Reciprocating linear rack motion system for three-dimensional quick box-pasting machine

A reciprocating linear motion system technology, applied in mechanical equipment, transmission, transportation and packaging, etc., can solve the problems of affecting the safety of operators, huge loss of production line, high frequency of use, etc., to improve the working environment, high production efficiency, and cooperation smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

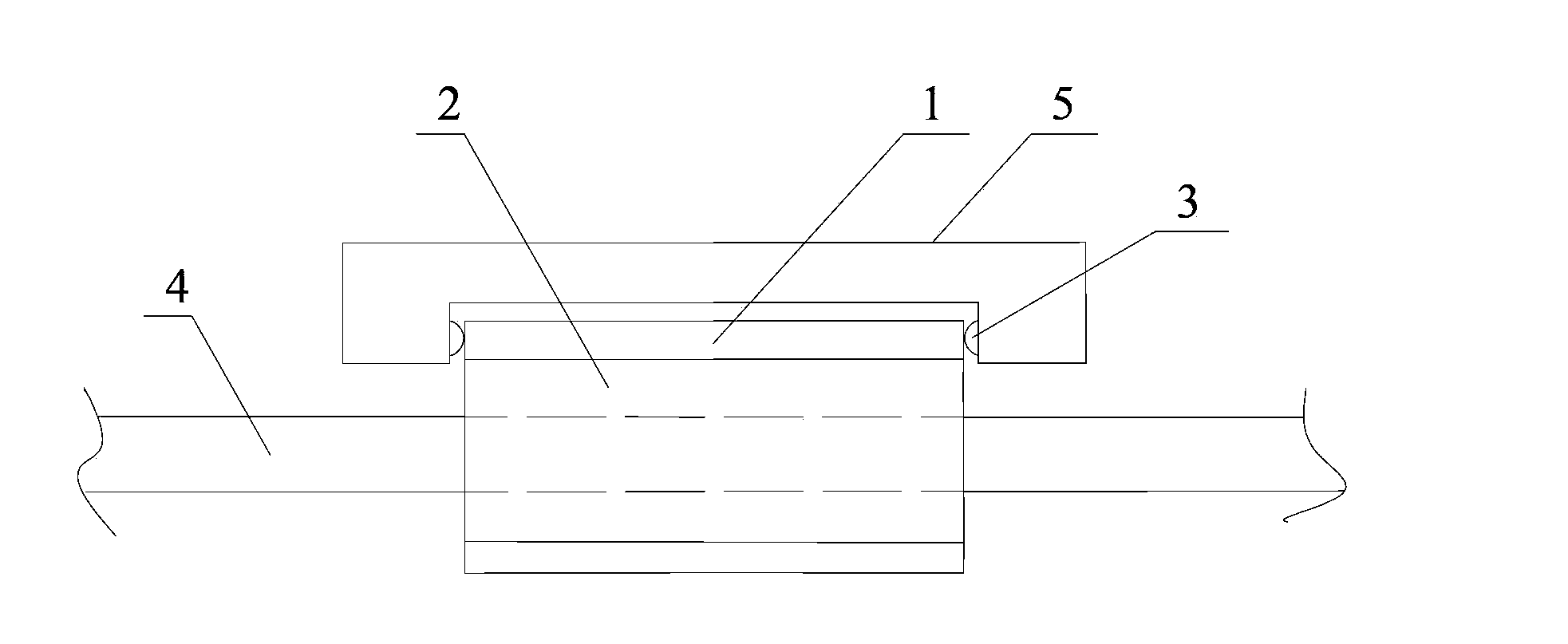

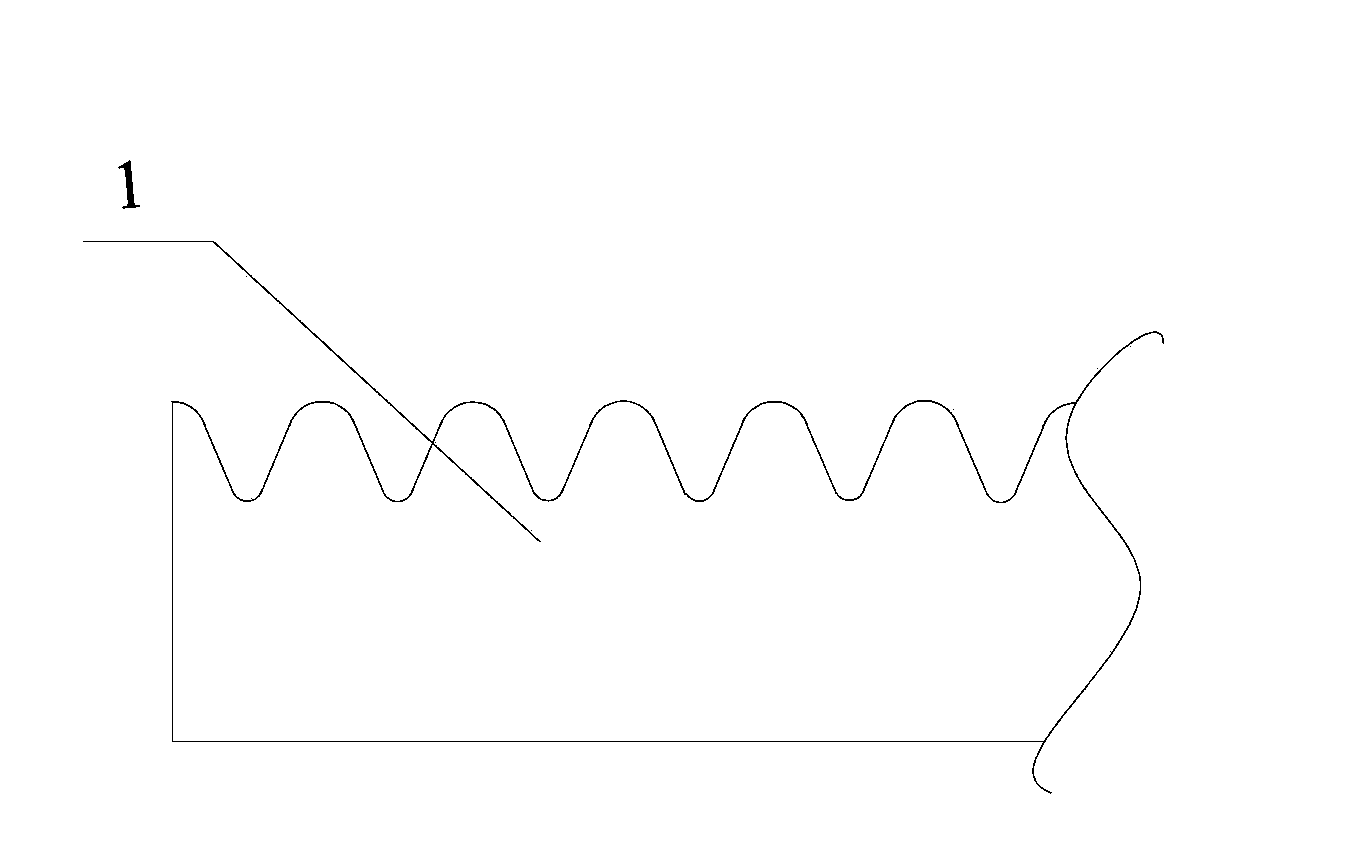

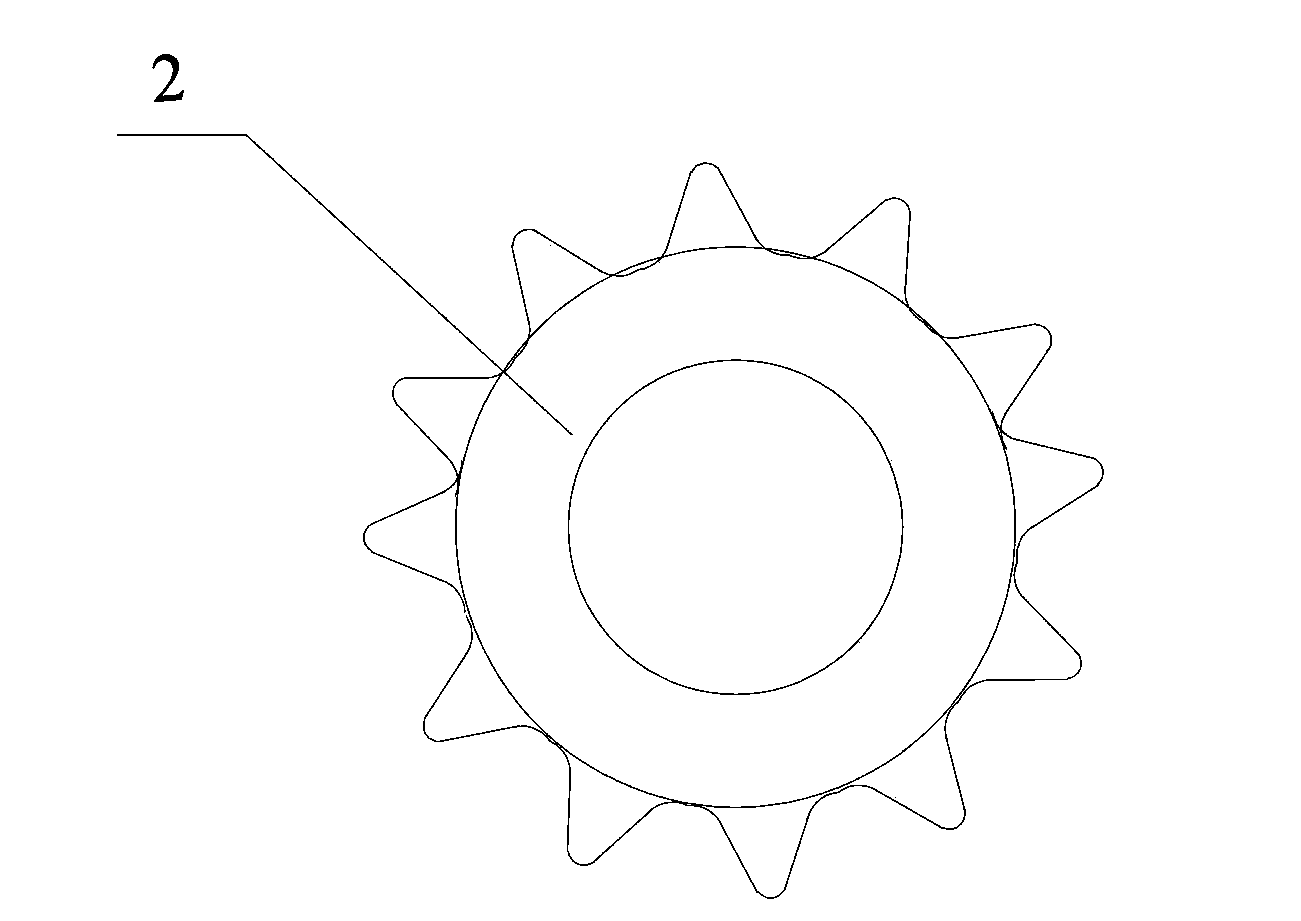

[0015] like figure 1 , 2 Or as shown in 3, the present invention provides a three-dimensional fast box-gluer reciprocating linear rack motion system, including a punching rail rack 1 and a gear 2 used in conjunction; the punching rail rack 1 is provided with a slider 5; The surface of the rack rack 1 is rounded; a ball 3 is arranged between the slider 5 and the rack rack 1 .

[0016] The working process of this example: the drive shaft 4 is connected with the motor, which drives the gear 2 to rotate at a specified speed; the slider 5 is fixed on the fast three-dimensional folder-gluer, the punching rail rack 1 passes through the slider 5, and the slider 5 and the punching rail Balls 3 are arranged between the racks 1; a push plate is provided at the front end of the punching rail rack 1, and the gear 2 is used in conjunction with the punching rail rack. The transmission of gear 2 drives the movement of the rack and rack, and pushes the fallen packaging box to the operating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com