Dismountable high-intensity pull riveting pin and connecting and dismounting method

A rivet pin, high-strength technology, applied in the direction of connecting components, rivets, threaded fasteners, etc., can solve the problems of inability to disassemble and reuse, poor clamping of the jaws, and easy blockage of the pull grooves, and achieves fast tightening. Strengthen the force, solve the stress concentration and stuck, reduce the effect of the head breaking and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

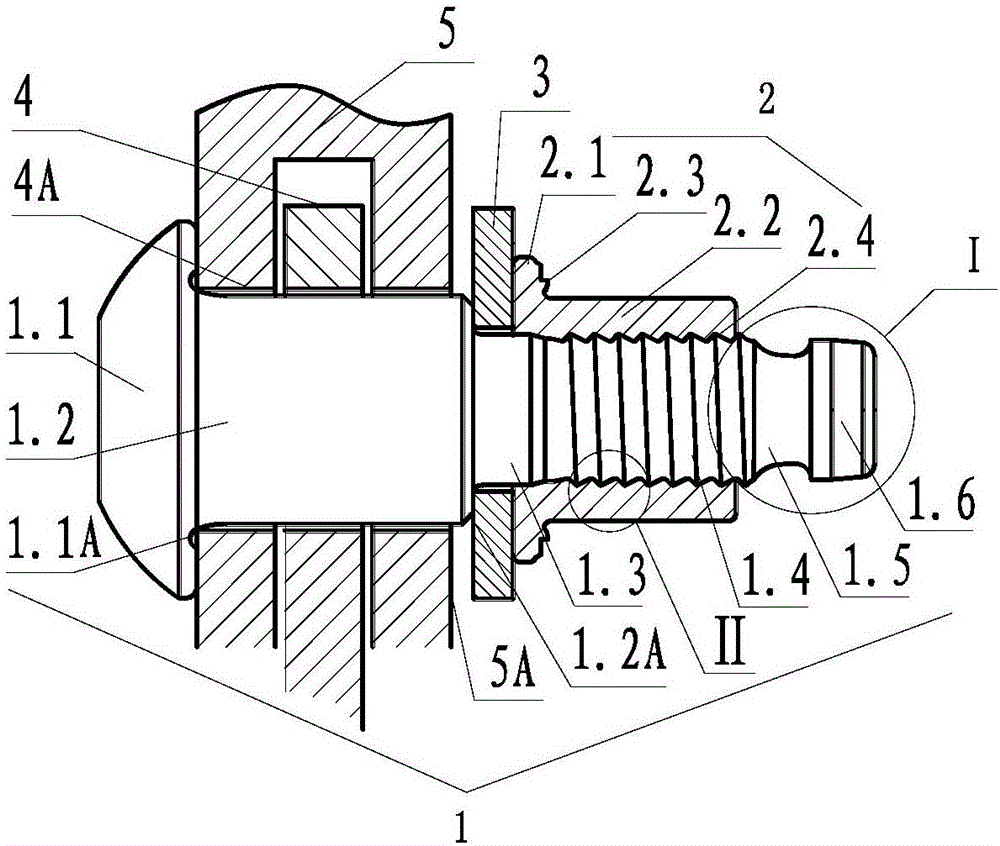

[0043] See figure 1, In this embodiment, the detachable high-strength blind riveting pin is composed of a pin shaft 1, a collar 2 and a washer 3. The pin shaft 1 includes a riser 1.1, a pin post 1.2, a short polished rod 1.3, a locking groove section 1.4 and a tail connected in sequence from the front end to the rear end. The pin 1.2 is tightly matched with the pin hole 4A of the rotating part 4 and the horseshoe-shaped part 5 of the connected part. The collar 2 is tightly sleeved on the locking groove section 1.4. Washer 3 is sleeved on the outside of short polished rod 1.3. The collar 2 includes a flange 2.1 and a straight cylinder 2.2 from the front end to the rear end, the rear end surface of the flange has a convex point 2.3, and the rear end of the inner hole of the straight cylinder has a locking tooth 2.4. New design of the present invention has:

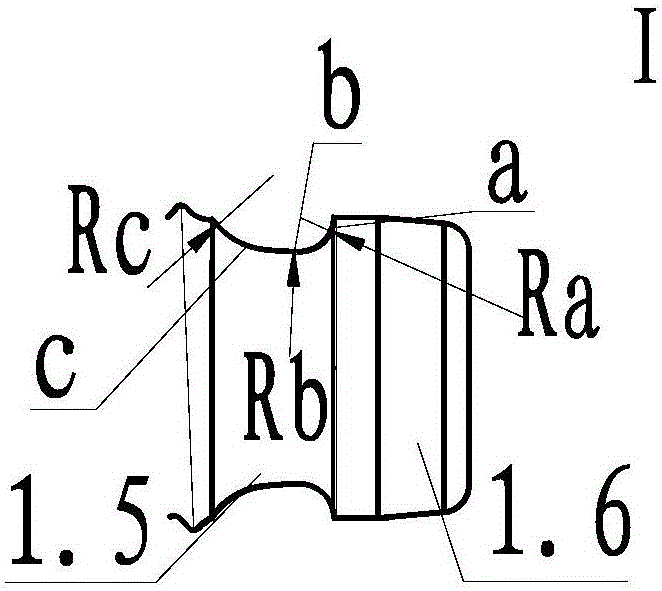

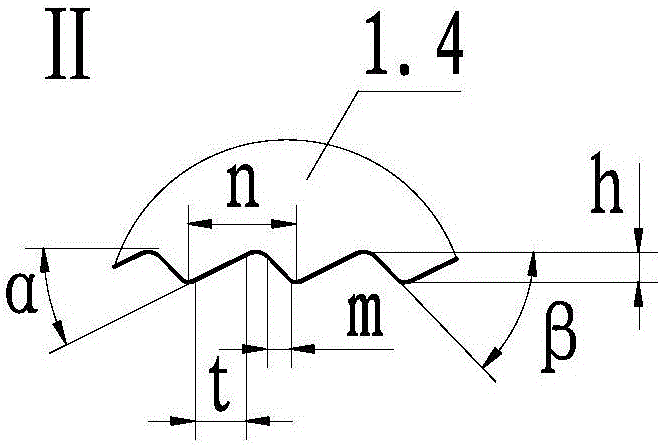

[0044] 1) see figure 1 , figure 2 , the tail is a single-groove short tail composed of a continuous smooth arc su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com