Automatic marking system

An automatic and laser marking technology, applied in the field of laser marking, can solve problems such as board indentation, uneven marking surface, and low marking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

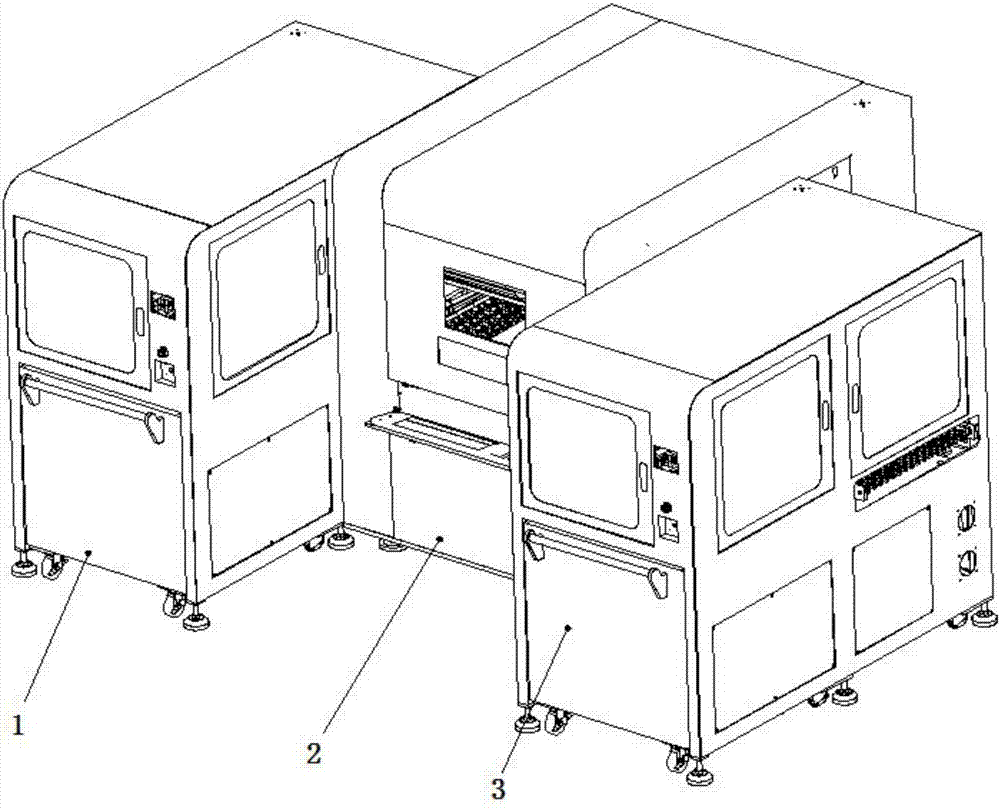

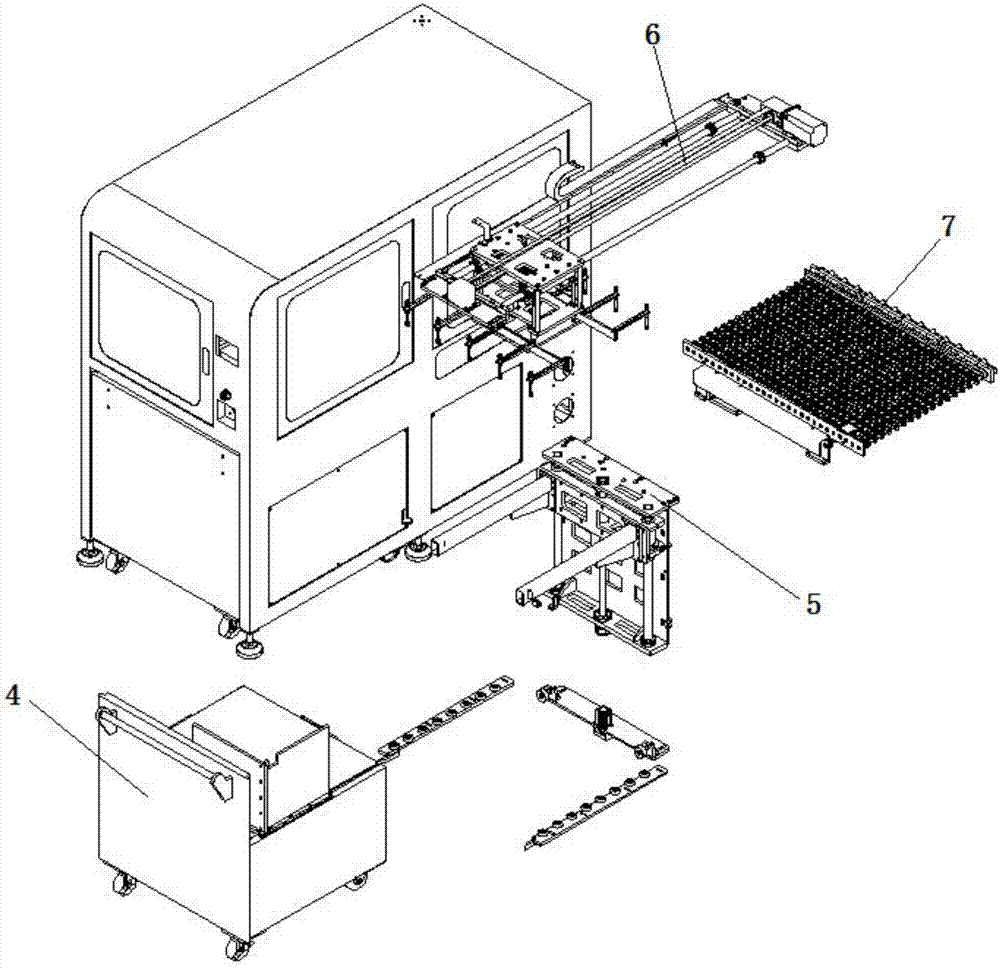

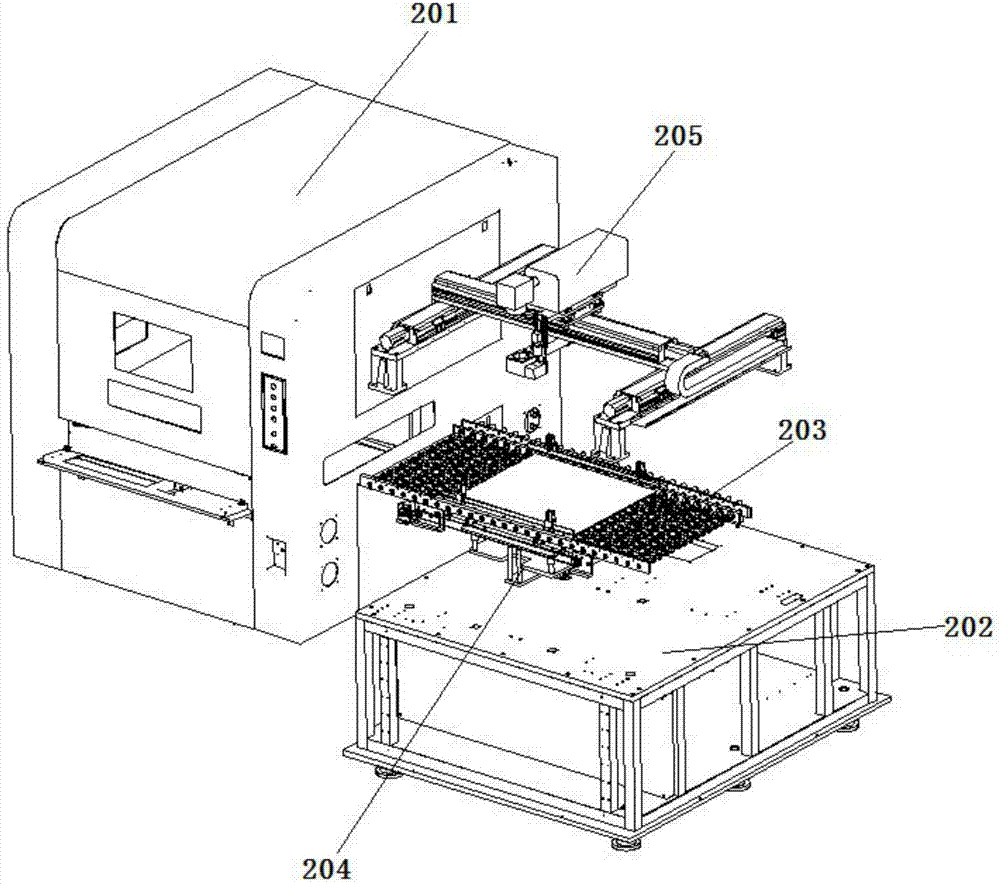

[0034] see figure 1, figure 2 , image 3 , Figure 4 , Figure 5 , an automatic marking system provided by the embodiment of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the system includes an upper board device 1, a laser marking device 2 and a lower board device 3; The board outlet of the marking device 2 is set opposite to the board inlet of the lower board device 3;

[0035] The upper board device 1 has the same structure as the lower board device 3; the upper board device 1 includes a frame for supporting and carrying various components, and a trolley assembly 4 and a lifting assembly are arranged in the frame. 5. The traversing assembly 6 and the first rail transmission assembly 7; specifically, the frame, which is used to support and carry other components; the trolley assembly 4, which is movably placed on the machine In the cavity opened by the frame, the trolley is provided with a PCB carrier plate for pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com