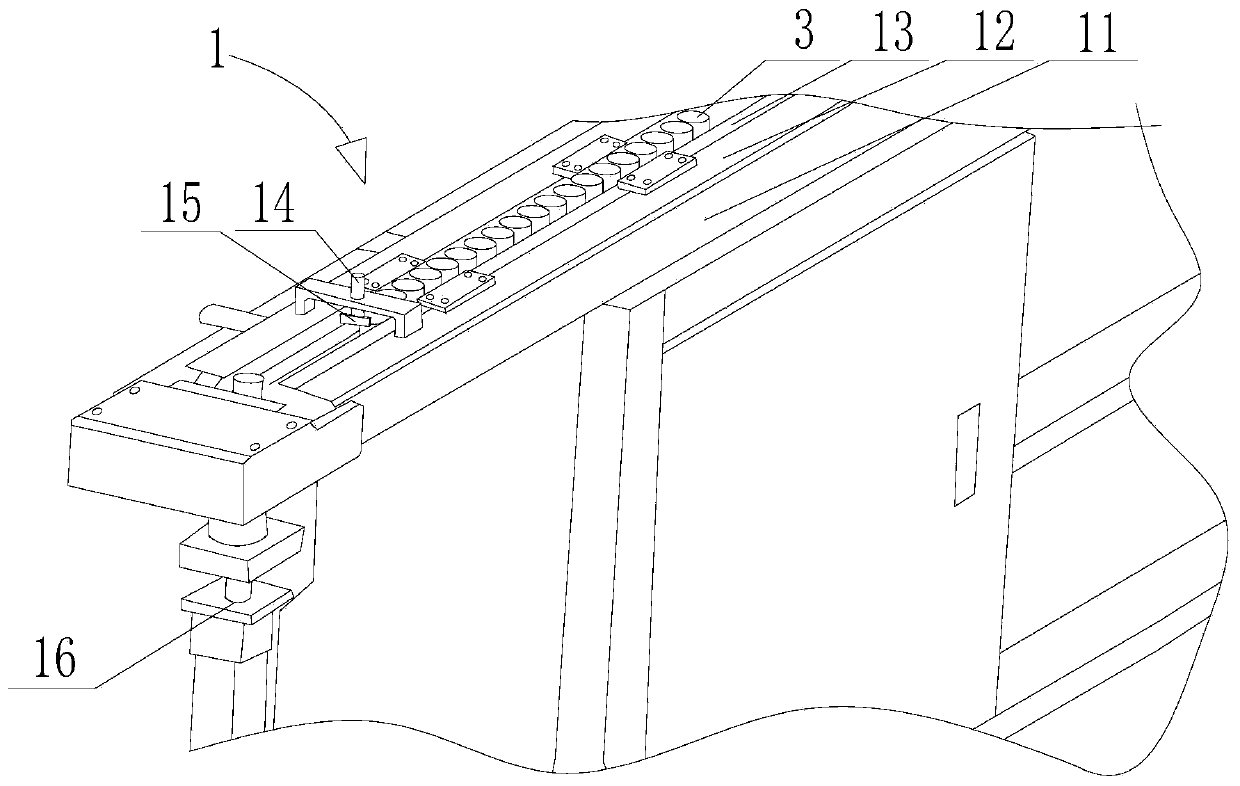

[0054] Such as Figure 1 to Figure 3 As shown, the automatic processing technology of VVT valve sleeve includes the following steps:

[0055] 1), the feeding device 1 transports the VVT valve sleeve 3 to the grip position of the robot;

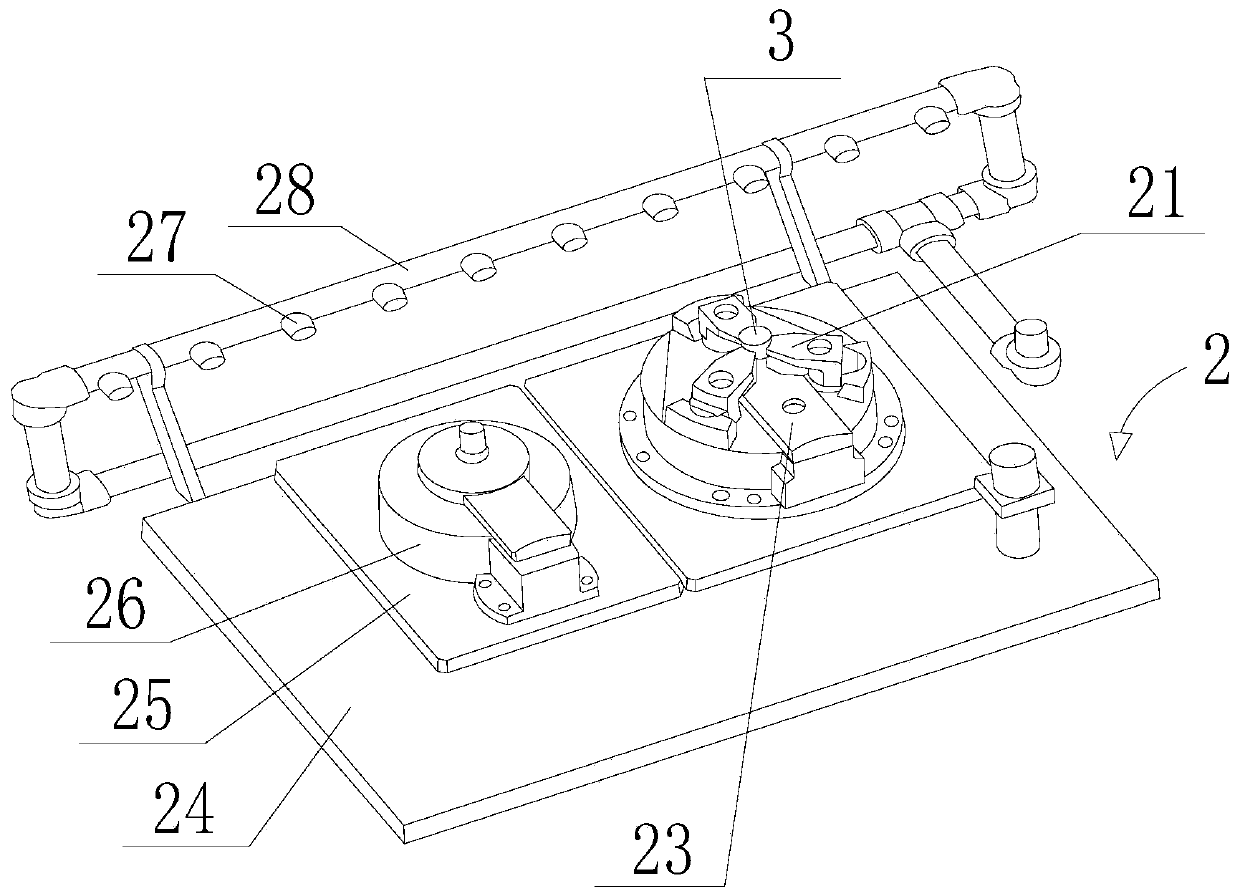

[0056] 2), the robot grabs the positioning surface 23 of the VVT valve sleeve 3 close to the fixture 2 and prepares for clamping;

[0057] 3), the positioning surface 23 and the VVT valve sleeve 3 of the clamp 2 are blown to clean the clamp 2, specifically, through the automatic control technology, the injection port 27 is automatically sprayed, and the gas is injected to the processing surface of the positioning surface 23 and the VVT valve sleeve 3 ( upper end surface) to clean the positioning surface 23 and the VVT valve sleeve 3, so as to avoid impurities such as iron filings and dust affecting the positioning accuracy of the parts;

[0058] 4), the robot installs the VVT valve sleeve 3 on the positioning surface 23 of the fi...

Embodiment 2

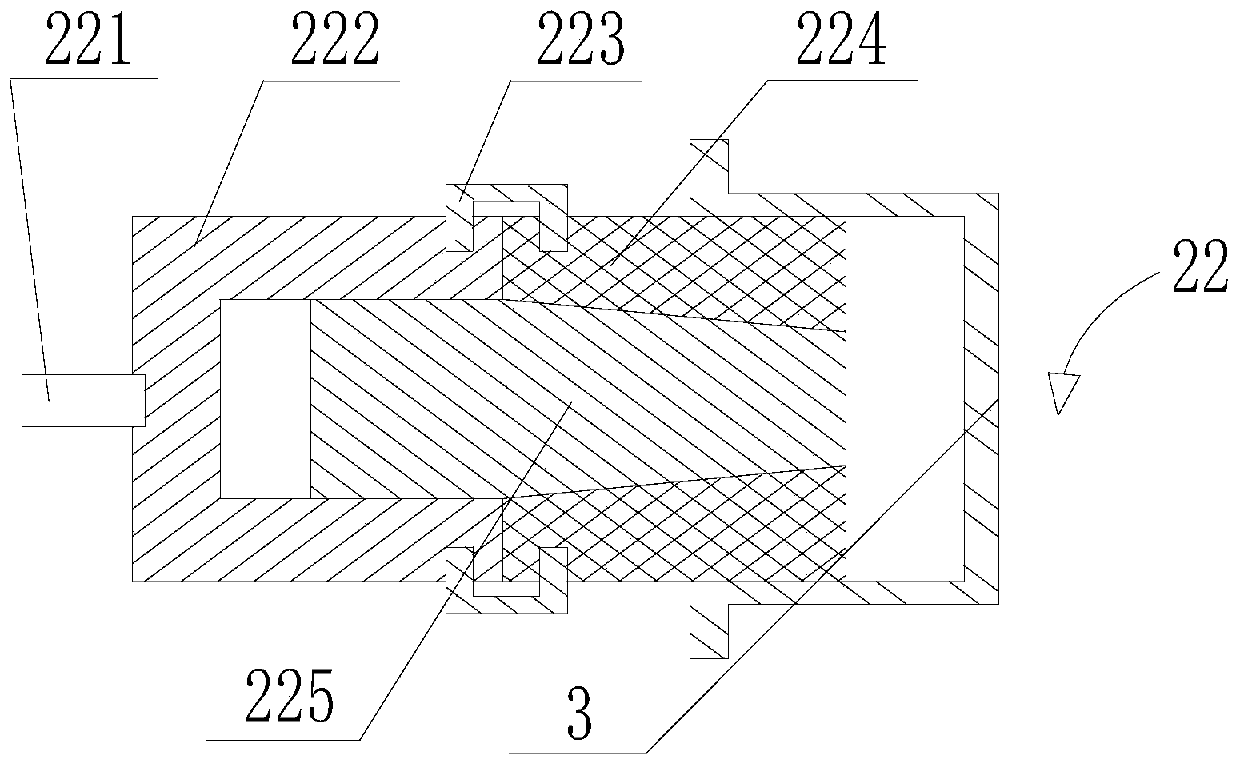

[0075] Such as Figure 1 to Figure 3 As shown, this embodiment is based on Embodiment 1. The fixing groove 222 and the inner expansion sleeve 224 are connected by a connecting piece 223. The section of the connecting piece 223 in the axial direction is a U-shaped structure, and the U-shaped structure One side is inserted into the fixing groove 222 , and the other side is inserted into the inner expansion sleeve 224 .

[0076] In this embodiment, through the arrangement of the connecting piece 223 , the detachable arrangement between the inner expansion sleeve 224 and the fixing groove 222 is realized, which facilitates the replacement of the inner expansion sleeve 224 .

[0077] Example 2:

[0078] Such as Figure 1 to Figure 3 As shown, the present embodiment is based on Embodiment 1 or Embodiment 2. The machining center also includes an automatic measuring machine, which is configured in the production line, and adopts internationally renowned sensors such as Keyence and I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com