Novel reforming furnace for preparing reducing gas

A reforming furnace and a new type of technology, applied in the metallurgy and petrochemical fields, can solve the technical and economic problems of reducing gas, and achieve the effects of saving materials, reducing floor space and improving economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

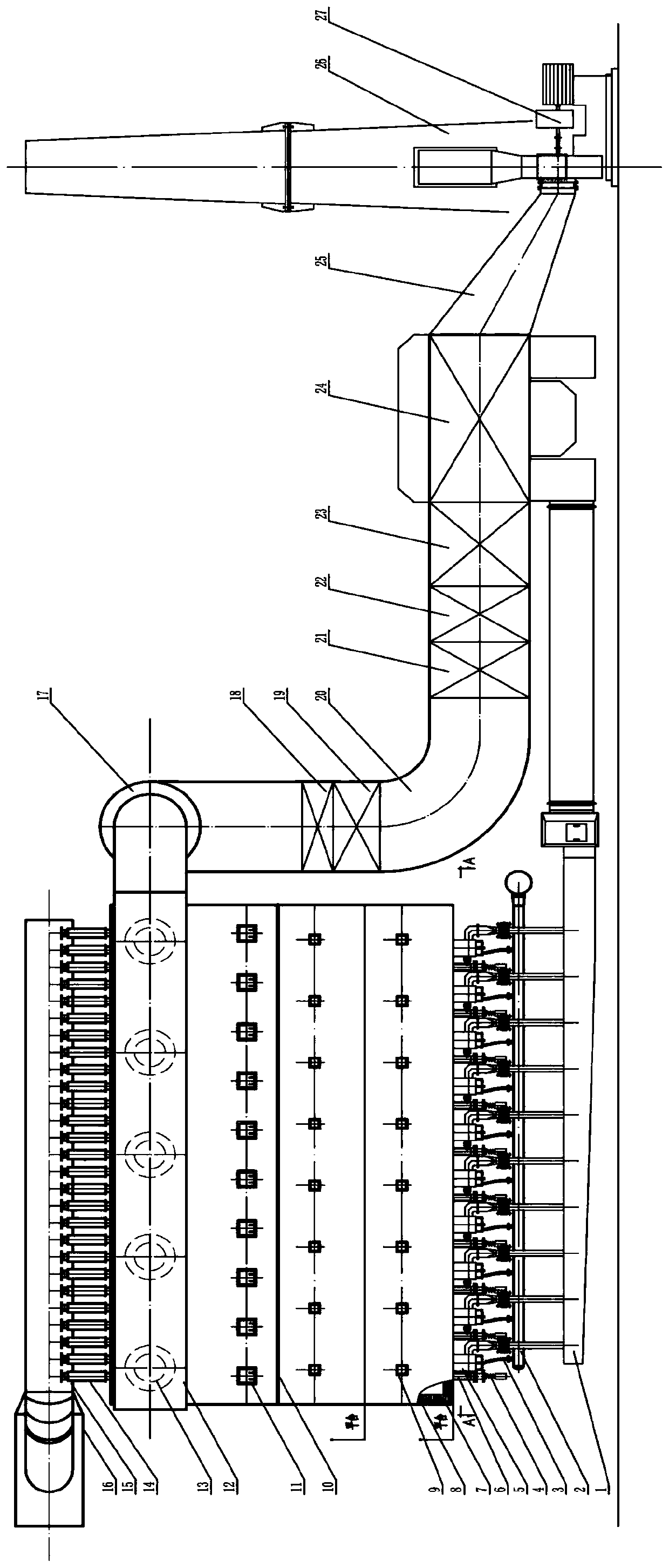

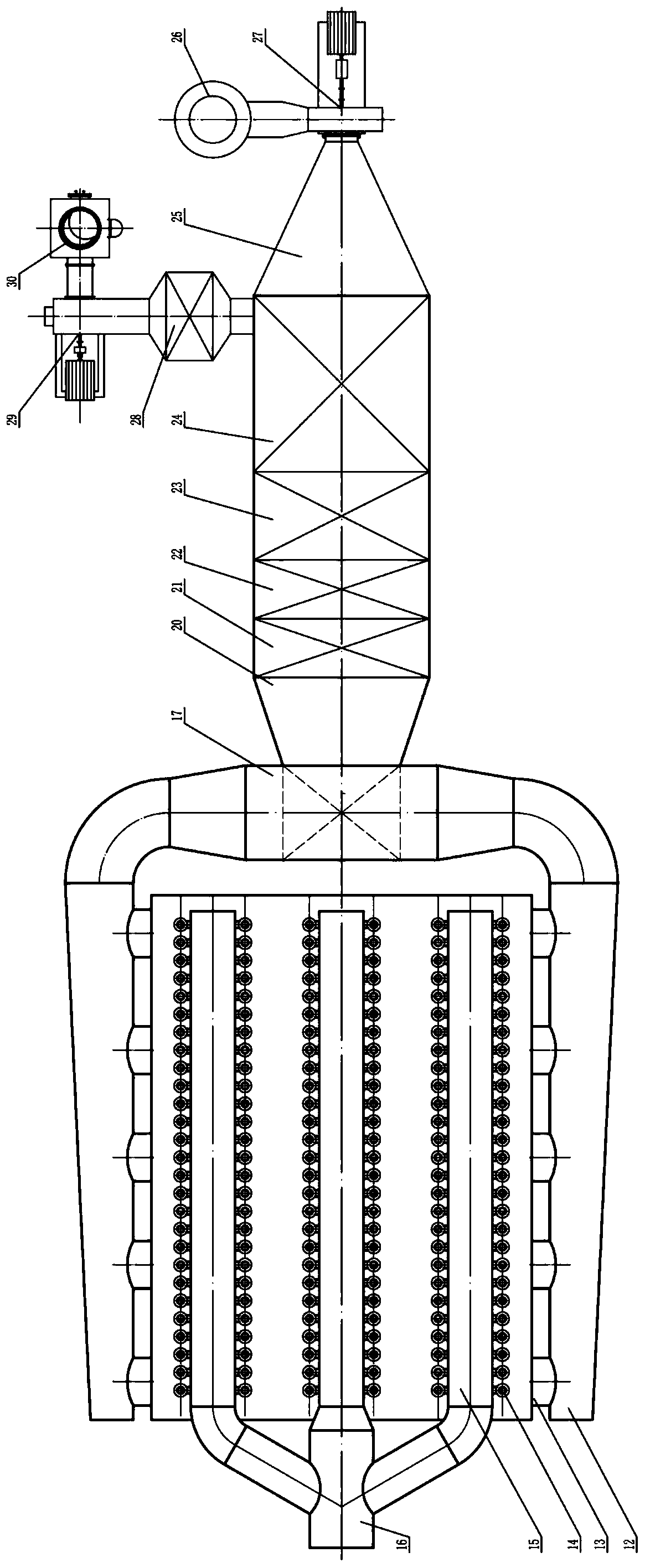

[0038] figure 1 A front view of a novel reformer showing one embodiment of the invention; figure 2 A top view of a novel reformer showing one embodiment of the present invention; image 3 A left side view of a novel reformer showing an embodiment of the present invention; Figure 4 A sectional view A-A of a novel reformer of one embodiment of the present invention is shown.

[0039] Such as figure 1 , 2 , 3, and 4, the new reformer adopts a bottom-fired structure, and the reformer tubes 6 (inner diameter ≥ 200mm) are vertically arranged inside the radiation chamber box 8, which are specifically arranged in six parallel rows. The whole furnace tube 6 passes through the roof of the radiation chamber 8 and is connected to the cold wall branch pipe 15 through the inclined tee 14. Two adjacent rows of reforming furnace tubes are connected to a cold wall branch pipe 15, and the three cold wall branch pipes are assembled at the end. Cold wall dry pipe 16, which sends the high-t...

Embodiment 2

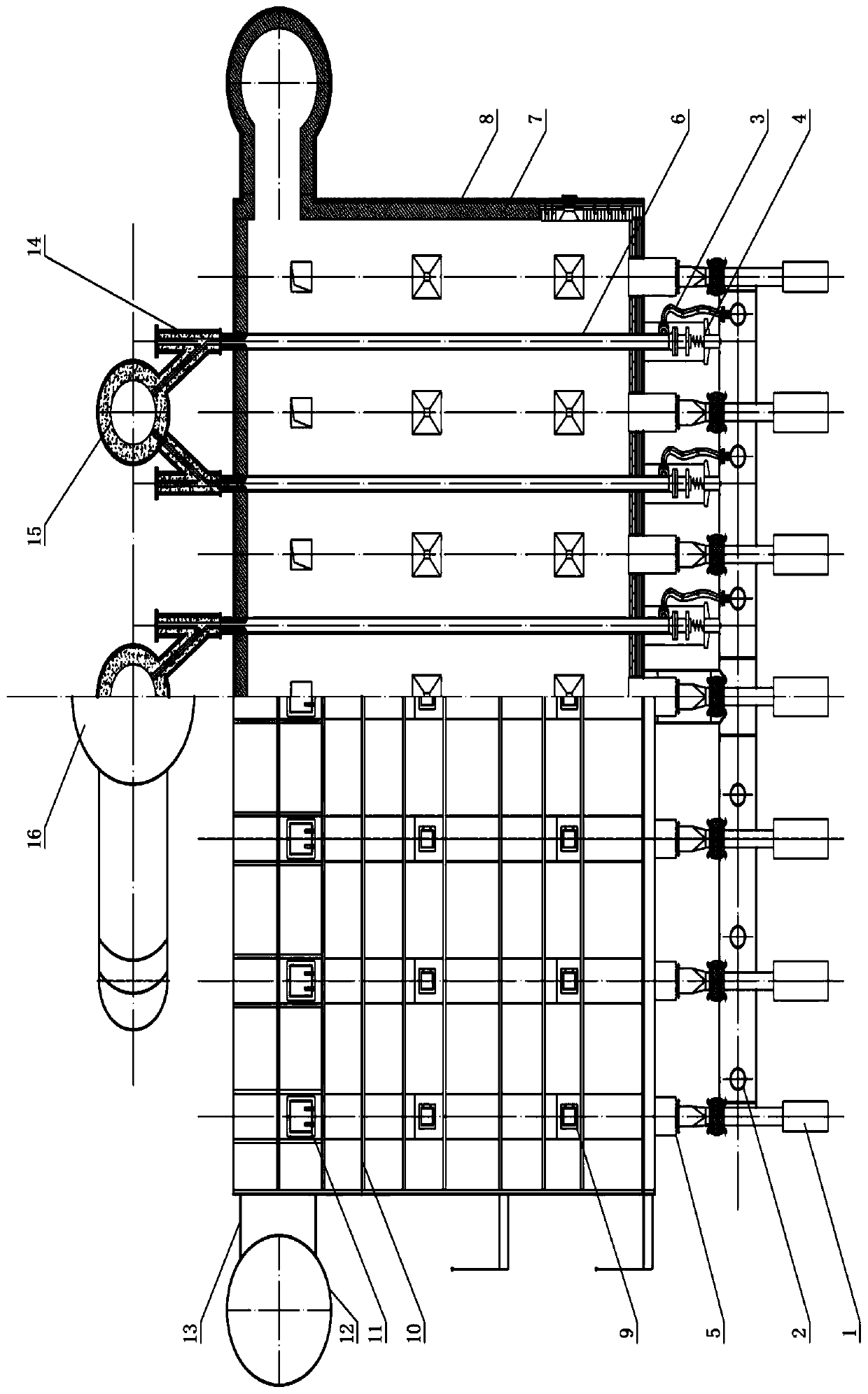

[0049] Figure 5 Shows the front view of the novel reforming furnace of Embodiment 2 of the present invention; Figure 6 A plan view of the novel reformer according to Embodiment 2 of the present invention is shown.

[0050] Such as Figure 5 , 6 As shown, the arrangement of the reformer radiation chamber, cold wall pipe, inclined tee, reforming feed gas inlet piping system and burner in this embodiment is the same as that in Embodiment 1.

[0051] The two branch main pipes 12 in the transition section are directly connected to the inlet of the convection section 20, and the convection section 20 is vertically arranged in the shape of a "1". Preheater 19, steam superheater 21, desulfurization coke oven gas preheater 22, furnace top gas preheater 23, combustion air preheater 24, heat water, raw material gas, saturated steam, coke oven in sequence through convective heat exchange Gas, furnace top gas, and air fully recover the heat of the flue gas, so that the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com