Disk feeder device of numerical control machine tool automation line

A technology of CNC machine tools and automatic lines, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of low reliability, inaccurate positioning, unstable workpiece transportation, etc., to improve production efficiency, transfer workpieces stably, and position accurately. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

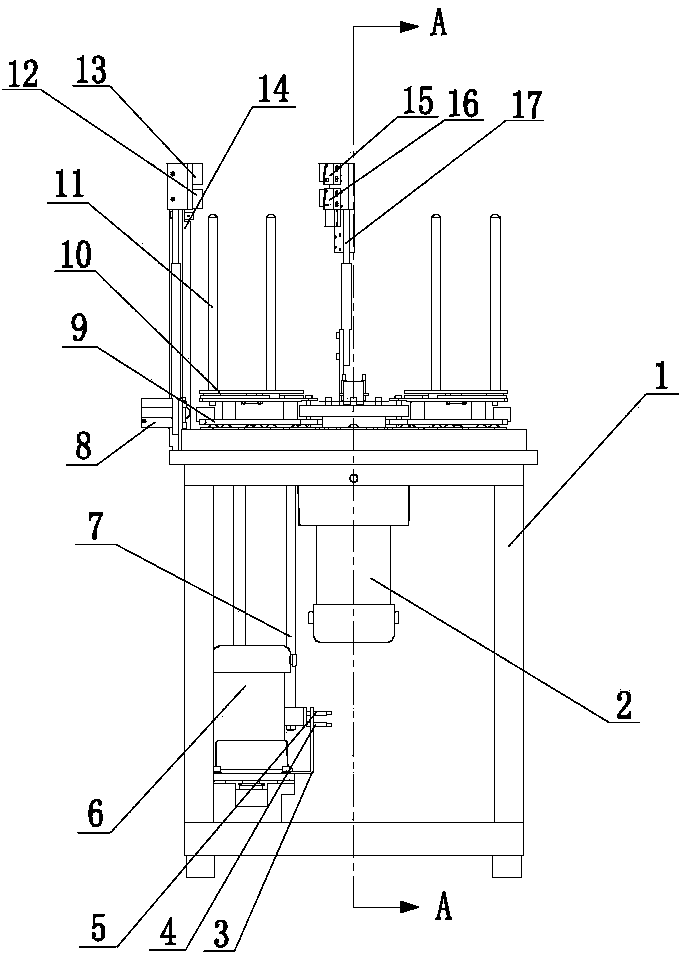

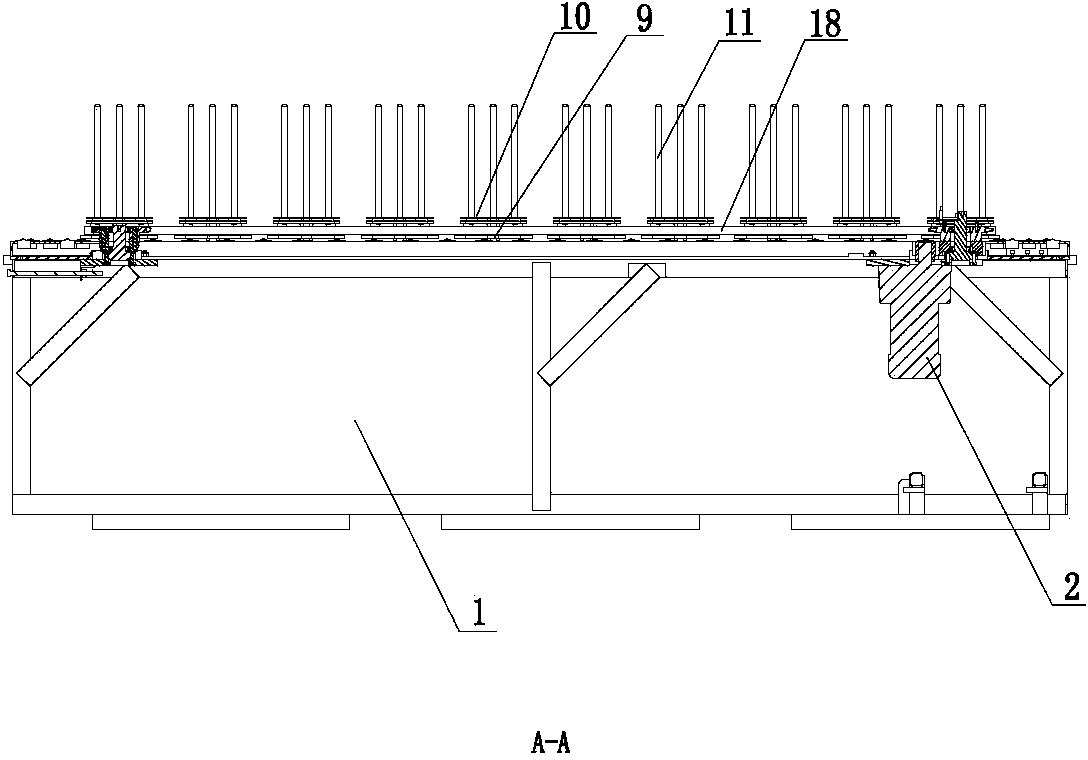

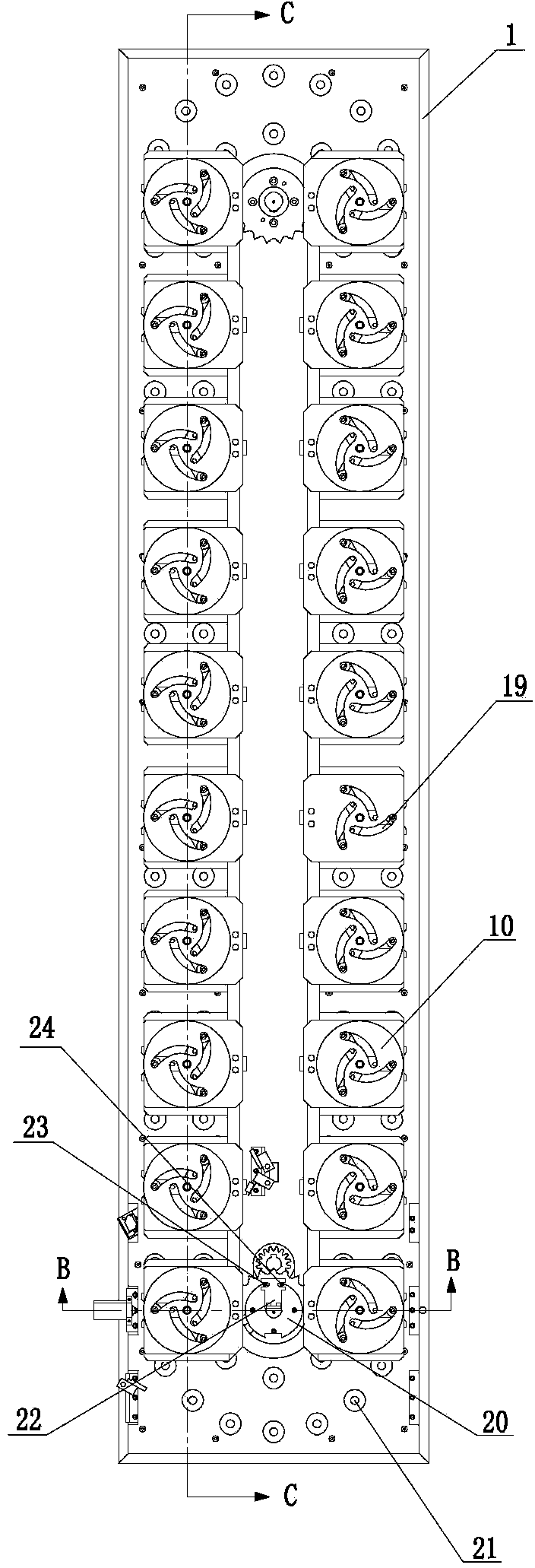

[0021] Such as Figure 1 to Figure 5As shown, the present invention comprises a feeder support 1, a lifting mechanism, an induction mechanism, a transposition mechanism, a positioning mechanism and a plurality of pallet mechanisms; Chain 18 and two sprockets supporting the chain, the sprocket drive motor 2 is fixedly installed on the feeder support 1, and the two sprockets are respectively installed on the two ends of the workbench through bearings and shaft supports, and the sprocket axis is vertical to the worktable, wherein A sprocket is used as the driving sprocket and is connected with the sprocket drive motor 2 through a transmission mechanism; a plurality of universal balls 21 are arranged on the work table, and the plurality of universal balls 21 form a raceway circuit connected end to end, and the raceway circuits are equidistant from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com