Matrix type sorting system

A sorting system, matrix technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems that cannot be infinitely improved, poor system flexibility and scalability, complex equipment structure, etc., to improve flexibility and usability High degree, conducive to standardized design, simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

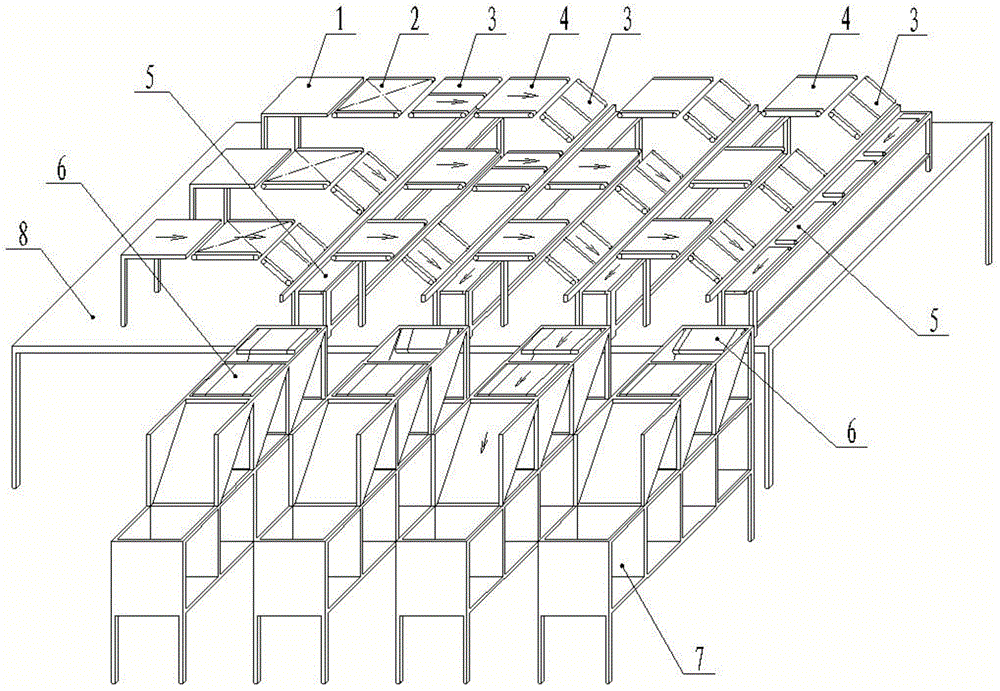

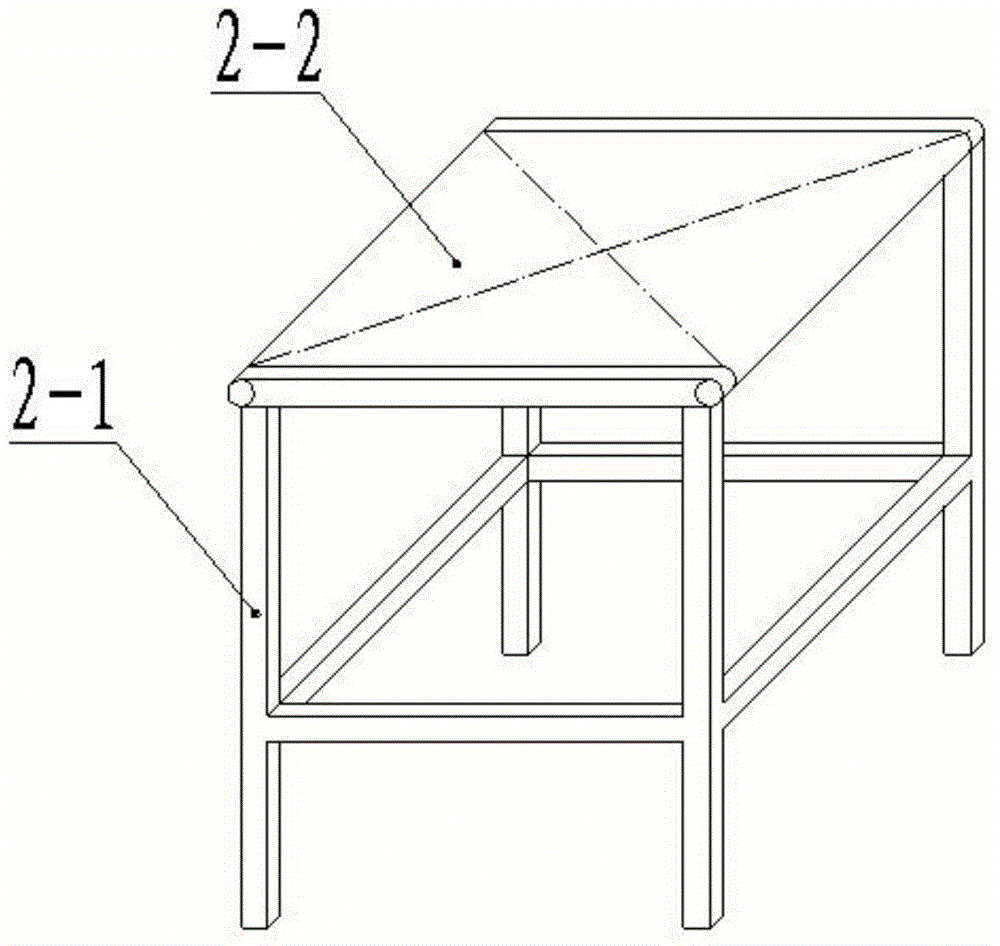

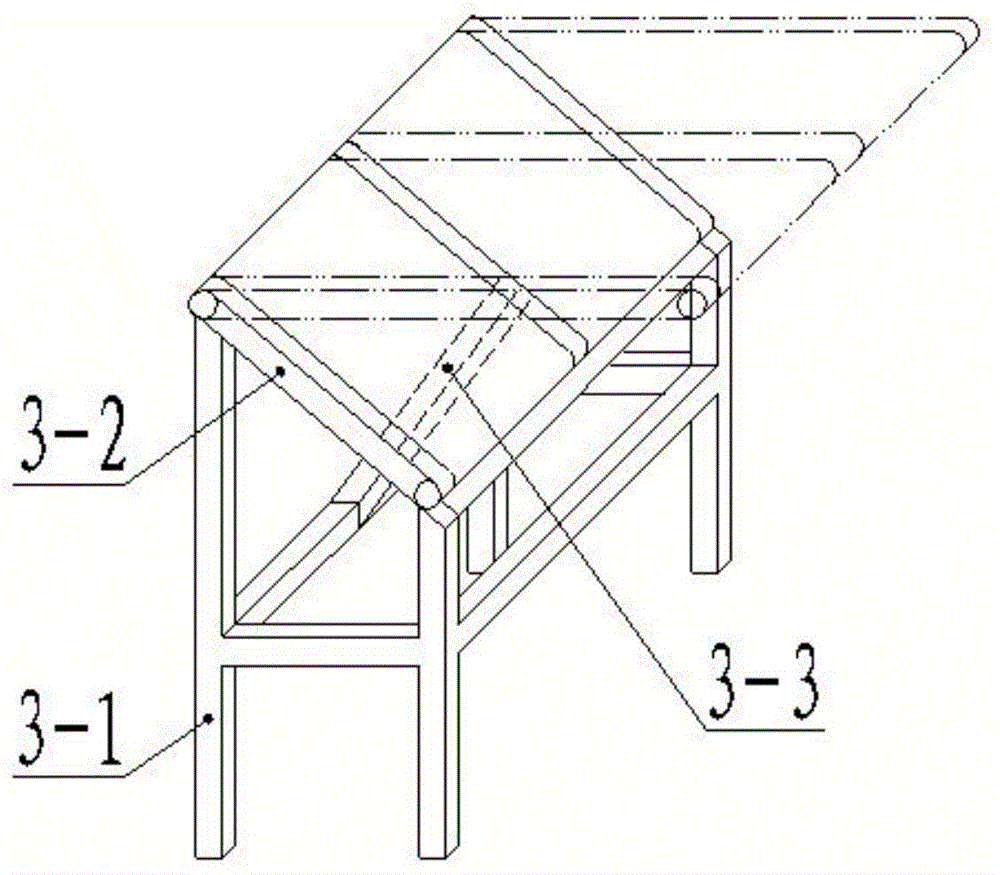

[0037] like figure 1 As shown: three article stacking platforms 1 are fixed on the workbench 8 in a horizontal arrangement, and on the right side of each article stacking platform 1 there are four longitudinal conveying lines 5 fixed on the workbench 8 in a longitudinal arrangement from left to right . Wherein, above the first, second, and third longitudinal conveying lines 5, corresponding to the positions of the feeding devices 2, respectively, there are transverse conveying equipment 4 fixed on the workbench 8. Distributed between the lines 5 are reversing devices 3 correspondingly connected to the horizontal conveying devices 4 of the previous stage, and the output ends of each reversing device 3 are respectively connected to the longitudinal conveying line 5 of the next stage, or connected to the next-stage longitudinal conveying line 5. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com