Composite core-pulling device for realizing single mould cavity and dual injection mould

A core-pulling device and composite technology, applied in the field of injection molding, can solve the problem of mold working space, guarantee of working cycle accuracy, mold cost, product production cost that is difficult to meet the expected requirements, unable to meet large-scale two-shot mold mass production, production cost To achieve the effect of improving work efficiency and product quality, occupying a small space, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

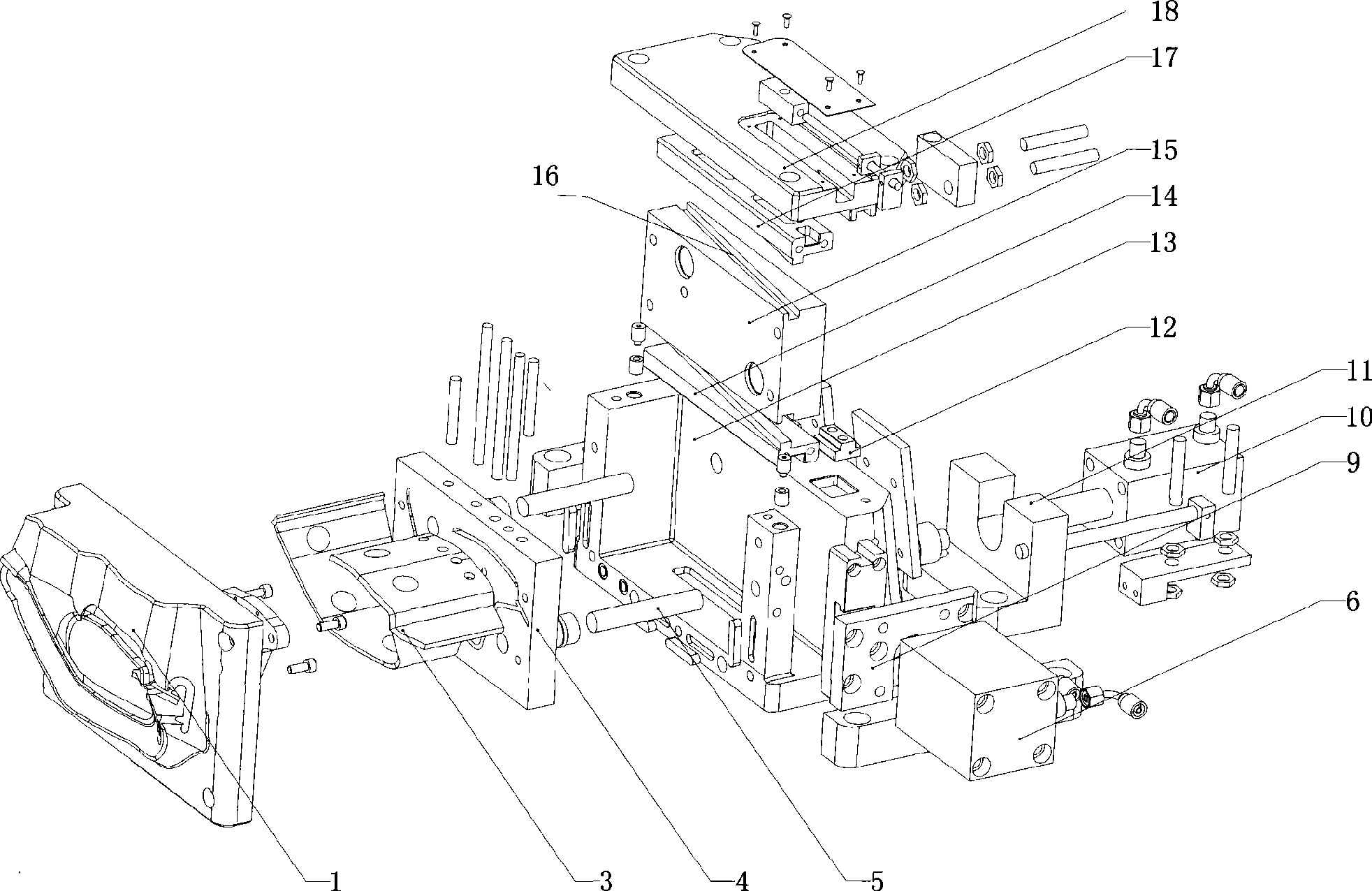

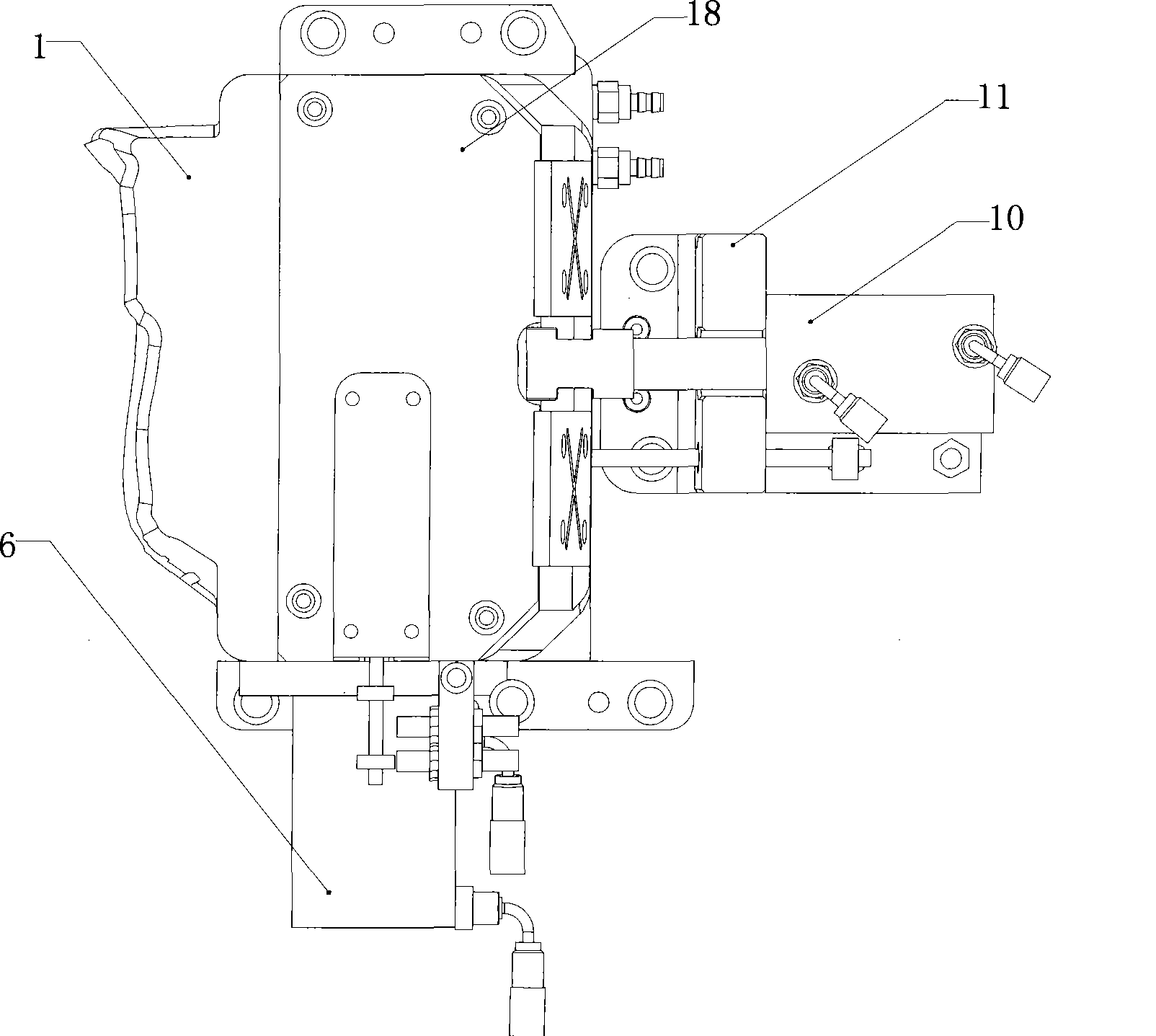

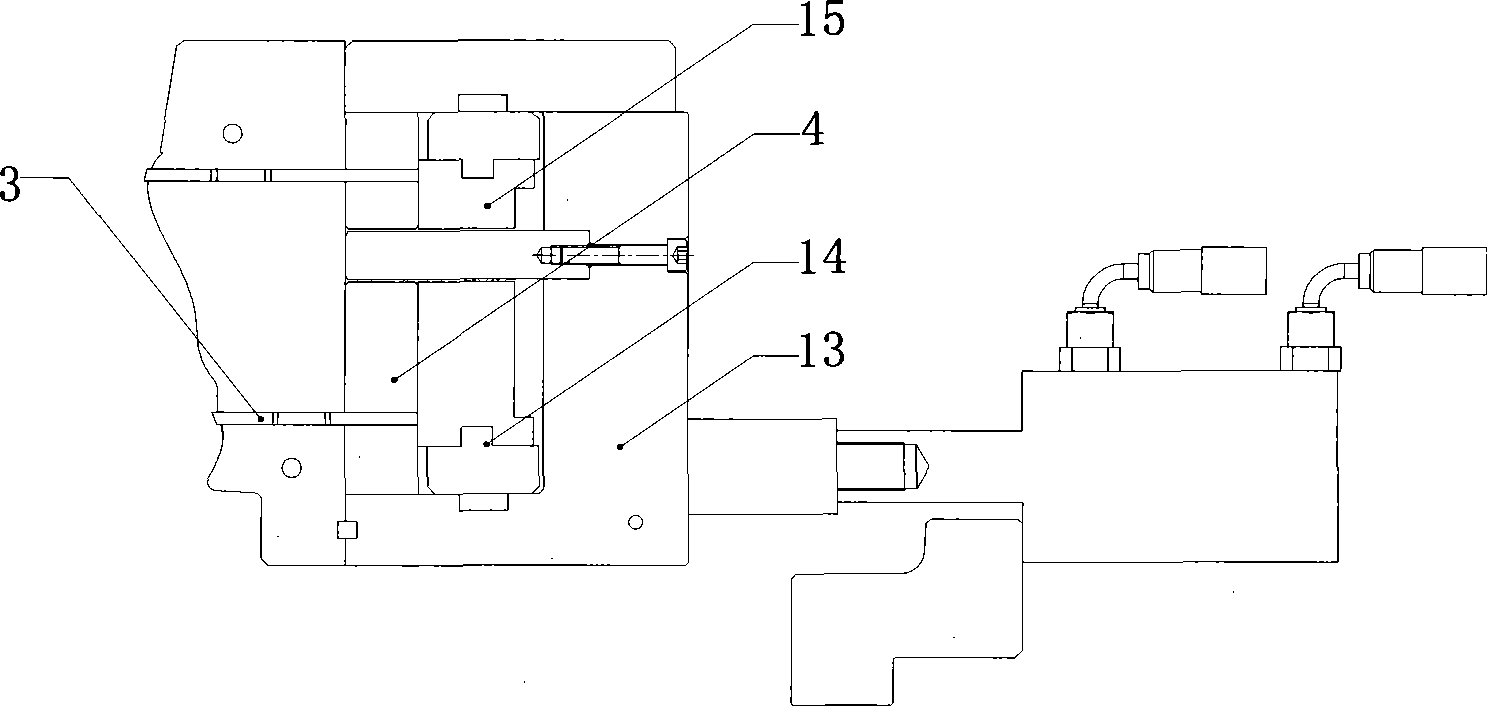

[0020] Such as figure 1 , 2 , 3, a composite core-pulling device for realizing single-cavity double-shot molds, the mold has a single cavity, the core-pulling device is located in the cavity, and the composite core-pulling device is composed of a first-stage core-pulling device Nested in the secondary core-pulling device, the secondary core-pulling device includes a slider molding 1, a main slider 13 and a secondary core-pulling cylinder 10, and the secondary core-pulling cylinder 10 passes through the cylinder backing plate 11 is connected with the main slider 13, the first-level core-pulling device is arranged in the main slider 13, and the first-level core-pulling device is combined by the slider forming part 1, the positioning block 12, and the main slider pressing plate 18, wherein the The primary core-pulling device includes a core-pulling insert 3, a primary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com