Locking mechanism

A technology for locking mechanism and fastening parts, which is applied in the direction of cabinet/cabinet/drawer parts, etc., which can solve the inconvenient operation of the screw-in locking mechanism, the locking mechanism is easy to get stuck, and cannot be locked normally and other problems, to achieve the effect of excellent locking effect, simple structure and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

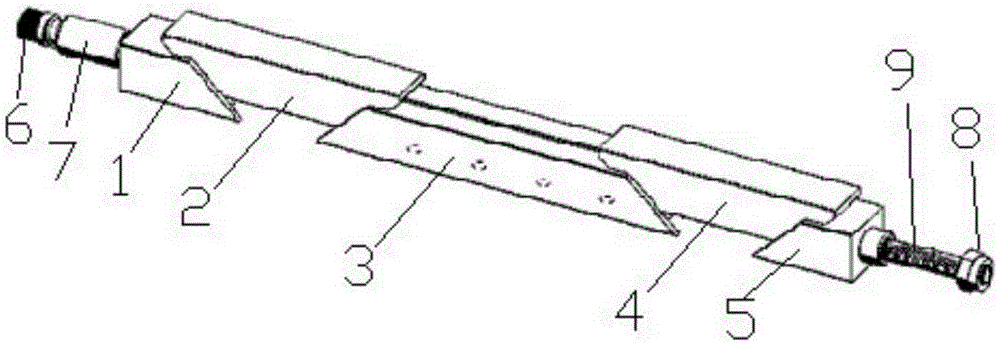

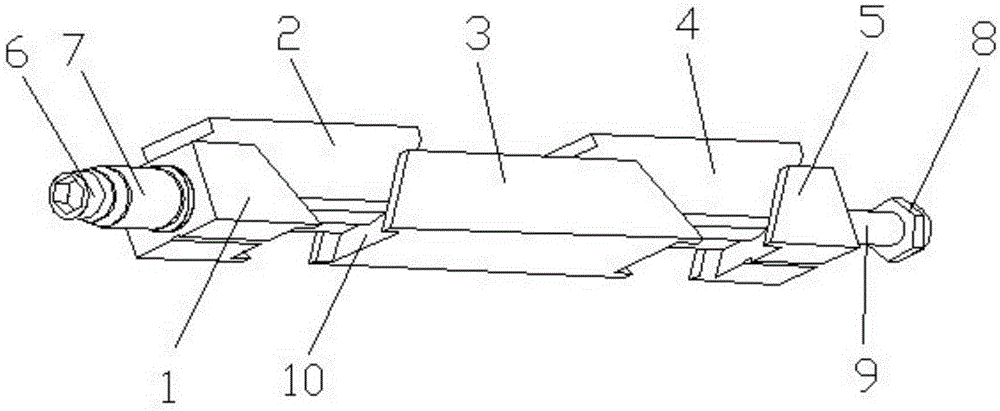

[0026] Such as figure 1 , 2 As shown, the present invention provides a locking mechanism, including a screw rod 9, and fastening components that are sequentially threaded on the screw rod 9 and cooperate with each other, a top block 1, a first upper slider 2, a lower slider 3, The second upper slider 4, screw block 5, nut 8; both ends of the first upper slider 2 and the second upper slider 4 are wedge-shaped surfaces with an angle of α, and the top block 1 and the second upper slider The adjacent end of an upper slider 2, the two ends of the lower slider 3, and the adjacent end of the screw block 5 and the second upper slider 4 are wedge-shaped grooves 10 with an angle of α. , the wedge-shaped groove 10 is matched with the wedge-shaped surface; α=46°;

[0027] The fastening part includes a step 6 integrally connected to the left end of the screw rod 9, a spring threaded on the screw rod 9, and a sleeve structure 7 threaded on the screw rod 9 and used to cover the spring , t...

Embodiment 2

[0030] The nut 8 is a stainless steel rivet nut.

[0031] Other structures in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0033] The screw 9 is a stainless steel screw.

[0034] Other structures in this embodiment are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com