Bottle blank conveying chain of bottle blowing machine

A conveyor chain and bottle blowing machine technology, which is applied in the field of preform conveyor chain, can solve the problems of insufficient use of heat in the heating box, uneven rotation of the conveyor chain, and non-adjustable distance between preforms, etc., to achieve fewer parts, The effect of firmly supporting the preform tube and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through embodiments in conjunction with the accompanying drawings.

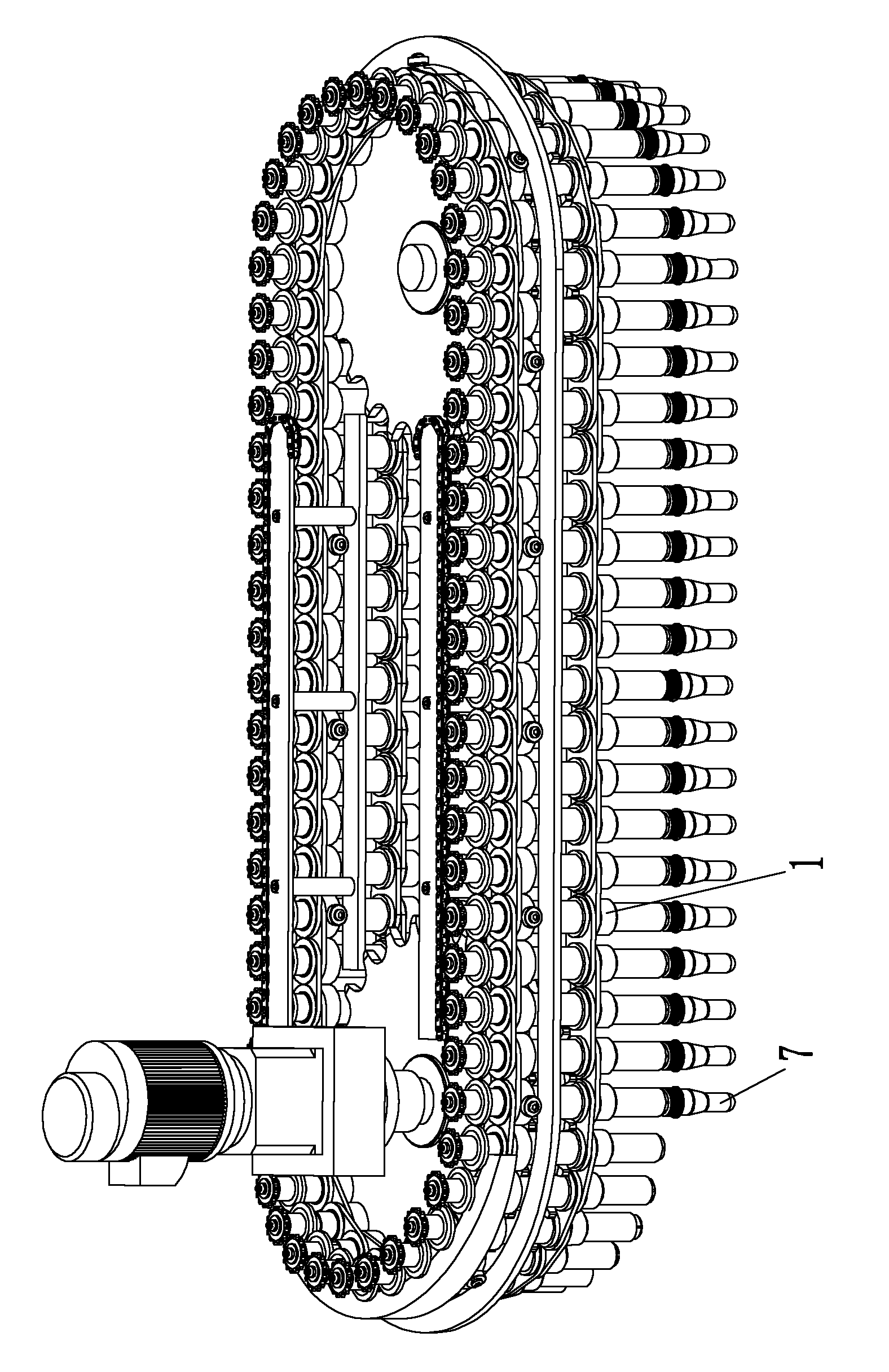

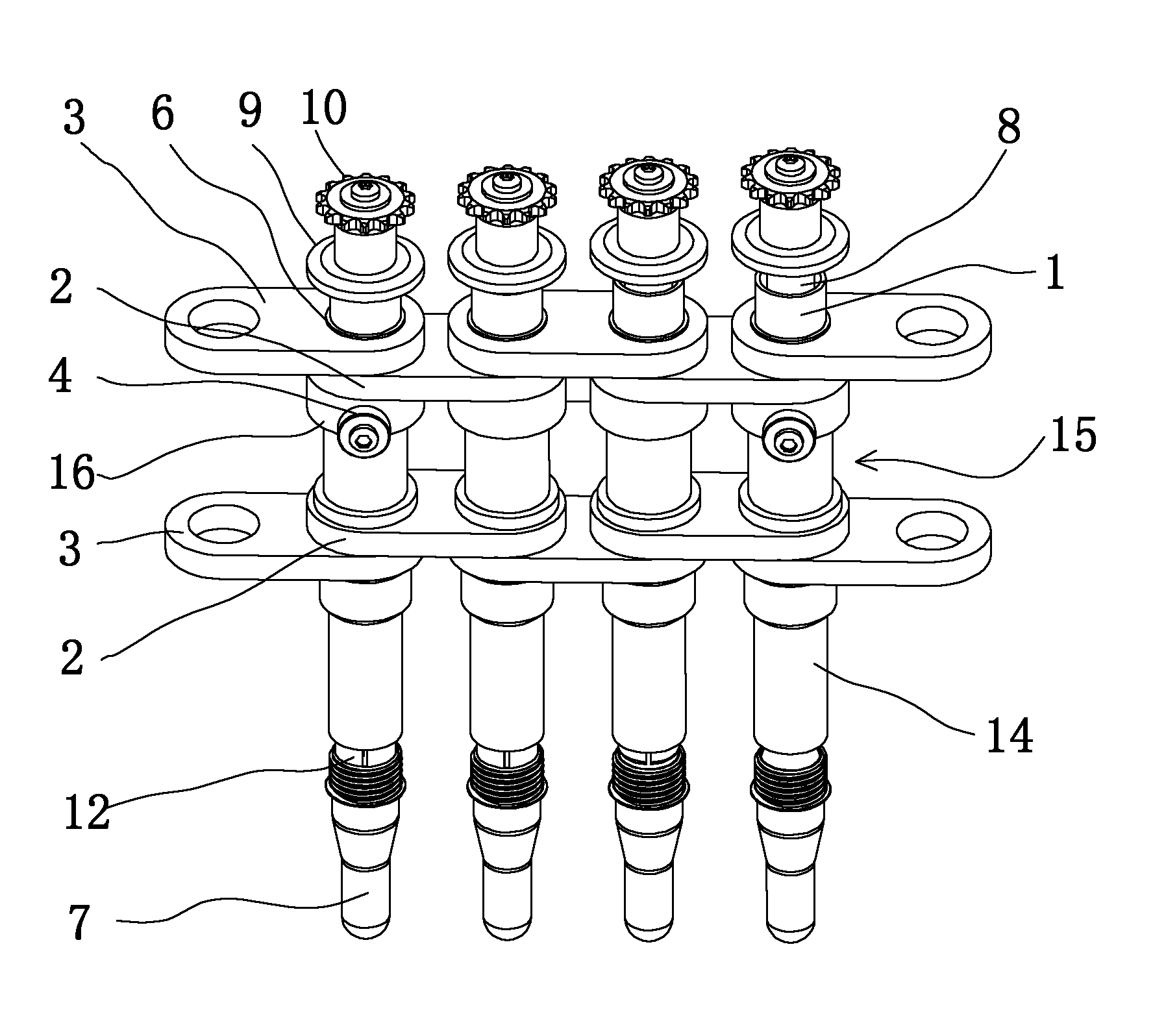

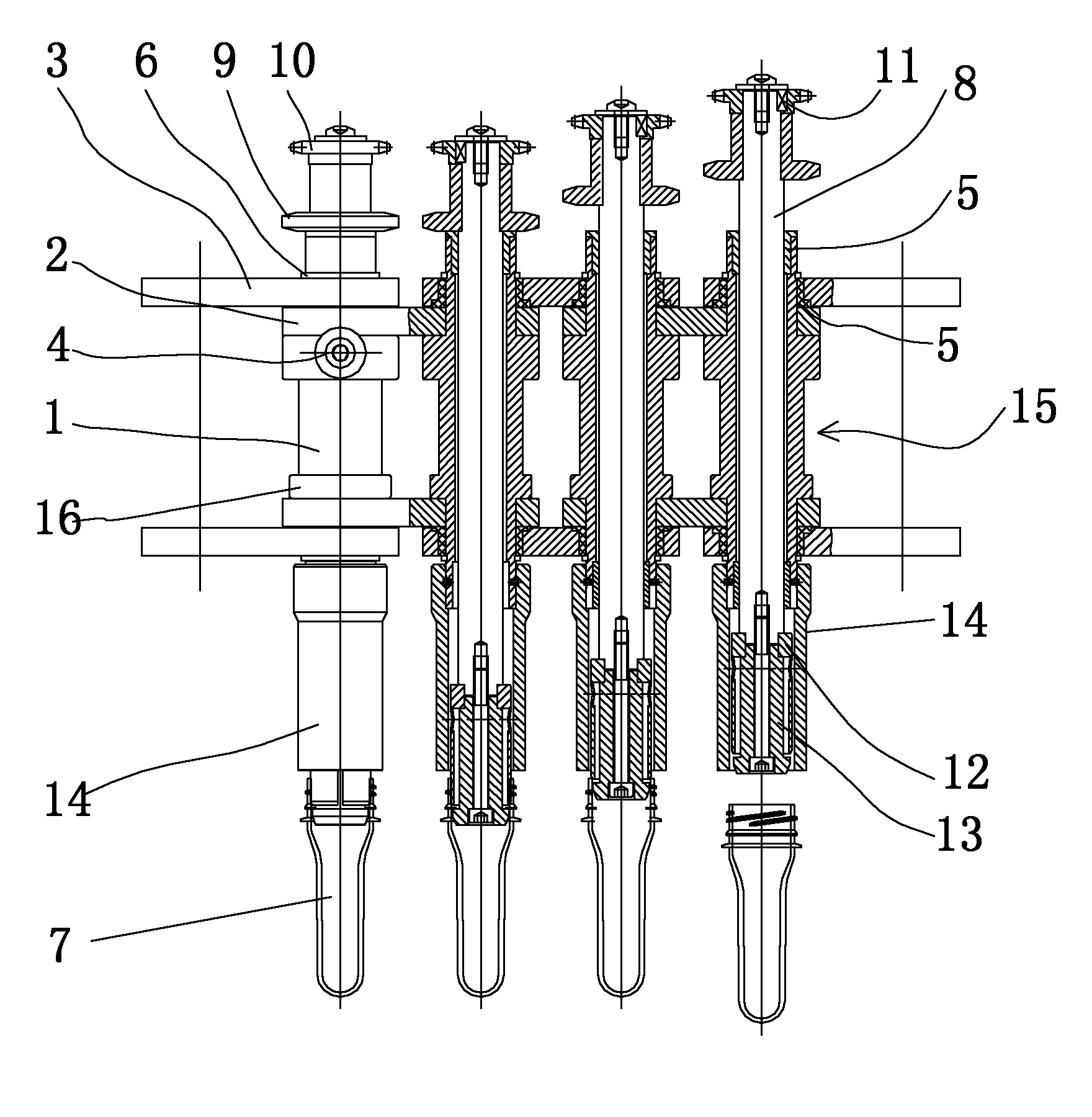

[0024] like Figure 1-Figure 5 As shown, the preform conveying chain of a bottle blowing machine described in this embodiment includes a preform seat 1 which is a hollow tubular part, and each preform seat 1 is connected to the left, The adjacent preform bases 1 on the right are connected to form an annular chain. The preform bases 1 are erected and pass through the flat inner and outer chain plates. The inner chain piece 2 and the outer chain piece 3 are superimposed. superimposed. The inner chain piece 2 can be fixed on the preform holder 1 with screws. A shaft sleeve 5 is installed between the outer chain piece 3 and the preform seat 1 and can rotate relatively. Each preform seat 1 is provided with two annular protrusions 16 at the position between the two inner chain pieces 2 , and a driving tooth slot 15 is formed between the two annular pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com