Vane type revolving compressor

A rotary compressor and vane-type technology, applied in the field of compressors and vane-type rotary compressors, can solve the problems of high friction power consumption and increase of compressor shaft power, so as to reduce shaft power consumption, friction loss and leakage loss. , with smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

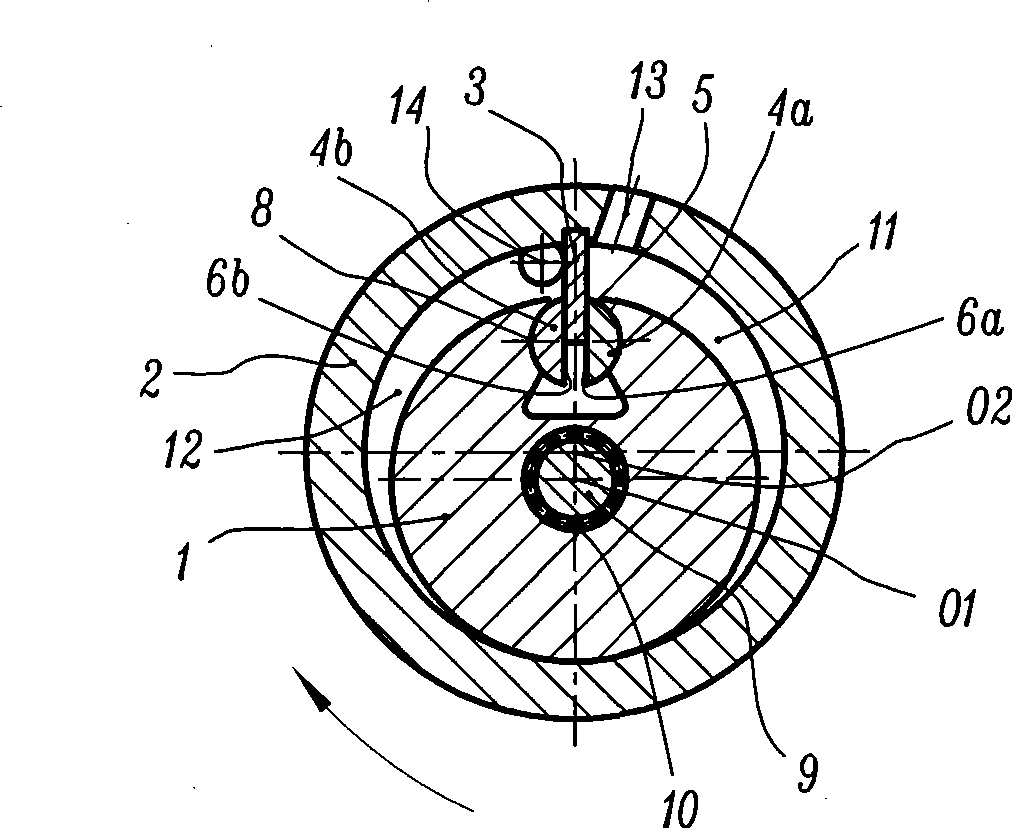

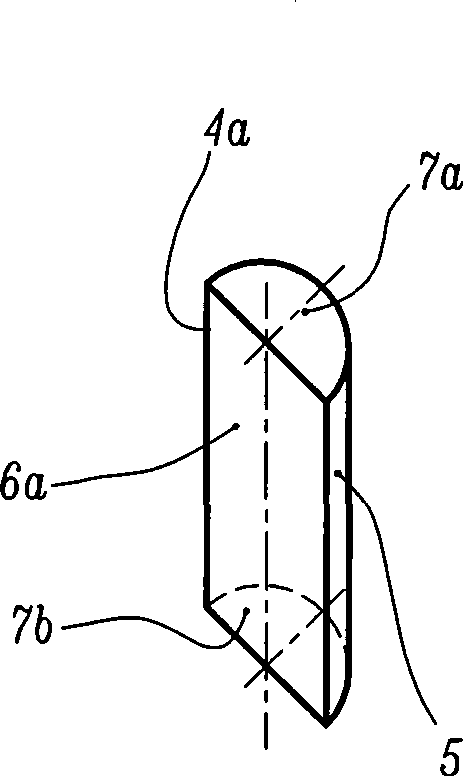

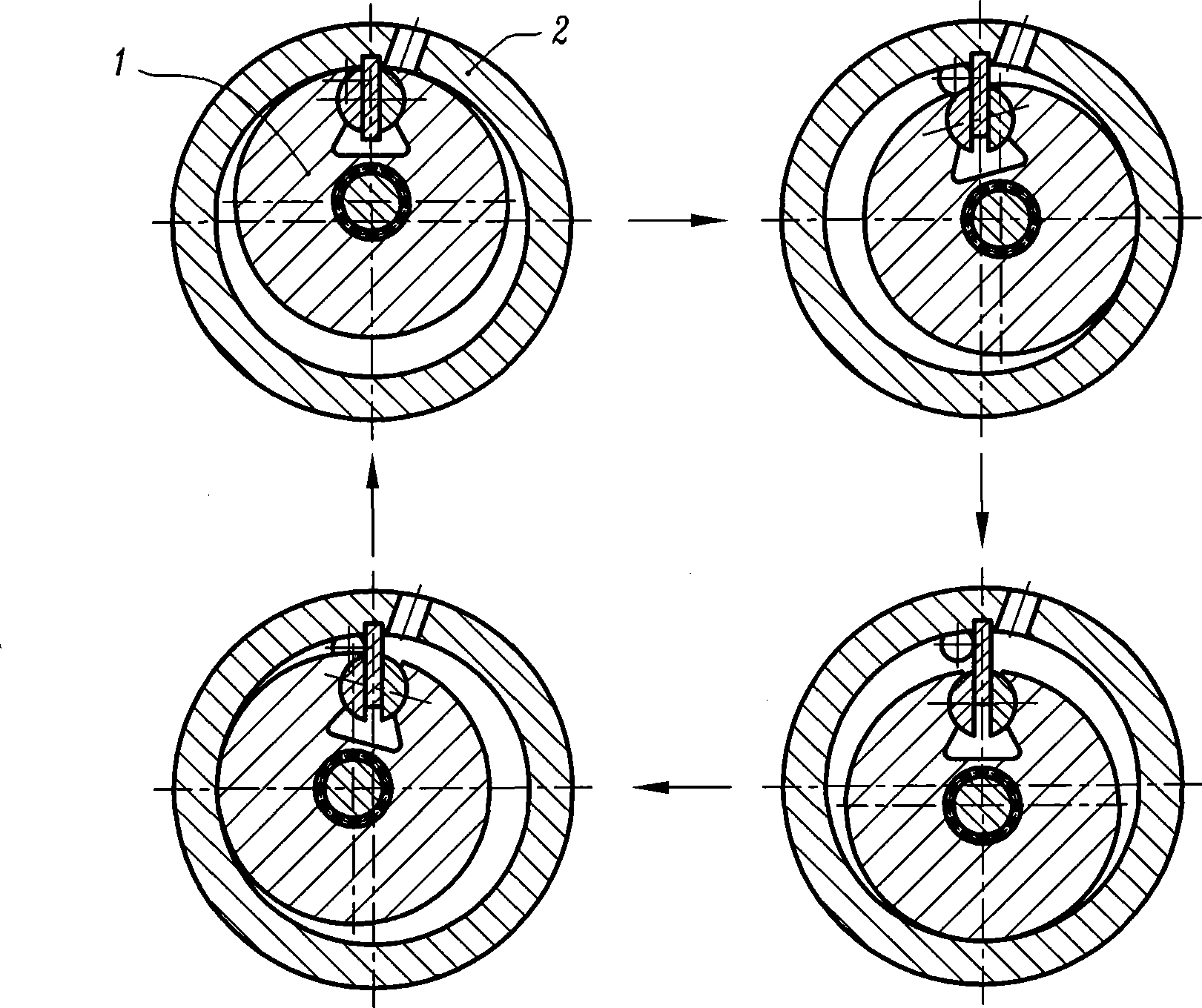

[0014] figure 1 with figure 2 A schematic structural view of an embodiment of a vane type rotary compressor of the present invention and an axonometric view of a slider are respectively shown. In this embodiment, the vane rotary compressor includes a rotor 1, a cylinder 2, a vane 3, a first slider 4a, a second slider 4b, and an end cover (not shown); the rotor 1 has A cylindrical outer surface, the cylinder 2 has a circular hole-shaped inner surface, the blade 3 is flat and its two working surfaces are parallel to each other, and the first slider 4a and the second slider 4b have cylindrical arc-shaped arc surface 5, planar sliding mating surfaces 6a and 6b, two column end faces 7a and 7b parallel to each other and perpendicular to sliding mating surfaces 6a and 6b; the rotor 1 is biased in the cylinder 2, and the axis of the rotor 1 is The rotor axis O1, the axis of the cylinder 2 is the cylinder axis O2, the rotor axis O1 and the cylinder axis O2 are set parallel to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com