AGV type automatic storage device and application thereof

A storage and drive shaft technology, applied in the field of AGV-type automated storage devices, can solve the problems of inconvenience, limited number of automated machines, and low efficiency in accessing goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

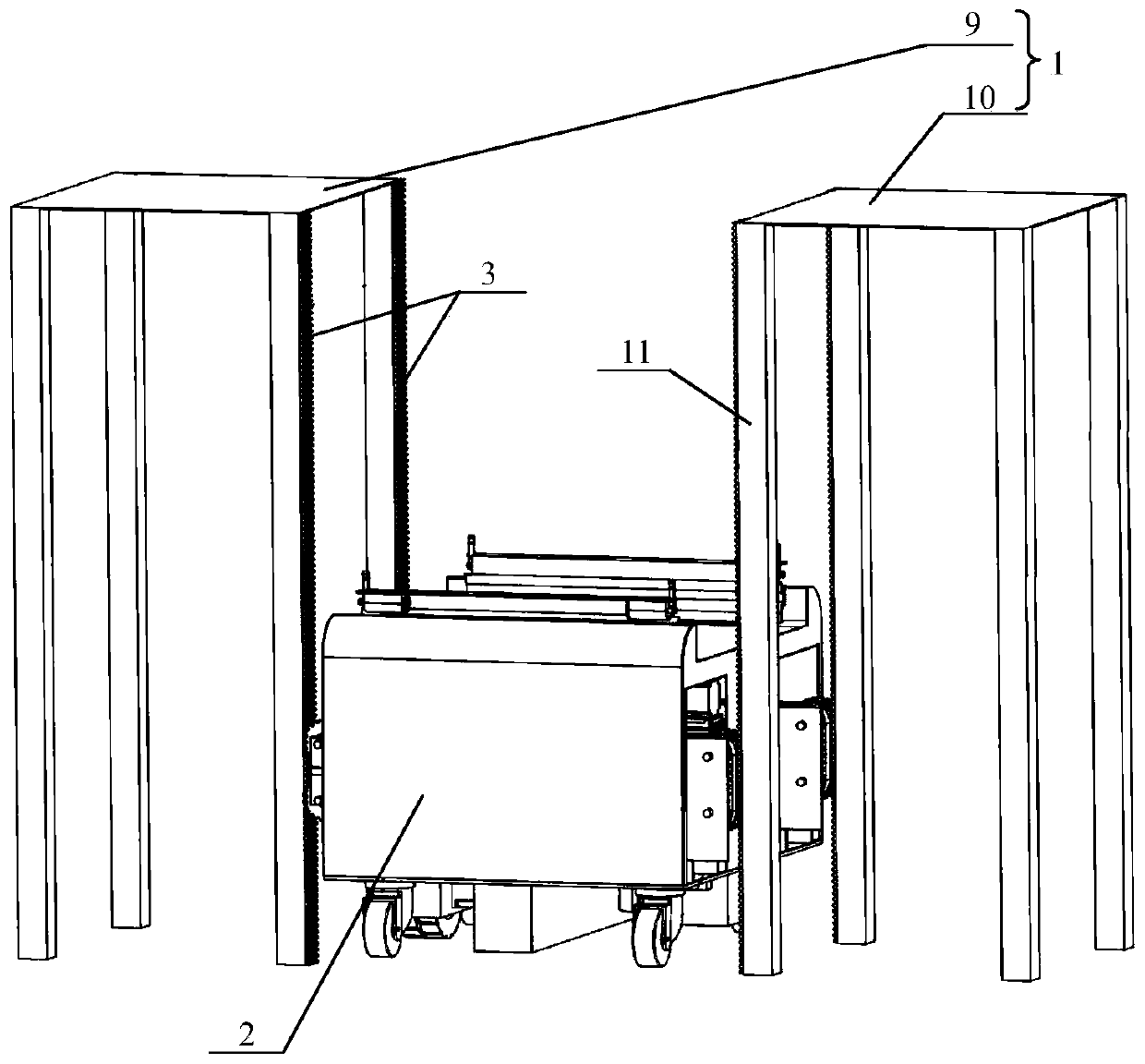

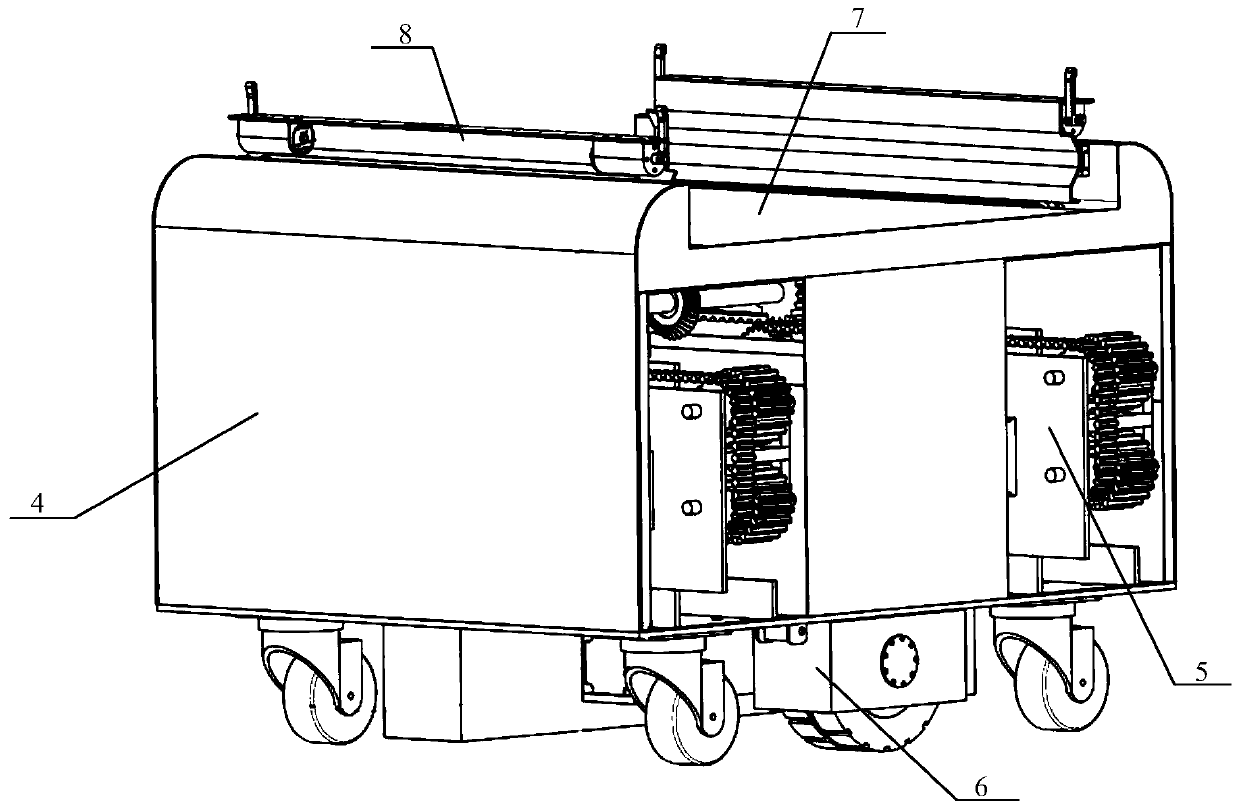

[0065] An AGV type automatic storage device, such as Figure 1-13 As shown, it includes a storage shelf 1 for storing goods and an AGV 2 located between the storage shelves 1. The storage shelf 1 is provided with a climbing track 3, and the AGV 2 includes a car body 4 and a climbing mechanism arranged on the car body 4. 5. The climbing mechanism is used to drive the car body 4 to move on the climbing track 3. The storage shelf 1 can also be a multi-layer structure, and the number of AGVs is generally multiple, which can be flexibly selected according to the amount of goods on site;

[0066] Can be a plurality of storage shelves in the present invention, can be provided with a plurality of independent storage areas, wherein, this storage area is used for depositing goods, generally speaking, storage area can store various goods (different types, different sizes, shape different), but the goods stored in the same storage area must have the same attributes (such as the same or si...

Embodiment 2

[0069]An AGV type automatic storage device, the structure is as described in Embodiment 1, the difference is that the storage shelf 1 includes a symmetrically arranged first shelf 9 and a second shelf 10, and there is a gap between the first shelf 9 and the second shelf 10. There is an aisle for AGV 2 to move, the bottom of the first shelf 9 and the second shelf 10 are equipped with columns 11, the climbing track 3 is a climbing synchronous belt, and the climbing synchronous belt is set on the first shelf 9 and the second shelf 10 close to the aisle Upright 11;

[0070] The climbing synchronous belts on the first shelf 9 and the second shelf 10 are two in parallel, and the number of climbing mechanisms on one side of the car body 4 is also two. The AGV 2 can move in the lane between the storage shelves, and can also move along the The climbing rails of the storage racks move vertically.

[0071] Through this automatic storage method, the AGV 2 can be moved vertically along th...

Embodiment 3

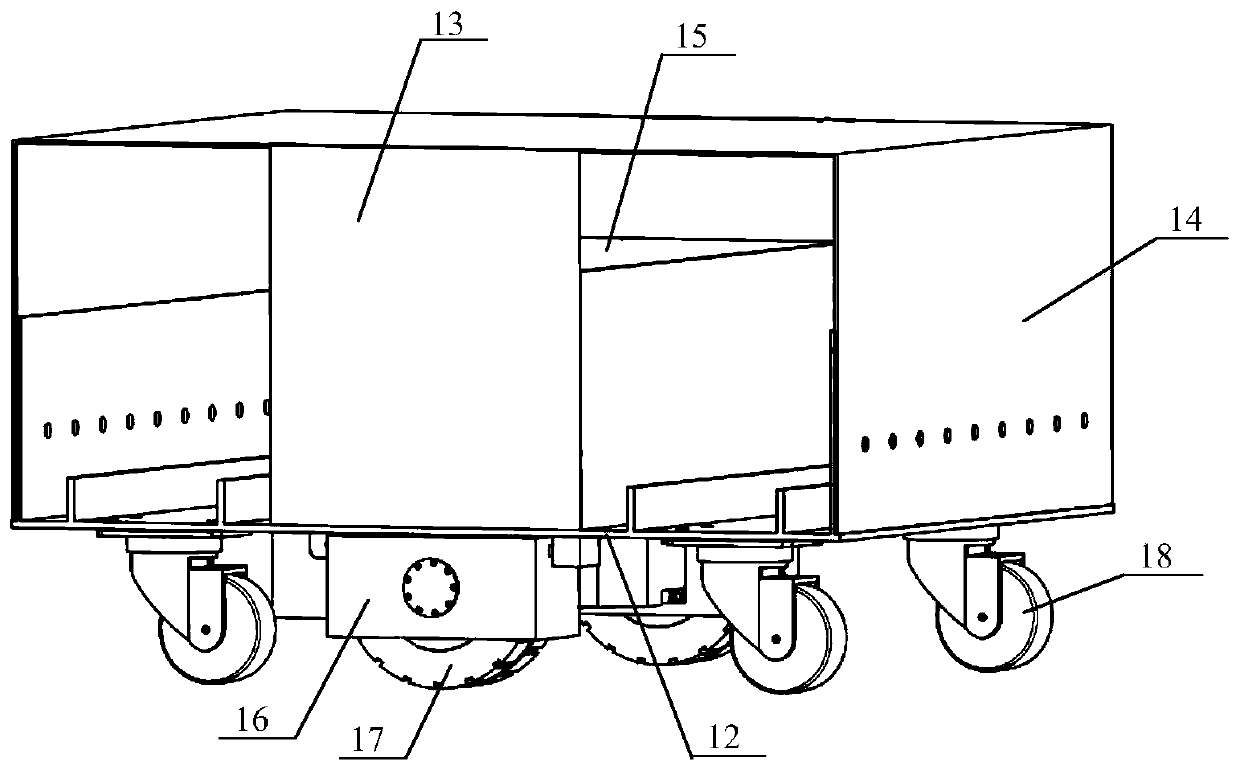

[0073] An AGV type automatic storage device, the structure is as described in Embodiment 2, the difference is that the traveling mechanism 6 includes a bottom plate 12, a three-dimensional plate 13, a shell plate 14 and a top plate 15, the bottom plate 12, the three-dimensional plate 13, and the shell plate 14 and the top plate 15 are connected by welding, the shell plate 14 is the outer shell of the car body, the middle part of the bottom plate 12 is provided with a driving assembly 16 and a driving wheel 17, and the front and rear ends of the bottom plate 12 are all provided with a plurality of driven wheels 18, as Figure 4 As shown, the driving assembly 16 includes a walking drive motor 19 and a speed reducer 20, the walking driving motor 19 is connected to the driving wheel 17 through the speed reducer 20, and drives the driving wheel 17 to walk, the driving wheel drives the driven wheel to move, and the driving wheel 17 is fixed by the driving wheel Part 21 is fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com