Storage battery package assembly line

A packaging line and storage battery technology, applied in packaging, etc., can solve the problems of high management cost, labor, and low production efficiency, and achieve the effect of increasing safety, reducing labor, and reasonable station arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

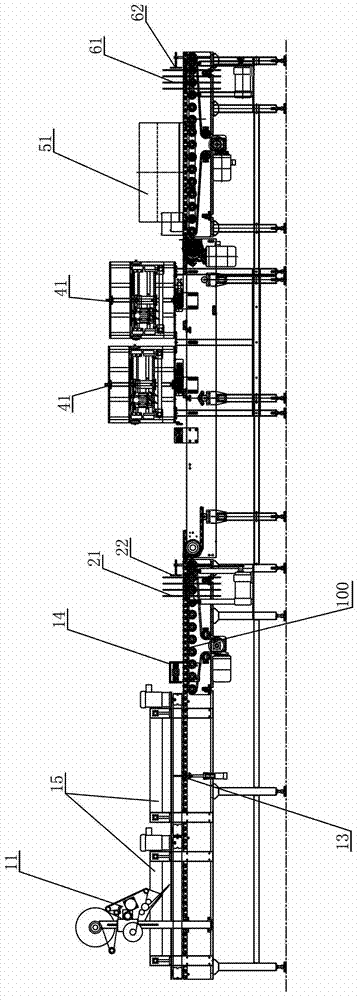

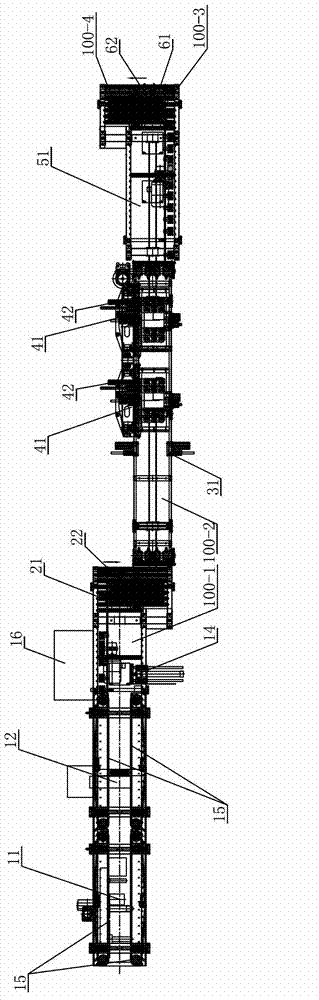

[0024] A storage battery packaging line, which includes a storage battery conveying line 100 that sequentially sends the storage battery to each station;

[0025] There is a coding station at the front of the battery packaging line, and all the following devices are installed at the coding station:

[0026] 1), the labeling machine 11 is used for labeling the top surface of the battery passing through the labeling machine 11 on the battery conveying line;

[0027] 2) Coding machine 12, used to code the top surface of the storage battery at the location of the coding machine at the marking station on the storage battery conveying line; corresponding to the location of the coding machine, the battery packaging line also There is a first movable blocking mechanism 13 for the storage battery. The first movable blocking mechanism 13 temporarily stops the storage battery on the storage battery conveying line at the location of the coding machine and is coded by the coding machine 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com