Automatic pre-tightening device for ball screws

A ball screw, automatic technology, used in transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as loss of preload adjustment accuracy, large friction resistance, and clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

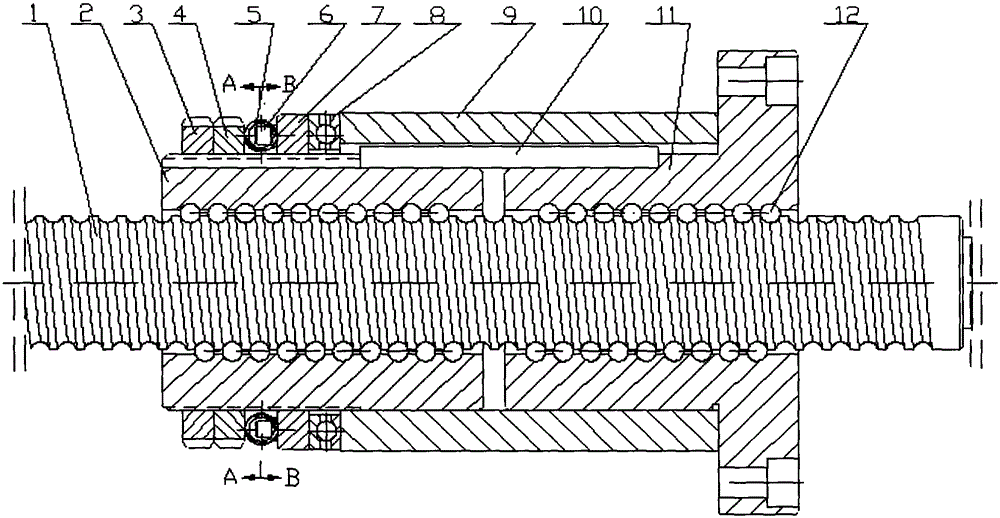

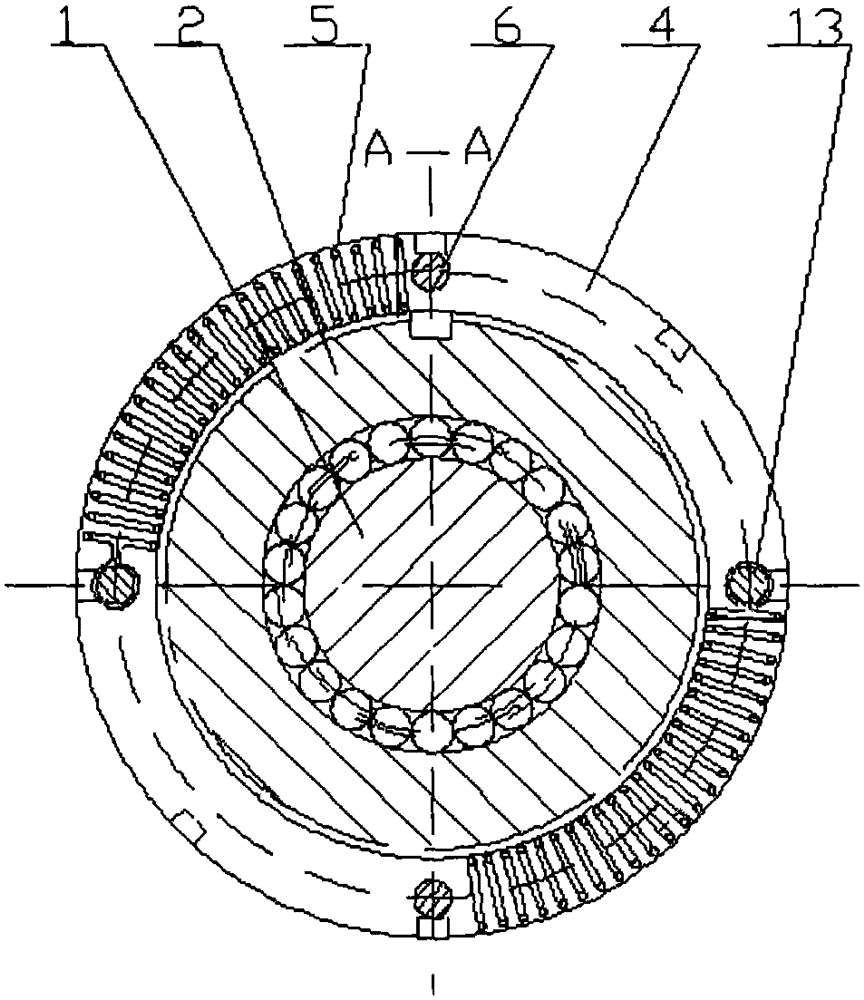

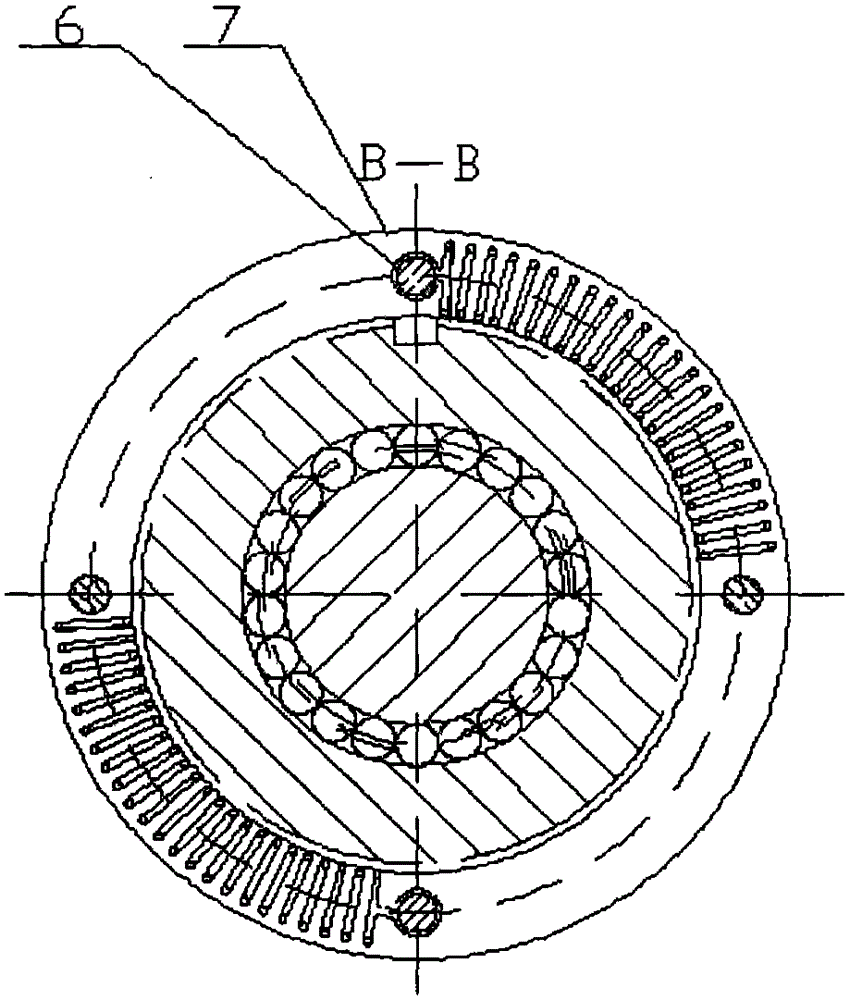

[0015] This implementation example is a specific structure of an automatic pretensioning device for a ball screw, and illustrates the composition and working principle of the device of the present invention through an example. An automatic pre-tightening device for a ball screw consists of a ball screw 1, a backlash-removing ball nut 2, a lock nut 3, a torque applying nut 4, an energy storage spring 5, a left spring pile 6, a pre-tightening nut 7, and an end bearing 8 , Outer sleeve 9, flat key 10, drive ball nut 11, ball 12, right spring pile 13 forms. The anti-backlash ball nut 2 set on the outside of the ball screw 1 is adjacent to the transmission ball nut 11 and installed inside the outer sleeve 9. The outer diameter of the anti-backlash ball nut 2 is provided with a fine thread, which is installed sequentially on the fine thread End face bearing 8, preload nut 7, energy storage spring 5, torque applying nut 4, lock nut 3. The pre-tightening torque is applied to the ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com