Bridge fabrication machine capable of building and assembling two bridge segments

A bridge building machine and segment technology, applied in the field of bridge construction, can solve problems such as high cost and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention will be further described below in conjunction with accompanying drawing:

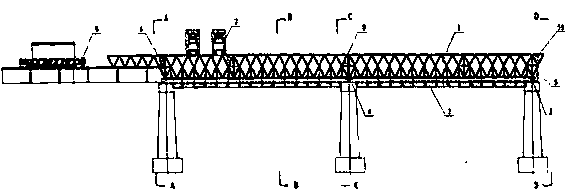

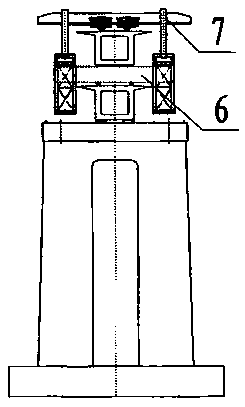

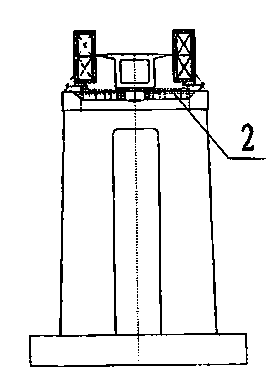

[0023] Such as figure 1 , 2 , 3, 4, and 5, 1 is the main beam, 2 is the lower joist system, 3 is the front fulcrum supporting wheel system, 4 is the middle fulcrum supporting wheel system, 5 is the front outrigger, 6 is the rear fulcrum beam, 7 8 is a beam lifting machine, 8 is an intermediate beam, 9 is a beam transport vehicle, and 51 is a front outrigger beam.

[0024] Such as Figure 6 As shown, 11 is the main truss, 12 is the short joint tail truss, and 13 is the upper chord steel pin of the main truss.

[0025] As shown in Figure 7, 21 is a lower joist beam, 22 is a lower joist longitudinal beam, and 23 is a leading screw or a hydraulic jacking device.

[0026] It consists of main girder 1, lower joist system 2, front fulcrum supporting wheel system 3, middle fulcrum supporting wheel system 4, front outrigger 5, rear fulcrum beam 6, beam lifting crane 7 and other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com