Cutting and trimming machine for plastic pipes

A technology of plastic pipes and trimming machines, which is applied in metal processing and other directions, and can solve the problems of entering the interior of machines such as motors, increasing manufacturing and production costs, and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

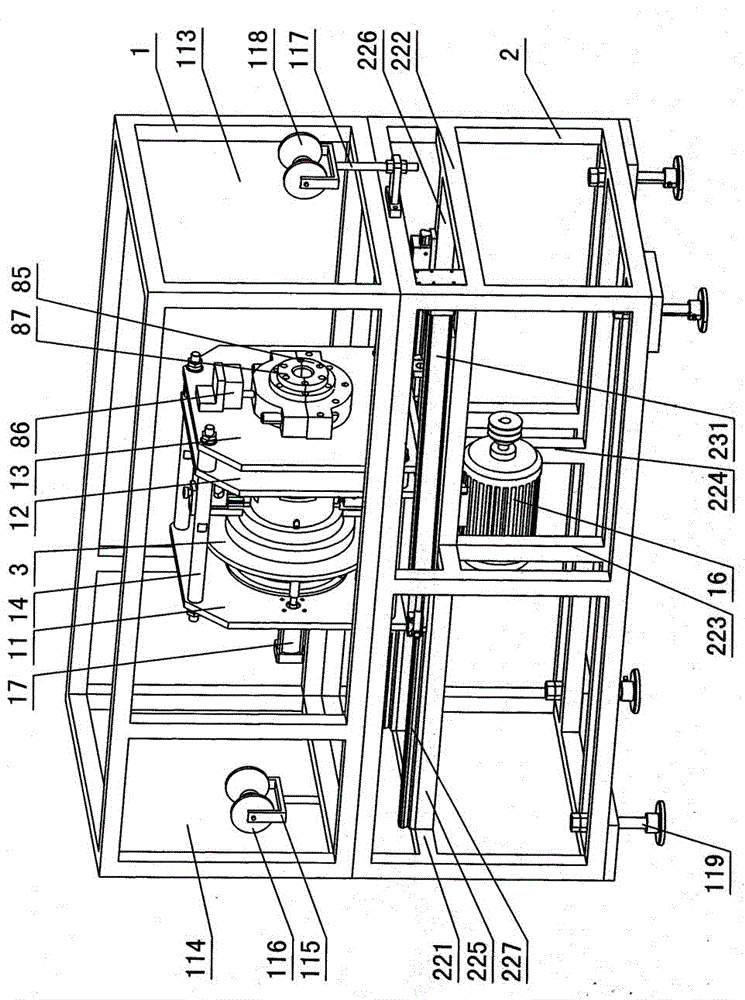

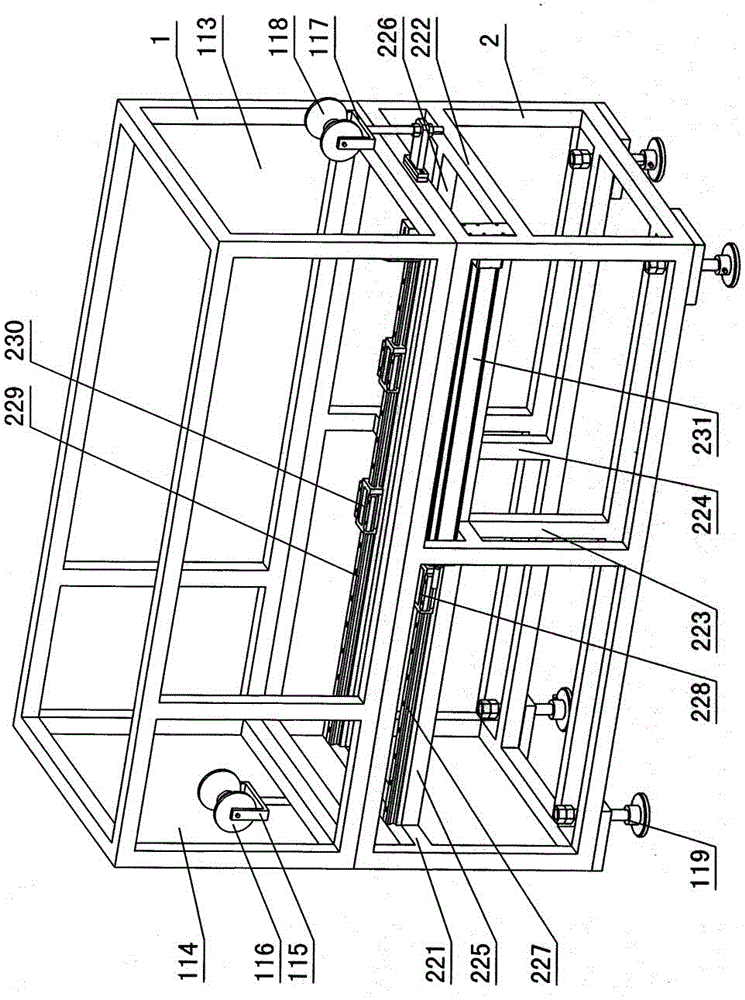

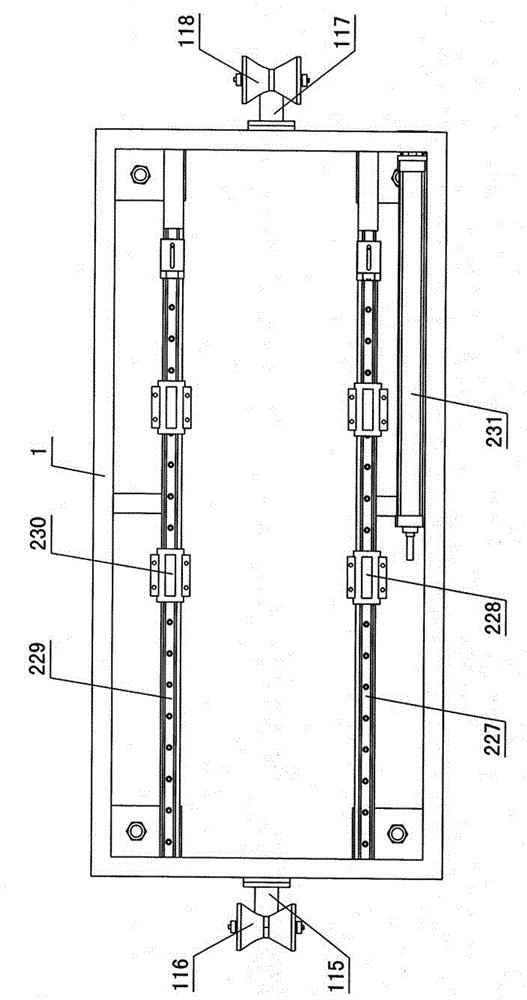

[0018] The invention relates to a cutting and trimming machine for plastic pipes, such as figure 1 — Figure 11As shown, it is characterized in that it includes a frame and a pipe material cutting and trimming mechanism, the frame includes an upper frame 1 and a lower frame 2, observation windows are respectively installed on the front and rear sides of the upper frame 1, and the left and right sides of the upper frame Side is left input port 113 and right output port 114 respectively, and left roller bracket 115 is installed in the left input port, and left roller bracket 116 is installed in the left roller bracket, and left roller through pin and left roller bracket rotates and cooperates, and right roller bracket is installed in the right input port 117, the right roller 118 is installed in the right roller bracket, and the right roller is rotated and matched with the right roller bracket through a pin. The left side of the lower frame 2 is formed with a left crossbeam 221,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com